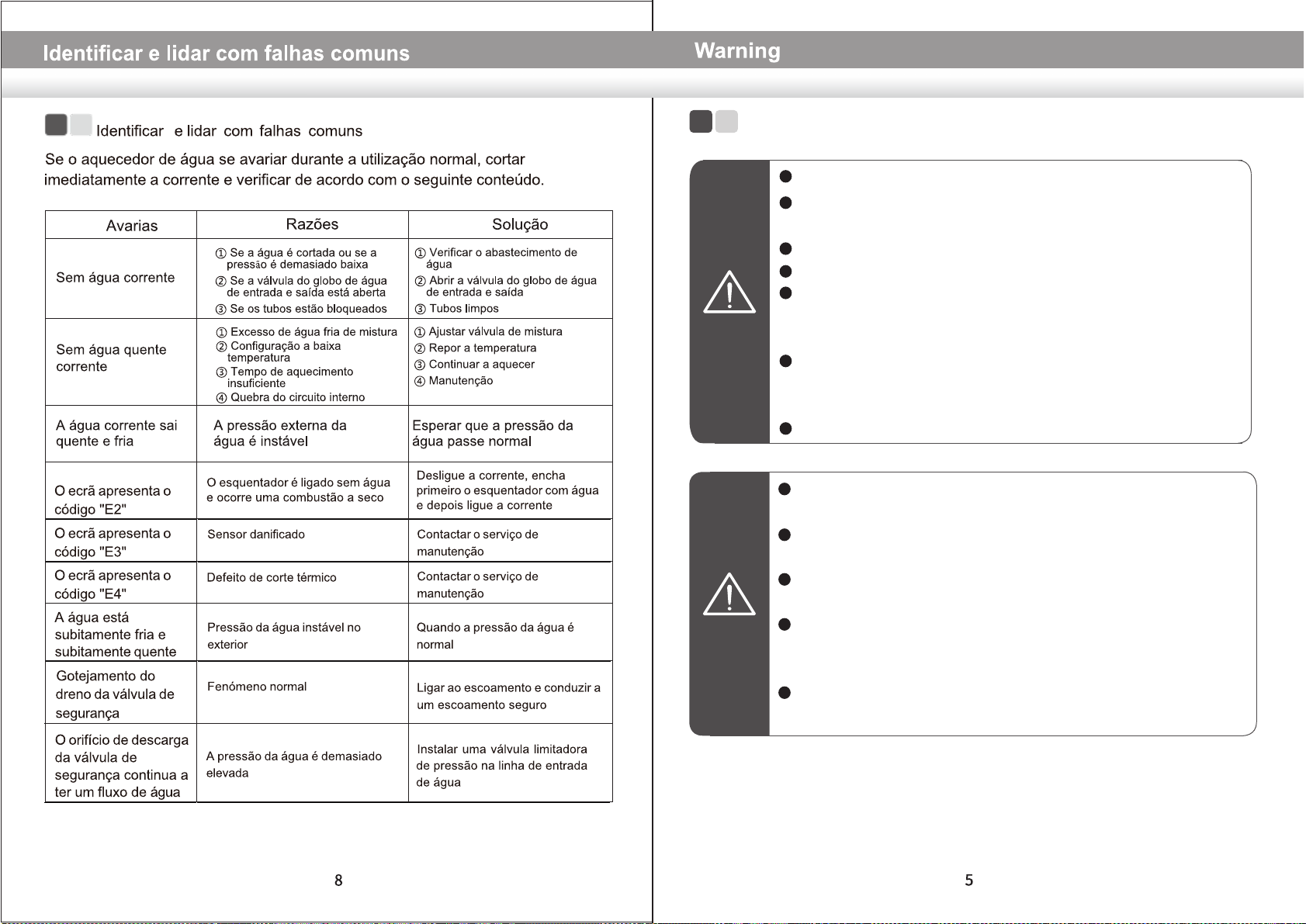

(1) “ ” key: Repeatedly operate this key and the system will enter power-on-wait.

(2) “ ” key: repeatedly operate this key to enter and exit the “Smart” mode in the

power-on state.

(3) “ ” key and “ ” key: in the power-on state, touch this key to adjust the set

temperature.One time increases or decreases 5 (ie 30-35-40-45...80-30), long

press is invalid. “ ” for Decrease, “ ” means increase.

(4) After the power is turned on, the actual temperature of the display (constantly

bright)/set water temperature (flashing), when setting the appointment time

(flashing display). A fault code is displayed when a fault occurs.

(5) “Smart ” light: In the “Smart ” working mode, it flashes during the statistical data

period, and is always on after the statistical data is completed.

(6) “Heating” light: the light is on in normal heating state, flashes at 1Hz in antifreeze

heating in shutdown state, and goes out in non-heating state.

2. Function description:

a. Immediate heating: in the power-on state, the water heater directly heats, when

the water heater reaches the set temperature, it stops heating and enters the

heat preservation state. After that, if the water temperature drops below the set

temperature by 8 degrees, it will be reheated, and so on. The heating light is on

when heating.

b. “Smart ”mode: In this working mode, the system analyzes, processes and

memorizes the user's water usage habits for a week, and then the system will

heat in advance according to the memorized water usage time.

c. Antifreeze: After the system is powered on (regardless of whether it is turned on

or not), as long as T≤5℃, the electric heating tube will automatically start to enter

the heating state, and when T=10℃, it will automatically exit the antifreeze

heating state.

d. Power-off memory: When the system is powered off, all parameters and working

modes are saved. After the power is restored, the parameters before power-off

are still entered into the real-time working mode.

e. Fault code display: When the system self-check fails, the two-digit digital tube

flashes to display the corresponding fault code. Among them: the dry burning

fault is E2, the sensor fault is E3, and the over-temperature fault is E4.

Description of Usage