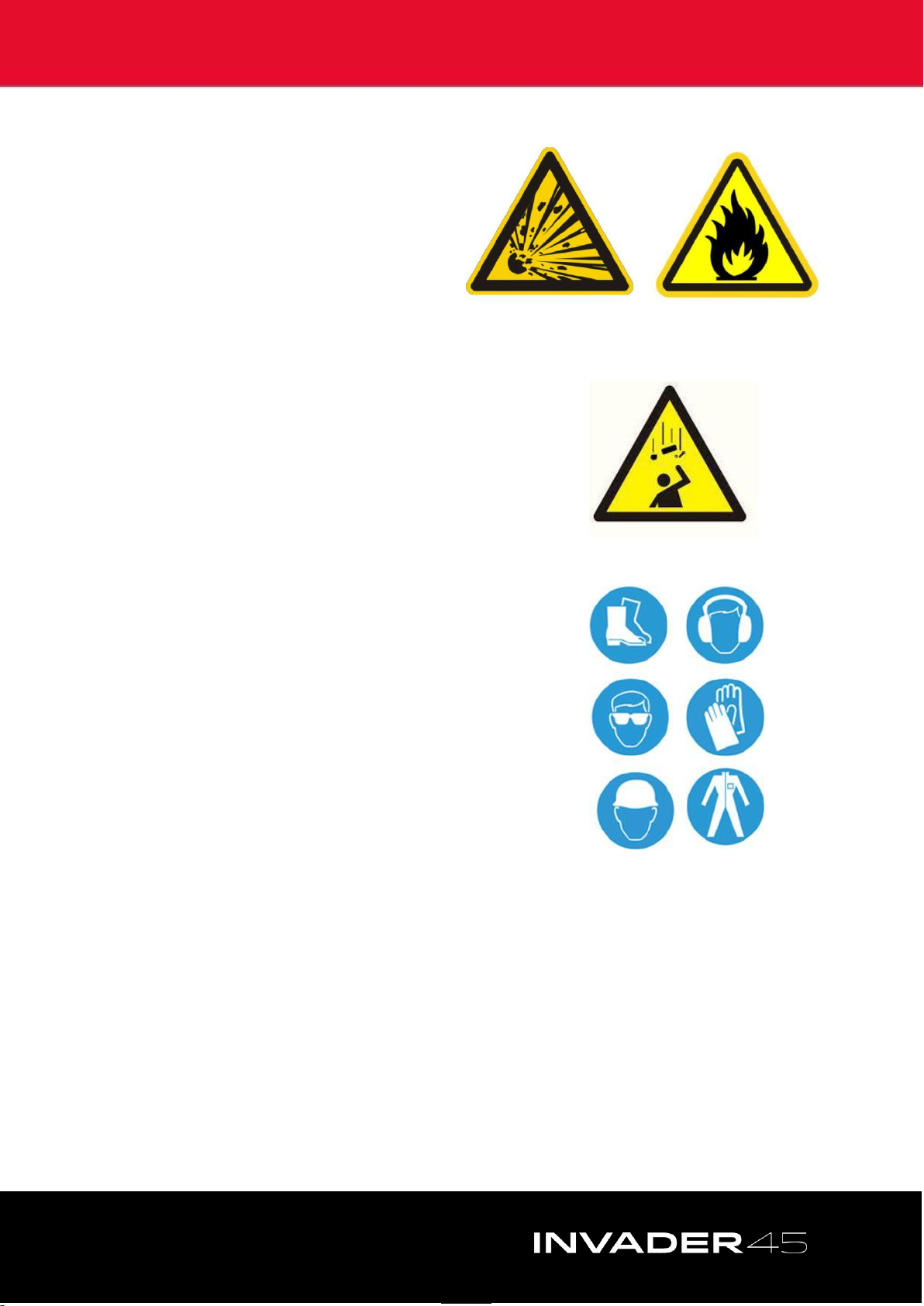

3. SAFETY

FAILURE TO FOLLOW THE INSTRUCTIONS AND SAFETY ADVICE IN THIS

MANUAL COULD RESULT IN DEATH OR SERIOUS INJURY.

Do Not Operate The Conveyor Unless You:

1. Have read and understand the principles relating to the

safe operation of your conveyor contained in this

manual.

2. Avoid hazardous situations.

3. Always check the conveyor/s before every use.

4. Inspect the workplace for hazards.

5. Only use the conveyor for the purpose it is intended.

6. Are properly trained to safely operate the conveyor.

HAZARDS –Set-up

Make sure that the work area is free of any overhead obstructions and any other

hazards such as unstable ground or other work activities taking place.

Do not use the conveyor if you are under the influence of alcohol or drugs or

prescribed medication that may affect your judgement.

Assess suitability of the ground surface condition prior to conveyor set-up.

Ensure the conveyor is adequately supported and wheels are braked/chocked

before use.

Do not alter or disable the conveyor components with items that in any way affect

safety and stability.

Do not ride on the belt.

Do not operate in high winds or adverse weather conditions

Inspect the undercarriage wheels to ensure the tyres are in good condition.

Do not alter or disable the control box, motor, power leads or plugs without prior

consultation with the manufacturer.

HAZARDS - Electrocution

The conveyor is not electrically insulated and will not

provide protection from contact with or proximity to

electrical current.

Do not use if cables are damaged

Do not operate during lightning or storms.

Do not use the conveyor as an earth for welding.

Ensure safe routing of power cable to minimise risk of

electrocution.