container. If possible, these cylinders should be refitted

so the incoming liquid enters the vapor section of the

cylinder. If refitting is impossible or impractical, rock the

cylinder as it is being filled so that liquid will splash up into

the vapor section. This will help keep the cylinder filling

pressure down to a reasonable limit. A properly fitted

cylinder and filling manifold will permit filling a cylinder at

no more than 50 to 60 psi differential pressure. When the

pump is new, it is recommended to record the flow rate,

discharge pressure, and suction pressure.

2.2 Pumping From

Underground Tanks

Pumping boiling liquids, like LPG and other liquefied

gases, offers a unique set of challenges for underground

tank installations. When the piping system is designed

to function with a pump, Coro-Flo pumps offer superior

performance in these applications. Liquefied gases are

stored at exactly their boiling points. Any increase in

temperature, as well as any decrease in pressure, cause the

product to boil and form vapor. To minimize the amount of

vapor formation at the pump’s suction, properly designed

suction piping is critical. For boiling liquids, the net positive

suction head available (NPSHA) of an installation is reduced

to the height of the liquid level above the pump minus the

frictional losses. With an underground tank where the pump

is located above the liquid level, the net static suction head

becomes the net suction lift, which is negative not positive.

This means the installation NPSHA is always negative so

the pump will always have vapor in the liquid stream.

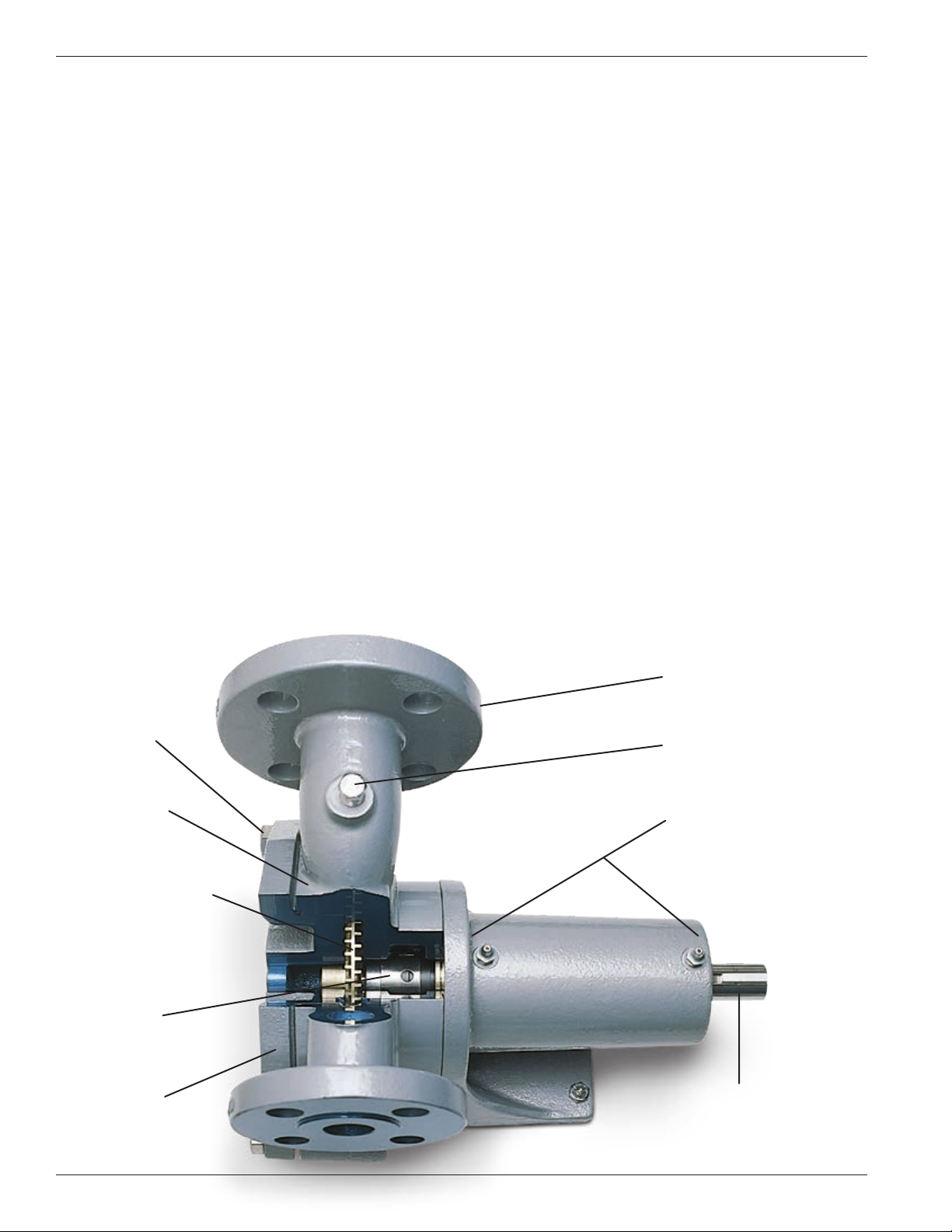

Coro-Flo regenerative turbine pumps are designed to

handle some vapor without the damaging effects of

cavitation. They are designed with a free floating impeller

that helps minimize wear and noise in this type of

application. When properly installed, Coro-Flo pumps

provide excellent service in underground tank applications.

Design Criteria for Underground Applications

• Minimize frictional losses:

— Pump should be as close as possible to the tank’s

liquid outlet connection.

— Use a minimal number of fittings and elbows.

— No strainer is necessary since the tank itself acts

as a gravity collector.

— Use full-port ball or low restriction valves.

— Use adequate piping sizes and do not go below

the inlet and outlet size of the pump.

• Limit the net static suction lift to approximately 14 feet

(4.3 meters) maximum.

• Use vapor eliminator valves and return to the vapor

space of the tank. A Corken B166 bypass valve has

this feature.

• An excess flow valve should be used in parallel for

additional vapor elimination.

• Always use back-pressure check valves downstream of

the pump.

• Limit the capacity of the pump to a maximum of 1.5%

of the tank’s capacity. For example, with a 1,000 Gal

(3,785 L) tank, limit the capacity of the pump to 15 gpm

(56.8 L/min).

For more details on underground piping systems, see

Appendix H.

Chapter 3—Preventative

Maintenance

Purpose

An effective preventive maintenance program minimizes

downtime and manpower requirements while maximizing

the performance of the equipment.

Scope

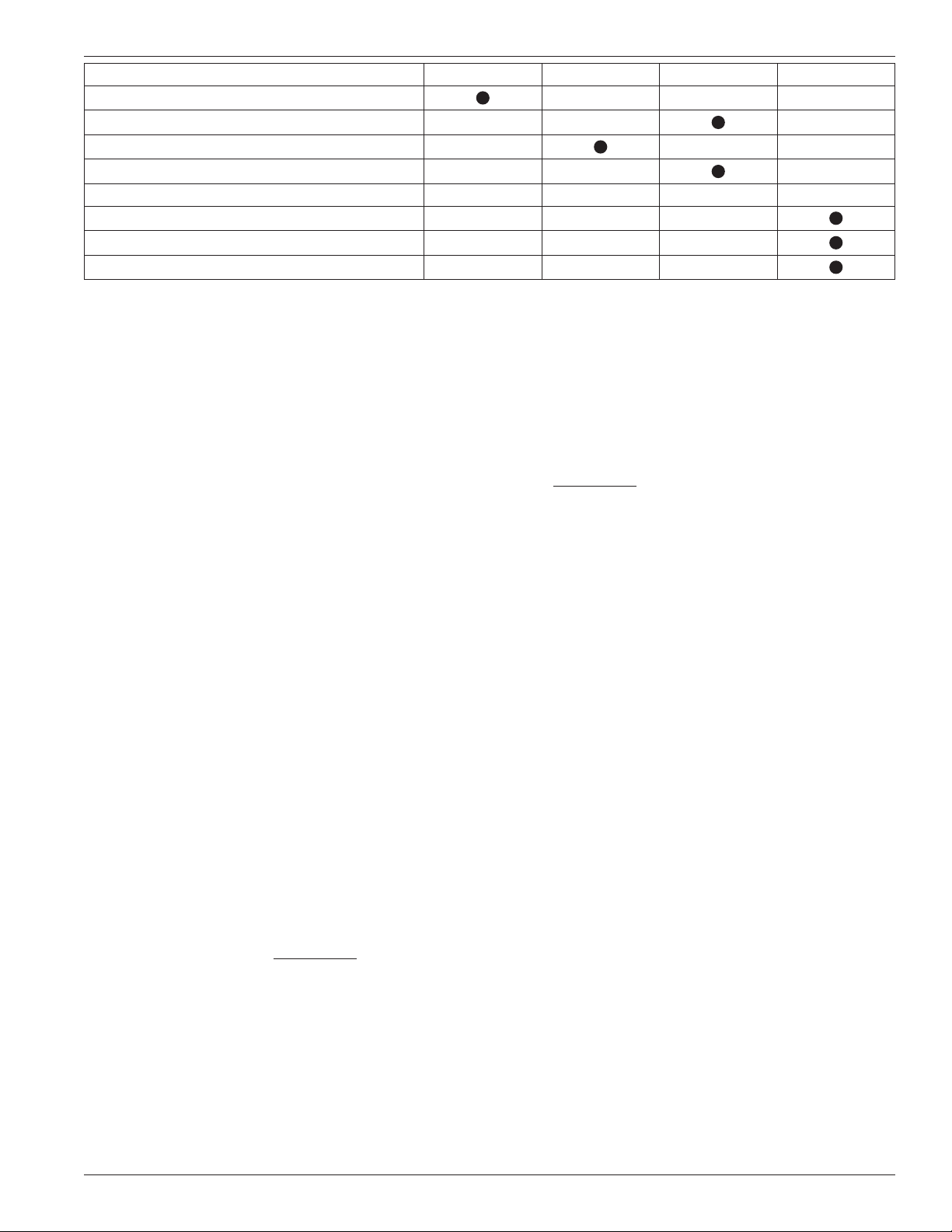

The preventive maintenance chart in figure 3.1 includes

items to be inspected with a recommended time schedule.

These are basic maintenance recommendations so

each company should develop a comprehensive

preventive maintenance schedule based on operational

requirements for the application.

Only a properly trained technician that follows all of the

applicable safety procedures should perform maintenance.

Procedures

Every procedure herein recommended must be performed

in a safe manner utilizing tools and/or equipment free of

hazards. Be certain to follow the safety codes of practice

set by the authorities having jurisdiction. These are

general guidelines and are not intended to cover all the

safety aspects that must be considered and followed

while performing these procedures.

1. Visual inspection:

This includes checking for leaks, corroded areas,

condition of hose, piping and fittings, and any

unsafe conditions which may hinder the safety of the

personnel and/or the facility.

2. Clean inlet strainer screen:

A clogged strainer screen restricts flow causing

vapor to form and leads to cavitation. The presence

of cavitation reduces the pump’s capacity and

accelerates wear on internal parts.

8