35

1. Description

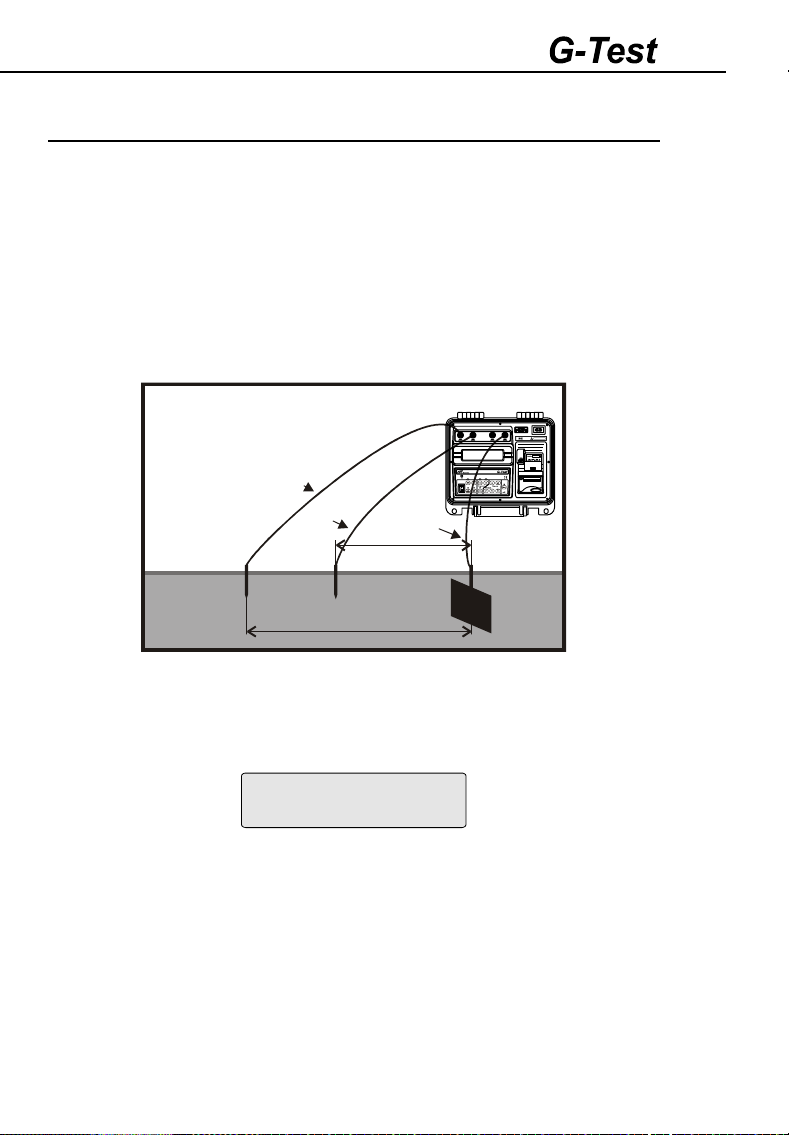

The G-TEST is a microprocessor controlled earth tester that allows meas-

uring earth resistance and ground resistivity (by Wenner's method), as well

as detecting parasitic voltages that may be present in the ground. Totally

automatic and easy to operate, the G-TEST is suitable to measure earth

systems in power substations, industries, distribution networks, etc., ac-

cording to IEC 61557-5, or to measure soil resistivity in a terrain, in order to

optimize the earth systems project.

Before starting each test, the G-TEST will check if all conditions are within

the appropriate limits and will notify the operator if there are any abnormali-

ties, such as too high interference voltage, too much resistance in the test

spikes, very low test current, etc. If all conditions are normal, the equipment

will automatically select the adequate range and will show the results on the

display.

In order to conveniently test earth systems, the G-TEST allows measure-

ments using test currents with selectable frequency, of 270Hz or 1470Hz.

Measurements in the 270Hz frequency allow to analyse the system behav-

iour when in contact with fault currents of industrial frequency, while those in

the 1470Hz frequency show better the system behaviour when in contact

with electrical currents caused by lightning. Measurements in the higher

frequency also offer high immunity to interference voltages in the soil, what

allows accurate results in often unfavorable conditions.

The G-TEST has memory to store up to 4000 measurements, a built-in

printer and a serial data output that allows to transfer the stored results to a

computer or data logger for later analysis. Practical, lightweight and strong,

the G-TEST is suitable to field use, even under severe weather conditions.

It is powered by a rechargeable battery (220 - 240V charger), and is sup-

plied with all the necessary accessories in a practical auxiliary case.