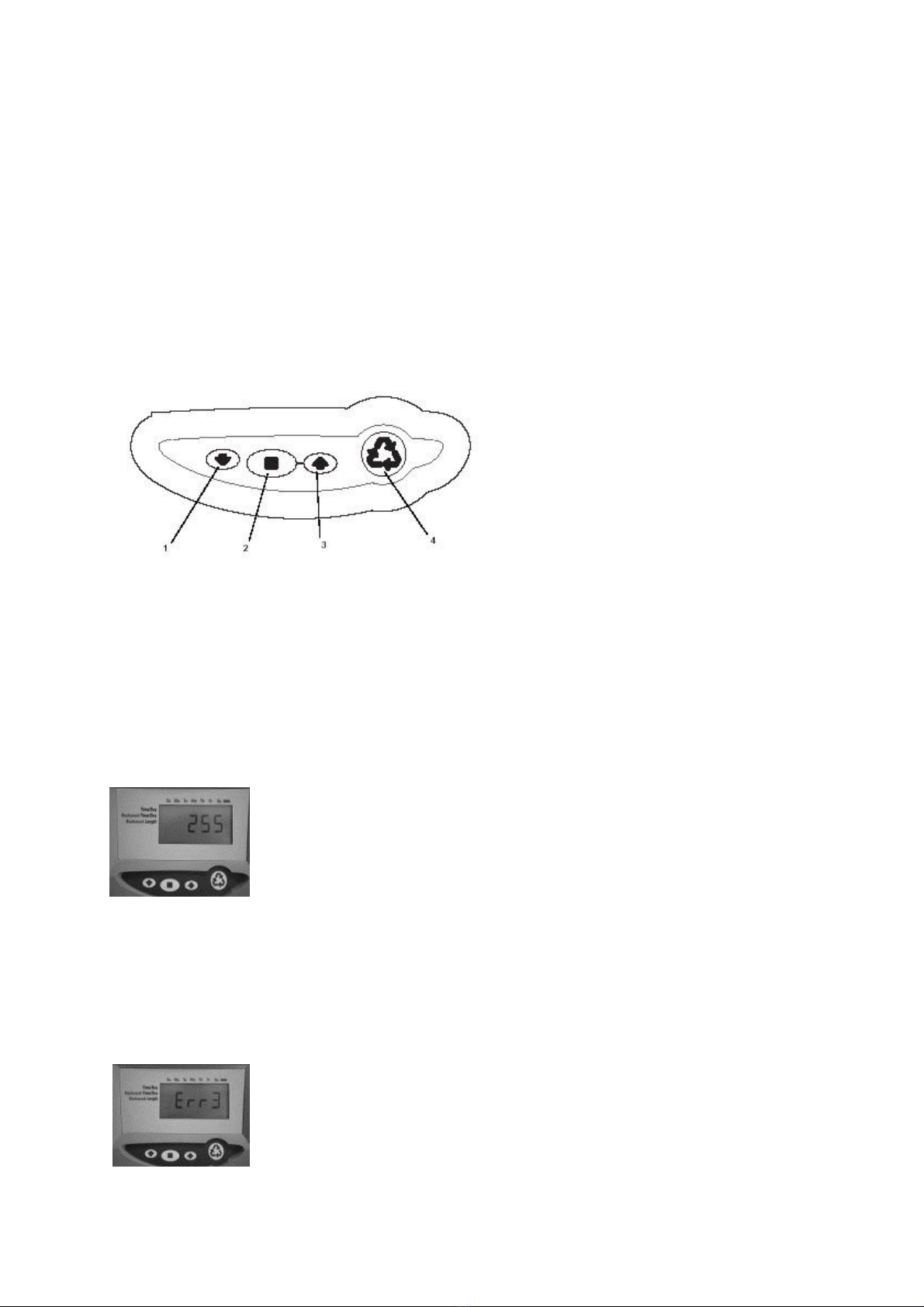

Hardness Setting (760 & 762 only)

The hardness setting will need to be set on site, the

setting is in ppm.

Press the set button to start the display flashing and

adjust the hardness value up or down using the up and

down arrows, when the correct figure is displayed press

the square button to set.

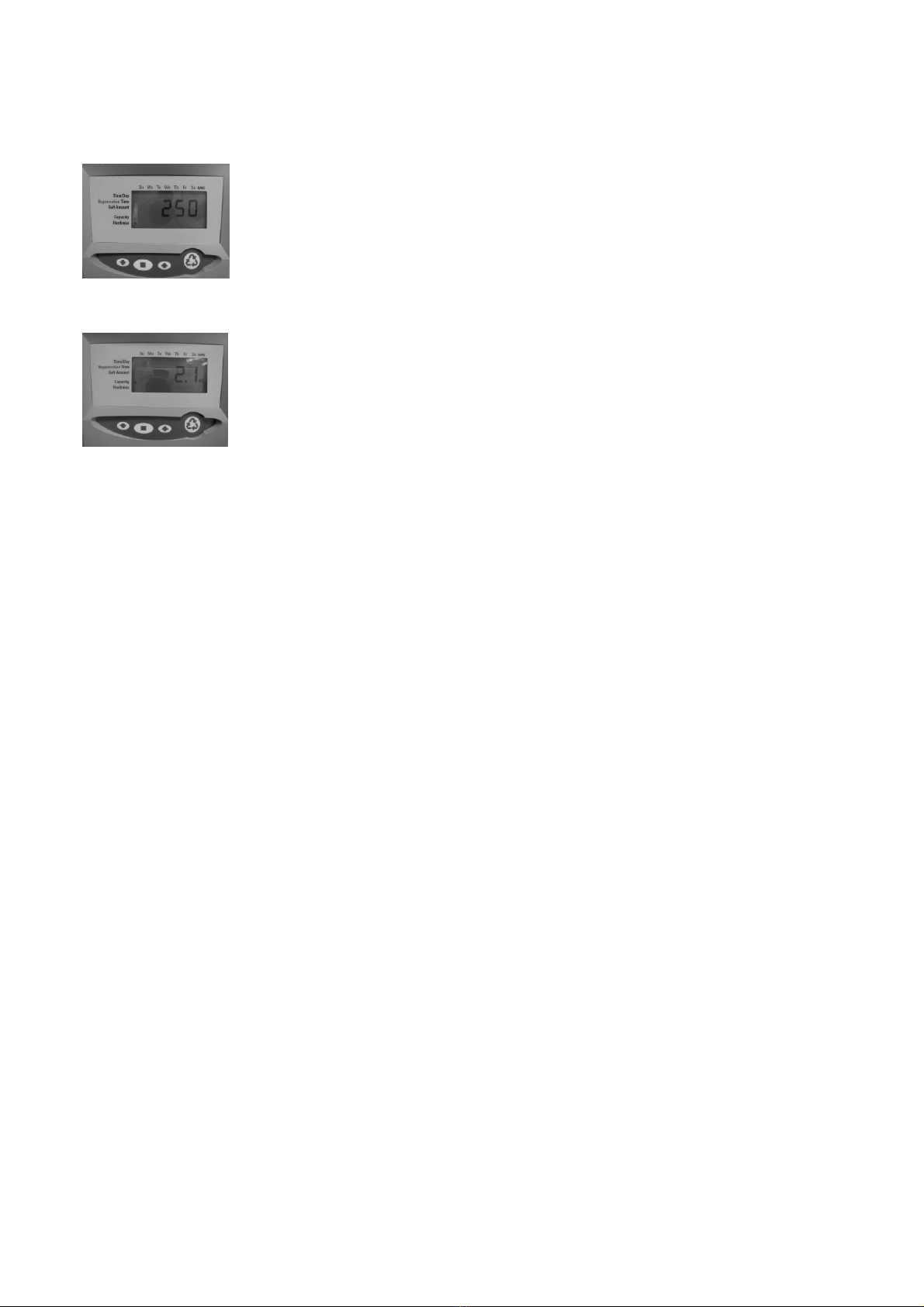

Capacity.

System capacity is displayed in kilograms of hardness

removed before regeneration is necessary. This should be

factory set but should it require setting you need to press

the set button to start the display flashing, then adjust the

figure using the up and down arrows and press the set

button to confirm the figure. Not adjustable on the 740 or

760 control.

Normal valve operation.

During normal valve operation the 740 & 742 will display the time of day,

the 760 will alternate between the time of day and volume of water remaining

in cubic meters before regeneration. The 762 will display the current water

flow and remaining capacity before regeneration.

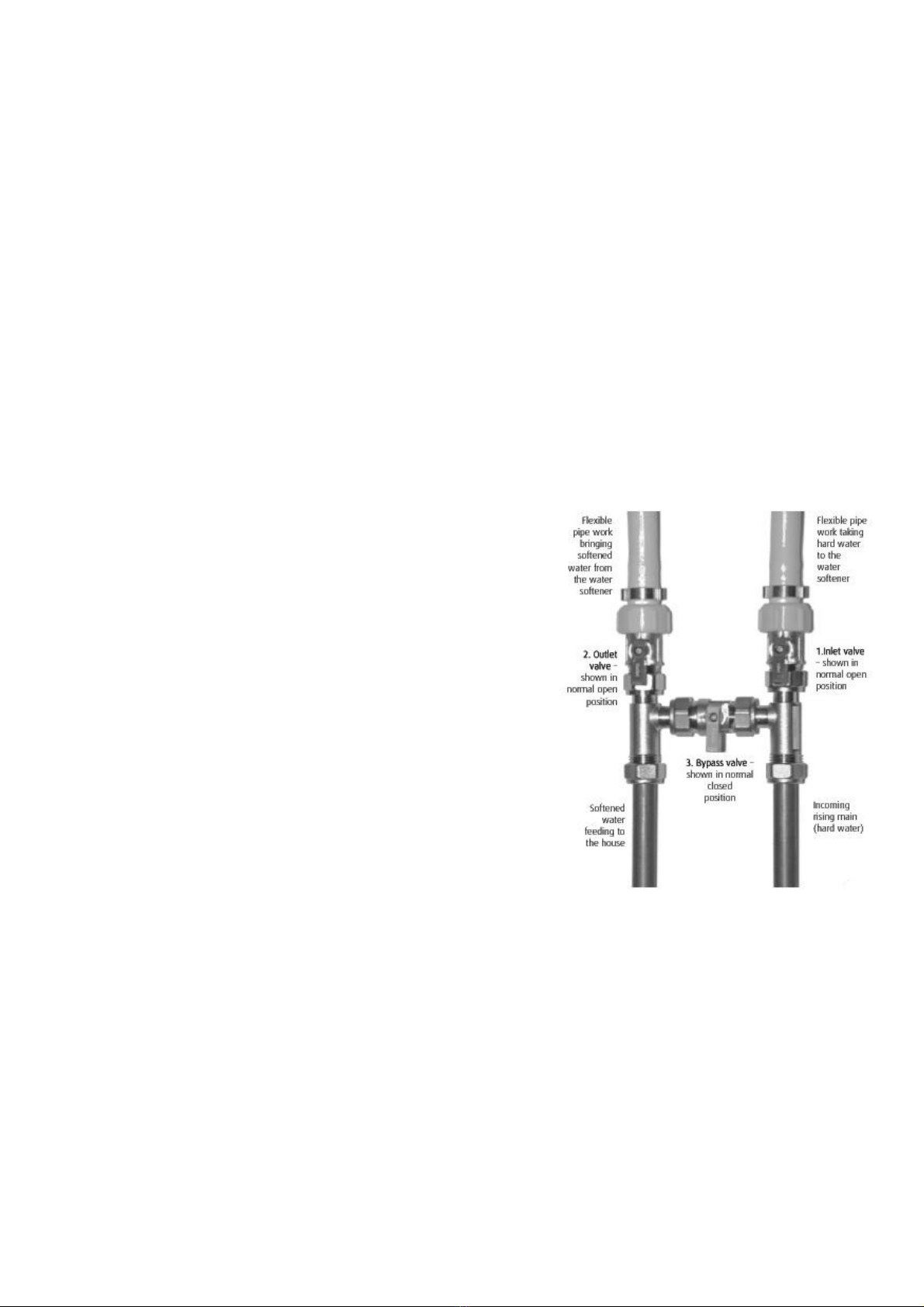

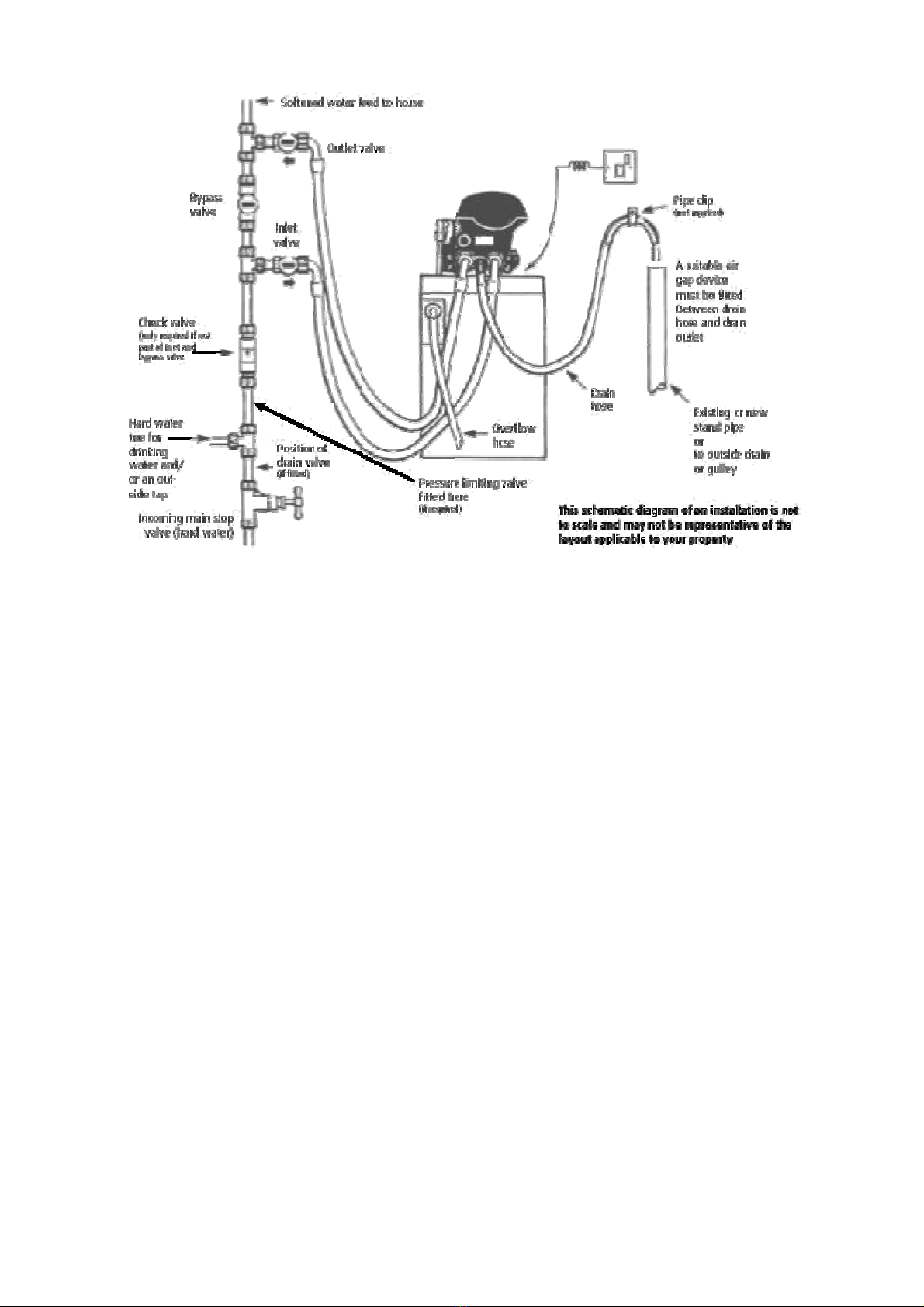

Commissioning the Softener.

Open the outlet from the softener, press and hold the regeneration button (4)

until the cam starts to rotate, when the cam stops moving open the inlet to the

softener slowly until it is about a quarter open. Water will start flowing into the

softener and start purging the air from the softener, you will hear the air coming

out and eventually water will begin to run steadily from the drain line; you can

now fully open the inlet valve to the softener. Advance the regeneration cycle

to the (refill) position C8; do this by pressing the set button and up arrow

together at the same time and letting go, this advances the cycle to the next

position, repeat this until you reach C8. Now allow the valve to continue on it’s

own to the end of the cycle, this will purge air from the regenerant line and put

the correct amount of water into the salt chamber for its first regeneration.

Finally turn on a tap close to the softener and run the water, you may find there

is some colouration in the water; this will clear after a short while and is

normal. Your softener is now supplying soft water to your home, please bear in

mind it may take some time to reach all of the outlets in your home.

It is advised that you instigate a delayed regeneration for the first night

(see below)