Contents

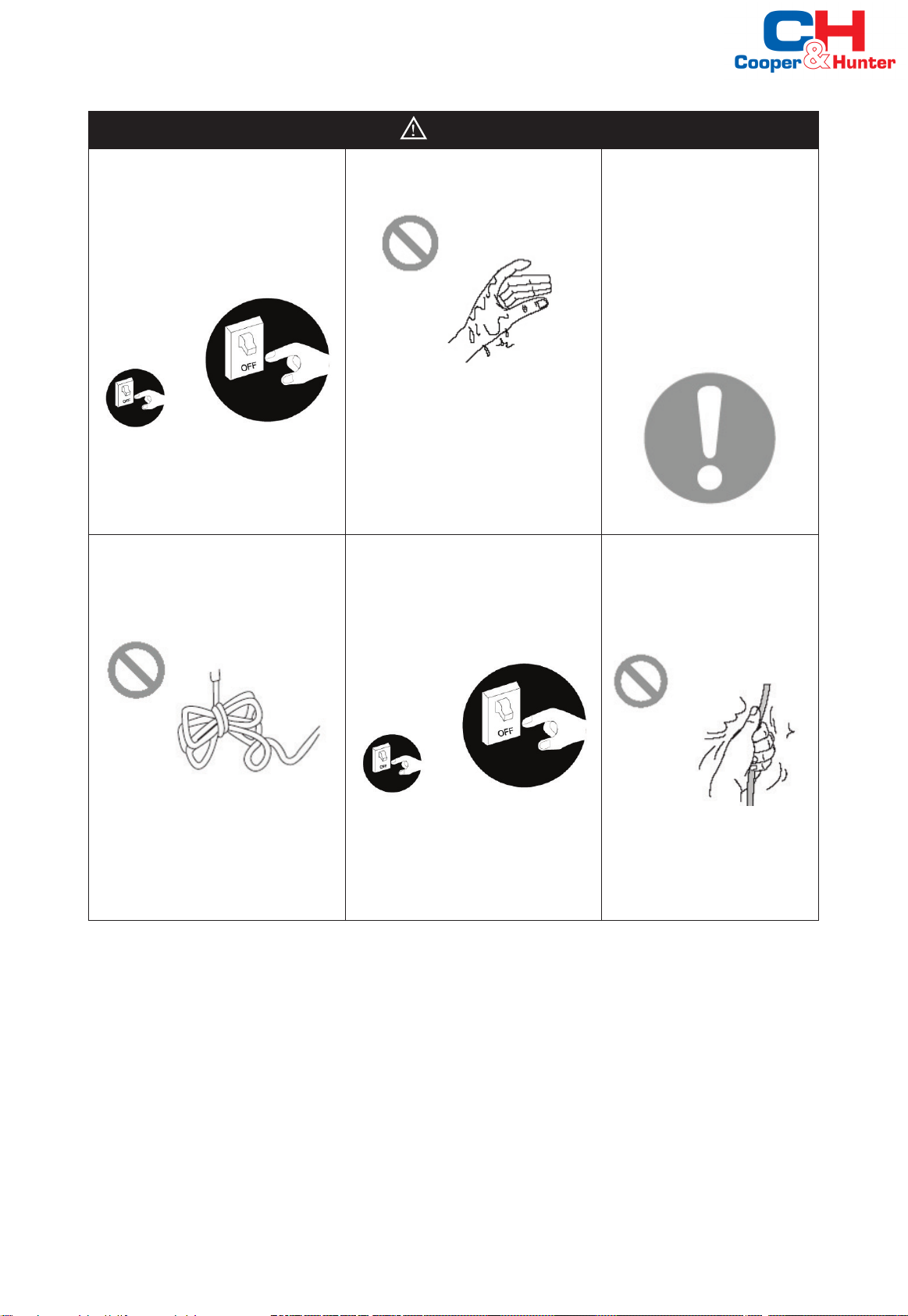

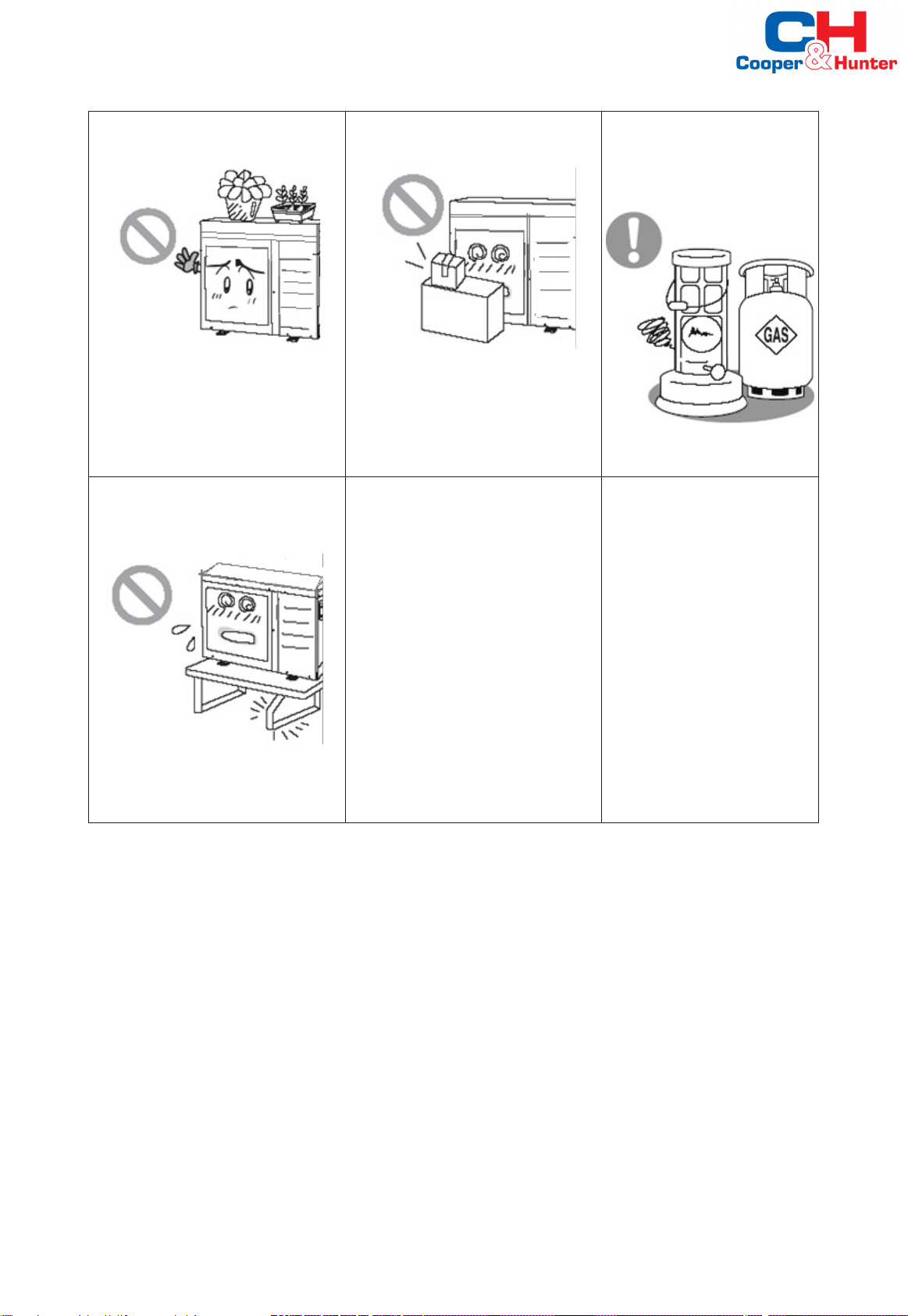

Safety Notices (Please be sure to abide ) ................................................................... 1

1. Diagram of the Operating Principle .........................................................................8

2. Operating Principle of the Unit.................................................................................8

3. Nomenclature...........................................................................................................10

4. Installation Example ............................................................................................. 11

5. Main Components ..................................................................................................14

5.1 Indoor unit .......................................................................................................................14

5.2 Outdoor unit ..................................................................................................................16

6. Installation Guideline of Outdoor Unit...................................................................17

6.1 Instruction to installation .................................................................................................17

6.2 Installation of outdoor unit...............................................................................................17

7. Installation of Indoor Unit.......................................................................................19

7.1 Selection of the installation location for the indoor unit ..................................................19

7.2 Space requirements for installation.................................................................................19

7.3 Installation process of indoor unit ...................................................................................20

7.4 Outline dimension of indoor unit ...................................................................................21

7.5 Precautions on installation of indoor unit ........................................................................21

7.6 Water volume and pump capacity (with pump)...............................................................21

7.7 Water volume and expansion vessel pressure ...............................................................22

7.8 Selection of expansion vessel.........................................................................................22

8. Connection of Pipeline ...........................................................................................23

8.1 Connection of outlet pipe for indoor & outdoor unit ........................................................23

8.2 Installation of protective layer on connection pipe .........................................................23

9. Remote Air Temperature Sensor............................................................................ 25

10. Thermostat.............................................................................................................26

11. 2-Way Valve ............................................................................................................26

12. 3-Way Valve............................................................................................................27

13. Other Auxiliary Heat Sources .............................................................................27

14. Gate-controller.......................................................................................................29

15. Charging and Discharging of Refrigerant...........................................................29

16. Refrigerant Collecting...........................................................................................30

17. Handling of the Unit ..............................................................................................30

18. Installation of Insulated Water Tank ...................................................................31

18.1 Installation measure......................................................................................................31