Page 2

Before using this product, it is essential to read the ENTIRE Owner’s Manual and ALL

installation instructions. The Owner’s Manual describes equipment setup and instructs

members on how to use correctly and safely.

Read all warnings posted on the machine.

Health related injuries may result from incorrect or excessive use of exercise equipment.

Core Health & Fitness strongly recommends you to encourage your members to discuss their

health program or fitness regimen with a health care professional, especially if you or they

have not exercised for several years, are over 35, or have known health conditions.

WARNING!

IMPORTANT SAFETY INSTRUCTIONS

DANGER - to reduce the risk of electrical

shock:

1. Always unplug the machine from the electrical

outlet before cleaning or servicing.

2. This machine is not intended to be serviced by

the end user, refer servicing to qualified personnel

only.

3. This machine is designed for aerobic exercise in

a gymnasium or heath club environment (FOR

COMMERCIAL USE). It is wired for either 110

VAC 20A OR 230 VAC 15A nominal power input.

It is factory-equipped with a specific electric

cord and plug to permit connection to the proper

electric circuit. Make sure that the treadmill is

connected to a dedicated power line having an

outlet with the same configuration as that of the

plug:

• 20A for 110V models

• 15A for the 230V models

4. If the power supply cord is damaged, it must be

replaced by the manufacturer, its service agent,

or similarly qualified persons in order to avoid

hazard.

5. Do not operate machine in damp or wet locations.

WARNING - to reduce the risk of injury to

person:

24 in (0.6 m)

78.8 in (2.0 m)

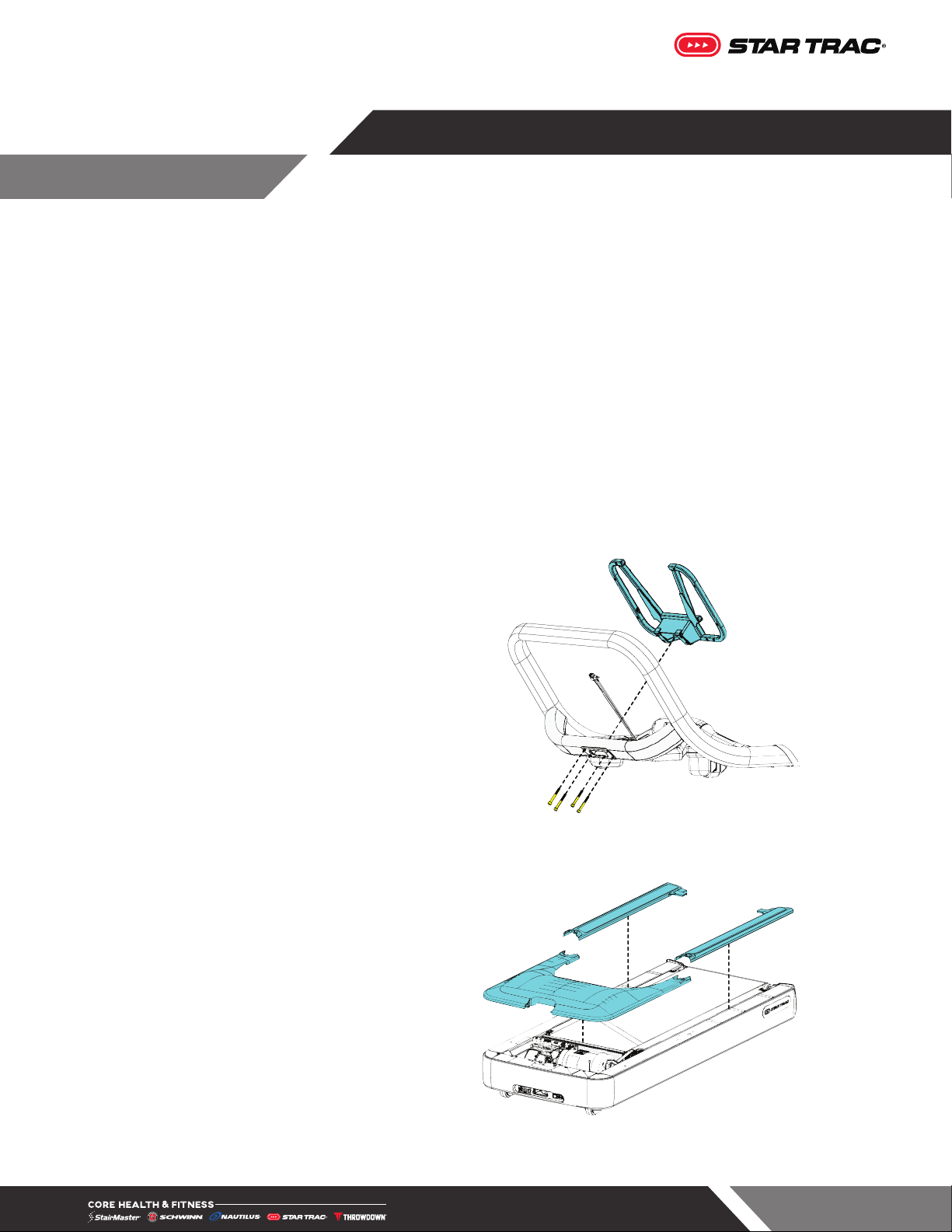

Fig. 1 8TRx Shown - Required Clearance

1. Assemble and operate the machine on a solid

level surface. Position the machine with a

minimum of 23.6 inches (0.6 meters) of clearance

on each side to allow for ease of mounting and

dismounting. Allow for 78.8 inches (2.0 meters) of

clearance behind the machine. Leave a minimum

of 19.7 inches (0.5 meters) between two adjacent

units. These dimensions are the recommended

minimum distances.

The actual area for access and passage shall be

the responsibility of the facility and should take

into account this training envelope, Americans

with Disabilities Act Accessibility Guidelines

(ADAAG) requirements and any required local

codes or regulations (www.access-board.gov/

ada).