is under pressure by removing the flush seal plug.

Turning the adjusting screw clockwise will decreases

the internal relief valve setting. Replace the flush seal

plug after adjustment.

13.After initial operation, re-check the strainer screen.

Chapter 3—Maintenance Procedures

ALL REPAIRS TO THE PUMP MUST BE

PERFORMED BY QUALIFIED PERSONNEL IN A

SAFE MANNER, UTILIZING TOOLS AND/OR

EQUIPMENT THAT ARE FREE OF HAZARDS, AND

FOLLOWS THE APPLICABLE SAFETY CODES OF

PRACTICE SET BY THE LOCAL AUTHORITIES HAVING

JURISDICTION. MAKE SURE THE SYSTEM PRESSURE

HAS BEEN RELIEVED BEFORE ATTEMPTING ANY

REPAIR TO THE PUMP.

A pump requires regular maintenance and care like

all mechanical equipment. A neglected or improperly

repaired pump will result in premature failure and cause

unsafe conditions.

To promote product longevity and safety, maintenance

must be performed by properly trained technicians. Make

sure all safety systems are in place and the system pressure

has been relieved before attempting ANY maintenance.

Make sure the transfer hoses are not “kinked” which can

cause excessive pump discharge pressure. Always make

sure your hoses are not out of date.

There are two lubrication points in which to grease

the pump bearings; one zerk per bearing cap located

at opposite ends of the pump. Four grease relief and

seal ventilation fittings have been provided, two at

each end of the pump, to prevent overgreasing the

bearings. Overgreasing can cause seal failure if grease

passageways are blocked in some way. Clean each

fitting before lubricating the bearings. This practice helps

to prevent foreign-material contamination of the bearings

and accidental over-pressurization of the mechanical

seals. Use only ball bearing grease (MIL-G-10924C) with

a temperature rating of -50°F.

Normal wear parts are the mechanical shaft seals, bearings,

vanes and sideplates. All of these parts plus O-rings and

grease seals are offered in the Corken “repair kit” listed in

this manual directly after the Seal Replacement Instruction

on page 10. Use only genuine Corken replacement parts

when repairing the pump.

When it becomes necessary to repair your pump or

remove it from the system, you must be absolutely

certain that all propane, anhydrous ammonia or whatever

product being pumped is bled from the pump and

connecting piping. Once all the product has safely been

bled from the pump and connecting piping, make certain

no pressure is left in the system.

SPECIAL CARE MUST BE TAKEN DURING THE

BLEED DOWN PROCESS TO AVOID DANGER

TO PERSONNEL AND PROPERTY IN THE AREA.

Bleeding a system too fast is a common mistake and

may leave “refrigerated” liquid in the pump and piping

even though the pressure gauge shows no pressure.

As the “refrigerated” liquid begins to warm, more

gas will escape causing a dangerous condition. Take

your time in bleeding your system and make proper

provisions to vent or capture the gas in accordance

with local regulations. ONLY A PROPERLY TRAINED

INDIVIDUAL SHOULD BE ALLOWED TO BLEED A

PUMPING SYSTEM.

Pump Maintenance Schedule

Daily Monthly Three

Months

Lubricate bearings X

1

Inspect drive coupling X

Clean inlet strainer X

Check for leaks X

Inspect hose and fittings X

1 Continuous duty applications may require monthly lubrication.

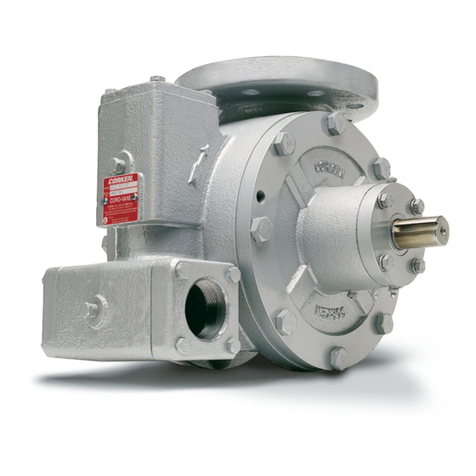

Figure 3

If the pump’s use is seasonal, then special care must be

taken during the off season to protect your pump from

corrosion. If it is feasible and safe to keep the pump

pressurized with product during the off season, this will

prevent the entrance of any moisture or air. This system

should be checked periodically to make certain all of the

gas has not bled out.

If the pump is to be removed from service for some time,

the pump must be protected., as propane, butane and

anhydrous ammonia all leave the metal “bare” and open to

corrosion. Piping and tanks not in service should also be

protected, as the rust that forms can destroy the pump’s

seals almost immediately after start-up. To prevent these

problems, complete the following:

1. Fill or thoroughly flush the pump with a light rust

inhibiting oil. If the pump is flushed with oil, placing

some desiccant packets inside the pump will provide

added protection.

2. Plug all pump openings.

3. Store in a dry location.

4. Before placing the pump back into service, drain the

oil and remove any desiccant packets.

5. Before operating the pump, refer to chapter 2 of this

manual for operation procedures.

8