PrintMaster Monet.

Basic Operation.

8.

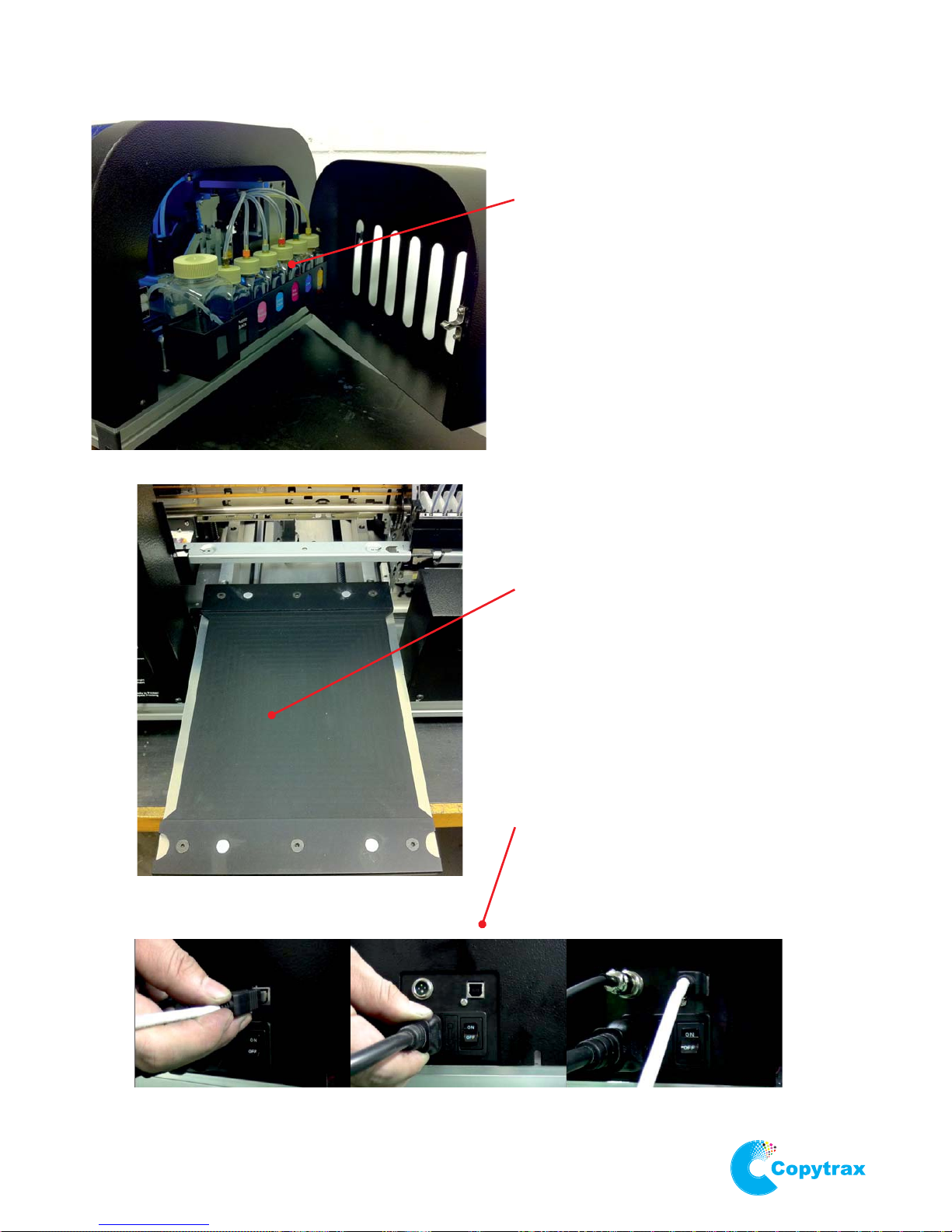

Attention: Do not load media before you power on

Switch on the PrintMaster Monet by the button next to the

power cable on the left side of the printer

The printer will start up into

Wait 5 seconds then press button marked

The printer will now initialise

When ready the top two leds will stop flashing and turn

to solid lights

Press the button to move the flatbed to the front

of the printer

Press the button to move the flatbed to the rear

of the printer

The PrintMaster Monet is now initialised and the flatbed position

is calibrated. The control panel should read “

Press the button to fully extend the flatbed to the

front of the printer

Load media into your custom jig

Press button to perform the auto height function

When the flatbed is at the rear of the printer and the height is set the PrintMaster Monet is ready for

printing from the software of your choosing with the template provided for your custom jig.

After a print, unload the jig and reload with unprinted media. If the media is the same as the previous

print there is no need to use the function to load the flatbed ready for printing. Instead

use the button load the flatbed.

Some materials provide a better print result when heat is added. This can be done using the halogen

lamp inside the PrintMaster Monet.

The halogen lamp is automatic and will ignite at the start of a print and extinguish after the flatbed

has ejected

See section for instructions on how to adjust the brightness of the lamp and

how to enable/disable this function

To power off the printer properly press button on the control panel. The machine will

then enter When in this state you may press the power switch on the left side of the

printer to fully turn off the machine. If the power switch is pressed without first powering off the

printer by the control panel, the print head may not fully cap on the cleaning station allowing the ink

in the nozzles to dry.

TEST MODE

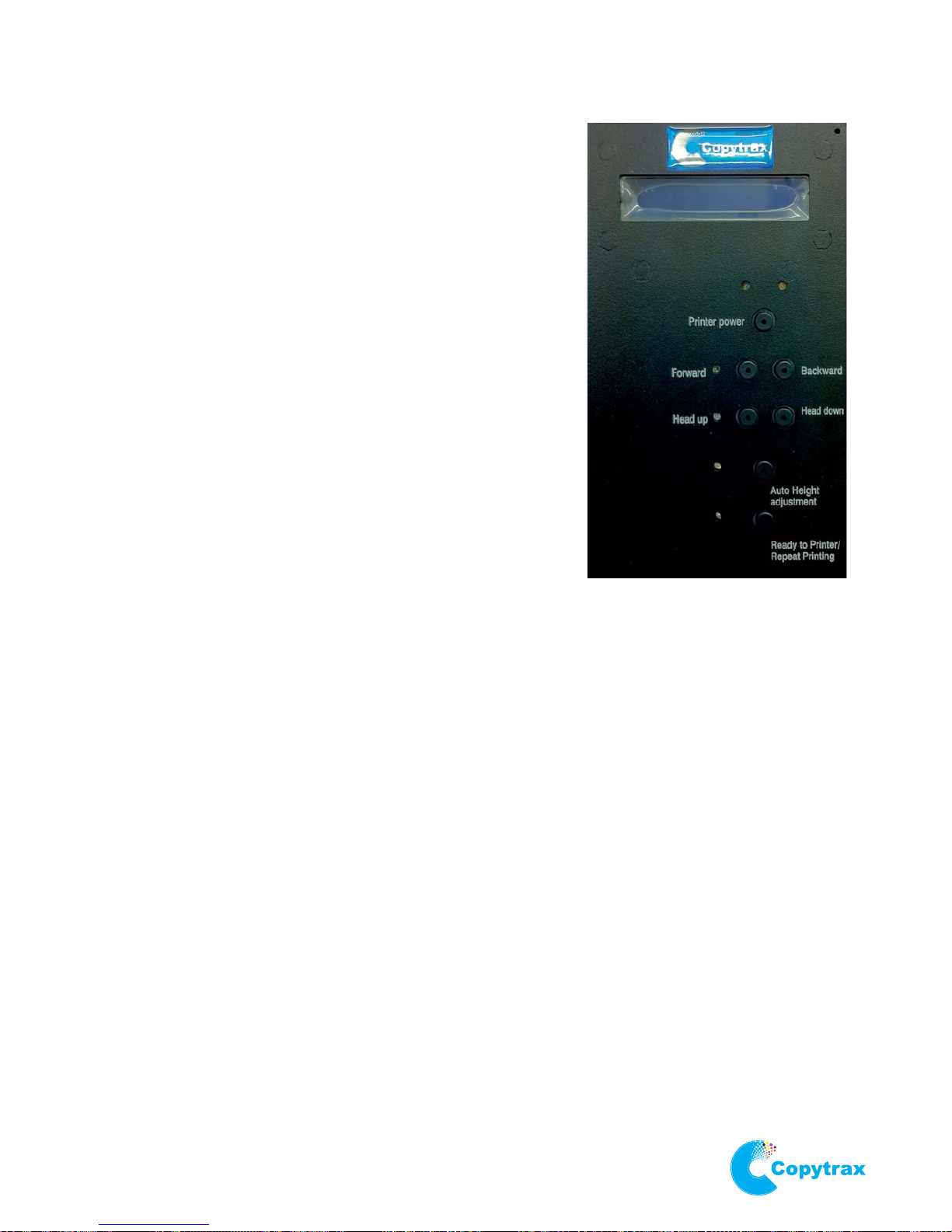

Printer power

Forward

Backward

Ready to print”

Forward

Auto Height adjustment

auto height

Ready to Printer/Repeat Printing

Run Mode Functionality

Printer power

TEST MODE.