42019.01

back onto the valve using a 1/2” wrench. The insert allows the ferrule to collapse onto the insert which creates

a seal and prevents leaking. If you purchased a plumbing kit, the tubing and insert are both included. A small

amount of water is sufcient to keep the belt wet. If water is splashing all over the place, it is likely that you

are using too much water. There is a spray nozzle and a small piece of felt on the underside of the hood. The

spray nozzle sprays the water across the surface of the belt. The felt attaches to the spray nozzle and helps

distribute the water evenly across the face of the belt. The felt does not need to fully lay against the belt to

be effective. If you nd that the belt wants to grab the felt, you can press the felt up into the hood (while

the sander is turned OFF). The felt will still distribute the water evenly while

preventing the belt from grabbing it.

• If you purchased a pump or a plumbing kit, installation of the pump is easy.

You will need a bucket to place the pump into for your fresh water supply. The

other end of the 1/4” tubing simply presses into place in the quick connect

tting attached to the pump (see image 4). Should you need to attach the foot to

your pump, gently remove the front plate on your pump and slide the foot plate

into place (image 5). Replace the front plate on the front of your pump. This

prevents large pieces of debris from being sucked into the pump and clogging

it. This pump is a submersible pump and is designed to be placed directly into

a bucket of water. Once you plug the pump into an electrical supply, the pump

will begin running. These pumps have a straight cord as a safety feature. A

switch cannot be installed on the pump because it would eliminate the water-

tight aspect of the cord and can cause severe electrical shock to the user.

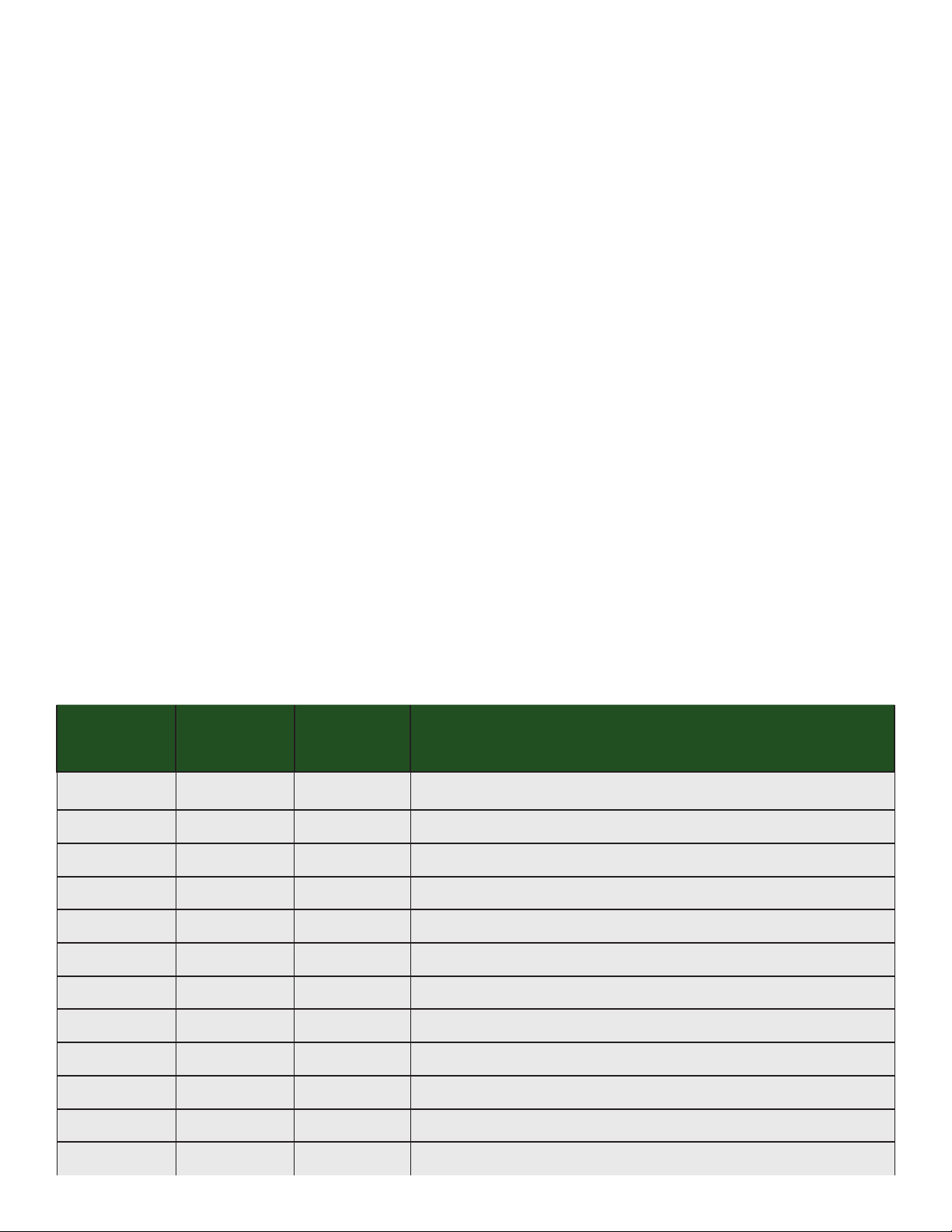

• If you purchased a drain kit or a plumbing kit, you will need the 7/16” wrench

that came with your unit and a 1/4” nut driver or a phillips head screw driver to

attach the drain kit. It is best to disassemble the drain kit before trying to attach

it to your sander. To attach the drain kit, you will need to remove the plug (see

the silver plug in image 1) on the front of your sander using the 7/16” wrench.

You’ll need to turn the plug counter-clockwise (remember, lefty-loosey) to get

it to unscrew. It may take a little effort to remove the plug from the casting pan.

Once the plug is removed, screw the brass pipe nipple into place on the front

of your unit. Make sure the brass is securely tightened to prevent any leaking

from this part of your unit. Once your brass is securely attached to the sander

base, slide the hose clamp over the tubing, and then slide the tubing over the

brass insert. Push the tubing as close up to the pan as you can. Make sure the

hose clamp is fully seated around the brass insert before tightening it down

onto the tubing with your 1/4” nut driver or phillips head screw driver. Once the hose clamp is secure, your

drain kit is ready to go. Put the end of the drain kit into an empty bucket to collect the dirty water. We never

recommend recirculating your water supply because this can cause contamination issues with your sander.

MAINTENANCE

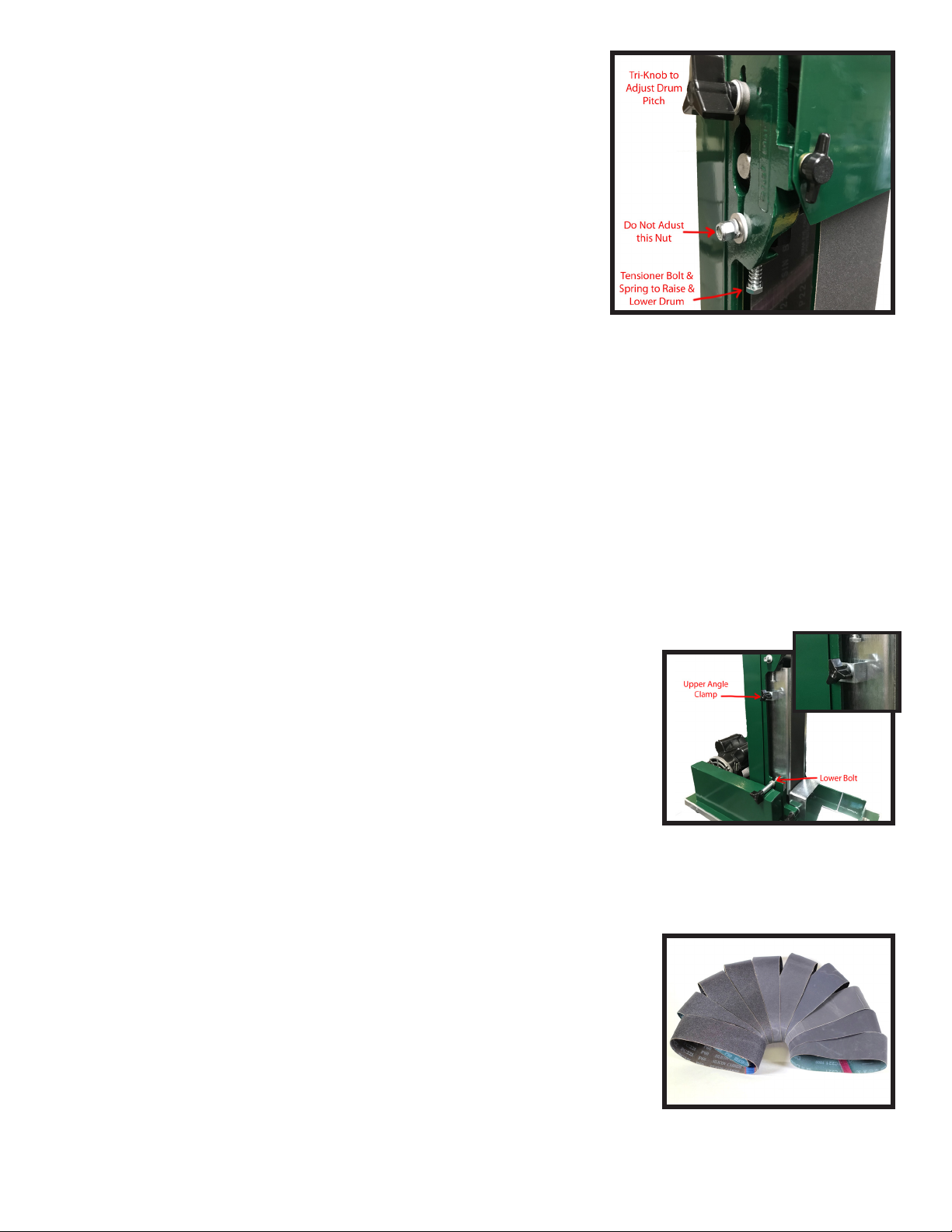

• Replacing Your Belt: The upper sander arbor works on a pivot. At the top of the arbor there is a tri-knob that

controls the tilt of the drum and at the bottom there is a lock-nut and spring. Never tighten the nylon lock-nut

because this can cause severe damage to your casting or your arbor because of the pivot point (see image 7).

Below the arbor, there is a bolt that is also attached to a spring. This bolt moves the arbor up and down within

the upright casting. It is easiest to remove your belt while the machine is running. When you are ready to make

a belt change, hold the switch in your right hand and put your left hand on the tri-knob. While the machine

is ON, slowly turn your tri-knob towards the back (counter-clockwise) to loosen the upper part of the arbor.

The belt will immediately begin to run off of the drums to the open section of the machine. As soon as the belt

is loose and slapping (approximately 1/2 way off the drums), turn the machine OFF. With the machine OFF,

Image 4

Image 5

Image 6