CPG CK HPSU212 User manual

1

USER MANUAL

Gas Step Up Hot Plate

MODELS: CK HPSU212, CK HPSU424,

CK HPSU636

06 / 2017

2

IMPORTANT FOR FUTURE REFERENCE

Please complete this informaon and retain this manual for the life of the equipment. For Warranty

Service and/or parts, this informaon is required.

Model Number Serial Number Date Purchased

WARNING: For your safety, do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliances. Keep the area free and clear of

combusbles. (See ANSI Z83. 14B, 1991).

WARNING Improper installaon, adjustment, alteraon, service or maintenance can

cause property damage, injury, or death. Read the installaon operang and

maintenance instrucons thoroughly before installing, or servicing this equipment.

WARNING Instrucons must be posted in a prominent locaon. All safety precauons

must be taken in the event the user smells gas. Safety informaon can be obtained from

your local gas supplier.

CAUTION: These models are designed, built, and sold for commercial use only. If these models

are posioned so the general public can use the equipment, make sure that cauons,

warnings, and operang instrucons are clearly posted near each unit so that anyone

using the equipment will use it correctly and not injure themselves or harm the equipment.

GASPRESSURE

The appliance and it’s individual shutoffvalve (to be supplied by user) must be disconnected from

the gas supply piping system during any pressure tesng of that system at test pressures in excess of

½psi (3.45 kPa).

The appliance must be isolated from the gas supply piping system by closing it’s individual manual

shut offvalve during any pressure tesng of the gas supply piping system at test pressures equal to

or less than ½ psi (3.45 kPa).

WARNING A factory authorized agent should handle all maintenance and repair. Before

doing any maintenance or repair, contact your authorized service representave.

3

Congratulaons on your purchase of CPG commercial cooking equipment. CPG takes pride in the

design and quality of our products. When used as intended and with proper care and maintenance,

you will experience years of reliable operaon from this equipment. To ensure best results, it is

important that you read and follow the instrucons in this manual carefully.

TABLE OF CONTENTS:

ITEM PAGE ITEM PAGE

Safety precauons 4 Cleaning & Maintenance 8

General Installaon Instrucons 5 Service/Repair 8

Specificaons & Dimensions 5 Explosion View Drawing 9

Conversion 6 Spare Parts List 10 11

Lighng Instrucons 7 Warranty 12

4

LOCATION OF DATA PLATE

The data plate is located on the side panel.

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

Equipment should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is received damaged, either

apparent or concealed, a claim must be made with the delivering carrier.

A) Apparent damage or loss must be noted on the freight bill at the me of delivery. It must then be

signed by the carrier representave (Driver). If this is not done, the carrier may refuse the claim. The

carrier can supply the necessary forms.

B) If concealed damage or loss is not apparent unl aer equipment is uncrated, a request for

inspecon must be made to the carrier within 15 days. The carrier should arrange an inspecon. Be

certain to hold all contents and packaging material.

Installaon should be performed by a qualified installer who thoroughly read, understands and

follows these instrucon.

If you have quesons concerning the installaon, operaon, maintenance or service of this product,

visit Cooking Performance Group’s website at www.CookingPerformanceGroup.com.

SAFETY PRECAUTIONS

DANGER This symbol warns of imminent hazard which will result in serious injury or

death.

WARNING: This symbol refers to a potenal hazard or unsafe pracce, which could result

in serious injury or death.

CAUTION: This symbol refers to a potenal hazard or unsafe pracce, which could result

in minor or moderate injury or product or property damage.

NOTICE: This symbol refers to informaon that needs special aenon or must be fully

understood even though not dangerous.

NOTICE: This product is intended for commercial use only. Not for household use.

NOTICE: Local codes regarding installaon vary greatly from one area to another. The Naonal

Fire Protecon Associaon, Inc., states in its NFPA96 latest edion that local codes are

“Authority Having Jurisdicon” when it comes to requirement for installaon of

equipment. Therefore, installaon should comply with all local codes.

5

GENERAL INSTALLATION INSTRUCTIONS

Ensure gas supply and gas type, as shown on unit nameplate, match.

Unit installaon must conform with the Naonal Fuel Gas Code, ANSI Z223.1/NFPA 54, the Naonal

Gas Installaon Code, CSA B149.1, or the Propane Installaon Code, CSA B149.2 as applicable and

in accordance with local codes.

Screw legs into the permanently fastened nuts on the four corners of the unit and ghten by hand.

Level the unit by turning the adjustment screw at the boom of each leg. Do not slide unit with legs

mounted, li if necessary to move unit.

Pipe threading compound must be resistant to the acon of liquefied petroleum gases.

Cauon: DO NOT use an open flame to check for leaks. Check all gas piping for leaks with a soap and

water soluon before operang unit.

THESE UNITS ARE SUITABLE FOR INSTALLATION ON NON COMBUSTIBLE SURFACES ONLY.

Combusble clearances:

6" sides (152 mm) 6" rear (152 mm) 4" floor (102 mm)

Noncombusble clearances:

0" sides (0 mm) 0" rear (0 mm) 4" floor (102 mm)

Do not obstruct the flow of combuson and venlaon air, under the unit by the legs or behind the

unit by the flue.

Adequate clearance for air openings into the combuson chamber is required. Do not place objects

between the boom of the unit and the counter top.

There must be adequate clearance for removal of the front panel. All major parts except the burners

are removable through the front if the gas line is disconnected.

SPECIFICATION AND DIMENSIONS

MODEL WIDTH

IN. (MM)

DEPTH

IN. (MM)

HEIGHT

IN. (MM)

# OF

BURNERS

BTU/PER

NAT/LP

TOTAL

BTU/ Hr

W.C.

IN.

CK HPSU212 12(305) 26.8(680) 18.9(480) 2 30,000 60,000 6/10

CK HPSU424 24(610) 26.8(680) 18.9(480) 430,000 120,000 6/10

CK HPSU636 36(915) 26.8(680) 18.9(480) 6 30,000 180,000 6/10

Note: regulator – 75mm/3.25 inch depth. Dimensions above do not include regulator.

6

CONVERSION

Instrucons are for conversion from Natural Gas to Propane (L.P.) on all models. The conversion

should be done before connecng the unit to the gas supply.

Units are shipped from the factory equipped for use with natural gas. Orifices necessary for LP

(propane) are provided in a bag ed to the valve on the front panel.

1. Remove the knobs and front panel.

2

. Uns

2. Remove the burner from the top

of the gas pipe.

1. Remove the trivets from the

top of the appliance.

Note: Unit Number on side

of orifice fings.

Plasc Insert

3. Replace the orifice

fin

g

s into the valve.

5. Before installing the regulator,

unscrew the octagonal cap up, you can

read (NAT) on the plasc insert out of

the cap, flip it over and snap back in

6. Connue with

installaon.

Regulator with brass cap L.P Posion of insert

4. Install the front

p

anel knobs

7

LIGHTING INSTRUCTIONS

Lighng pilot

The pilot light on the appliance has been set at the factory. A screwdriver may be required for the

first lighng to adjust the flame for your elevaon.

1. Turn offthe manual valve and wait 5 minutes to clear the gas.

2. Turn all knobs to the "OFF"posion.

3. Hold an ignion source (match) at the pilot. When the flame is established, remove the ignion

source.

4. Turn the burner knobs to "ON". If the burner does not ignite, promptly open the pilot valve

more. If the pilot flame appears larger than necessary, turn it down and reset burner ignion. The

pilot flame should be as small as possible but large enough to guarantee reliable ignion of the

burners when the knobs are turned to "ON".

Lighng main burner

To light burner, turn knob to “ON.”Then back offto the desired flame level. The range of adjustment

is virtually infinite between “ON” and “OFF”.

Main burner air supply:

1. For efficient burner operaon, a proper balance of gas volume and primary air supply must be

maintained which will result in complete combuson. Insufficient air supply results in a yellow

streaming flame.Primary air supply is controlled by an air shuer on the front of the burner.

2. Loosen the screws on the front of the burner and adjust the air shuer to eliminate the yellow

ps of the burner flame. Lock the air shuer in place by ghtening the screws.

CAUTION

All burners are lit from constantly burning pilots. Turning the valve to the desired flame height is all

that is required to put the unit in service.

Do not permit fans to blow directly at the unit. Wherever possible, avoid open windows next to the

units' sides or back. Avoid wall type fans which create air crosscurrents within a room.

It is also necessary that sufficient air should be allowed to enter the room to compensate for the

amount of air removed by any venlang system. Otherwise, a subnormal atmospheric pressure will

occur, affecng operaon and causing undesirable working condions.

A properly designed and installed hood will act as the heart of the venlang system for the room

or area in which the unit is installed, and will leave the unit independent of changing dra

condions.

All valves must be checked and lubricated periodically. This must be done by an authorized service

representave in your area.

8

CLEANING & MAINTENANCE

CAUTION: Use only non abrasive cleaners. Abrasive cleaners could scratch the finish of your unit,

marring it’s appearance and making it suscepble to dirt accumulaon. Do not use steel

wool, other abrasive cleaners or cleaners/sanizers containing chlorine, iodine,

ammonia or bromine chemicals as these will deteriorate the stainless steel and glass material and

shorten the life of the unit.

Daily

1. Thoroughly clean back, sides, top and front of unit.

2. Clean grates daily.

Weekly

1. Clean unit thoroughly. Clean stainless steel or chromed surfaces with a damp cloth and polish

with a so, dry cloth. A detergent may be used for cleaning. To remove discoloraons, use a

nonabrasive cleaner.

2. To clean the drip pan: remove the drip pan by grabbing the handle and pulling it out of the

opening in the front panel. To replace the pan, reverse this procedure.

3. Burner air shuer openings must be kept clean. Main burner ports must be kept clean. To clean

burners, boil them in a strong soluon of lye water for 15 to 20 minutes. Then either brush with

a wire brush or clean gas ports with a sharp pointed metal instrument to ensure open ports.

CAUTION: Clean the regulator at least once a month. Make sure the vent opening is open

and not blocked in any way. Failure to do so will cause variaons in pressure. Your unit

will not funcon as well and it could shorten the life of the product.

SERVICE /REPAIR

NOTE:THIS APPLIANCE MUST ONLY BE SERVICED BY AN AUTHORIZED AGENT.

NOTE: Parts protected by the manufacturer or his agent are not to be adjusted by the installer

unless the installer is an authorized service agent.

If you have any quesons or problems contact your nearest Service Representave.

9

EXPLOSION VIEW DRAWING

MODEL:CK HPSU424

10

Spare Parts List

YTQEDOCLEDOMNOITPIRCSED.ON

1 Dial

CK-HPSU212

CK-HPSU424

CK-HPSU636

06.05.1472429

2

4

6

2 Tray CK-HPSU212

CK-HPSU424

CK-HPSU636

01.05.1029410

01.05.1029318

01.05.1029365

1

3 Foot

CK-HPSU212

CK-HPSU424

CK-HPSU636

01.02.1005373 4

4 Regulator

CK-HPSU212

CK-HPSU424

CK-HPSU636

01.22.1069501 1

5 Orifice

CK-HPSU212-NAT

CK-HPSU424-NAT

CK-HPSU636-NAT

01.20.1068643

2

4

6

CK-HPSU212-LPG

CK-HPSU424-LPG

CK-HPSU636-LPG

01.20.1068652

2

4

6

6 Burner

CK-HPSU212

CK-HPSU424

CK-HPSU636

06.05.1472521

2

4

6

7 Grate

CK-HPSU212

CK-HPSU424

CK-HPSU636

01.03.1015096

2

4

6

8 Pilot pipe assy.-Rear

CK-HPSU212

CK-HPSU424

CK-HPSU636

01.24.1071026

1

2

3

9 Orifice connection-Front

CK-HPSU212

CK-HPSU424

CK-HPSU636

01.18.1067402

1

2

3

10 Orifice connection-Rear

CK-HPSU212

CK-HPSU424

CK-HPSU636

01.18.1067404

1

2

3

3511473191

3511029410(15")

3511029318(24")

3511029365(36")

3511005373

3511069501

3511068643

3511068652

3511472521

3511015096

3511071026

3511067402

3511067404

11

11 Pilot pipe assy.-Front

CK-HPSU212

CK-HPSU424

CK-HPSU636

01.24.1071015

1

2

3

12 Main pipe assy.-Front

CK-HPSU212

CK-HPSU424

CK-HPSU636

06.05.1473192

1

2

3

13 Main pipe assy.-Rear

CK-HPSU212

CK-HPSU424

CK-HPSU636

06.05.1473193

1

2

3

14 Valve connection

CK-HPSU212

CK-HPSU424

CK-HPSU636

66.04.1820085

2

4

6

15 Valve

CK-HPSU212

CK-HPSU424

CK-HPSU636

01.20.1068502

2

4

6

16 Pilot valve

CK-HPSU212

CK-HPSU424

CK-HPSU636

01.20.1068508

1

2

3

Cooking Performance Group

Lancaster, Pennsylvania

website: www.cookingperformancegroup.com

3511071015

3511473192

3511473193

3511820085

3511068502

3511068508

12

Limited Warranty

Cooking Performance Group Cooking Equipment Models:

Griddles: G15, G24,G36, G48, G15T, G24T, G36T, G48T

Char broilers: CBL15, CBL24, CBL36, CBL48, CBR15, CBR24, CBR36, CBR48

HotPlates: HP212, HP424, HP636, CK HPSU212, CK HPSU424, CK HPSU636

Fryers: CF15, CF30

All new Cooking Performance Group Griddles, Char broilers, Hot Plates, and Fryers used for

commercial purpose are warranted against defects in materials and workmanship under normal use

and maintenance.The Warranty runs for oneyear from the date of original installaon and is for

the benefit of the original purchaser only. All other warranes, expressed or implied, statutory or

otherwise, including without limitaon any implied warranty of merchantability for fitness for

purposes are excluded. The seller shall in no event be liable for direct, indirect or consequenal

damages in connecon with Cooking Performance Group commercial products.

Exclusions

The following condions are not covered by warranty:

Equipment damage or equipment failure occurs because of accident, carelessness, lack of

proper set up, supervision when required, or if the equipment is installed or operated in any

manner contrary to the installaon and operang instrucons.

Equipment damage or equipment failure due to improper installaon, improper ulity

connecon or supply, and problems due to venlaon.

Equipment that has not been used appropriately, or has been subject to misuse, neglect,

abuse, accident, alteraon, negligence, damage during transit, delivery or installaon, fire,

flood, or act of God.

Equipment that has the model number or serial number removed or altered.

Equipment that has been changed, altered, modified or repaired by other than an

Authorized Service Agency. Cooking Performance Group shall not be held liable for any

damages to any person or property which may result from the use of the equipment

thereaer.

This warranty does not apply to, and Cooking Performance Group is not responsible for, any

warranty claims on products sold or used outside of the conguousUnited States.

This equipment is intended for commercial use only. Warranty is void if equipment is installed in

other than commercial applicaons.

This manual suits for next models

2

Table of contents

Other CPG Cooktop manuals

Popular Cooktop manuals by other brands

Jenn-Air

Jenn-Air CCE3400 use and care manual

US COOKING EQUIPMENT

US COOKING EQUIPMENT USSP-18-1 operating instructions

Dynasty

Dynasty DCT Series user manual

Whirlpool

Whirlpool Gold GJC3034R installation instructions

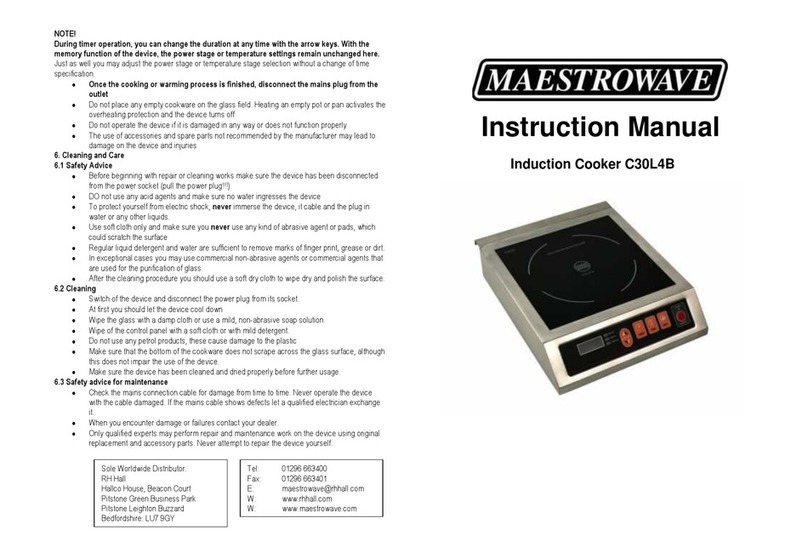

maestrowave

maestrowave C30L4B instruction manual

IKEA

IKEA ICS304WM0 installation instructions