If machine doesn’t turn on,

turn power OFF, wait 30 minutes,

and repeat steps 1 to 5. If problem

persists, contact service team.

If machine makes any

abnormal noise during reset,

immediately switch power OFF

and contact service team.

-(usually

because the viscosity is set too high for the selected product) to prevent motor damage. Use

the green reset buon to return the machine to normal operaon.

1. Switch power switch OFF.

2. Press green reset buon on side or

back of machine.

3. Wait 15 to 20 minutes; switch power

ON.

4. Press RESET, then WASH buon on

front.

5. Observe machine performance and

return to normal use if funconing

properly.

Make only small adjustments to viscosity seng; allow at least 10 to 15 minutes

between adjustments to evaluate product rmness. Viscosity seng should NOT need

connuous adjustment. A seng of 3 is a good starng point for most product.

Machines without air pumps can experience product consistency changes if they go unused for an ex-

tended period of me. Product may become icy or dense if le in the freezing cylinder too long, oen

occurring during a business’s longer slow-periods.

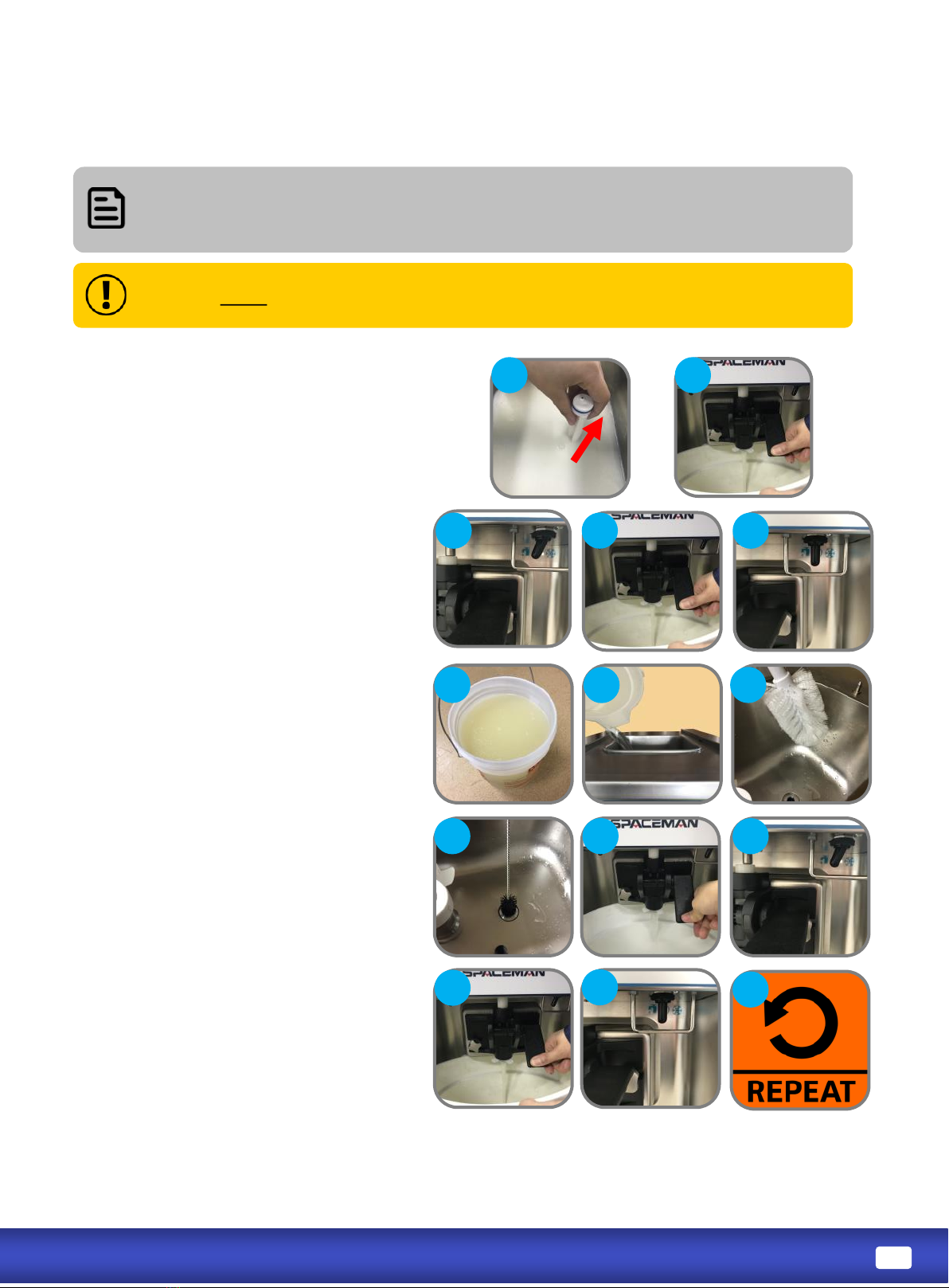

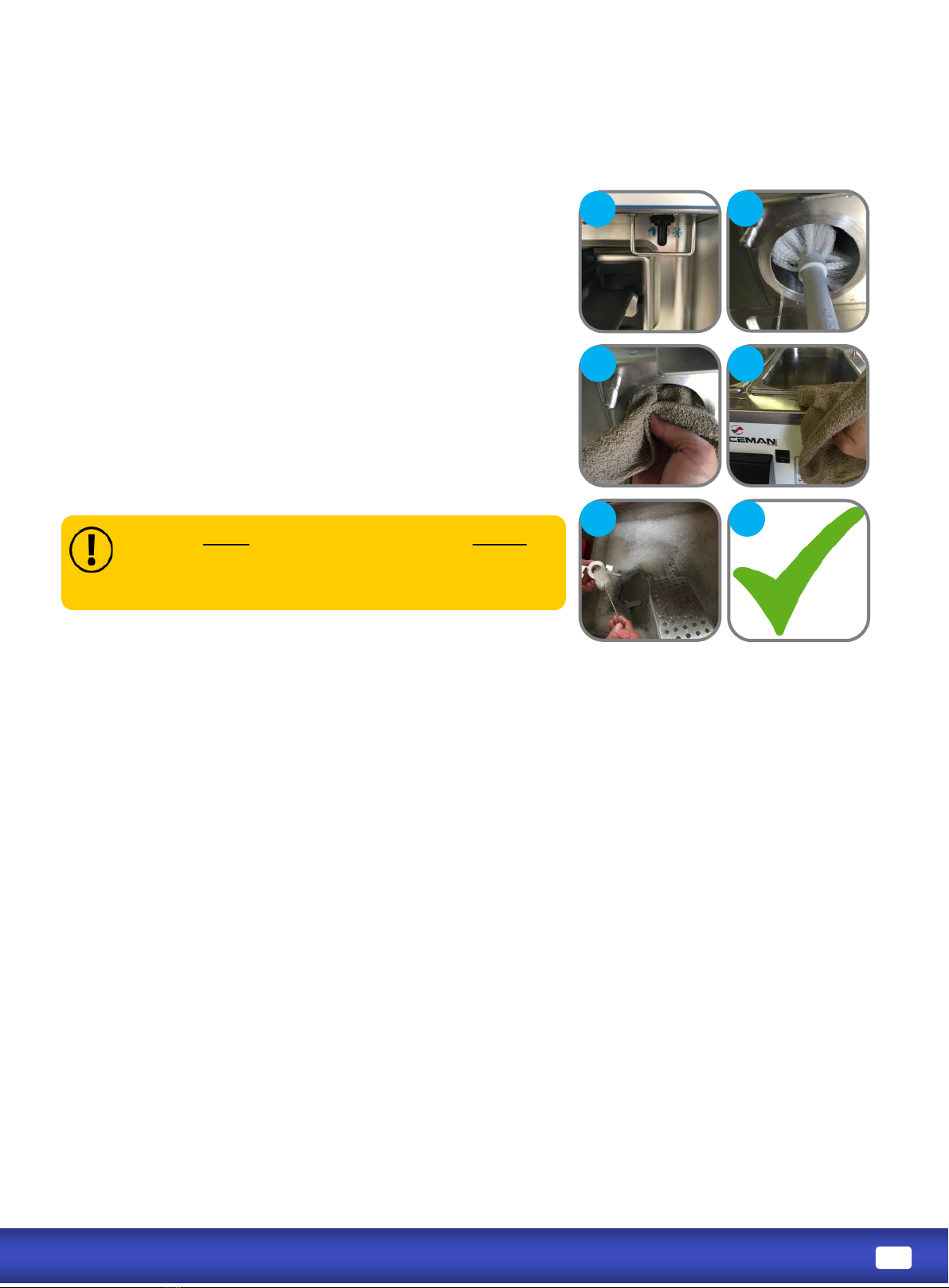

1. With machine in FREEZE mode, remove air tube.

2. Clean air tube and insert into machine upside-down (inlet hole on the side of the air tube at the top).

3. Conrm product is above low-mix line in hopper.

4. Open draw handle to draw 170 g to 227 g (6 oz. to 8 oz.) of product; discard product.

5. Wait unl machine nishes freeze cycle and motor stops turning.

6. Remove and clean air tube.

7. Insert air tube into machine with correct orientaon (inlet hole on the side of the air tube at the

boom).

8. Machine is ready for normal operaon.

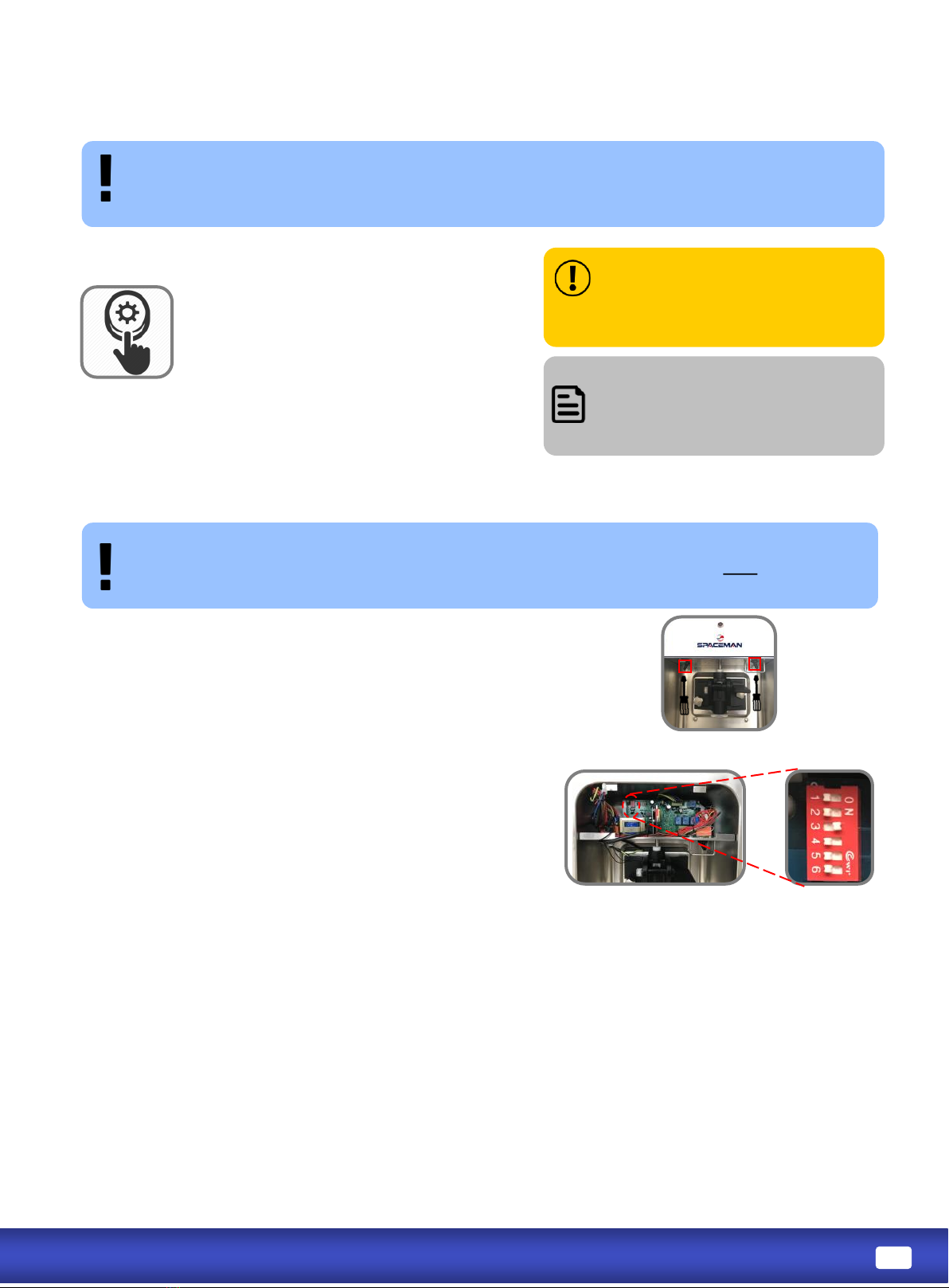

Take O Faceplate

Control Board and Dip Switches

1. Take o faceplate cover by unscrewing le and right

screws from below.

2. Viscosity is adjusted on the Electronic Control Board.

3. Move the switch UP for the desired viscosity level.

Move all other switches DOWN.

4. Viscosity is from Harder to Soer from level 1- 6.