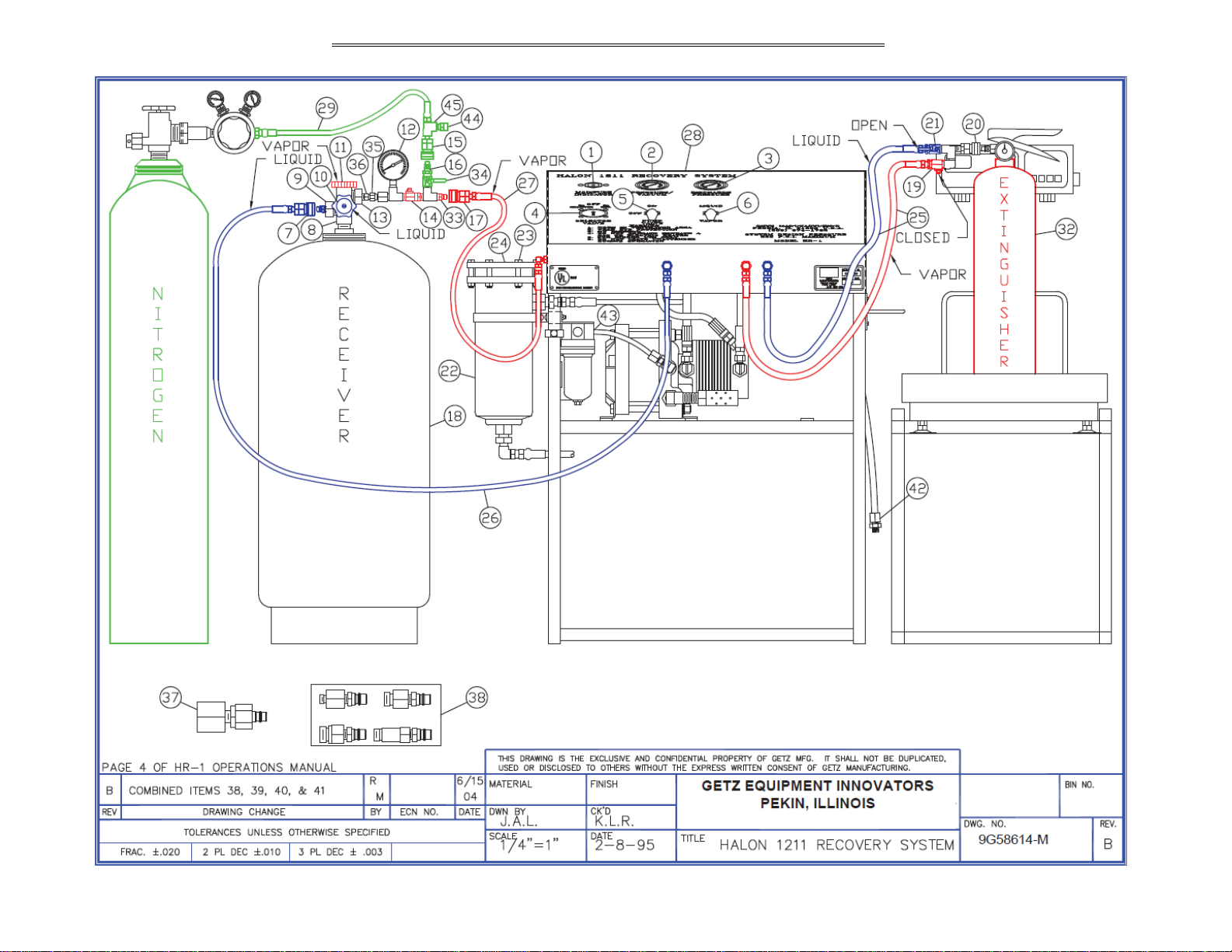

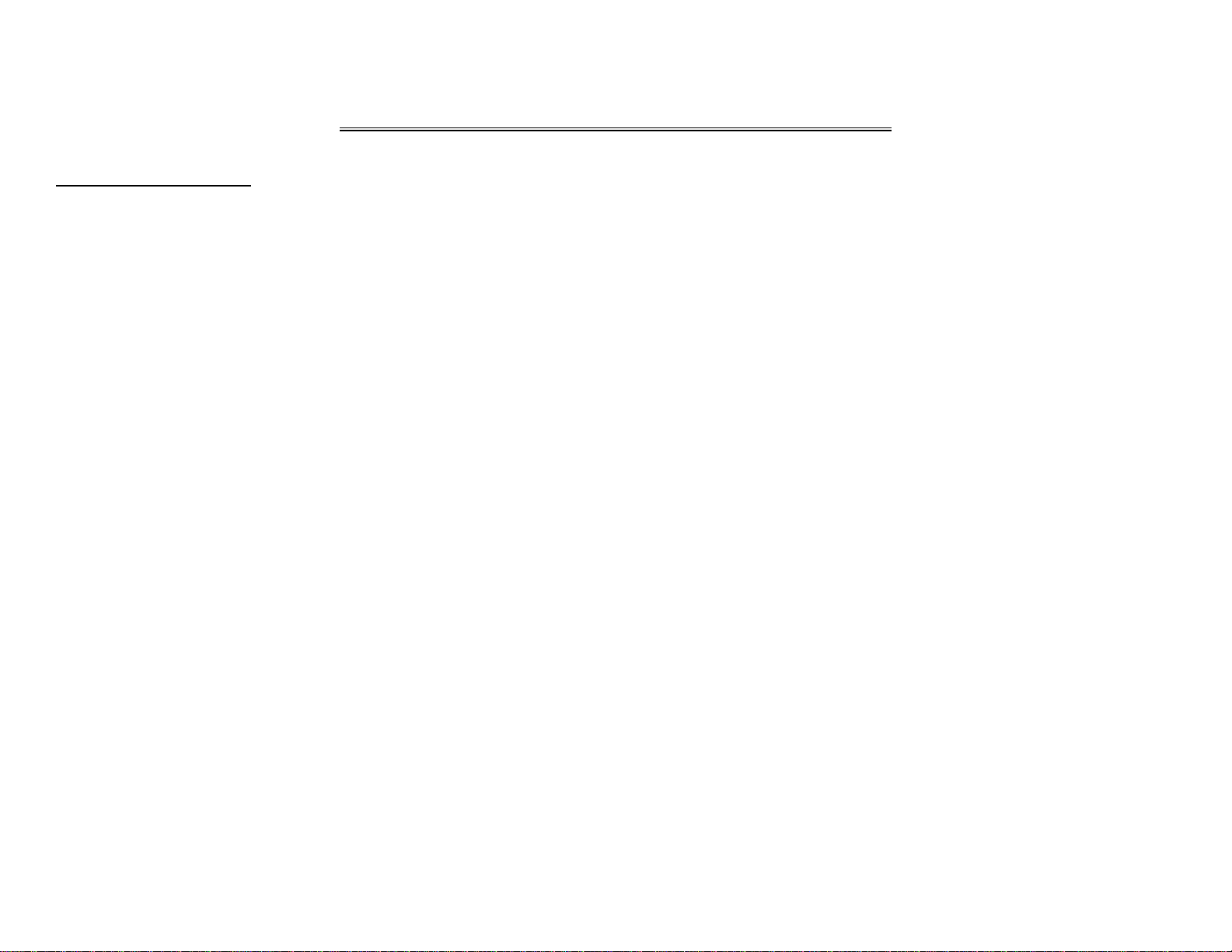

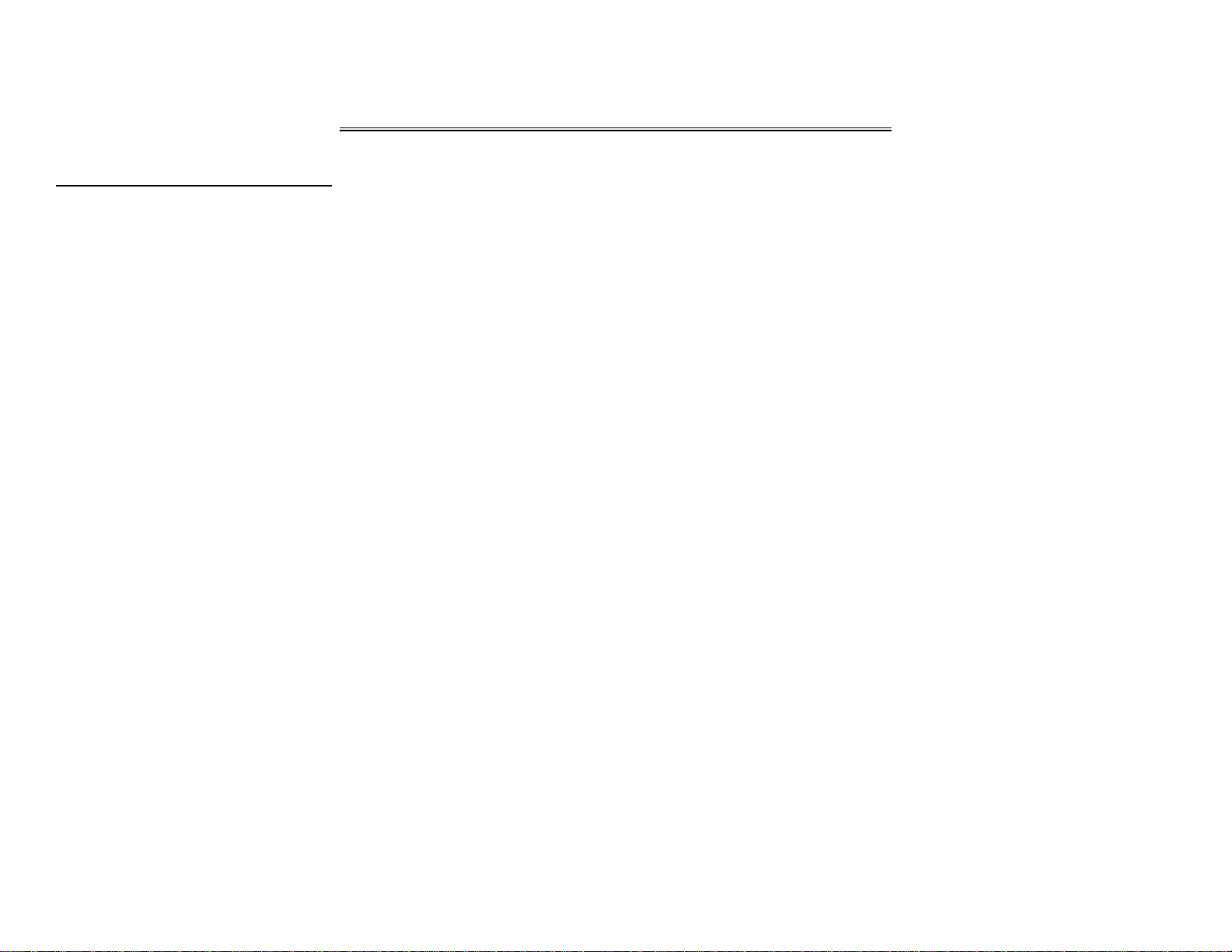

MODEL HR-1L HALON 1211 RECOVERY/RECHARGE SYSTEM

ITEM NUMBERS / DESCRIPTION: ITEM NUMBERS / DESCRIPTION:

1. MOISTURE INDICATOR –3G59055

2. PRESSURE / VACUUM GAUGE –1G0440

3. DISCHARGE PRESSURE GAUGE –1G0439

4. SELECTOR VALVE –1G51922

5. PUMP VALVE –1G51908

6. LIQUID / VAPOR VALVE –1G51902

7. FEMALE QUICK COUPLER (LIQUID) –1G0189

8. DUAL PORT VALVE –1G51918

9. ADAPTER ASSEMBLY –3G59076

10. BLUE HANDWHEEL (LIQUID) –1G53736

11. RED HANDWHEEL (VAPOR) –1G53735

12. RECEIVER TANK PRESSURE GAUGE –1G0453

13. ADAPTER ASSEMBLY –1G0452

14. 1/4" RED BALL VALVE (VAPOR) –1G51898

15. FEMALE QUICK COUPLER (NITROGEN) –1G0189

16. MALE QUICK CONNECT (NITROGEN) –1G51658

17. FEMALE QUICK COUPLER (VAPOR) –1G0189

18. RECEIVER TANK –2G58624

19. 1/4" RED BALL VALVE (VAPOR) –1G51898

20. FEMALE QUICK COUPLER (DUAL HOSE ASSEMBLY)

21. 1/4" BLUE BALL VALVE (LIQUID) –1G51898

22. FILTER SHELL –1G0416

23. BOLTS –1G0416

24. FILTER HOUSING –1G0416

25. DUAL HOSE ASSEMBLY –3G58939

26. LIQUID SUPPLY HOSE ASSEMBLY –3G59198

27. VAPOR SUPPLY HOSE ASSEMBLY –3G59428

28. CONTROL CONSOLE –1G51245

29. NITROGEN SUPPLY HOSE ASSEMBLY –3G59676

30. (RESERVED)

31. (RESERVED)

32. HALON 1211 EXTINGUISHER

33. MALE QUICK CONNECT (VAPOR) –1G51658

34. 1/4" GREEN BALL VALVE (NITROGEN) –1G51898

35. FEMALE SWIVEL ASSEMBLY –1G51006

36. MALE NIPPLE –1G51227

37. BULK HALON 1211 LIQUID FILL ADAPTER

ASSEMBLY

38. EXTINGUISHER ADAPTER (AMEREX, BADGER,

GENERAL OLD KIDDE, MAP, PEM ALL),

39. EXTINGUISHER ADAPTER (ALL ANSUL SENTRY

EXCEPT 2 ½ LB.)

40. EXTINGUISHER ADAPTER (AMEREX, BADGER,

GENERAL, MAP, PEM ALL, POWER PAK, R.C.,

STRIKE, STOP-FIRE, OLD BUCKEYE)

41. EXTINGUISHER ADAPTER (NEW BUCKEYE,

PYRONAUTS)

42. MALE QUICK CONNECT (AIR INLET)

43. MOISTURE FILTER –1G51314

44. PRESSURE RELIEF –1G51939

45. 1/4" TEE –1G0428 (3G59676)

46. BRASS STRAINER (LOCATED BEHIND REAR ACCESS

COVER) –3G59106

GETZ EQUIPMENT INNOVATORS - - PEKIN, ILLINOIS PAGE 5. HR-1L/0518