CF 137 1 02-09

DPG 1600 DIGITAL PRESSURE GAUGE USER’S GUIDE

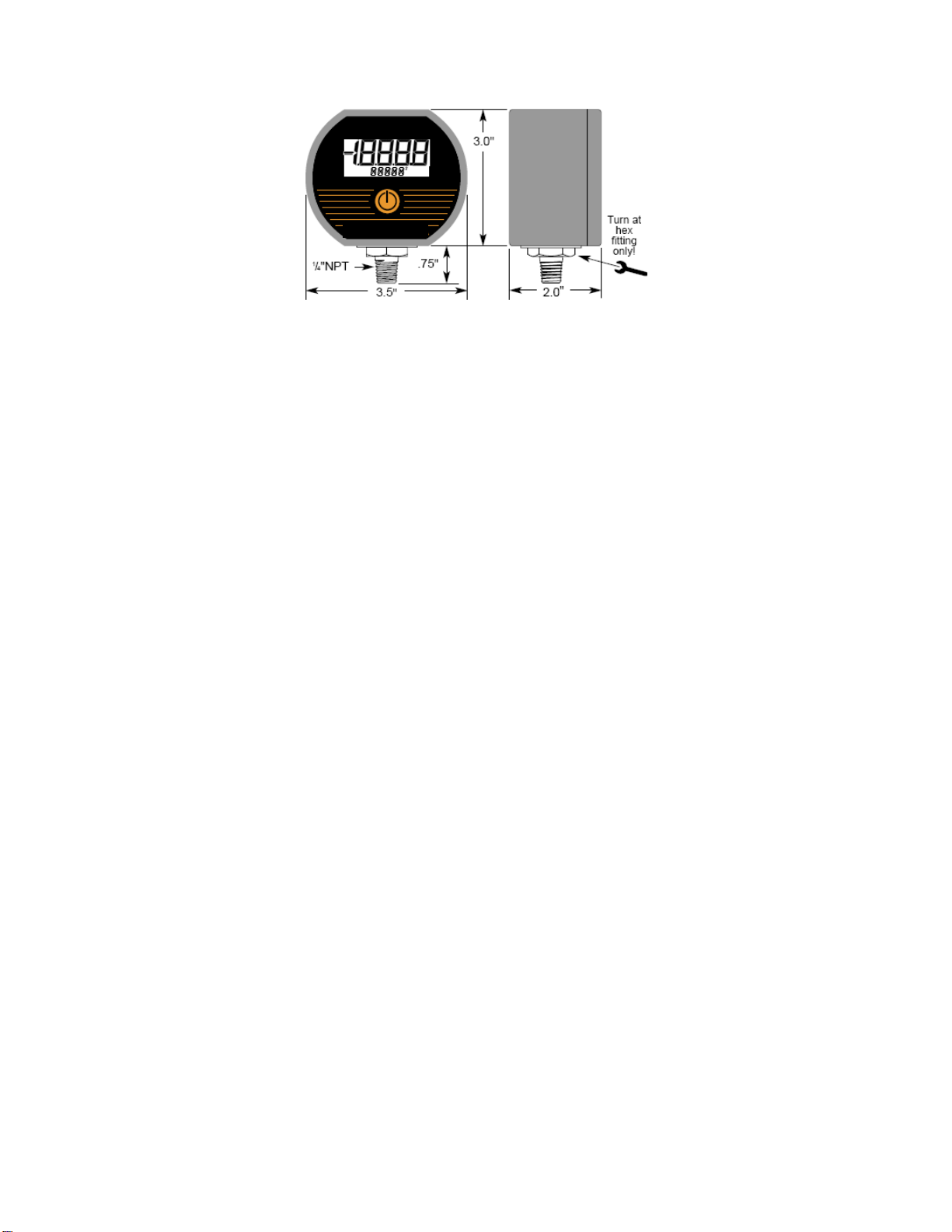

Installation and Precautions

Install or remove gauge using wrench on hex fitting only. Do not attempt to tighten by turning housing or any other

part of the gauge.

Use fittings appropriate for the pressure range of the gauge.

Do not apply vacuum to gauges not designed for vacuum operation.

Due to the hardness of 316 stainless steel, it is recommended that a thread sealant be used to ensure leak-free

operation.

NEVER insert objects into the gauge port or blow out with compressed air. Permanent damage not covered by

warranty will result to the sensor.

Power-Up

1. Press and hold the pushbutton for approximately 1 second.

2. The full-scale range is indicated and the display segments are tested.

3. The actual pressure and units are displayed.

Power-Up With Zero (Gauge reference models only)

1. Be sure the gauge port is exposed to normal atmospheric pressure and no pressure is applied. The zeroing

function is only activated at each power-up and the stored zero correction is erased when the gauge is shut off.

2. Press and hold the pushbutton.

3. The full-scale range is indicated and the display segments are tested.

4. Continue to press the pushbutton until

o o o o

is displayed and then release the button. This indicates that

the gauge has been zeroed.

5. The actual pressure is displayed.

Attempting to zero the gauge with pressure greater than approximately 3% of full-scale applied will result in an error

condition, and the display will alternately indicate E

r r

0 and the actual measured pressure. The gauge must be

powered down to reset the error condition.

Absolute reference gauges do not use the zero feature since they read atmospheric pressure under normal

conditions.

Normal Operation

Following the start-up initialization, the display indicates the pressure reading updated approximately 3 times per

second. The auto shutoff timer starts when the gauge is powered up or whenever the button is pushed, unless the

gauge was ordered without an auto shutoff time (-ON option).

If excessive vacuum is applied to a pressure-only gauge, the display will indicate – E r r until the vacuum is

released. Applying vacuum to a gauge designed for pressure may damage the pressure sensor. If excessive

pressure is applied (112.5% over range), an out-of-range indication of | - - - or | -.-.-.- will be displayed

depending on model.

Minimum and Maximum Readings

Minimum and maximum readings are continuously stored and updated whenever gauge is on. The stored readings

can be manually cleared if desired. The HI and LO memory is also cleared whenever the gauge is off.

Press and hold the pushbutton for about 1 second until HI is displayed. The maximum stored value is displayed.

After HI is displayed, press and hold the pushbutton again for about 1 second until LO is displayed. The minimum

stored value is displayed.