1

U.S. Gear

06/20

IMPORTANT INSTALLATION INSTRUCTIONS

WARNING – To reduce the risk of severe injury or death to

persons:

1. READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

2. Install only on a properly operating and balanced door. A door that is operating improperly could

cause severe injury. Have qualified service personnel make repairs to cables, spring assemblies,

and other hardware before installing the operator.

3. Remove all pull ropes and remove, or make inoperative, all locks (unless mechanically and/or

electrically interlocked to the power unit) that are connected to the door before installing the

operator.

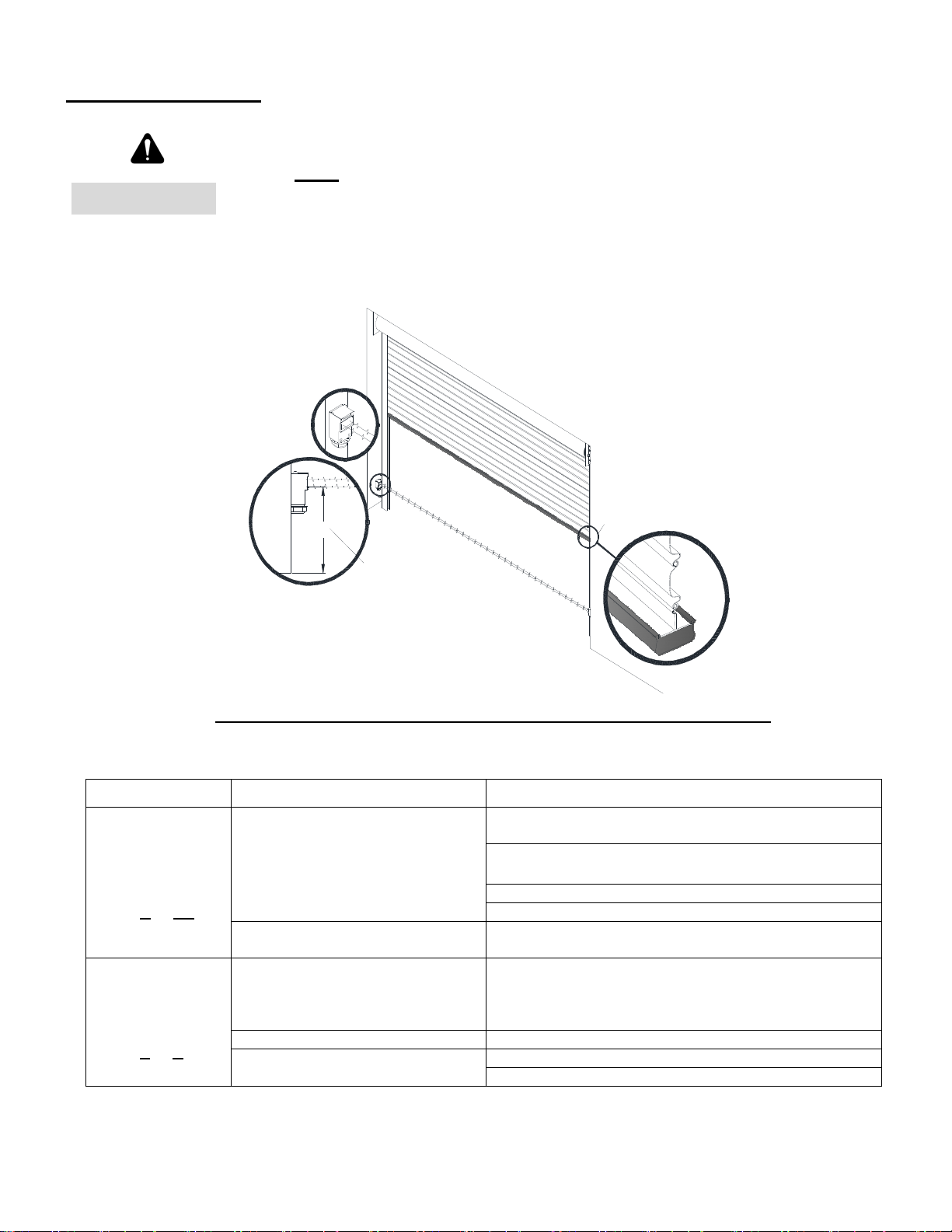

4. Install the door operator at least 8 feet or more above the floor if the operator has exposed moving

parts. If the operator must be mounted less 8 ft (2.44 m) above the floor, then exposed moving

parts must be protected by covers or guarding. Contact the manufacturer.

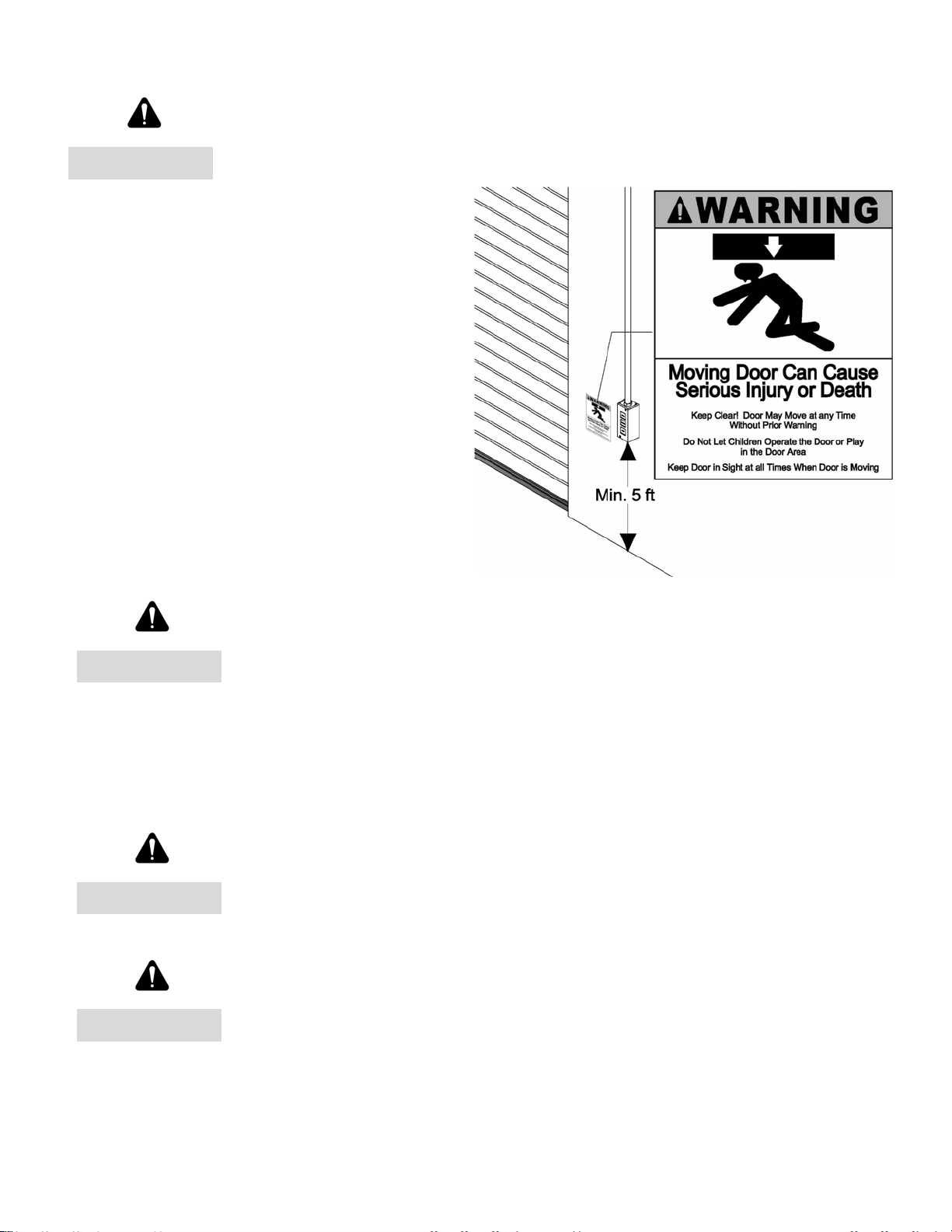

5. Locate the control station: (a) within sight of the door, and (b) at a minimum height of 5 feet above

floors, landings, steps, or any other adjacent walking surface and (c) away from all moving parts of

the door.

6. Install the Entrapment Warning Placard next to the control station in a prominent location.

7. Make sure the available power supply to be connected to the operator is of the same voltage,

frequency, phase and wattage as indicated on the nameplate of the operator.

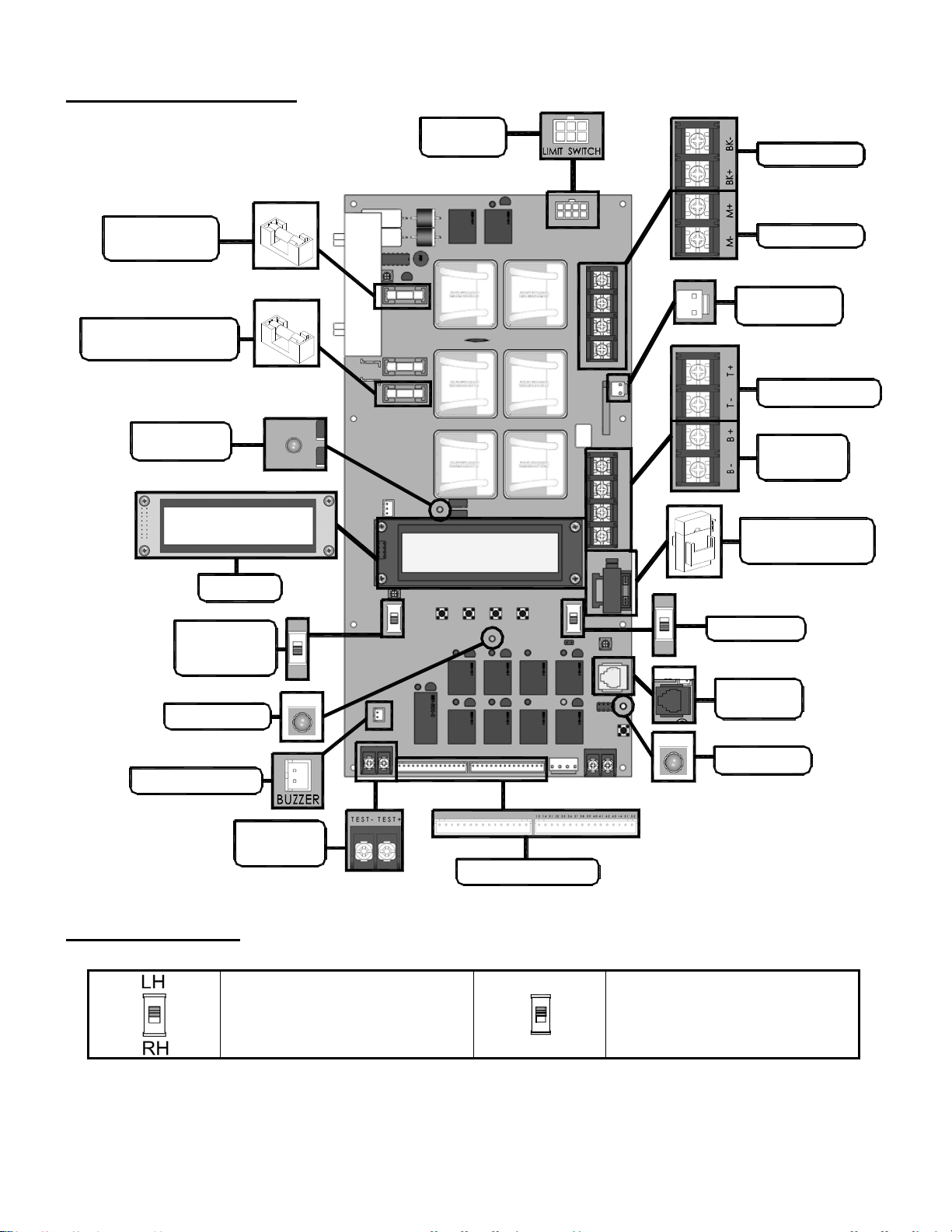

8. Read and understand the wiring diagram of the operator and the control station (open-close-stop

push button), and any other equipment to be connected to the operator.

9. To avoid damage to the door and operator, make all door locks inoperative. Secure locks in the

unlocked position, or install external electrical interlocks to prevent operation with the locks

engaged.

10. Always disconnect power whenever installing or servicing the door operator or door.

11. All wiring must be permanent and comply with National Electrical Code (NEC) and local code

requirements.

12. Any change in mounting position may result in a change of operator rotation and consequently in a

change of control functions. Consult factory for any changes.

13. If the operator is provided with an auxiliary chain operator, the hand chain should be kept inside

the chain bag when operating electrically.