GAS SUPPL CONNECTION

The product is supplied set up for Natural Gas. This cooktop is

suitable for installation with Natural Gas, or LP Gas. Refer to table for

the relevant pressures and appropriate injector si es.

- Gas connection to the product must use the elbow supplied. The

regulator will not seal if installed without it.

-Ensure the blue washer (supplied) is located between the

elbow and the product inlet. Failure to use this will cause

the product to leak.

AFTER INSTALLATION, MAKE SURE ALL CONNECTIONS ARE

GAS SOUND.

FLEXIBLE HOSES

Flexible hose assemblies should be AS/NZS 1869 Class B or

Class D certified.

Flexible hoses should not be exposed to temperatures exceeding

their certified value. They should not touch hot surfaces on the

cooktop or neighbouring products.

Flexible hoses should not be subject to abrasion, kinking or

permanent deformation.

FOR LP GAS MODELS

For LPG Models the gas supply for the appliance must be regulated to

a pressure of 2.72kPa (11" WG). See below for conversions.

FOR NATURAL GAS MODELS

For NG Models the gas supply is connected to the regulator which is

supplied loose with a built in test point - 1kPa (4" WG) and the inlet

connection of 1/2 " B.S.P. (male thread). Do not over tighten.

The test point pressure should be preset to 1.0 kPa with the wok and

semi - rapid burners operating at maximum.

GAS SUPPL CONNECTION CHECK

To enable the gas supply to be readily shut off, the gas supply must

be connected with an isolating valve close to the product.

After installation and making all connections check thoroughly for

possible leaks.

1. Turn all control knobs on the unit to “off” position.

. Open the valve on the gas supply.

3. Using a suitable leak testing solution (e.g. Rocol) check each gas

connection one at a time by brushing the solution over the connection.

4. The presence of bubbles will indicate a leak. Tighten the fitting and

recheck for leaks. Ensure the blue washer (supplied) is located

between elbow and manifold.

5. Turn on each gas valve and light each burner.

6. Check for a clear blue flame without yellow tipping. If burners

show any abnormalities, check that they are located properly and in

line with injector nipple. Check correct orifices are installed.

7. The operation of the appliance, including the ignition system, must

be tested before leaving.

If after following the instructions given, satisfactory performance

cannot be obtained, contact the local gas authority or your local

Approved Service Agent for advice and assistance.

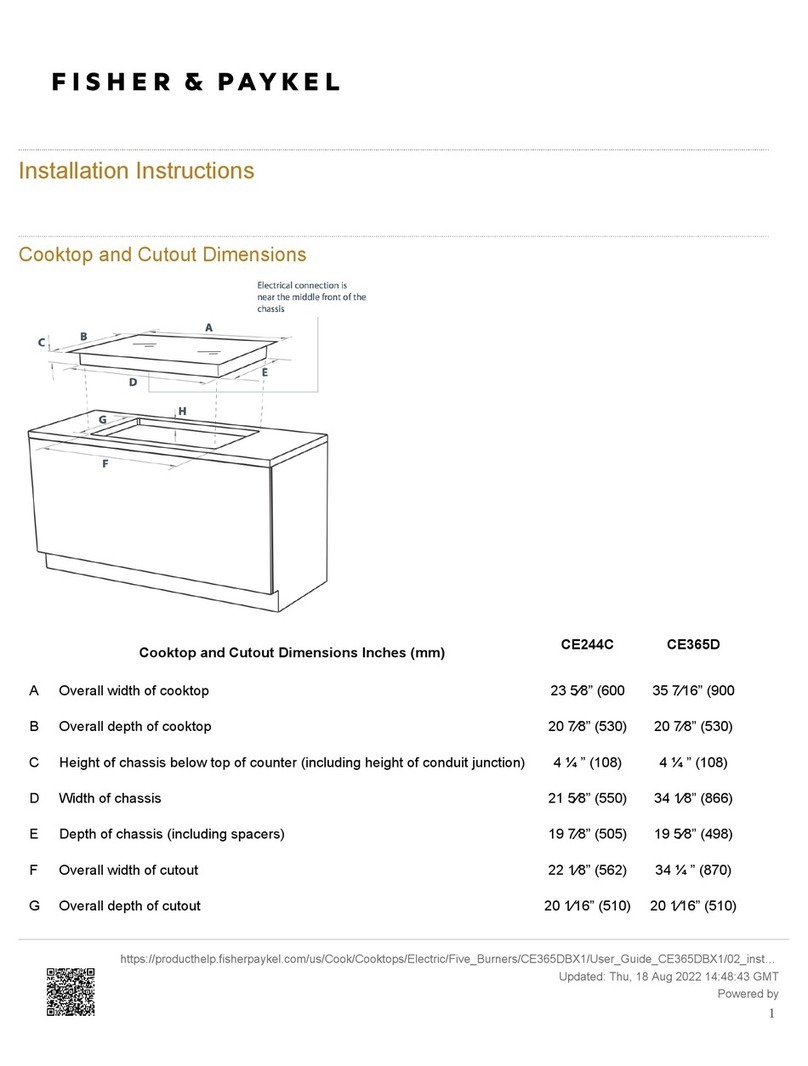

GAS RATE SUMMAR

Your product is factory set for Natural Gas but may be converted to

LPG use. See overleaf. Refer to the chart below for ratings.

BURNERS Natural Gas LP Gas

Injector MJ/h Injector MJ/h

Orifice @1 kPa Orifice @2.75kPa

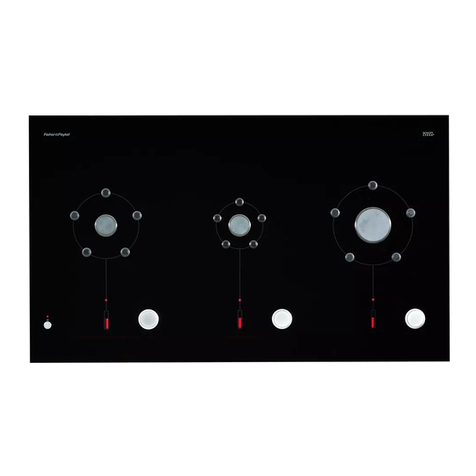

GC 9002 series

Semi-Rapid Burner

(LH & RH Rear) 1.3mm 7.9MJ/h 0.80mm 7.9MJ/h

Aux Burner (RH Front) 0.85mm 3.7MJ/h 0.55mm 4.1MJ/h

Fish Burner (Centre) 1.45mm 10MJ/h 0.85mm 10MJ/h

Wok Burner (LH Front) 1.8mm 15MJ/h 1.05mm 15MJ/h

GC 600 Series

Semi-Rapid Burner

(LH & RH Rear) 1.1mm 6.1MJ/h 0.70mm 6.4MJ/h

Aux Burner (RH Front) 0.85mm 3.7MJ/h 0.55mm 4.1MJ/h

Wok Burner (LH Front) 1.75mm 15MJ/h 1.05mm 15MJ/h

CG 901 M

Semi-Rapid Burner (LH Rear) 1.1mm 6.1MJ/h 0.7mm 6.4MJ/h

Simmer Burner (RH Front) 0.85mm 3.2MJ/h 0.55mm 3.2MJ/h

Rapid Burner

(LH Front, RH Rear) 1.3mm 7.9MJ/h 0.8mm 8.4MJ/h

Wok Burner (Centre) 1.8mm 15MJ/h 1.08mm 15MJ/h

The data plate information can be found in the duplicate data plate

which should be placed on an accessible surface adjacent to the

cooktop.

CONVERSION TO DIFFERENT GAS T PE

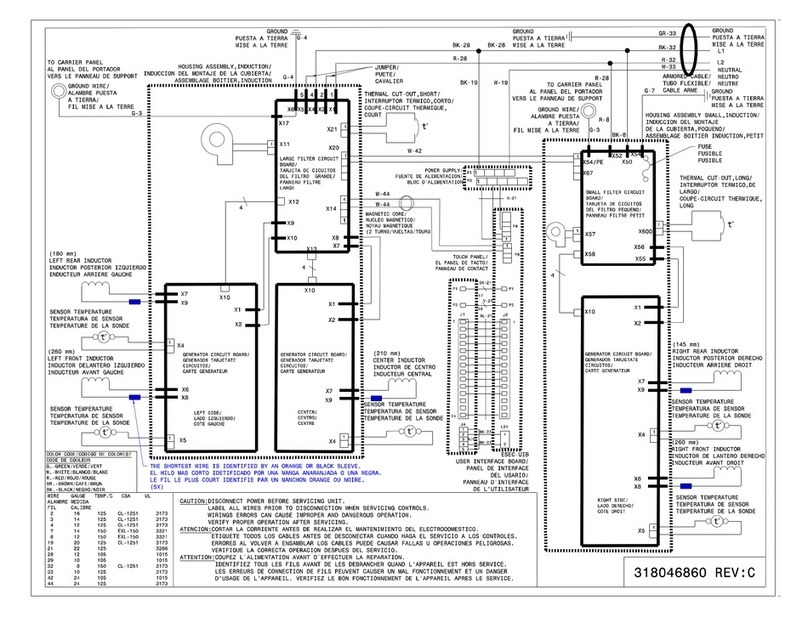

Burners can be used with NG or LPG, provided that the injector

orifices appropriate for the gas delivered are installed.

To change the injector orifices, you will need a 7mm box spanner and

a 10mm ring spanner (CG901M only).

1. Turn off the main electrical supply. WARNING: Shock Ha ard Inside.

. Ensure all gas valves are turned off.

3. Remove all trivets and burner heads.

4. Pull off knobs.

5. Unscrew the nut securing the flame failure probe of the

mini-auxiliary burner.

6. Remove the 2 screws holding each burner (3 on the wok burner).

7. Partially lift the hob and unplug the electrode on the mini-auxiliary

burner to allow hob removal. Caution The edge can be sharp.

8. Unscrew the orifices and replace them with the correct ones.

(si e numbers are stamped on the side, eg. 70= 0.70mm)

9. Reset the venturi position aligning the end

of the venturi tube with the edge of the slot

in the bracket below it. Outermost position

for LPG, innermost for NG (see figure right).

Some fine adjustment may be required for

local conditions.

10. To replace the CG901M hob, repeat steps 1-7 in reverse.

11. Reset the minimum setting (see next column).

The label supplied with the orifices should

be placed over the e isting gas type label

to indicate the change.

MINIMUM SETTING OR TURN DOWN

This has been set at the factory for NG but can be checked after the

correct pressure has been reached.

To adjust the minimum setting you will need a Ø 2.5 x 45 screwdriver.

1. Remove the knob.

. Ignite the burner and set the knob to its minimum position.

3. Rotate the turn down screw (down the hole in the valve spindle).

Rotate slowly until a minimum regular flame is achieved. (The flame

will diminish when the screw is turned clockwise and increase when

turned anti-clockwise).

4. When the setting is right check regulation by quickly rotating the

knob from the maximum to the minimum delivery position. The flame

must not go out.

5. Replace the knob.

Before you call for service or assistance...

Check the things you can do yourself.

Refer to your User Guide and check....

1. Your product is correctly installed.

. You are familiar with its normal operation.

If after checking these points you still need assistance, please call

your Fisher & Paykel retailer who is trained to provide information on

your product, or if we can be of any further help, please contact our

Customer Care Centre.

NEW ZEALAND

P. O. Box 58732, Greenmount, Auckland.

Toll Free 0800 FP CARE (0800 37 2273)

Fax 09 273 0656

AUSTRALIA

P. O. Box 798, Cleveland, QLD 4163.

Toll Free 1300 650 590

Tel 07 3826 9100

Fax 07 3826 9298

SINGAPORE

150Ubi Avenue 4, 02-00, Sunlight Building, Singapore 408825

Tel +65 5470100

Fax +65 5470123

Gas Supply

Adjusting the Cooktop Customer Support