COXREELS SLP series Manual

INSTALLATION AND MAINTENANCE MANUAL FORM #PM-002 REV B 12/09

Page 1 of 4

For assembly drawings, parts lists, or specific repair instructions, refer to web site at www.coxreels.com or consult factory.

Coxreels, Inc., 5865 S. Ash Ave., Tempe, Arizona, USA, 85283 Tel: 1-800-269-7335

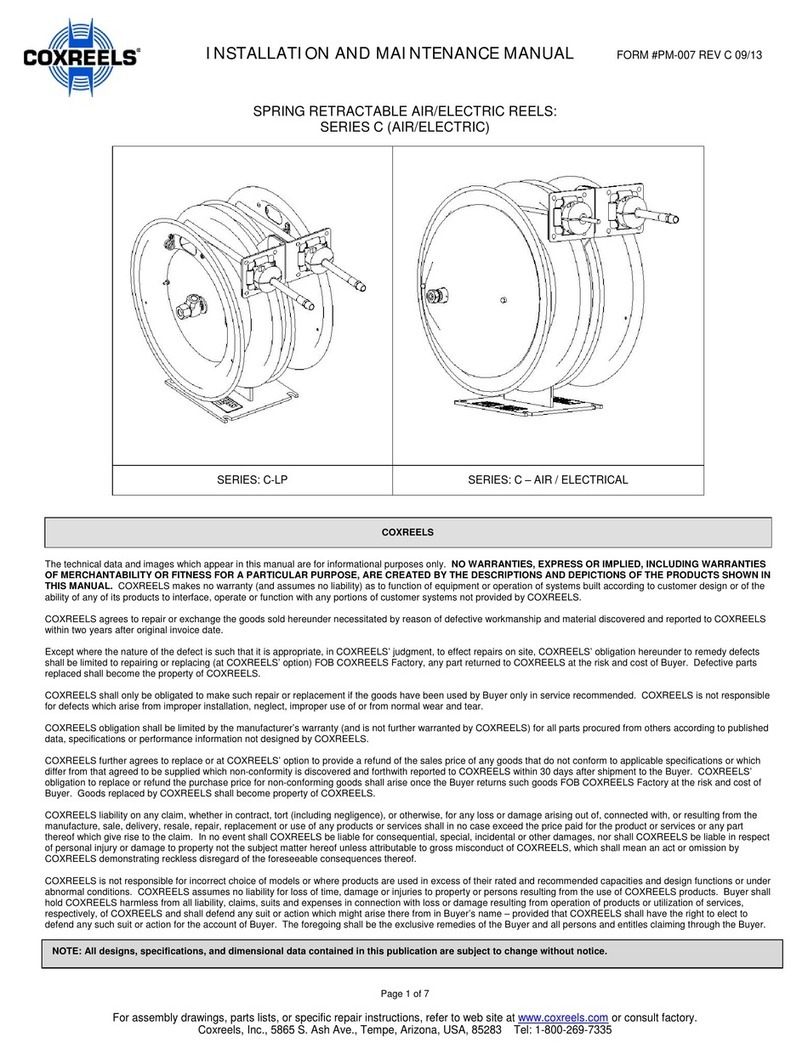

SPRING RETRACTABLE HOSE REELS:

SERIES SLP, SMP, DLP, DMP, V-SLP, VA-DLP

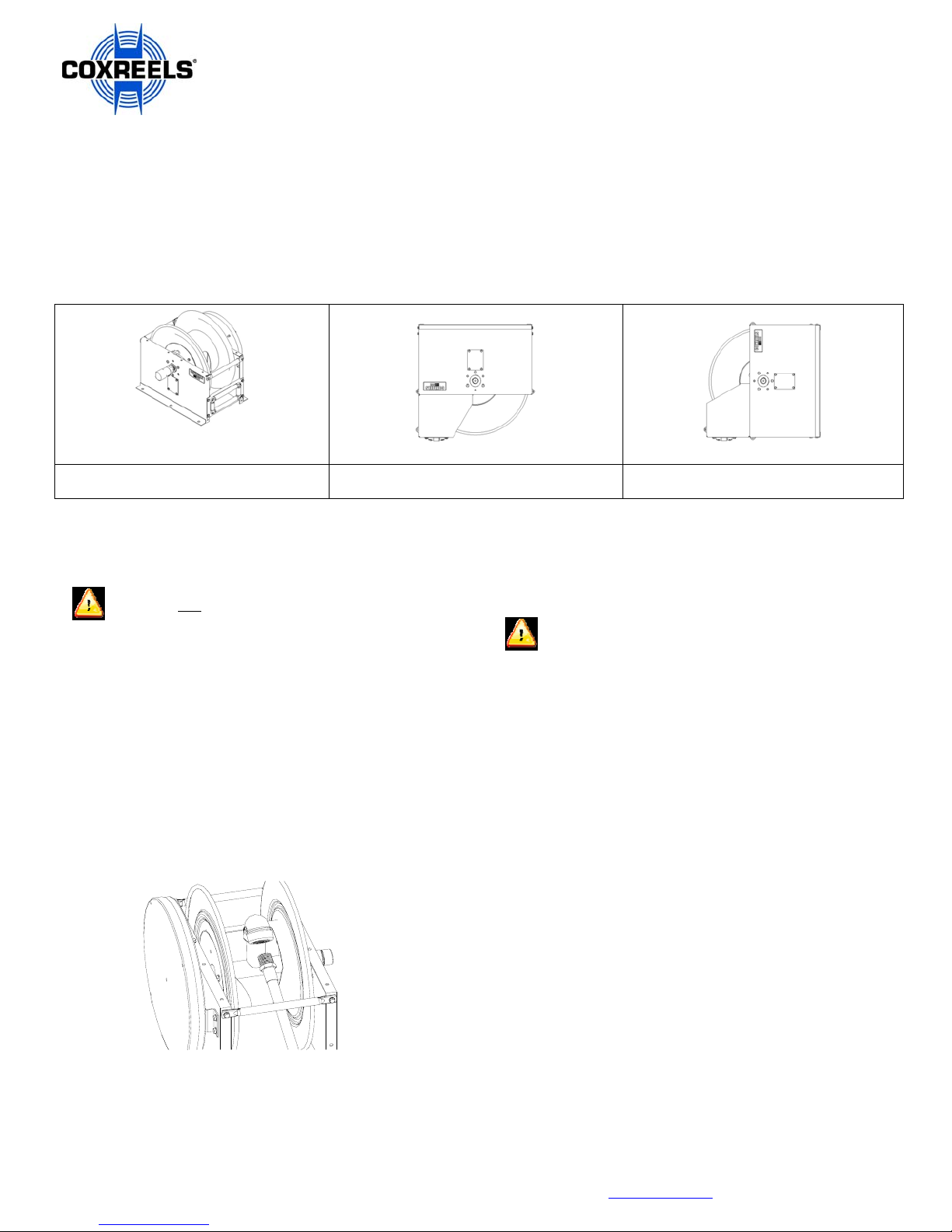

SLP V-SLP DLP

COXREELS

The technical data and images which appear in this manual are for informational purposes only. NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, ARE CREATED BY THE DESCRIPTIONS AND DEPICTIONS OF THE PRODUCTS SHOWN IN THIS MANUAL. COXREELS makes no warranty (and

assumes no liability) as to function of equipment or operation of systems built according to customer design or of the ability of any of its products to interface, operate or function with any portions of

customer systems not provided by COXREELS.

COXREELS agrees to repair or exchange the goods sold hereunder necessitated by reason of defective workmanship and material discovered and reported to COXREELS within two years after

shipment of such goods to Buyer.

Except where the nature of the defect is such that it is appropriate, in COXREELS’ judgment, to effect repairs on site, COXREELS’ obligation hereunder to remedy defects shall be limited to repairing or

replacing (at COXREELS’ option) FOB point of original shipment, any part returned to COXREELS at the risk and cost of Buyer. Defective parts replaced shall become the property of COXREELS.

COXREELS shall only be obligated to make such repair or replacement if the goods have been used by Buyer only in service recommended. COXREELS is not responsible for defects which arise from

improper installation, neglect, improper use of or from normal wear and tear.

COXREELS obligation shall be limited by the manufacturer’s warranty (and is not further warranted by COXREELS) for all parts procured from others according to published data, specifications or

performance information not designed by COXREELS.

COXREELS further agrees to replace or at COXREELS’ option to provide a refund of the sales price of any goods that do not conform to applicable specifications or which differ from that agreed to be

supplied which non-conformity is discovered and forthwith reported to COXREELS within 30 days after shipment to the Buyer. COXREELS’ obligation to replace or refund the purchase price for non-

conforming goods shall arise once Buyer returns such goods FOB point of original shipment by COXREELS at the risk and cost of Buyer. Goods replaced by COXREELS shall become property of

COXREELS.

COXREELS liability on any claim, whether in contract, tort (including negligence), or otherwise, for any loss or damage arising out of, connected with, or resulting from the manufacture, sale, delivery,

resale, repair, replacement or use of any products or services shall in no case exceed the price paid for the product or services or any part thereof which give rise to the claim. In no event shall

COXREELS be liable for consequential, special, incidental or other damages, nor shall COXREELS be liable in respect of personal injury or damage to property not the subject matter hereof unless

attributable to gross misconduct of COXREELS, which shall mean an act or omission by COXREELS demonstrating reckless disregard of the foreseeable consequences thereof.

COXREELS is not responsible for incorrect choice of models or where products are used in excess of their rated and recommended capacities and design functions or under abnormal conditions.

COXREELS assumes no liability for loss of time, damage or injuries to property or persons resulting from the use of COXREELS products. Buyer shall hold COXREELS harmless from all liability,

claims, suits and expenses in connection with loss or damage resulting from operation of products or utilization of services, respectively, of COXREELS and shall defend any suit or action which might

arise there from in Buyer’s name – provided that COXREELS shall have the right to elect to defend any such suit or action for the account of Buyer. The foregoing shall be the exclusive remedies of the

Buyer and all persons and entitles claiming through the Buyer.

WARNING – APPLICATION

THE PRODUCTS IN THIS INSTALLATION AND MAINTENANCE MANUAL HAVE BEEN TESTED UNDER CONTROLLED LABORAROTY CONDITIONS TO MEET SPECIFIC TEST CRITERIA. THESE TESTS

ARE NOT INTENDED TO REFLECT THE PERFORMANCE OF THE PRODUCTS OR ANY OTHER MATERIAL IN ANY SPECIFIC APPLICATION, BUT ARE INTENDED TO PROVIDE THE USER WITHY

APPLICATION GUIDELINES. THE PRODUCTS ARE INTENDED FOR USE BY KNOWLEDGEABLE PERSONS HAVING THE TECHNICAL SKILL NECESSARY TO EVALUATE THEIR SUITABILITY FOR SPECIFIC

APPLICATIONS.

WARNING – USER RESPONSIBILITY

THE USER, THROUGH ITS OWN ANALYSIS AND TESTING, IS SOLELY RESPONSIBLE FOR MAKING THE FINAL SELECTION OF THE SYSTEM AND COMPONENTS AND ASSURING THAT ALL

PERFORMANCE, ENDURANCE, MAINTENANCE, SAFETY AND WARNING REQUIREMENTS OF THE APPLICATION ARE MET.

TO THE EXTENT THAT COXREELS PROVIDE COMPONENT OR SYSTEM OPTIONS BASED UPON DATA OR SPECIFICATIONS PROVIDED BY THE USER, THE USER IS RESPONSIBLE FOR DETERMINING THAT

SUCH DATA AND SPECIFICATIONS ARE SUITABLE AND SUFFICIENT FOR ALL APPLICATIONS AND REASONABLY FORESEEABLE USES OF THE COMPONENTS OR SYSTEM.

WARNING – SAFETY

READ ALL SAFETY INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL, OPERATE, OR MAINTAIN THIS PRODUCT. ONLY QUALIFIED PERSONNEL SHOULD UNDERTAKE THE

INSTALLATION AND COMMISSIONING OF THIS PRODUCT. FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE.

FAILURE TO FOLLOW RECOMMENDED APPLICATION INFORMATION AND RECOMMENDED PROCEDURES FOR SELECTION, INSTALLATION, CARE, MAINTENANCE AND STORAGE OF REEL ASSEMBLY,

SWIVEL, HOSE, COUPLINGS OR HOSE ASSEMBLIES MAY RESULT IN FAILURE TO PERFORM PROPERLY AND MAY RESULT IN DAMAGE TO PROPERTY AND SERIOUS BODILY INJURY.

FOLLOW GOOD MAINTENANCE PRACTICES – ESTABLISH A PROGRAM OF INSPECTION, TESTING AND REPLACEMENT OF REEL COMPONENTS FROM FACTORS INCLUDING:

oSEVERITY OF APPLICATION, FREQUENCY OF EQUIPMENT USE, AND PAST PERFORMANCE OF REEL COMPONENTS

ONLY PROPERLY TRAINED PERSONS SHOULD INSPECT, TEST OR SERVICE REEL AND HOSE/CABLE ASSEMBLIES. PERIODIC UPDATING OF TRAINING IS RECOMMENDED.

DOCUMENT MAINTENANCE, INSPECTIONS AND TESTING.

PROP 65 WARNING: Handling of brass material on this product exposes you to lead, a chemical known to the State of California to cause birth defects or other reproductive harm.

“WASH HANDS AFTER USE”

NOTE: All designs, specifications, and dimensional data contained in this publication are subject to change without notice.

INSTALLATION AND MAINTENANCE MANUAL FORM #PM-002 REV B 12/09

Page 2 of 4

For assembly drawings, parts lists, or specific repair instructions, refer to web site at www.coxreels.com or consult factory.

Coxreels, Inc., 5865 S. Ash Ave., Tempe, Arizona, USA, 85283 Tel: 1-800-269-7335

PRESSURE WARNINGS

•This equipment should be properly installed before use in

accordance with local codes and ordinances.

•The pressure from the hose reel should be disconnected from the

hose reel before any service functions are performed.

•This hose reel must not be used for pressure greater that the rating

listed in the COXREELS catalog / website www.coxreels.com.

OPERATIONAL WARNINGS

•Exercise care when handling the hose reel during normal operation.

Some hose reels have a rotating drum powered by a spring under

tension.

•Do not use hose different from that for which the reel is intended.

Changes in diameter, weight per foot, length of hose or flexibility

(Minimum Bend Radius) will affect the operation of the reel.

•Mounting hardware and fasteners should be installed to maintain

tightness under vibration and checked periodically to ensure

tightness.

•Overhead installation mountings should be such that the reel is not

solely supported by bolts in tension. A safety chain, cable, enclosure

or netting is strongly recommended to minimize damage and/or

possible injury in the event of a mounting failure.

MAINTENANCE WARNINGS

•Modification of the equipment may cause excessive wear and will

void the warranty. Contact COXREELS regarding changes or

modifications of equipment which could affect reliability or safety.

•DO NOT DISASSEMBLE A SPRING MOTOR FOR ANY REASON!

Serious personal injury could result. Some hose reels are equipped

with a spring under tension. Contact COXREELS for assistance.

SPECIFICATIONS & LISTINGS

•The identified Series of Hose Reel products within this manual are

not certified or listed by any independent certifying or regulatory

body.

•This series of hose reels is intended for industrial use and are

provided with permanent mounting means.

PRESSURE & TEMPERATURE RATING

•All reels covered in this manual with or without hose have specific

P.S.I. ratings. (Please refer to the COXREELS catalog, website or

contact Customer Service for Reel specific data). Reels should not

be used at pressures greater that the rating of the hose.

•Multipurpose hose is installed with tube compounded for maximum

oil resistance. Hose can be used for air, water, oil and many other

chemical applications.

•Operational temperature ranges vary across the wide range of hose

options. (Please refer to the COXREELS catalog, website or

contact Customer Service for hose specific data). Hose reels

should not be used at temperatures below or above the rating of the

hose.

•The operational rating of a reel not equipped with hose is determined

by the capacity of the installed hose. The pressure rating of the reel

without hose must not be greater than the than the operational

capacity of a reel. (Please refer to the COXREELS catalog, website

or contact Customer Service for reel/hose specific data). Variations

in the OD of higher rated hose will affect the operational capacity of

the reel.

LABELS & MARKINGS

Hose Reels with and without hose

•The marking of the hose reel provided with or without hose includes

the following

oThe label on the frame includes the COXREELS name

and Logo, the product catalog number, the individual

product serial number, PSI rating and what type and

length of hose intended for use on the reel.

oThe maximum pressure rating for every hose reel

supplied without house is marked on the COXREELS

Identification Label. In absence of this information, refer

to website, catalog, or customer service. Actual rating is

determined by the installed hose and is not to exceed the

indicated maximum operational rating. The pressure

rating of the hose installed on reels provided without

hose must be marked on the label upon installation.

PERSONAL SAFETY

•Ensure reel has been properly installed before connecting supply

line.

•Before connecting to reel, be certain supply line does not exceed

rated pressure of the hose reel.

•If reel was purchased without hose, thoroughly review the “Hose

Installation” instructions to properly install hose.

•Perform “Operational Check” per instructions to ensure reel is

operating properly.

•NEVER use a spring retractable reel that is not performing as

intended.

•If a leak should occur after applying pressure to the reel, immediately

discontinue supply line pressure.

WARNING: Prevent static sparking. When working around flammables,

ensure that the hose reel, hose, and equipment are properly grounded.

INSTALLATION

WARNING: READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL, OPERATE, OR MAINTAIN THIS PRODUCT. ONLY

QUALIFIED PERSONNEL SHOULD UNDERTAKE THE INSTALLATION AND COMMISSIONING OF THIS PRODUCT. FAILURE TO COMPLY WITH

INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE.

WARNING: REEL SHOULD NOT BE INSTALLED ABOVE 15 FEET MAXIMUM FROM THE FLOOR.

SAFETY

INSTALLATION AND MAINTENANCE MANUAL FORM #PM-002 REV B 12/09

Page 3 of 4

For assembly drawings, parts lists, or specific repair instructions, refer to web site at www.coxreels.com or consult factory.

Coxreels, Inc., 5865 S. Ash Ave., Tempe, Arizona, USA, 85283 Tel: 1-800-269-7335

MOUNTING OF REEL

•Review mounting configuration for floor, ceiling, or wall mount. Standard configuration is floor mount (see Fig. 1.0). Refer to Fig. 2.0 for optional ceiling mount

or Fig 3.0 for wall mount positions.

•Mount reel to a solid structure using six 7/16” or M12 bolts, washers, and nuts. Six masonry bolts may be used depending on mounting application. Mounting

hardware is NOT provided. The mounting base of the reel has six ½” holes.

•Fit reel. Install hardware in reel base. Securely fasten all bolts and nuts.

•Overhead or Wall installation mountings should be such that the reel is not solely supported by bolts in tension. A safety chain, cable, enclosure or netting is

strongly recommended to minimize damage and/or possible injury in the event of a mounting failure.

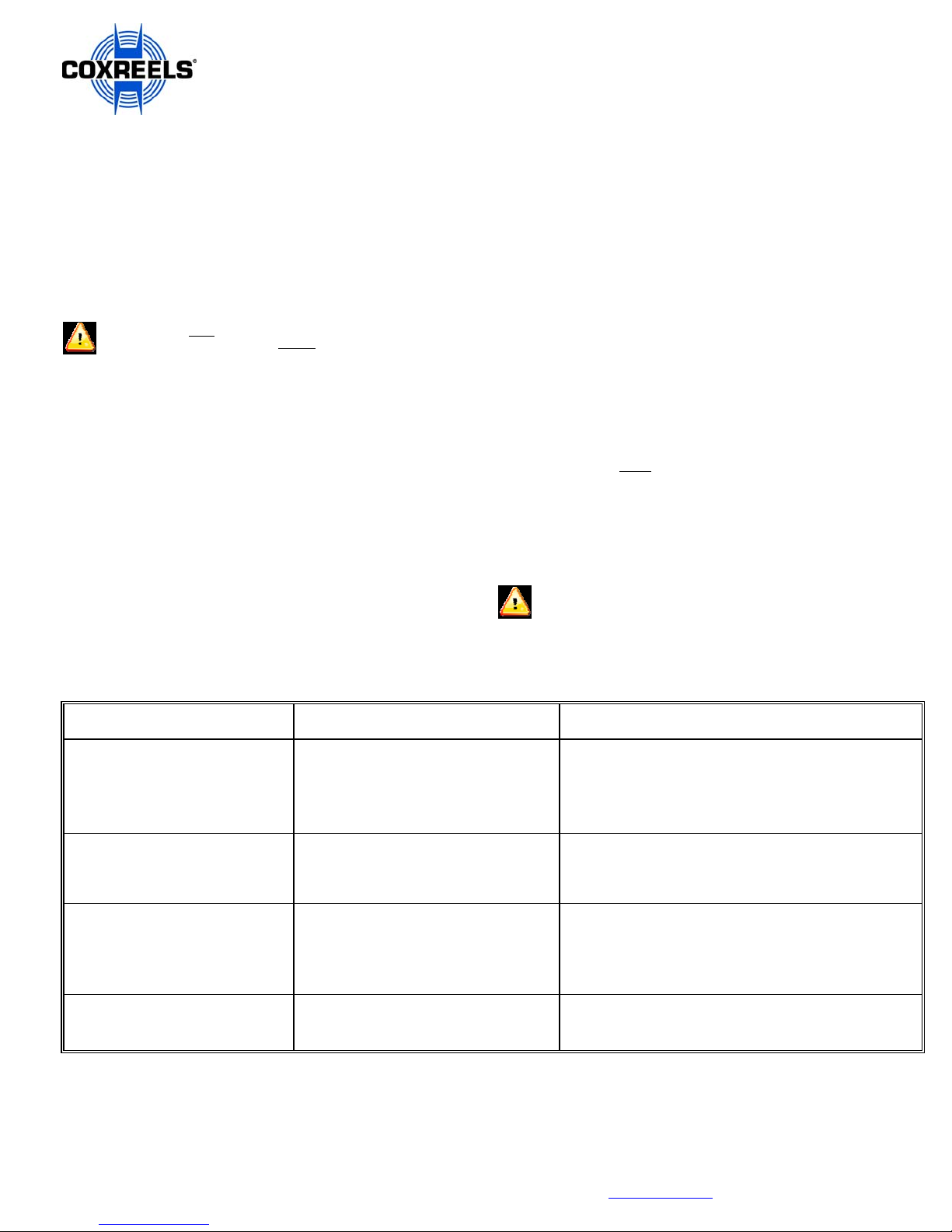

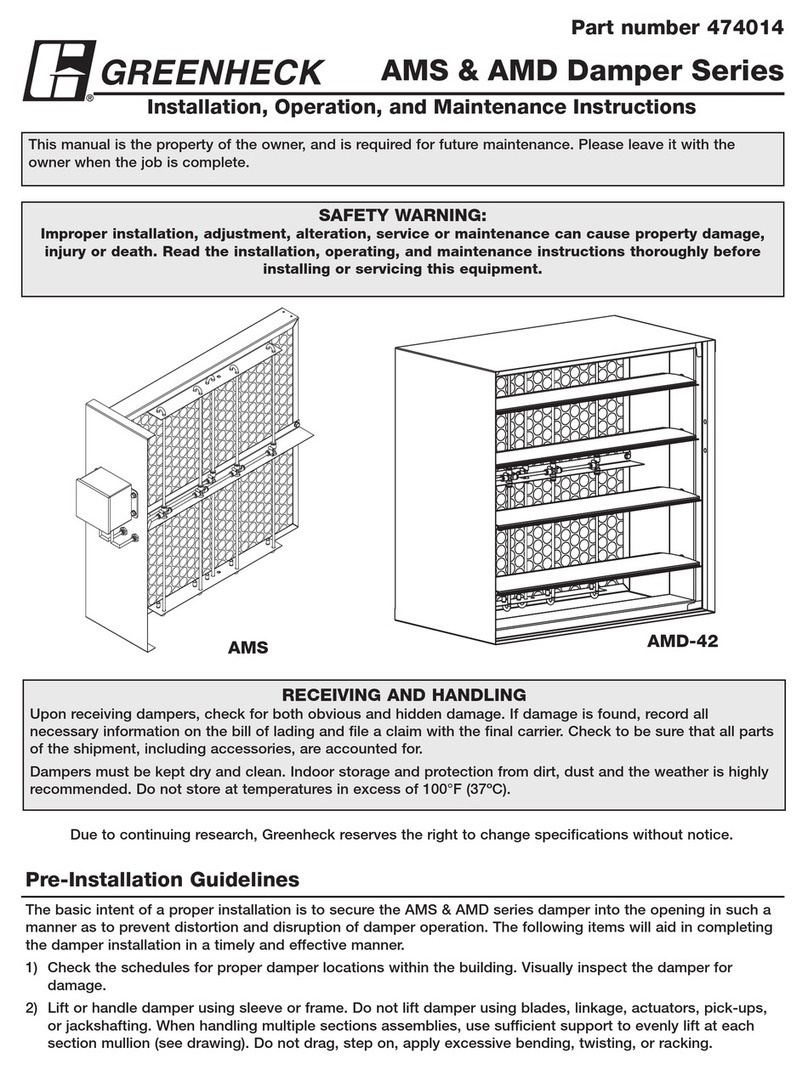

FIGURE 1.0 FIGURE 2.0 FIGURE 3.0

INSTALLATION OF INLET HOSE

•Apply thread sealant to inlet hose and connect to the swivel joint on

reel.

CAUTION: IT IS IMPORTANT TO USE A “FLEXIBLE” INLET

HOSE. DO NOT USE SOLID PIPING OR RESTRAIN INLET HOSE

AS TO CAUSE ANY SIDE FORCE ON SWIVEL JOINT. THE

WARRANTY IS VOID IF NOT PROPERLY INSTALLED.

•Flush some product through the system before connecting inlet hose

to the source.

•If reel includes hose (Otherwise, See Installation of Hose), flush

some product through system before connecting end fitting, nozzle,

or tool.

•(Reel supplied less hose) Apply thread sealant to outlet hose fitting.

Connect end, nozzle, or tool as desired.

•If a hose stopper adjustment is required to allow easy reach of end

fitting or tool; latch reel at approximate desired location, loosen (two)

ball stop bolts. Move ball stop and tighten bolts. Unlatch reel.

•Connect Inlet hose to supply source.

INSTALLATION OF OUTLET HOSE

NOTE: Before proceeding, ensure that you are installing the proper size, length

and type of hose per the reel rating. Consult factory if unsure of rating. Damage

may occur if wrong hose is installed.

•Securely stabilize the reel.

•Wind the reel drum counter-clockwise (facing the swivel) until the

spring is tight.

Use Extreme Caution!

•Back off approximately two turns and lock the reel drum to keep from

rotating.

•Insert the MALE fitted end of the hose through the roller guide and

up to the outlet riser. See Fig. 4.0

•Apply thread sealant; connect hose fitting to the outlet riser.

•CAREFULLY release the locking ratchet and SLOWLY allow the

hose to retract onto the reel.

NOTE: See “Spring Tension Adjustment” procedure for proper tensioning of

reel.

CAUTION: Fully extend and charge hose before winding on to reel. Briefly open

control valve to purge hose of gases. When fluid appears at control valve, close

valve. This prevents flattening of the hose and excessive pressure on the drum

when fluid supply is reinitialized at a later time.

FIGURE 4.0

C

M P

os

i

t

i

o

n

W

MPosition

Standard “FM” Position

INSTALLATION AND MAINTENANCE MANUAL FORM #PM-002 REV B 12/09

Page 4 of 4

For assembly drawings, parts lists, or specific repair instructions, refer to web site at www.coxreels.com or consult factory.

Coxreels, Inc., 5865 S. Ash Ave., Tempe, Arizona, USA, 85283 Tel: 1-800-269-7335

OPERATIONAL CHECK

•Check reel for correct operation by slowly pulling out hose. A

clicking noise will be heard after each half revolution of the drum.

•LATCH the reel. Pull out the hose and allow it to slightly retract after

the first, second or third “click” is heard.

•UNLATCH the reel. Slowly pull the hose until the clicking noise

stops, and then allow the hose to retract. The hose stopper should

rest against the roller hose guide.

CAUTION: DO NOT ALLOW HOSE TO RETRACT WITHOUT

RESTRAINING RECOIL SPEED. NEVER LET GO OF THE HOSE

WHEN REWINDING.

•Apply line pressure and inspect for leaks. Periodically check hose

for improper wear and swivel for possible leaks.

•Reels are shipped with approximately three pre-wraps of tension.

This is adequate for most applications. However, if your application

requires more or less tension, see “Spring Tension Adjustment”

instructions.

•Lubrication is NOT required.

SPRING TENSION ADJUSTMENT

Remove outlet nozzle, gun, or tool. Remove hose stopper.

Add or subtract one wrap of hose as desired to acquire the proper

tension on the reel.

NOTE: Spring tension adjustment is accomplished by adding wraps of hose

around the drum (to increase tension) or subtracting wraps of hose (to decrease

tension).

Install hose stopper and reconnect nozzle, gun, or tool.

SWIVEL SEAL REPLACEMENT

Release supply line pressure. Remove inlet hose from swivel.

Remove swivel from reel by unscrewing swivel from axle shaft or

removing attachment bolts depending on model.

Remove retaining ring on swivel; pull out spool from body.

Replace seals, lubricate and reassemble swivel.

Fit swivel to reel. Do not over-tighten.

Reconnect inlet hose and test for leakage.

SPRING CANISTER REPLACEMENT

Pull out approximately 3 feet (1m) of hose and latch the reel.

Remove outlet nozzle, gun or tool and hose stopper.

Carefully unlatch the reel and firmly hold the drum. Allow the drum

to slowly unwind until it stops.

Remove four nuts located on the spring canister mounting bracket.

CAUTION: Do not remove spring can nuts.

Pull spring canister off center shaft.

Reverse above procedure to re-assemble.

Re-tension the reel by turning the drum three complete turns

counter-clockwise (from swivel side) and latch the drum.

Feed the hose through the hose guide. Fit hose stopper, then

unlatch the drum. Hose stopper should sit snugly against the hose

guide.

CAUTION: Release line pressure prior to making any repairs or

adjustments to the reel.

TROUBLE SHOOTING GUIDE

TROUBLE CAUSE REMEDY

HOSE WILL NOT FULLY RETRACT

a) Outlet nozzle, gun or tool is too heavy.

b) Spring is fatigued.

c) Field installed hose is too long.

a) Add spring tension. See "Spring Tension Adjustment".

b) Add spring tension. See "Spring Tension Adjustment".

Replace Spring Canister if required.

c) Call local Distributor for correct specified hose length.

HOSE WILL NOT RETRACT AT ALL Spring has lost all tension or has possibly

broken.

a) Reinstall Spring Tension

b) Replace Spring Canister. See "Spring Canister

Replacement".

REEL WILL NOT LATCH

a) Incorrect operation.

b) Dog spring or locking cam is

broken or worn.

a) Reel latches on first, second, third or fourth "click".

After forth "click" it automatically rewinds.

b) Replace dog spring or locking cam.

FLUID LEAKS FROM SWIVEL Swivel seals are damaged or worn. Replace swivel seals. See "Swivel Seal Replacement".

Caution: Be sure leak is not at Hose Fitting!

This manual suits for next models

5

Other COXREELS Other manuals

Popular Other manuals by other brands

Aquadistri

Aquadistri SuperFish Aqua 20 Warranty and manual

Motorvac

Motorvac 500-1125B user manual

EHEIM

EHEIM CO2SET 200 operating manual

STEER SMARTS

STEER SMARTS Yeti JK Extreme installation instructions

Greenheck

Greenheck AMD-42 Installation, operation and maintenance instructions

Draw tite

Draw tite 24944 installation instructions