CR Remeha 400 solar Release note

IMPORTANT

Please read & understand all these instructions before commencing installation.

Please leave this manual with the customer for future reference.

Installation Manual

Unvented Solar Water Heaters

Installation & Servicing Instructions

commercial

2

Contents

1. Introduction ...........................................................................................3

1.1 General...............................................................................................3

1.2 Symbols used.....................................................................................3

1.3 Abbreviations......................................................................................3

1.4 Liabilities.............................................................................................3

2. Safety......................................................................................................4

2.1 General safety warnings.....................................................................4

2.2 Recommendations .............................................................................4

2.3 Specic safety instructions .................................................................4

3. Technical specications .......................................................................5

3.1 Technical data ....................................................................................5

3.2 ErP data .............................................................................................6

3.3 Dimensions and connections .............................................................7

3.4 Electrical diagram(s)...........................................................................8

4. Description of the product .................................................................10

4.1 General description ..........................................................................10

4.2 Operation principle ...........................................................................10

4.3 Main components .............................................................................10

4.4 Standard delivery .............................................................................10

5. Before installation ...............................................................................12

5.1 Installation regulations......................................................................12

5.2 Installation requirements ..................................................................12

5.3 Choice of location.............................................................................12

5.4 Transport ..........................................................................................13

6. Installation ...........................................................................................13

6.1 General.............................................................................................13

6.2 Water connections............................................................................13

6.3 Electrical connections.......................................................................18

6.4 Filling the installation ........................................................................18

7. Commissioning ...................................................................................19

7.1 General.............................................................................................19

7.2 Checklist before commissioning.......................................................19

7.3 Commissioning procedure................................................................19

8. Operation .............................................................................................20

8.1 General.............................................................................................20

9. Maintenance.........................................................................................21

9.1 General.............................................................................................21

9.2 Standard inspection & maintenance operations...............................21

10. Troubleshooting ................................................................................23

10.1 Fault nding....................................................................................23

11. Decommissioning..............................................................................24

11.1 Decommissioning procedure ..........................................................24

12. Spare parts.........................................................................................24

12.1 Spare parts list ...............................................................................24

12.2 Accessories ....................................................................................25

Benchmark checklist ..............................................................................30

Service records .......................................................................................31

Guarantee.................................................................................................32

3

1. Introduction

1.1 General

The following instructions are offered as a guide to the

user and installer.

The installation must be carried out by a competent

plumbing and electrical installer in accordance with

Building Regulation G3 (England and Wales), Technical

Standard P3 (Scotland) or Building Regulation P5

(Northern Ireland) and the Water Fitting Regulations

(England and Wales) or Water Byelaws (Scotland).

1.2 Symbols used

In these instructions, various risk levels are employed

to draw the user’s attention to particular information. In

doing so we wish to safeguard the user, avoid hazards

and guarantee the correct operation of the appliance.

DANGER

Risk of a dangerous situation causing serious

physical injury.

WARNING

Risk of dangerous situation causing slight

physical injury.

CAUTION

Risk of material damage.

Signals important information.

1.3 Abbreviations

`T&P - Temperature & Pressure relief valve

`PRV - Pressure Reducing Valve

`Prv - Pressure relief valve

1.4 Liabilities

Manufacturers liability

Our products are manufactured in compliance with

the requirements of the various applicable European

Directives.

This appliance complies with the requirements of the

CE marking directive.

In the interest of UK customers, we are continuously

endeavouring to make improvements in product

quality. All the specications stated in this document

are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in

the following cases:

`Failure to abide by the instructions on using the

appliance.

`Faulty or insufcient maintenance of the

appliance.

`Failure to abide by the instructions on installing the

product.

Installer's liability

The installer is responsible for the installation and the

commissioning of the appliance. The installer must

respect the following instructions:

`Read and follow the instructions given in the

manuals provided with the appliance.

`Carry out installation in compliance with the

prevailing legislation and standards.

`Perform the initial start up and carry out any checks

necessary.

`Complete the commissioning checklist.

`Explain the installation to the user.

`If maintenance is necessary, warn the user of the

obligation to check the appliance and maintain it in

good working order.

`Give all the instruction manuals to the user.

Users liability

To guarantee optimum operation of the appliance, the

user must respect the following instructions:

`Read and follow the instructions given in the

manuals provided with the appliance.

`Call on qualied professionals to carry out

installation and initial start up.

`Get your tter to explain your installation to you.

`Have your required checks and services done.

`Keep the instruction manuals in good condition and

close to the appliance.

This appliance can be used by children aged

from 8 years and above and persons with

reducedphysicalsensoryormental capabilities

or lack of experience and knowledge if they

have been given supervison or instruction

concerning use of the appliance in a safe

way and understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be

made by children without supervision.

Children must be supervised to ensure they

do not play with the appliance.

4

2. Safety

2.1 General safety warnings

2.2 Recommendations

2.3 Specic safety instructions

WARNING

`If water discharges from the

temperature/pressure relief valve on

the cylinder shut down the boiler. Do

not turn off any water supply. Contact a

competent installer for unvented water

heaters to check the system.

`Do not tamper with any of the safety

valves tted to the system. If a fault

is suspected contact a competent

installer.

`DO NOT bypass the thermal cut-out(s)

in any circumstances.

WARNING

`Only competent persons having

received adequate training are

permitted to work on the appliance and

the installation.

`Do not tamper with any of the safety

valves or controls supplied with the

cylinder.

`Before any work, switch off the mains

supply to the appliance.

`Do not switch on if there is a possibility

that the water in the cylinder is frozen.

DANGER

This cylinder is unvented and as such becomes

pressurised when in operation. The combination

of pressurisation and hot water could lead to

serious physical injury if the safety instructions

in this manual are not adhered to.

CAUTION

Do not operate immersion heaters until the

cylinder has been lled with water.

WARNING

When handling the unit, take appropriate

precautions for the weight of the unit. Weights

can be found in section 3, table 1 , page 5.

CAUTION

Annual maintenance is recommended by a

competent person.

5

3. Technical specications

3.1 Technical data

400

solar

500

solar

800

solar

1000

solar

1250

solar

1450

solar

2000

solar

2500

solar

Max direct kW rating 24 24 45 45 54 54 54 54

Direct heat time (based on max kW rating in

mins) 52 66 56 70 73 84 117 146

Solar coil surface area m2 2 3 5 7.5

Auxiliary coil surface area m2 1 1.5 2.5 5

Solar coil rating (kW)

15 l/min 29.4 28.7 31.3 32.9 35.0 30.1 40.2 37.5

30 l/min 43.6 41.8 52.7 51.4 63.6 61.2 98.4 86.4

60l/miin 59.7 55.8 76.9 76.5 97.9 91.7 132.2 126.4

Auxiliary coil rating (kW) 15 l/min 28.4 27.2 30.5 33.2 48.6 46.4 97.9 91.7

Solar coil heat time (mins)

15 l/min 43 55 80 91 112 130 180 225

30 l/min 29 38 48 59 62 72 99 124

60l/miin 21 28 32 39 40 50 48 62

Pressure drop through solar coil

(Mpa)

15 l/min 0.002 0.001

30 l/min 0.004 0.008 0.006 0.007

60l/miin 0.032 0.044 0.025 0.03

Heat loss (kWh in 24h) 1.72 2.14 2.74 3.33 3.60 4.17 4.30 4.50

Hot water capacity (volume of water drawn off

>40°C) 384 482 776 961 1206 1399 1930 2482

Weight full (kg)

Weight empty (kg)

505 610 964 1188 1569 1872 2445 2950

105 110 164 188 319 322 445 450

Max supply pressure 1.6 MPa (16 bar)

Max design pressure 0.8 MPa (8 bar)

Max operating pressure 0.6 MPa (6 bar)

Max expansion vessel charge pressure 1.0 MPa (10 bar)

Expansion relief valve setting 0.8 MPa (8 bar)

T&P valve setting 1 Mpa (10 bar), 90-95°C

Maximum primary pressure 0.3 MPa (3 bar)

Table 1: Technical data

Notes:

1. Cylinders tested in conformance with BS EN 12897:2006.

2. Heat up time from cold through 45°C, based on a ow temperature of 80°C +/- 2°C & normal volume.

Commercial Cylinder

Volume (ltr)

Pressure Reducing Valve Pressure Relief Valve Single

Check Valve

400 - 500 1” Integrated inlet control valve

800 1.25” (1.5 - 6 bar) or (5 -10 bar) 1” x 1.25” (8 bar) or (13 bar) 1.25”

1000 1.25” (1.5 - 6 bar) or (5 -10 bar) 1” x 1.25” (8 bar) or (13 bar) 1.25”

1250 - 1450 1.5” (1.5 - 6 bar) or (5 -10 bar) 1” x 1.25” (8 bar) or (13 bar) 1.5”

2000 - 2500 2” (1.5 - 6 bar) or (5 -10 bar) 1.25” x 1.5” (8 bar) or (13 bar) 2”

Table 2: Inlet control specication dependant on model

6

Immersion allocation table

Table 3: Expansion vessel specication dependant on model

Solar

Supplier’s name or trade mark

Model(s) 400 500 800 1000 1250 1450 2000

Storage volume V in litres 400.0 500.0 800.0 1000.0 1250.0 1450.0 2000.0

Standing loss in W 72.0 89.0 114.0 139.0 150.0 163.0 179.0

The water heating energy

B

C

C

CCCC

Remeha Commercial

3.2 ErP data

Table 4: Immersion allocation table

Commercial Cylinder

Volume (ltr)

Expansion Vessel

Size (ltr)

Mounting Kit Weights

400 - 500 60 Floor Mounted 12kg

800 100 Floor Mounted 17kg

1000 - 1250 150 Floor Mounted 24kg

1450 200 Floor Mouinted 38.5kg

2000 - 2500 300 Floor Mounted 41kg

Table 5: ErP data

Technical parameters in accordance with European Commission regulations 814/2013 and 812/2013

6kW 9kW 12kW 18kW 24kW 30kW 36kW 45kW 54kW

94110301 94110302 94110303 94110304 94110305 94110306 94110307 94110308 94110309

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

Upper

Lower

400L üüüüü

500L üüüüü

800L üüüüüüüü

1000L üüüüüüüü

1250L üüüüüüüüü

1450L üüüüüüüüü

2000L üüüüüüüüü

2500L üüüüüüüüü

7

Figure 1: General dimensions - Solar

Table 6: General dimensions table - Solar

Item Connection 400I 500I Connection 800I 1000I Connection 1250I 1450I Connection 2000I 2500I

ANA 1500 1800 N/A 1906 2301 N/A 1937 2253 N/A 2011 2416

B1/2"BSP 1090 1390 1/2" BSP 1502 1897 1/2" BSP 1419 1735 1/2" BSP 1423 1829

C1" BSP 870 898 1 1/4" BSP 997 997 1 1/2" BSP 1140 1137 1 1/2" BSP 1230 1230

D1" BSP 670 698 1 1/4" BSP 797 797 1 1/2" BSP 910 907 1 1/2" BSP 990 990

E1/2" BSP 630 650 1/2" BSP 774 747 1/2" BSP 835 835 1/2" BSP 905 733

F1" BSP 498 498 1 1/4" BSP 622 622 1 1/2" BSP 710 710 1 1/2" BSP 780 780

G1" BSP 323 323 1 1/4" BSP 447 447 N/A 530 530 1 1/2" BSP 600 601

H1" BSP 309 309 1 1/4" BSP 440 440 1 1/2" BSP 530 530 2" BSP 607 607

I1/2" BSP 524 524 1/2" BSP 601 601 1/2" BSP 695 695 1/2" BSP 778 778

JN/A 950 1004 N/A 1428 1811 N/A 1371 1371 N/A 1376 1780

K1/2" BSP 894 959 N/A

L1" BSP 980 1070 1" BSP 1187 1437 1" BSP 1176 1376 1" BSP 1226 1476

MN/A 1083 1383 N/A 1490 1885 N/A 1407 1723 N/A 1412 1817

NN/A 956 956 N/A 1107 1107 N/A 1308 1308 N/A 1560 1560

ON/A 872 872 N/A 1024 1024 N/A 1224 1224 N/A 1476 1476

K

L

M

I

J

H

G

F

E

D

C

B

A

N

O

45°

30°

40°

35°

3.3 Dimensions and connections

8

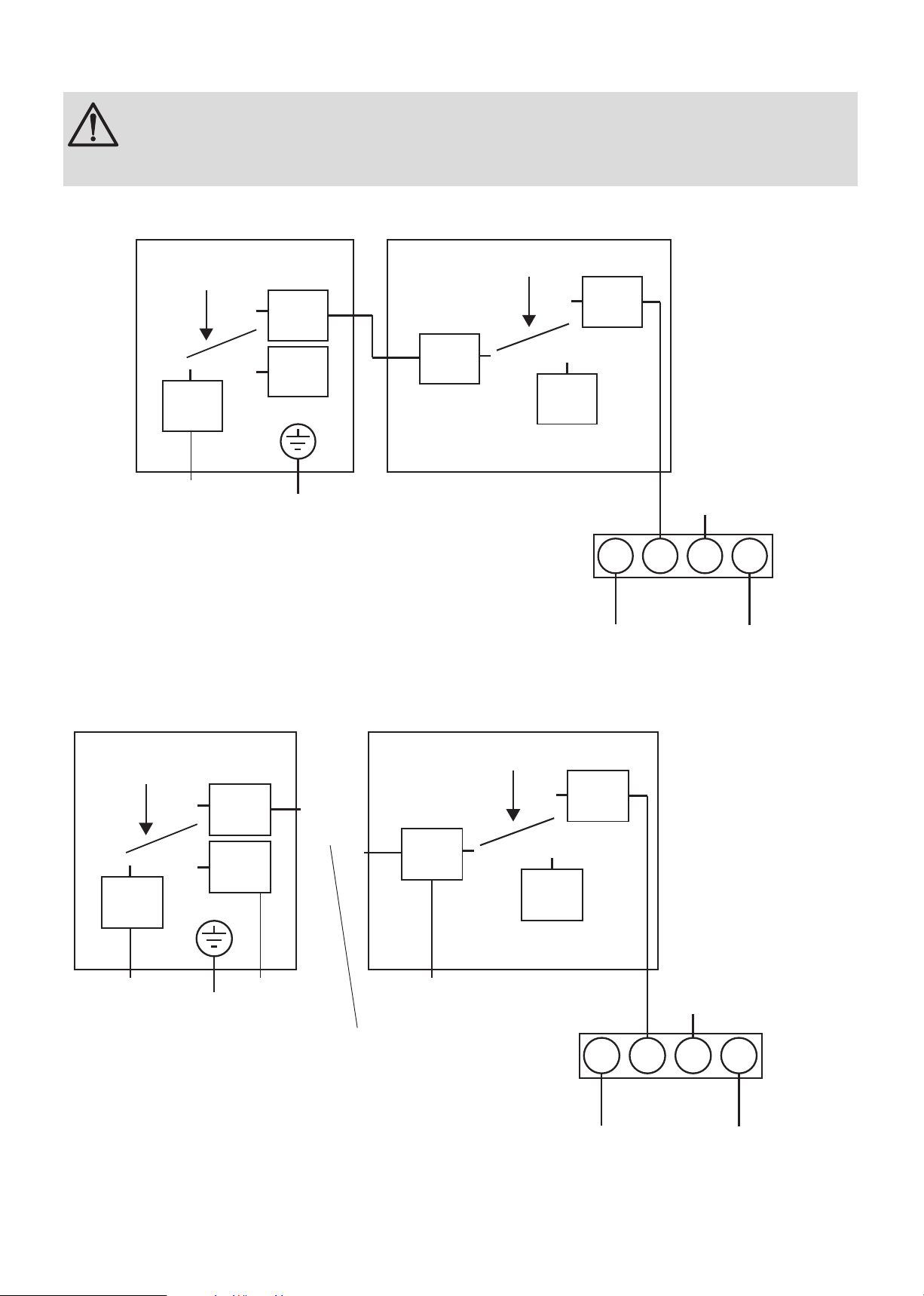

Thermostat Option 1

Zone valve

Switch out

G

L

Br Bl

N

0

Control High Limit

C

2

1C

1

2

o

o

o

+ C

0

S/L

o

o

o

o

+ C

0

L = Optional control utilising zone valve end

switch if required.

Figure 2: Wiring diagram 1

Figure 2a: Wiring diagram 2 - volt free option

Thermostat Option 2

Zone valve

Switch out

G

L

Br Bl

N

0

Control High Limit

C

2

1C

1

2

o

o

o

+ C

0

S/L

(volt free)

Switch out

Remove link

L

ooo

o

o

o

+ C

0

L = Optional control utilising zone valve end

switch if required.

WARNING

The high limit stat must always operate the zone valve in case of overtemperature.

NOTE: Option 2 untilises control thermostat to provide volt free control circuit.

9

Neutral

Fuse

(not supplied)

Live

A

B

1

2

Fuse

(not supplied)

L1

L2

L3

Contactors

(not supplied)

Neutral

L1

Neutral

L2 L3

A

B

1

2

Earth

Earth

Neutral

Earth

Immersion Heater

Earth

Live

Immersion Heater

Contactors

(not supplied)

Note:

The 2 external contactors must be approved

components certified for 10,000 cycles of

operation for the contactor controlled by the

thermostat and at least 30 for the contactor

controlled by the non-self-resetting thermal

cut-out.

Line terminal

marked L1

Earth

Neutral terminal

marked 'N'

Line terminal

marked L3

Typical head layout for

a three phase heater

4

0

5

0

6

0

7

0

8

0

Line terminal

marked L2

Earth

Neutral terminal

marked 'N'

Live

marked ‘L’

Typical head layout for

a single phase heater

4

0

5

0

6

0

7

0

8

0

Cut-Out Temperature 80°C

(Factorey set)

1 2

1 - 2 16A 240V ~

Thermal cut-out

1 2

1 - 2 20A 240V ~

Temperature control

1 2

1 - 2 16A 240V ~

Thermal cut-out

1 2

1 - 2 20A 240V ~

Temperature control

Figure 2: Single phase wiring schematic

Figure 3: 3 phase wiring schematic

10

Hot outlet

Sensor pocket

Solar flow

Solar return

Auxiliary flow

Auxiliary return

Upper immersion

/ inspection hatch

T&P

connection

Secondary

return

Sensor

pocket

Cold

inlet

4. Description of the product

4.1 General description

This product is a purpose designed unvented water

heater. The unit has a stainless steel inner vessel,

which ensures an excellent standard of corrosion

resistance. The outer casing is a combination of resilient

thermoplastic mouldings and soft jacket. All products

are insulated with CFC free polyurethane foam to give

good heat loss protection.

The unit is supplied complete with all the necessary

safety and control devices needed to allow connection

to the cold water mains. All these components are

preset and should not be tampered with.

4.2 Operation principle

The unvented cylinder is used to heat and store hot

water for use in commercial applications.

Depending on the model the water can be heated

directly using an element (supplied separately) or

indirectly through a coil in the unit using an indirect heat

source.

To provide pressure to the tap or shower an unvented

unit uses the incoming mains water pressure. To do this

the cylinder is sealed and not vented. However, when

the volume of water is heated it expands and without

any room for expansion could cause the cylinder to

rupture and fail. To allow expansion of this heated

water it is important that an expansion vessel is used.

This vessel is pressurised and gives the heated water

room to expand.

4.3 Main components

See Figure 4: Main components

4.4 Standard delivery

The delivery includes:

`Cylinder

`Literature pack

`Instructions (inc benchmark commissioning

checklist & service record)

`Cold water control pack (see table 2 page 5)

`Expansion vessel (see table 3 page 6)

`Combination valve (inc pressure reducing valve,

pressure relief valve and check valve)

`Tundish

`2 port zone valve.

Figure 4: Main components

Note: This is an indirect unit and shows the general

position of components but these will change depending

on the model.

11

5. Before installation

5.1 Installation regulations

5.2 Installation requirements

Water supply

In an unvented system the pressure and owrate is

directly related to the incoming water supply. For this

reason it is recommended that the maximum water

demand is assessed and the water supply checked to

ensure this demand can be satisfactorily met.

`We suggest the minimum supply requirements

should be 0.15MPa (1.5 bar) pressure and 100

litres per minute ow rate.

`A 28mm cold water supply is recommended,

however, if a smaller supply exists, which provides

sufcient ow, this may be used (although more

ow noise may be experienced).

`The higher the available pressure and ow rate the

better the system performance.

`See table 1 on page 5 for cylinder operating

pressures. This is controlled by the cold water

combination valve assembly.

Outlet/terminal ttings (taps, etc.)

`The cylinder can be used with most types of

terminal ttings.

`Outlets situated higher than the cylinder will give

outlet pressures lower than that at the heater, a

10m height difference will result in a 1 bar pressure

reduction at the outlet.

`All ttings, pipework and connections must have a

rated pressure of at least 8 bar at 80°C.

Limitations

The cylinder should not be used in association with any

of the following:

`Solid fuel boilers or any other boiler in which the

energy input is not under effective thermostatic

control, unless additional and appropriate safety

measures are installed.

`Ascending spray type bidets or any other class 1

back syphonage risk requiring that a type A air gap

be employed.

`Steam heating plants unless additional and

WARNING

Installation of the appliance must be carried

out by a qualied engineer in accordance

with prevailing and national regulations as

listed below.

`Building Regulations

`The Building Standards (Scotland)

`The Building Regulations (Northern

Ireland)

`I.E.E Electrical Regs

`UK Water Regulations

appropriate safety devices are installed.

`Situations where maintenance is likely to be

neglected or safety devices tampered with.

`Water supplies that have either inadequate

pressure or where the supply may be intermittent.

`Situations where it is not possible to safely pipe

away any discharge from the safety valves.

`In areas where the water consistently contains a

high proportion of solids, e.g. suspended matter

that could block the strainer, unless adequate

ltration can be ensured.

`In areas where the water supply contains chloride

levels that exceed 250mg/l.

The solar cylinder must be incorporated into a fully

pumped solar primary circuit. Control of the solar

primary is achieved by the use of external controls not

supplied with the unit. Control must be via a purpose

designed solar hydraulic station and solar differential

temperature controller.

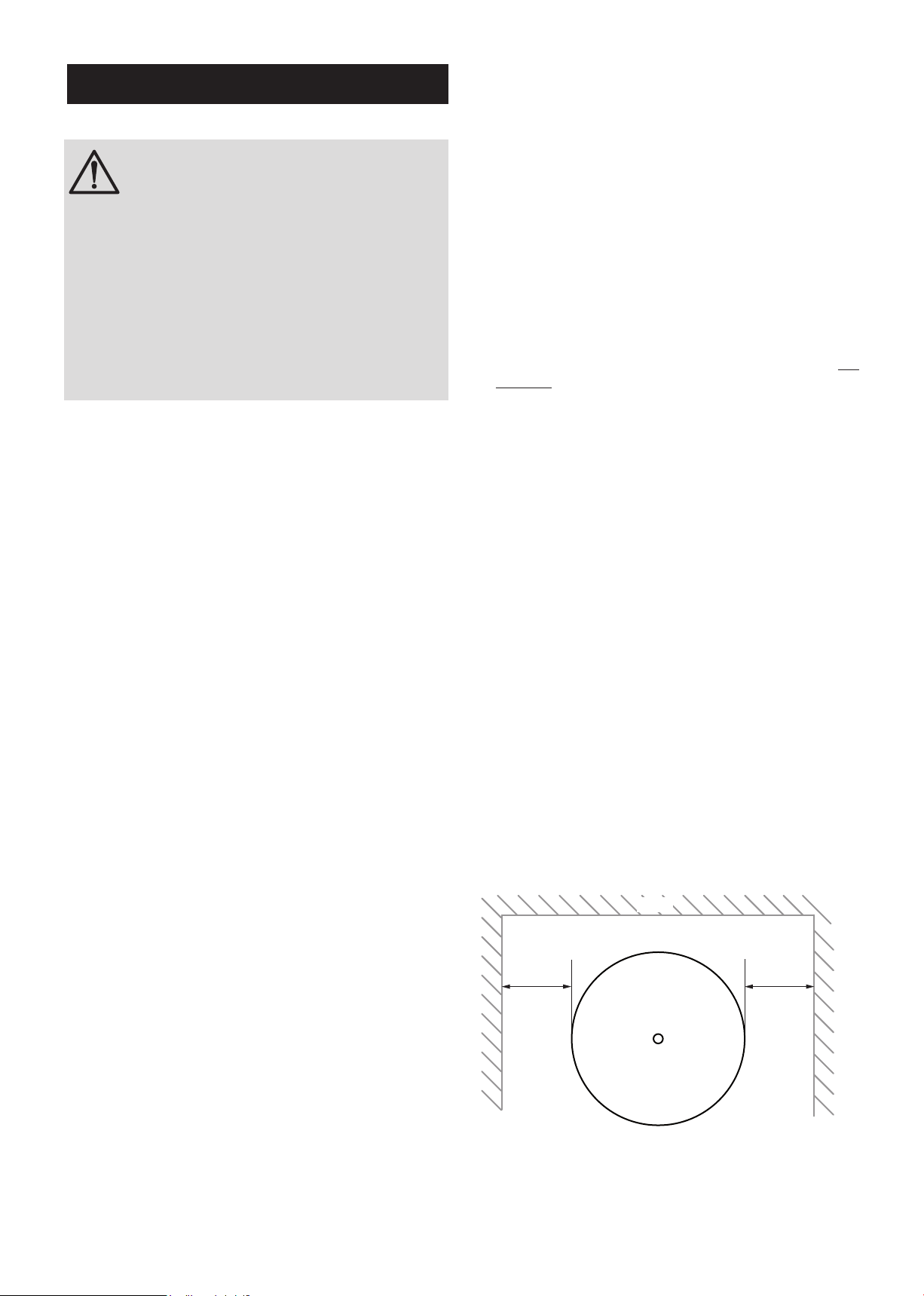

5.3 Choice of location

The cylinder must be vertically oor mounted. Although

location is not critical, the following points should be

considered:

`The cylinder should be sited to ensure minimum

dead leg distances, particularly to the point of most

frequent use.

`Avoid siting where extreme cold temperatures will

be experienced. All exposed pipe work should be

insulated.

`The discharge pipework from the safety valves

must have minimum fall of 1:200 from the unit and

terminate in a safe and visible position.

`Access to associated controls and immersion

heaters must be available for the servicing and

maintenance of the system. Where these controls

are installed against a wall a minimum distance of

250mm must be left.

`Ensure that the oor area for the cylinder is level

and capable of permanently supporting the weight

when full of water (see table 1, page 5 for weights).

Figure 5: Siting the unit

Min 250mm

Wall

Min 250mm

12

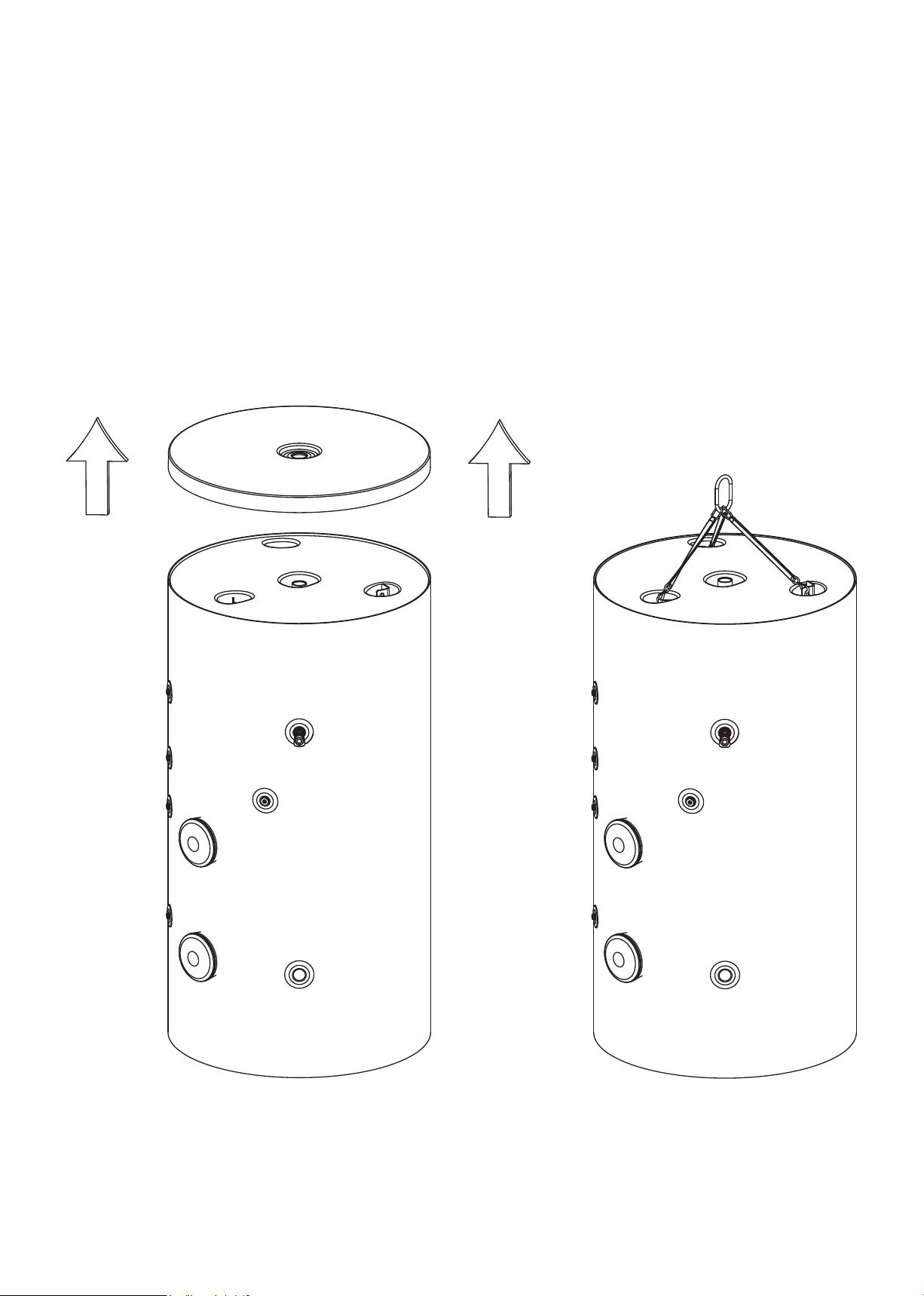

Figure 8: Lifting the unit

5.4 Transport

Prior to installation the unit should be stored and

transported in an area free from excessive damp or

humidity.

To aid installation, the water heater (800ltr upwards)

is provided with lifting points, located at the top of the

unit. To access the lifting eyes please remove the top

outlet grommet followed by the cylinder lid.

13

6.2 Water connections

WARNING

`Under no circumstances should the

factory tted temperature/pressure

relief valve be removed other than

by a competent person. To do so will

invalidate any guarantee or claim.

`The cold water combination valve

assembly must be tted on the mains

water supply to the cylinder.

`No control or safety valves should be

tampered with or used for any other

purpose.

`The discharge pipe should not be

blocked or used for any other purpose.

`The tundish should not be located

adjacent to any electrical components.

Refer to the installation schematic (g 6) for details on

the pipework layout. Specic details for the discharge

pipework layout is also provided in gure 8.

`All pipe ttings are made via BSP female pipe

connections directly to the unit.

`Astopcock or servicing valve should be incorporated

into the cold water supply to enable the cylinder and

its associated controls to be isolated and serviced

(not supplied).

`The expansion vessel must be connected between

6. Installation

6.1 General

After reading the previous sections in this booklet, and

choosing a good location for the unit, please install,

paying attention to the following hydraulic, electrical

and commissioning sections.

Boiler selection

`The boiler should have a control thermostat and non

self-resetting thermal cut-out and be compatible

with unvented storage water heaters.

`Where use of a boiler without a thermal cut-out

is unavoidable a “low head” open vented primary

circuit should be used. The feed and expansion

cistern head above the cylinder should not exceed

2.5m.

`Can be a sealed system or open vented type -

maximum primary pressure 3 bar.

`The boiler cannot be vented through the cylinder.

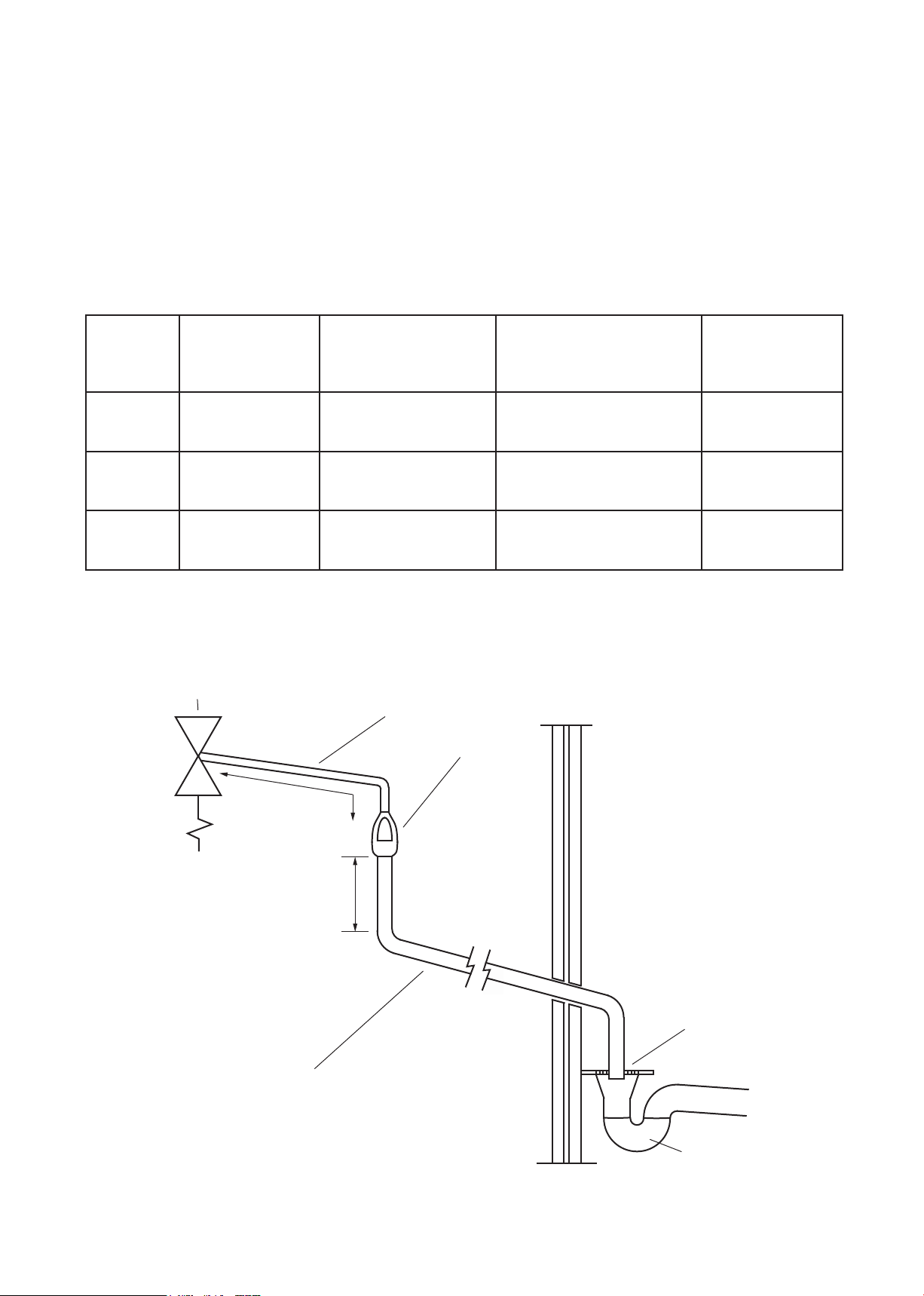

Figure 6: Typical installation schematic (not to scale)

WRAS approved

pump

Check valve

Air vent at highest

point in system

(not supplied)

To Drain

Hot water outlet

Direction

of flow

De-stratification pump

TYPICAL DE-STRATIFICATION

LOOP SYSTEM

Please note, that this is a typical installation and

other options are available.

Check Valve (not supplied)

Mains water

supply

Expansion

vessel

Balanced cold

water connection

Pressure reducing

valve

Pressure relief

valve

Discharge

pipe

Tundish

SECONDARY CIRCULATION

Secondary

return

Solar flow out

Solar flow in

Auxillary flow in

Auxillary flow out

14

3.5 bar Pressure

reducing valve

Mains water in

8 bar Pressure

relief valve

28mm compression connections

To cylinder

Pressure relief

discharge

Take note of ow

direction

Take note of ow

direction

Pressure gauge

connections (one

each side)

the cold water combination valve and the cylinder.

`The location of the expansion vessel should allow

access to recharge the pressure as and when

necessary.

`A suitable draining tap should be installed in the

cold water supply to the cylinder between the

expansion valve and the heater at as low a level

as possible.

`It is recommended that the outlet point of the drain

pipework be at least 1 metre below the level of the

heater (this can be achieved by attaching a hose to

the drain tap outlet spigot).

Cold water control pack

CAUTION

`The expansion vessel pressure must

be set in accordance with the inlet

pressure set on the pressure reducing

valve.

`Flush supply pipework before

connection to remove all ux and debris

prior to tting the inlet controls. Failure

to do this may result in irreparable

damage to the controls and will

invalidate any warranty.

`The cold water control pack can be connected

anywhere on the cold water cylinder supply prior to

the expansion vessel.

`The control pack incorporates the strainer, check

valve, core unit and expansion releif valve.

`The pressure settings are adjustable and should

be set between 1 & 6 bar.

`The valve can be tted in any orientation to suit

the installation as long as the valve is installed with

the direction of ow arrows pointing in the correct

direction.

`The expansion relief valve should be installed with

the discharge pipework in either the horizontal

position or facing downwards.

`No other valves should be placed between the cold

water combination valve and the cylinder.

`The blank plastic plugs in the body of the pressure

relief valve are pressure gauge connections to

enable pressure monitoring to be carried out, should

the system develop a fault. It is recommended that

these be accessible (the pressure reducing valve

has two – only one need be accessible).

Auxiliary circuit control

`The 2 port motorised valve supplied with the

cylinder MUST be tted on the auxiliary ow to the

cylinder heat exchanger and wired such that in the

event of the cylinder overheating it will close the

auxiliary circuit.

`Auxiliary circulation to the cylinder heat exchanger

must be pumped; gravity circulation WILL NOT

WORK.

`It is reccomended that an air bleed or automatic air

vent is incorporated in the primary return pipe work

close to the unit.

`Boiler ow temperature should be set to 82°

(maximum ow temperature to auxiliary heat

exchanger 89°C).

Figure 7: Cold water combination valve (400 & 500ltr)

15

Solar connections

`The lower (solar) coil must be connected to a

fully pumped solar primary circuit with its own

safety control which must be installed as per the

manufacturers instructions.

`There must be suitable check vales installed in

the solar primary ow and return to prevent the

possibility of any thermo-syphoning if the solar

circulation is stopped.

Secondary circulation

If secondary circulation is required it is recommended

that it be connected to the cylinder as shown (see g.

6).

`The secondary return pipe should be in 28mm pipe

and incorporate a check valve to prevent backow.

`A suitable WRAS approved bronze circulation

pump will be required.

`On large systems, due to the increase in system

water content, it may be necessary to t an

additional expansion vessel to the secondary

circuit. This should be done if the capacity of the

secondary circuit exceeds 10 litres.

Pipe capacity (copper):

15mm O.D. = 0.13 l/m (10 litres = 77m)

22mm O.D. = 0.38 l/m (10 litres = 26m)

28mm O.D. = 0.55 l/m (10 litres = 18m)

Note: Plastic pipe capacities may be reduced due to

thicker wall sections.

De-stratication kits

The correct size of de-stratication kit must be used

with your cylinder to ensure the volume can be

circulateed in 1 hour. The pump instructions will need

to be reviewed for information on the correct setting.

Please follow the installation schematic below for

guidance. When the system circulates needs to be

specied by the installer to ensure water is not drawn

off during the de-stratication process. If a hot water

demand is required during this period cold water may

be discharged from the hot outlet. It is recommended

that a check valve be installed before the pump to stop

any rick of cold water draw off through the pump when

it is not in use.

For guidance on installation please refer to gure 6.

Discharge

It is a requirement of Building Regulation G3 that any

discharge from an unvented system is conveyed to

where it is visible, but will not cause danger to persons in

or about the building. The tundish and discharge pipes

should be tted in accordance with the requirements

and guidance notes of Building Regulation G3. The G3

Requirements and Guidance section 3.50 - 3.63 are

reproduced in the following sections of this manual.

For discharge pipe arrangements not covered by G3

Guidance advice should be sought from your local

Building Control Ofcer. Any discharge pipe connected

to the pressure relief devices (expansion valve and

temperature/pressure relief valve) must be installed in

a continuously downward direction and in a frost free

environment.

Water may drip from the discharge pipe of the

pressure relief device. This pipe must be left open to

the atmosphere. The pressure relief device is to be

operated regularly to remove lime deposits and to

verify that it is not blocked.

G3 REQUIREMENT

“...there shall be precautions...to ensure that the

hot water discharged from safety devices is safely

conveyed to where it is visible but will not cause danger

to persons in or about the building.”

The following extract is taken from the latest G3

Regulations

Discharge pipes from safety devices

Discharge pipe D1

3.50 Each of the temperature relief valves or combined

temperature and pressure relief valves specied in

3.13 or 3.17 should discharge either directly or by way

of a manifold via a short length of metal pipe (D1) to a

tundish.

3.51 The diameter of discharge pipe (D1) should be

not less than the nominal outlet size of the temperature

relief valve.

3.52 Where a manifold is used it should be sized to

accept and discharge the total discharge from the

discharge pipes connected to it.

3.53 Where valves other than the temperature and

pressure relief valve from a single unvented hot water

system discharge by way of the same manifold that

is used by the safety devices, the manifold should be

factory tted as part of the hot water storage system

unit or package.

Tundish

3.54 The tundish should be vertical, located in the

same space as the unvented hot water storage system

and be tted as close as possible to, and lower than,

the valve, with no more than 600mm of pipe between

16

the valve outlet and the tundish (see g 8).

Note: To comply with the Water Supply (Water Fittings)

Regulations, the tundish should incorporate a suitable

air gap.

3.55 Any discharge should be visible at the tundish. In

addition, where discharges from safety devices may

not be apparent, e.g. in dwellings occupied by people

with impaired vision or mobility, consideration should

be given to the installation of a suitable safety device

to warn when discharge takes place, e.g. electronically

operated.

Discharge pipe D2

3.56 The discharge pipe (D2) from the tundish should:

(a) have a vertical section of pipe at least 300mm

long below the tundish before any elbows or bends in

the pipework (see g. 8); and

(b) be installed with a continuous fall thereafter of at

least 1 in 200.

3.57 The discharge pipe (D2) should be made of:

(a) metal; or

(b) other material that has been demonstrated to be

capable of safely withstanding temperatures of the water

discharged and is clearly and permanently marked to

identify the product and performance standard (e.g. as

specied in the relevant part of BS 7291).

3.58 The discharge pipe (D2) should be at least one

pipe size larger than the nominal outlet size of the safety

device unless its total equivalent hydraulic resistance

exceeds that of a straight pipe 9m long, i.e. for discharge

pipes between 9m and 18m the equivalent resistance

length should be at least two sizes larger than the

nominal outlet size of the safety device; between 18

and 27m at least 3 sizes larger, and so on; bends must

be taken into account in calculating the ow resistance.

See Fig 11, Table 4 and the worked example.

Note: An alternative approach for sizing discharge

pipes would be to follow Annex D, section D.2 of BS

6700:2006 Specication for design, installation, testing

and maintenance of services supplying water for

domestic use within buildings and their curtilages.

3.59 Where a single common discharge pipe serves

more than one system, it should be at least one pipe

size larger than the largest individual discharge pipe

(D2) to be connected.

3.60 The discharge pipe should not be connected to a

soil discharge stack unless it can be demonstrated that

the soil discharge stack is capable of safely withstanding

temperatures of the water discharged, in which case, it

should:

(a) contain a mechanical seal, not incorporating a

water trap, which allows water into the branch pipe

without allowing foul air from the drain to be ventilated

through the tundish;

(b) be a separate branch pipe with no sanitary

appliances connected to it;

(c) if plastic pipes are used as branch pipes carrying

discharge from a safety device they should be either

polybutylene (PB) to Class S of BS 7291-2:2006 or

cross linked polyethylene (PE-X) to Class S of BS

7291-3:2006; and

(d) be continuously marked with a warning that no

sanitary appliances should be connected to the pipe.

Note:

1. Plastic pipes should be joined and assembled with

ttings appropriate to the circumstances in which they

are used as set out in BS EN ISO 1043-1.

2. Where pipes cannot be connected to the stack it

may be possible to route a dedicated pipe alongside or

in close proximity to the discharge stack.

Termination of discharge pipe

3.61 The discharge pipe (D2) from the tundish should

terminate in a safe place where there is no risk to

persons in the vicinity of the discharge.

3.62 Examples of acceptable discharge arrangements

are:

(a) to a trapped gully with the end of the pipe below a

xed grating and above the water seal;

(b) downward discharges at low level; i.e. up to

100mm above external surfaces such as car parks,

hard standings, grassed areas etc. are acceptable

providing that a wire cage or similar guard is positioned

to prevent contact, whilst maintaining visibility; and

(c) discharges at high level: e.g. into a metal hopper

and metal downpipe with the end of the discharge pipe

clearly visible or onto a roof capable of withstanding

high temperature discharges of water and 3m from

any plastic guttering system that would collect such

discharges.

3.63 The discharge would consist of high temperature

water and steam. Asphalt, roong felt and non-

metallic rainwater goods may be damaged by such

discharges.

Worked example of discharge pipe sizing

Fig. 11: shows a G1/2 temperature relief valve with a

discharge pipe (D2) having 4 No. elbows and length of

7m from the tundish to the point of discharge.

From Table 4:

Maximum resistance allowed for a straight length of

22mm copper discharge pipe (D2) from a G1/2

temperature relief valve is 9.0m.

Subtract the resistance for 4 No. 22mm elbows at 0.8m

each = 3.2m

Therefore the permitted length equates to: 5.8m

5.8m is less than the actual length of 7m therefore

calculate the next largest size.

17

Maximum resistance allowed for a straight length of

28mm pipe (D2) from a G1/2 temperature relief valves

equates to 18m.

Subtract the resistance of 4 No. 28mm elbows at 1.0m

each = 4.0m

Therefore the maximum permitted length equates to:

14m

As the actual length is 7m, a 28mm (D2) copper pipe

will be satisfactory.

Valve

Outlet Size

Minimum Size Of

Discharge Pipe

D1

Minimum Size Of

Discharge Pipe D2

From Tundish

Maximum Resistance

Allowed, Expressed As A

Length Of Straight Pipe

(I.E. No Elbows Or Bends)

Resistance

Created By Each

Elbow Or Bend

G1/2 15mm

22mm

28mm

35mm

up to 9m

up to 18m

up to 27m

0.8m

1.0m

1.4m

G3/4 22mm

28mm

35mm

42mm

up to 9m

up to 18m

up to 27m

1.0m

1.4m

1.7m

G1 28mm

35mm

42mm

54mm

up to 9m

up to 18m

up to 27m

1.4m

1.7m

2.3m

Table 7: Sizing of copper discharge pipe (D2) for common temperature relief valve outlet sizes

Safety device

(e.g. Temperature

relief valve) Metal discharge pipe (D1) from

Temperature relief valve to tundish

Tundish

Discharge below

fixed grating

(Building Regulation

G3 section 3.61 gives

alternative points

of discharge)

Fixed grating

Trapped

gully

600mm maximum

300mm

minimum

Discharge pipe (D2) from tundish,

with continuous fall. See Building

Regulation G3 section 3.56,

Table 1 and worked example

Figure 8: Typical discharge pipe arrangement (extract from Building Regulation G3 Guidance Section 3.50)

18

6.3 Electrical connections

In case of difculty contact service support; contact

details are available on page 32 of this booklet.

WARNING

`Disconnect from the mains electrical

supply before removing any covers.

`Never attempt to replace the

immersion heater(s) other than with the

recommended immersion heater(s).

`DO NOT bypass the thermal cut-out(s) in

any circumstances. All electrical wiring

should be carried out by a competent

electrician and be in accordance with

the latest I.E.E Wiring Regulations.

`Each circuit must be protected by a

suitable fuse and double pole isolating

switch with a contact separation of at

least 3mm in both poles.

`DO NOT operate the immersion heaters

until the cylinder has been lled with

water.

`The immersion heater(s) should be wired in

accordance with g's 2 and 3, page 9.

`All immersion heaters are tted with a thermostat

which is tted in the centre of the heater plate and a

cut-out which is tted to the side of the thermostat.

These MUST be wired in series with the operating

coil circuit of the contactor (not supplied).

Space and heating systems controls

`The controls provided with the cylinder will ensure

the safe operation of the unit within the central

heating system. Other controls will be necessary to

control the space heating requirements and times

that the system is required to function.

`The cylinder is compatible with most heating

controls. Please refer to the controls manufacturers

instructions, supplied with the controls selected.

6.4 Filling the installation

`Check expansion vessel pre-charge pressure.

The expansion vessel pressure must be set in

accordance with the inlet pressure set on the

pressure reducing valve.

`Ensure the drain cock is CLOSED.

`Open a hot tap furthest from the cylinder.

`Open the mains stop cock to ll the unit. When

water ows from the tap, allow to run for a few

minutes to thoroughly ush through any residue,

dirt or swarf, then close the tap.

`Open successive hot taps to purge the system of

air.

19

7. Commissioning

7.1 General

After lling the installation with water in the previous

section please follow the following steps to complete

the installation of the unit.

WARNING

DO NOT operate the immersion heaters or

primary circuit until the cylinder has been

lled with water.

7.2 Checklist before commissioning

`Check all water connections for leaks and rectify

as necessary.

`Turn off mains water supply.

`Remove the pressure reducing valve head work to

access the strainer mesh, clean and re-t.

`Turn the water supply back on.

`Manually open, for a few seconds, each relief valve

in turn, checking that water is discharged and runs

freely through the tundish and out at the discharge

point.

`Ensure that the valve(s) reseat satisfactorily.

7.3 Commissioning procedure

`Fill the solar primary circuit following the instructions

provided with the solar hydraulic controls.

`Heating of the solar coil is controlled by the solar

controller; refer to the manufacturer's instructions

for details.

`The solar controller should be programmed to give

a cylinder temperature of approximately 65°C.

`Fill the auxiliary circuit following the boiler

manufacturer’s commissioning instructions.

`To ensure the cylinder auxiliary heat exchanger is

lled, the 2 port motorised valve (supplied) should

be manually opened by moving the lever on the

motor housing to the MANUAL setting. When

the primary circuit is full return the lever to the

AUTOMATIC position.

`Switch on the boiler, ensure the programmer is set

to Hot Water and allow the cylinder to heat up to a

normal working temperature 65oC.

`If necessary the temperature can be adjusted as

shown in Figure 9. The minimum thermostat setting

is 10°C.

`Check the operation of the thermostat and 2 port

motorised valve, and that no water has issued from

the expansion relief valve or temperature/pressure

relief valve during the heating cycle.

0

30

40

50

60

70

°C

Temperature control

clockwise to increase,

counter-clockwise to

decrease

Thermal cut-out

reset under cap

Figure 9: Indirect controls (auxiliary coil)

Benchmark

The cylinder is covered by the Benchmark Scheme

which aims to improve the standards of installation

and commissioning of domestic heating and hot water

systems in the UK and to encourage regular servicing

to optimise safety, efciency and performance.

Benchmark is managed and promoted by the Heating

and Hotwater Industry Council. For more information

visit www.centralheating.co.uk.

Please ensure that the installer has fully completed the

Benchmark Checklist (page 30 & 31) of this manual and

that you have signed it to say that you have received a

full and clear explanation of its operation. The installer is

legally required to complete a commissioning checklist

as a means of complying with the appropriate Building

Regulations (England & Wales).

All installations must be notied to Local Area Building

Control either directly or through a Competent

Persons Scheme. A Building Regulations Compliance

Certicate will then be issued to the customer who

should, on receipt, write the Notication Number on the

Benchmark Checklist.

This product should be serviced regularly to optimise

its safety, efciency and performance. The service

engineer should complete the relevant Service Record

on the Benchmark Checklist after each service.

The Benchmark Checklist may be required in the event

of any warranty work.

20

8. Operation

8.1 General

WARNING

`If water discharges from the

temperature/pressure relief valve on

the cylinder shut down the heat source.

Do not turn off any water supply. Contact

a competent installer for unvented water

heaters to check the system.

`Do not tamper with any of the safety

valves tted to the system. If a fault

is suspected contact a competent

installer.

`DO NOT bypass the thermal cut-out(s)

in any circumstances.

Flow performance

When initially opening hot outlets a small surge in

ow may be noticed as pressures stabilise. This is

quite normal with unvented systems. In some areas

cloudiness may be noticed in the hot water. This is due

to aeration of the water, is quite normal and will quickly

clear.

Temperature controls

The cylinder units are tted with a thermostat and

thermal cut-out. These controls must be wired in

series with the 2 port motorised zone valve supplied

to interrupt the ow of primary water around the heat

exchanger coil when the control temperature has been

reached.

DO NOT bypass the thermal cut-out(s) in any

circumstances.

The solar cylinder must be incorporated into a fully

pumped solar primary circuit. Control of the solar

primary is achieved by the use of external controls not

supplied with the unit. Control must be via a purpose

designed solar hydraulic station and solar differential

temperature controller.

Operational faults

Operational faults and their possible causes are

detailed in the Fault Finding section (p.23) of this book.

It is recommended that faults should be checked by a

competent installer.

The air volume within the expansion vessel will

periodically require recharging to ensure expanded

water is accommodated within the system. A discharge

of water INTERMITTENTLY from the expansion valve

will indicate the air volume has reduced to a point

where it can no longer accommodate the expansion.

This manual suits for next models

15

Table of contents

Popular Inverter manuals by other brands

Ross

Ross RPG6250RCD manual

Generac Power Systems

Generac Power Systems QuietSource 005028-0 owner's manual

AirMan

AirMan SG Series instruction manual

Champion

Champion ParaLink 100468 Operator's manual

ECO-WORTHY

ECO-WORTHY CSP600 user manual

Badger Power Electronics

Badger Power Electronics BPE-HI-3.6K user manual