710.1759.01.01-00D 19/09/2018

2

TABLE OF CONTENTS

1

GENERAL USER AND MAINTENANCE MANUAL ....................................................................... 3

1.1 HOW TO USE THIS MANUAL .................................................................................................... 3

1.2 GENERAL DESCRIPTIONS / INTENDED USE ............................................................................... 3

GENERAL SAFETY INSTRUCTIONS ........................................................................................ 3

3

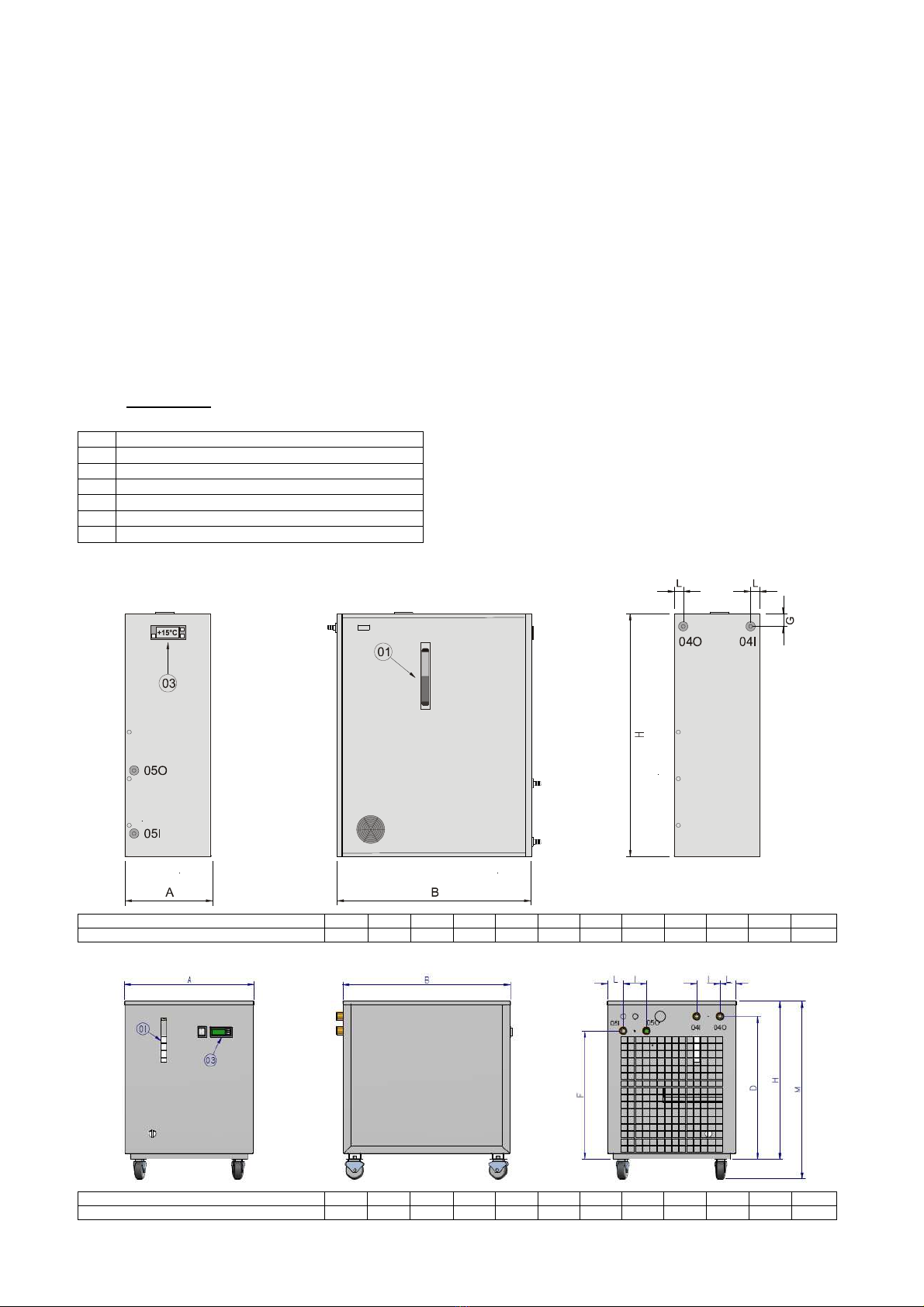

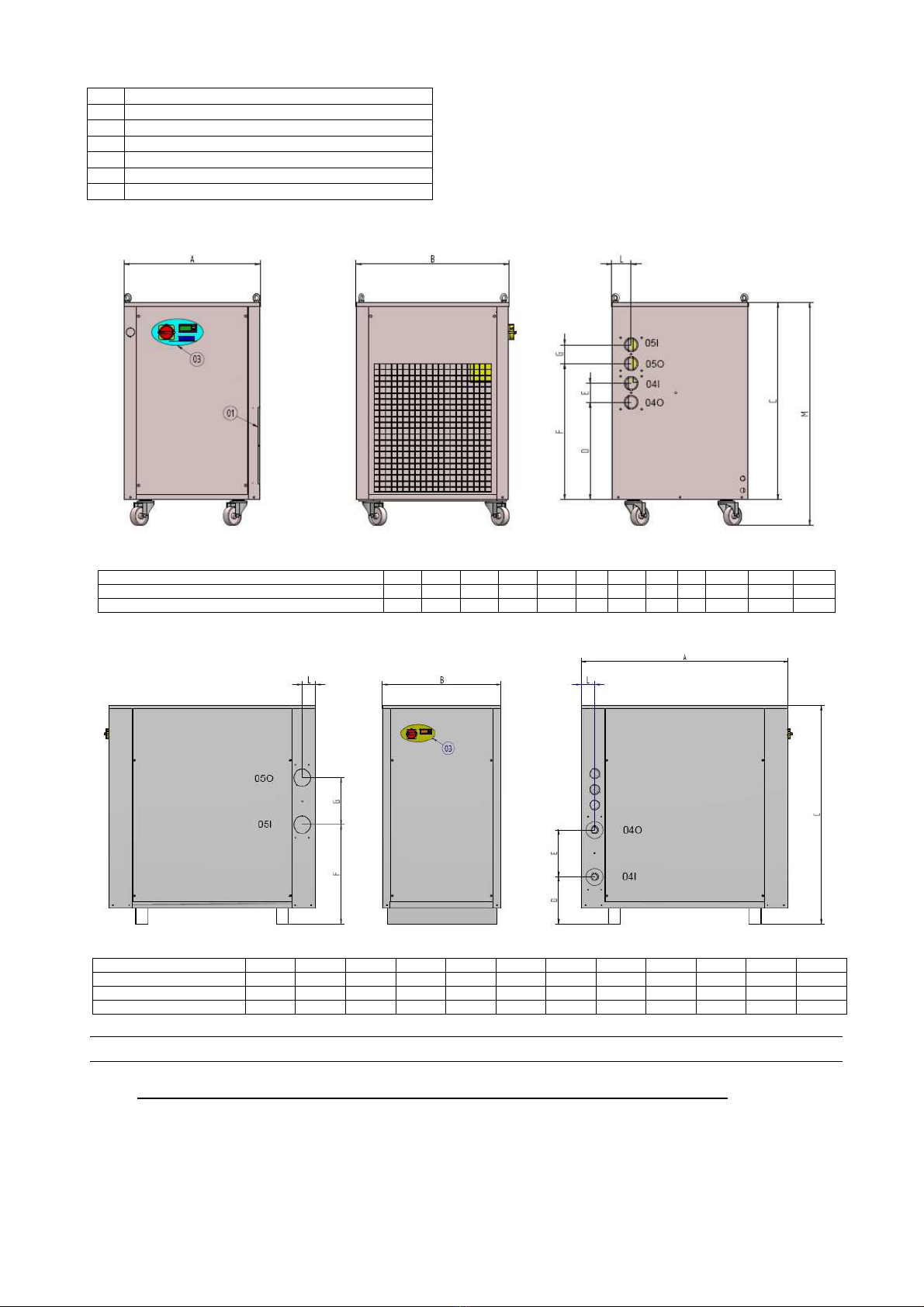

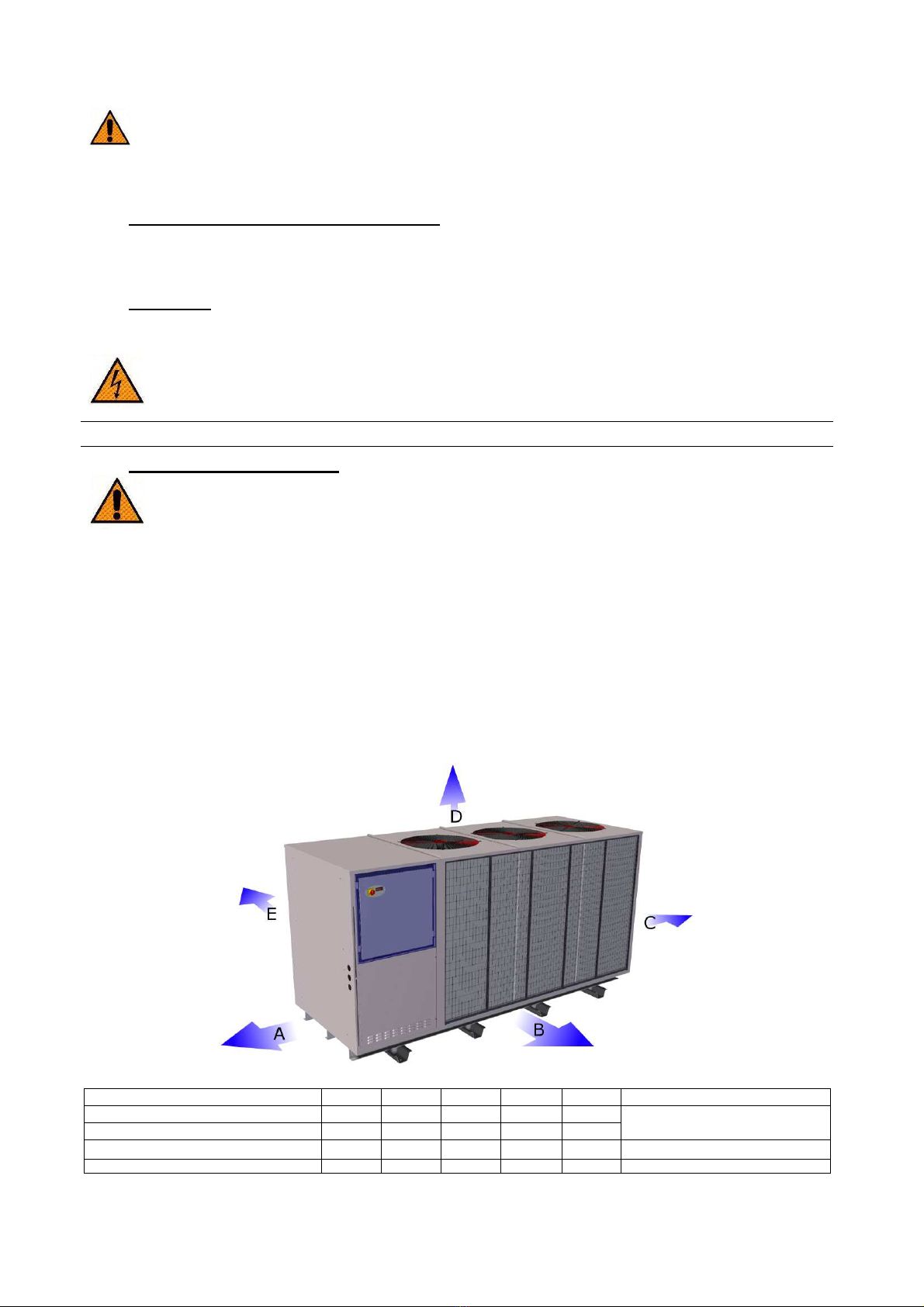

DESCRIPTION OF THE UNIT, COMPONENTS AND OPTIONS .................................................. 4

3.1 DESCRIPTION ........................................................................................................................ 4

3.2 REFRIGERATION CIRCUIT (HOT SIDE) ...................................................................................... 4

3.2.1 STANDARD COMPONENTS USED IN THE WATER COOLER ........................................................................ 4

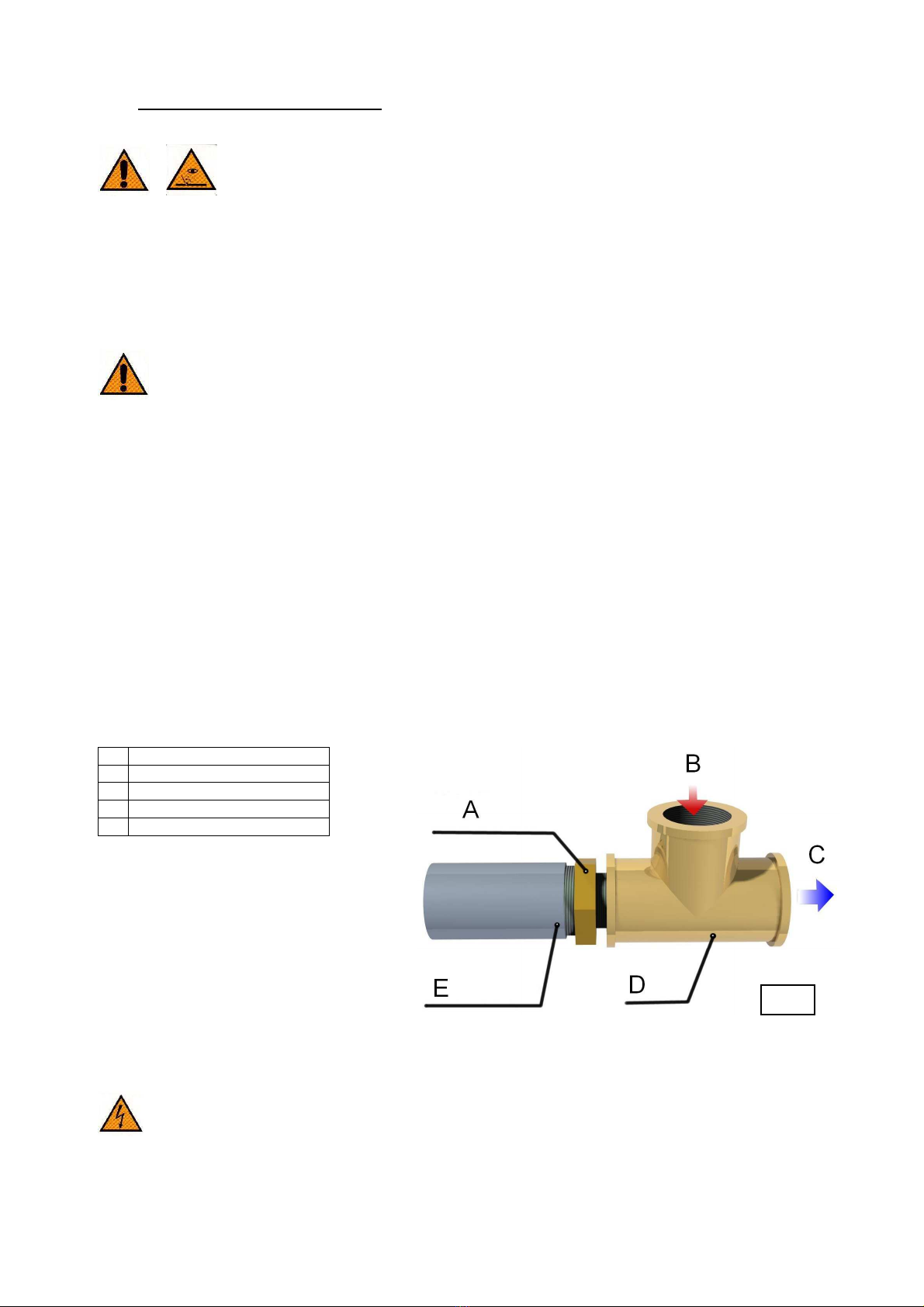

3.3 HYDRAULIC CIRCUIT (CONSUMER CIRCUIT) .............................................................................. 5

3.3.1 STANDARD COMPONENTS USED IN THE WATER COOLER ........................................................................ 5

3.3.2 OPTIONS – HYDRAULIC CIRCUIT .......................................................................................................... 5

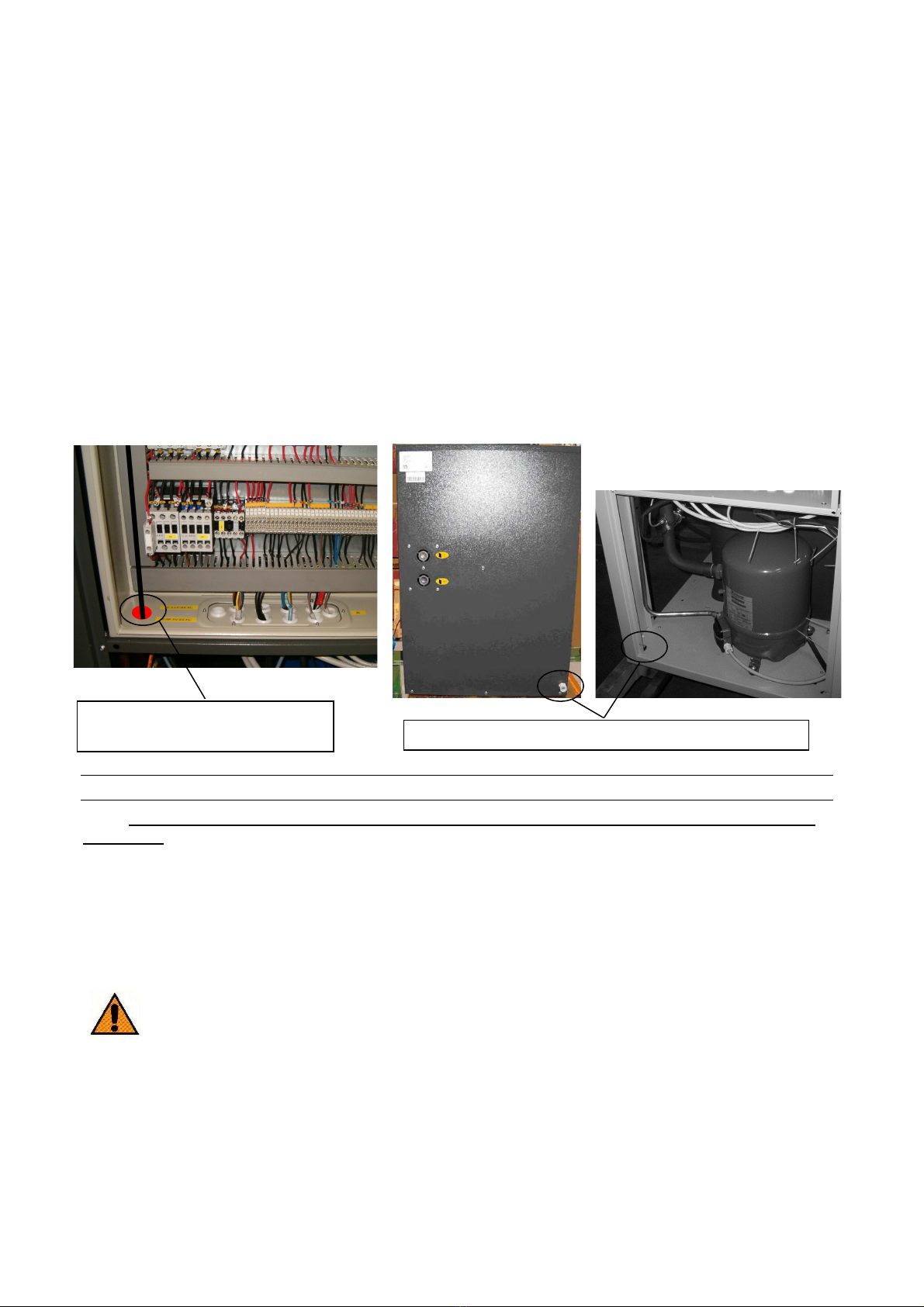

3.4 ELECTRIC CIRCUIT ................................................................................................................. 5

3.4.1 STANDARD COMPONENTS USED IN THE WATER COOLER ........................................................................ 5

3.4.2 OPTIONS – ELECTRIC CIRCUIT ............................................................................................................ 6

3.5 HOUSING .............................................................................................................................. 6

4

TRANSPORT / PACKING / STORAGE ..................................................................................... 7

4.1 REMOVING THE WATER COOLER FROM PACKAGING AND HANDLING ............................................ 7

4.2 DISPOSAL OF PACKING MATERIALS ......................................................................................... 8

4.3 STORAGE .............................................................................................................................. 8

5

INSTALLATION AND ASSEMBLY ............................................................................................ 8

5.1 CHOOSING A LOCATION ......................................................................................................... 8

5.2 ASSEMBLY (CONNECTIONS) ....................................................................................................

5.2.1 CONNECTION TO THE REFRIGERANT CIRCUIT (CONSUMER CIRCUIT) ....................................................... 9

5.2.2 ELECTRIC CONNECTION ...................................................................................................................... 9

6

OPERATION ........................................................................................................................ 10

6.1 CHECK LIST FOR THE INITIAL START-UP OF WATER/WATER HEAT EXCHANGER SYSTEMS ............ 10

6.1.1 CHEC LIST MODELS CHA 1.3-11 ....................................................................................................... 10

6.1.2 CHEC LIST MODELS CHA 24-60 ........................................................................................................ 11

6.1.3 CHEC LIST MODELS CHA 99-129 ...................................................................................................... 11

6.2 OPERATING SETTINGS OF THE ELECTRONIC CONTROLLER ....................................................... 12

6.2.1 ELECTRONIC CONTROLLER ................................................................................................................ 12

6.3 SHUTTING DOWN THE WATER COOLER .................................................................................. 14

6.3.1 SWITCHING ON/OFF IN DAILY OPERATION .......................................................................................... 14

6.3.2 TEMPORARY DECOMMISSIONING ....................................................................................................... 14

6.3.3 DECOMMISSIONING FOR THE PURPOSE OF TRANSPORT ....................................................................... 14

7

MAINTENANCE ................................................................................................................... 14

7.1 MAINTENANCE ..................................................................................................................... 14

8

DISPOSAL ........................................................................................................................... 15

9

MALFUNCTIONS / TROUBLE SHOOTING ............................................................................. 15

.1 POSSIBLE ALARM SIGNALS AND THEIR RECTIFICATION ........................................................... 16

9.1.1 CONTROLLER TYPE “A”, “D”, (CHA 1.3 TO CHA 129) ............................................................................. 16

10

GENERAL TECHNICAL DATA / FUNKCE A TECHNICKÁ DATA ................................................ 34

10.1 TECHNICAL FEATURES / TECHNICKÉ FUNKCE ........................................................................ 34

10.2

HYDRAULIC CIRCUIT DATA / VLASTNOSTI ČERPADLA A NÁDRŽE ........................................... 34

10.3

COMPONENTS WITH A WEIGHT OF MORE THAN 20 KG

KOMPONENTY O HMOTNOSTI PŘESAHUJÍCÍ 20 KG ............................................................... 34

10.4

FLUIDS RECOMMENDATIONS / DOPORUČENÍ PRO KAPALINY ................................................ 35

11

DIAGRAMS / SCHÉMATA ..................................................................................................... 36

11.1

LEGEND / LEGENDA ......................................................................................................... 36

1

PED INFORMATION / PED INFORMACE .............................................................................. 38

13

INDIVIDUAL SPECIFICATION / INDIVIDUÁLNÍ SPECIFIKACE ........................................... 38