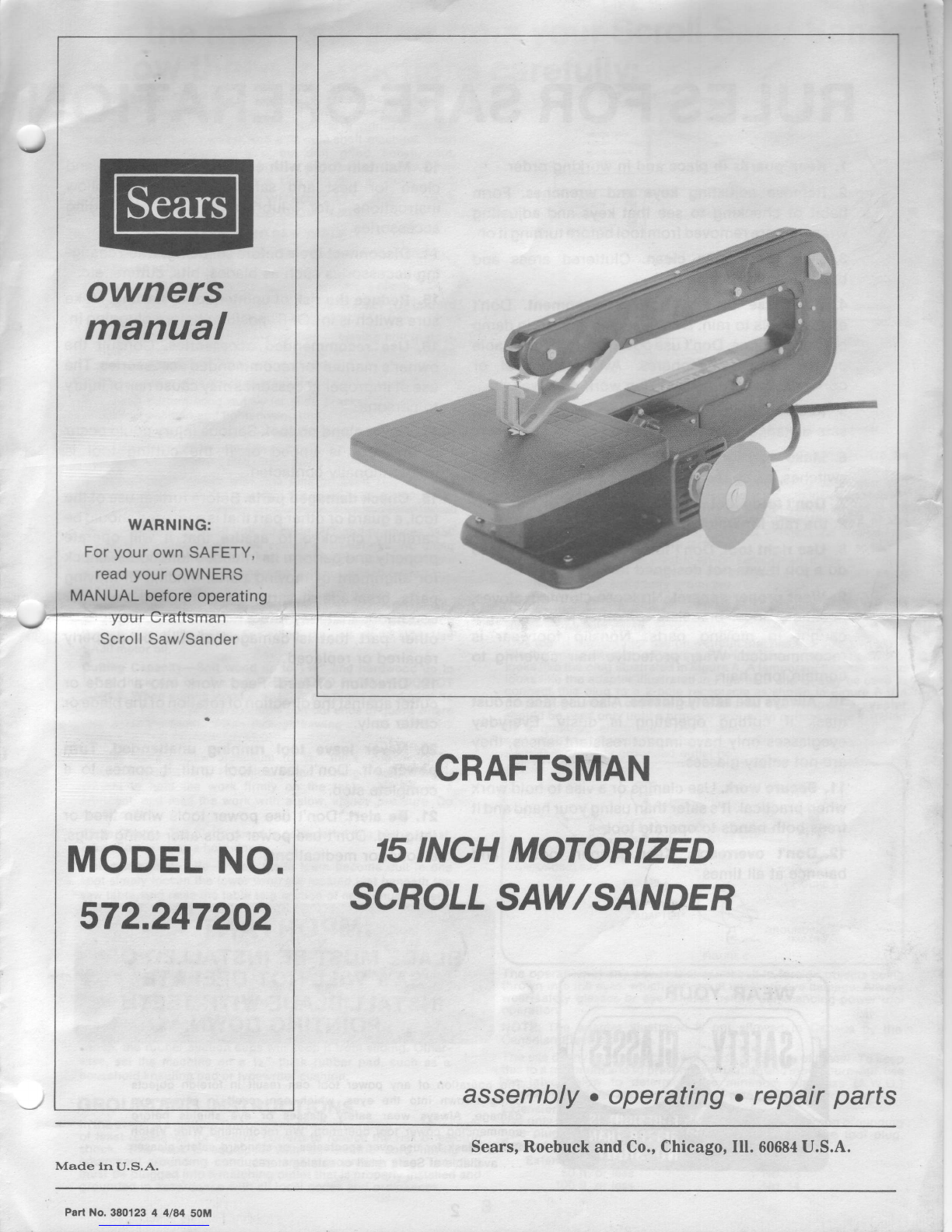

Crafstman 572.247202 User manual

owners

manual

WARNING:

For

your

own

SAFETY,

read

your

OWNERS

MANUAL

before

operating

ScrollSaw/Sander

CRAFTSMAN

MODEL

NO. 15

INCHMOTORIZED

572.247202 SCROLL

SAW/SANDER

assembly

. operatifig

. repairparts

Made lnU,S.A.

PartNo.3801234 4/84 50M

Sears,

RoebuckandCo.,

Chicago,Ill. 60684U.S.A.

RULES

FOR

SAFE

OPERATION

1. Keep

guardsInplace

and

inworking

order'

2. Remove

adlustlngkeys and wrenches'Form

habit

of checking

to see

thatkeys

andadjusting

wrenches

are

removed

from

tool

before

turning

iton'

3. Keep work area clean. Cluttered areas and

benches

invite

accidents.

4. Don't uge In dangerous

envlronment.

Don't

expose

tools

to rain.

Don't

use

power

tools

indamp

or

wet

locations.

Don't

use

powertools

inf

lammable

or explosive

atmospheres.

Avoid chemicalor

corrosive

environments.

Keep

work

area

well

lit'

5. Keep

chlldren

away.

All

visitors

should

be

kept

a

safe

distance

from

work

area'

6. Make

workshop

kld'proof

with

padlocks,master

switches,

or byremoving

starter

keys'

7. Don't

force

tool.

ltwill

do

the

iob

better

and

safer

attherate

forwhich

itwas

designed.

8. Use

rlght

tool.

Don't

force

tool

orattachment

to

doajobitwas

not

designed

for.

9. Wear

propel

apparel.

Noloose

clothing,

gloves,

necktieq

rings,

bracelets,

or other

jewelry

to get

caught in moving parts' Nonslip

footwear

is

recommended.

Wearprotectivehair covering

to

contain

long

hair.

10.

Always

use

safety

glaeses.

Also

use

faceor

dust

mask if cutting operatingis dusty. Everyday

eyeglasses

onlyhave

impact

resistant

lenses,

they

are

notsafety

glasses.

11.Secure

work.Use

clamps

ora

vise

tohold

work

when

practical.lt'ssafer

than

using

your

hand

and

it

frees

both

hands

to operate

tool'

12.Don't overreach.

Keep proper footing and

balance

at

alltimes.

\J

13.Maintain

tools

with

care.

Keep

tools

sharp

and

clean for best and safest

performance'

Follow

instructions for lubricating and changing

accessories.

14.

Disconnect

tools

before

servicing;

when

chang-

ing

accessories

such

as

blades,

bits,

cutters'

etc'

15.Reduce

the

risk

ol unintentional

starting'

Make

sure

switch

is

in

"OFF"

positionbefore

plugging

in'

16.

Use recommended

accessories'

Consult

the

owner's

manual

for

recommended

accessories'

The

use

of

improper

accessories

may

cause

risk

of

injury

to persons.

17.

Never

stand

on

tool.

Serious

injury

could

occur

if the tool is tipped

or if the cutting

tool is

uni

ntentionallY

contacted'

18.

Check

damaged

parts.

Before

further

use

of

the

tool,

a

guard

or

other

part

that

isdamaged

should

be

carefully

checked

to assure

that it will operate

properlyand

performits

intended

function

- check

foralignment

of moving

parts,

binding

of moving

parts,

breakage

of parts,

mounting,

and

any

other

conditions

that

may

atfect

itsoperation'

'A

guard

or V-'

otherpart that is damaged

should

be properly

repaired

or rePlaced.

19.

Dlrection

of feed.

Feed

work intoa blade

or

cutter

against

the

direction

of

rotation

of

theblade

or

cutter

onlY.

20.Neverleave

tool runnlngunattended'

Turn

poweroff. Don't leave

tool until it comes

to a

complete

stoP.

21.Bealert.

Don't

use

power

tools

when

tired

or

fatigued.

Don't

use

powertools

after

taking

drugs'

alcohol

ormedications.

WEAR

YOUR

Y

^01[$st$

The operation

of any power tool can result in foreign objects

being thrown into the eyes, which can result in severe eye

damage. Always wear safety glasses or eye shields before

comm-encing

powertool operation'

We recommend

Wide Vision

Safety

Mask for use over spectacles,

or standard

satety

glasses

. . . available

at Sears

retail

or catalog

stores'

Forthemost

pleasure

from

your

Scroll

Saw/

Sander

follow

these

instructions

carefully:

TheCratbman ScrollSaw isa multi-purposeworkshop.By con-

nectingdifferent

attachments

to the power take-off,the unit

is converted

from the basic scroll saw to a grinder,

sander,

buffing

wheel,brushwheel,and a flexibleshaft

machine.Then

you are able not only to saw, but drill, grind, polish, rout,

sharpen,sand,buff, carve,

engraveand perform many other

hobby,home

orshopoperations.

Use

with247'laccessory

pack.

DONOT

OPERATE

MACHINEWITHOUT

ATTACHING

TABLE.

CAUTION:DISCONNECT

PLUGFROM

OUTLET.

ATTACHING SAWTABLE

1. Remove

blade

guard

- push

oneside

in

- while

pulling

on

oppositeside.

2. Push

lever

(A)

downasillustrated

- to removeblade.

3. Loosen

bottom

wing nutandslidetablebracket

(C) upward

aboul

11/zinchesfrombottom,andtighten.

4. Remove

topwingnut (B)

andwasher

- leavingboltin posi-

tion - and attach table by inserting

bolt through curved

slot

(D)

withhole

attop positioned

over

pin.

5. Place

washer

onoutsideof bracket

andtightenwingnut.

6. Loosen

bottom

wing nut - letslide bracket (C) drop into

original

position

andtightenwingnut.

7. Replace

saw blade(be sure teethare pointingdownward)

by inserting

blade into lower blade holder - then push

lever

downandinsertintoupper

blade

holder.

8. Replaceblade

guardwith side pins on each side of blade

- pushing

onesideinandthentheother

- asin

step

1.

Motor-Runs on110-120

Volt,

60cycle,AC,

andproduces

3450

R.P.M.lt is equippedwithtwo

sealedballbearings.No oiling

isneeded.

Characteristically,

this

shaded

pole-type

motor

runs

a bit warm. However,

overheatingwill not affect overallop-

eration.

Oiling-A few dropsot ordinary

motor

oil shouldoccasionally

be placed

on the connectinglink bean-ngthrough

the FoTe

on

the left

sideof the

frame.

For

oiling,

lay

unit

on its

side,

Use

SA30motor

oil.

CultingCapacity-Soft wood up to 13/q"andhardwood

up to

%

" inthicknesscanbecut.

FEED

WOOD

SLOWLY.

DONOT

FORCE.

When

cuttingwoodover11A"

, theblade

guard

mustbe

removed.Toremove

guard,

simply

pull

outends

of

guard

where

theyenterthe fram?.Whenthrough

sawing. . . BE SURE

TO

REPLACETHEFINGER

GUARD,

Sawing

Metals*Saw aluminumto 7a" thick,

copper to 18

gauge,

andsteel

to 1/16" thick.When

sawingmetal,it is im-

portant

to hold the work firmlyon the table,

use oil as a

lubricant,

andfeedthe workwith a slow,

steady

pressure.

Do

not

forceit.

Blade

Guard-The blade

guard

isconsideredoneofthe

safest.

Itfunctions

alsoasahold-down.

lncreasingBladeLife-When blade

teethbecomedull in one

spotsimply

loosen

thelower

wingnutlocated

iust beneaththe

saw

table,

andraisethetable

toasectionof new,

unusedteeth.

Tilting Table-For angle sawing,

the table can be tilted in

eitherdirection.

Loosen

thetop wing nut located

iust beneath

thesawtable,andtiltto the

desiredanglefollowing

thecali-

brated

scale.

Making In3ide Culs-First, use the tlexible shaft to drill a

3/16" hole in the area to be sawed out. Then, remove

the

blade,

threadit through

the hole,and returnit to the cutting

position.

Hofding Scroll Saw In Place-On a tairly smooth table or

bench,therubber

suctioncupswill

keep

ittrom

sliding.Other-

wise,

set the machine

on a 1/2

" thick rubberpad,such as a

householdkneeling

pad

ortypewriter

cushion.

GROUNDING

INSTRUCTIONS

ln

theevent

ol amalf

unctionorbreakdown,

grounding

provides

a

path

of leastresistance

for electriccurrentto reducethe risk

of electric

shock. This tool is equipped with an electric cord having an

equipment-grounding

conductorand a groundingplug.

The plug

must

beplugged

intoa matching

outletthat

is

properly

installedand

grounded

in accordancewithalllocal

codes

andordinances.

BLAOE lA)

HOLDEB ' '

IIFORTAIT

TEETH ---\

MUST POINT

DOWNWARD

extendingtrom

theadaptermust

beconnectedtoa

permanent

ground

sucnasa outlet

box

HOL€

IN

aow

Donotmodify

the

plugprovided

- ifitwillnotfitthe

outlet,havethe

proper

outlet

installed

by a qualified

electrician.

lmproper connection

of the equipment-grounding

conductor can

resultinariskofelectric

shock.The

conductorwithlnsulation

havino

an outer surfacethat is green

with or without

yellow

stripesis th6

equipment-grounding

conductor. lf repair or replacement

of the

electriccord or plug is necessary,

do not connectthe equipment-

grounding

conductorto

a liveterminal.

Check

with a qualified

electrician

or servicemanif theqroundinq

instructions

ard not corhpletely

understood,

or if in Oo"uUtas t5

whether

thetool isproperly

grounded.

Useonly3-wire

extensioncordsthathave

3-prong

grounding

plugs

anil3-pole receplaclesthat acceptthe toot'splug.

Repair

or replacedamaged

or

worn

cord

immediately.

This

tool is intendedfor useon acircuit

thathasanoutletthatlooks

likethe

one

illustrated

in

Figure

A.The

toolhas

a

groundingplug

that

looks

likethe

plug

illustrated

inFigureA.

Atemporary

adapter,which

lookslike

theadapterillustrated

in Figures

B and

C,may

beusedto

connectthis plug to a 2-polereceptacle

asshownin Figure

B if a

properly

grounded

outlet is not available.

The temporary

adapter

should

beused

only

untila properly

grounded

outlet

canbe

installed

by a qualifiedelectrician.

The green-colored

rigid ear, lug, etc.

The operationof any power

toolcan resultinforeign

obiects

being

thrownintothe

eyes,

which

canresult

in

severeeye

damage.Always

wearsafety

glasses

or eye shieldsbeforecommencing

power

tool

operatron.

NOTE:The adapter_illustrated

is not allowed in Canada

by the

CanadianElectricalCode.

The

useofanyextensioncordwill

cause

someloss

ofpower.

Tokeep

thas

toaminimumandtoprevent

overheating

and

motorburn-out,

use

the table below to determine

the minimum wire size (A.W.G")

extensioncord.All cords

shouldbe3-wire

grounded.

Extension

Gords

Useonlythree-wire

extensioncords

thathavethree-prong

grounding

Vpe. plugs and.three-polereceptacles

that acceptthe tool plug.

Replace

or repair

damaged

or worncord immediately.

ExiensionCord Length

50ft. or less

100

ft.or less

Wire

SizeA.W.G.

No.16

No.14

3

--8UDE

\ro rrro *on^,uo

SAW LIFT BLADE GUARO

FROM THIS POSITION

l--nnl Inn.]

l\-!-/l l\.//l

\- lA I l--o' I

"-F [?-J:aa?i'r'""r=l

@I

GROUNDINGPIN FIGURE

A

TEMPORARY

ADAPTEF a>r FTGURE

B

\_(s

-X cRouNDrNG

l!) - MEANS

FIGURE

C

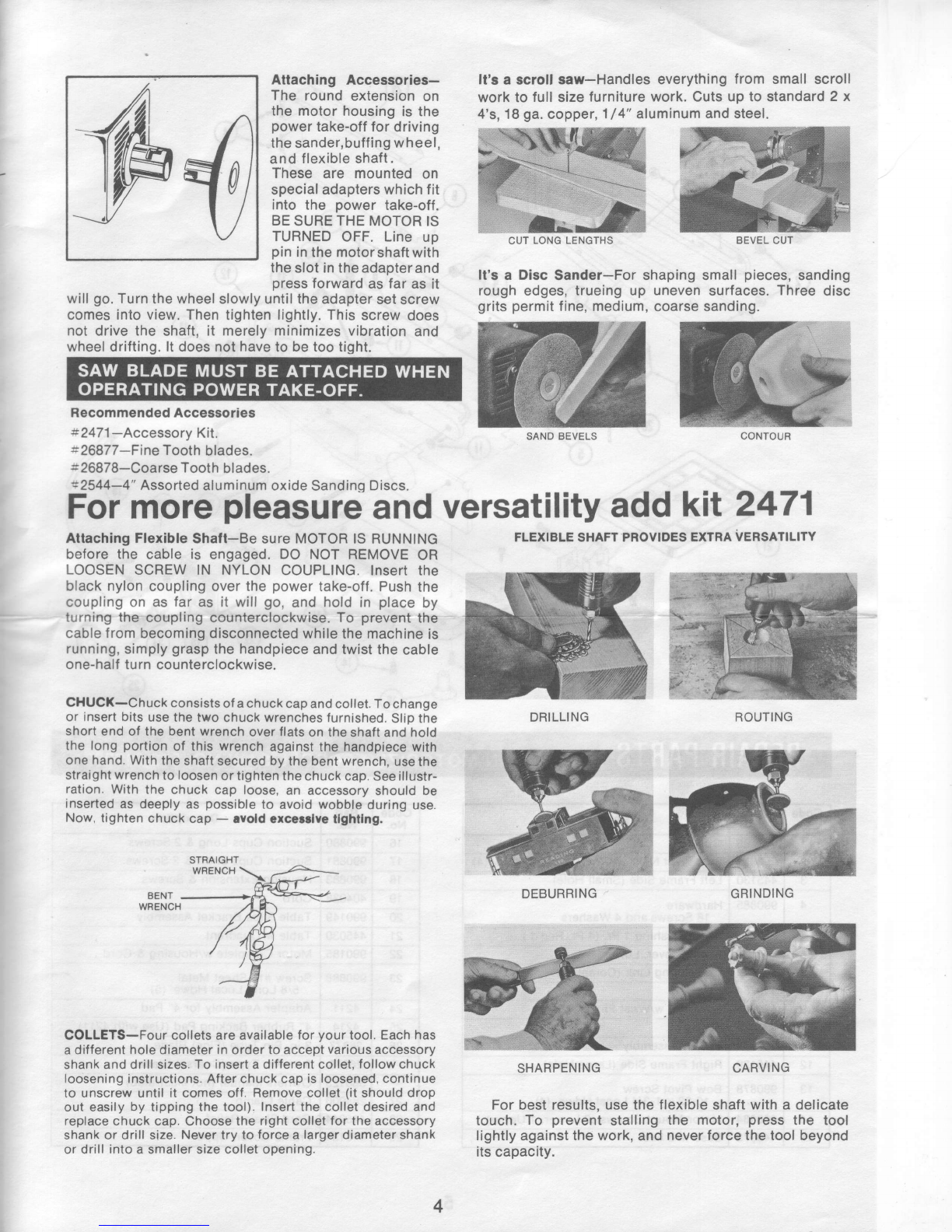

{@nAttaching Accessories-

The round

extension

on

themotorhousing

isthe

power

take-offfor

driving

thesander,buffingwheel,

and

flexibleshaft.

Theseare mounted

on

special

adapterswhichfit

into the power

take-off.

BE

SURE

THE

MOTOR

IS

TURNED

OFF.Lineup

pin

in

themotor

shaftwith

the

slotintheadapter

and

press

forward

asfaras

it

It's

ascroll

saw-Handleseverything

from

smallscroll

worktofull

size

furniturework.Cutsuptostandard

2 x

4's,

18

ga.

copper,

1/4"aluminum

and

steel.

It's

a DiscSander-Forshapingsmall

pieces,

sanding

roughedges,trueingup uneven

surfaces.

Three

disc

gritspermit

fine,medium,coarsesanding.

will

go.

Turn

thewheelslowlyuntiltheadapter

set

screw

comes

intoview.Then

tighten

lightly.

This

screw

does

not

drive

the

shaft,it merelyminimizes

vibration

and

BecommendeclAccessories

#2471-Accessory

Kit.

; 26877

-FineTooth

blades.

:*26878-Coarse

Tooth

bl

ades.

CUT LONGLENGTHS

SAND

BEVETS CONTOUR

e2544-4"

Assorted

aluminumoxide

Sanding

Discs.

Formore

pleasure

and

versatility

add

kit 2471

Altaching

Flexible

Shalt-Be sureMOTORlS RUNNING

beforethe cable is engaged.DO NOT REMOVE

OR

LOOSEN

SCREWIN NYLON COUPLING.

Insert the

black

nyloncouplingoverthepower

take-off.Push

the

couplingon as far as it will go, and hold in place

by

turningthe couplingcounterclockwise.To prevent

the

cable

from

becomingdisconnected

whilethemachine

is

running,

simply

grasp

the

handpiece

andtwist

the

cable

one-halfturncounterclockwise.

CHUGK-Chuck

consists

ofachuck

capandcollet.To

change

orinsert

bits

usethetwo

chuckwrenchesfurnished.

Slipthe

short

endofthebentwrench

over

flats

onthe

shaftandhold

thelong

portion

ot this

wrench

againstthehandpiece

with

onehand.With

the

shaftsecuredby

the

bent

wrench,

use

the

straight

wrench

toloosen

ortighten

the

chuckcap.Seeillustr-

ration.

With

the chuckcap loose,

an accessory

should

be

inserted

asdeeply

aspossible

to avoidwobble

duringuse.

Now,

tightenchuck

cap

- evoldexcertlyetlghtlng.

BENT

WRENCH

COLLETS-Four colletsareavailable

for your tool.Eachhas

adifferent

hole

diameter

in orderto accept

various

accessory

shankanddrillsizes.

To inserta differentcollet,

follow

chuck

looseninginstructions.Afterchuckcap is loosened,continue

to unscrewuntil it comes off. Removecollet (itshoulddrop

out easily

by tipping

thetool).Insertthe colletdesiredand

replacechuck cap.Choosethe right colletfor the accessory

shankor drill size.

Nevertry to force

a larger

diametershank

or drill

into

a smallersizecolletopening.

FLEXIBLESHAFTPROVIDESEXTRA

VERSATILITY

DRILLING ROUTING

DEBURRING GRINDING

SHARPENING CARVING

Forbestresults,usethe flexible

shaft

with a delicate

touch. To prevent stalling the motor, press the tool

lightly

against

thework,

andneverforcethetool beyond

its

capacity.

t

a

I

I

II

q

w

4

Code

No. Parl

No. Description

4451

05 Guard

99087

1 Bow PivotNuts

10-32HexLocal

Hdwe.

(4)

3445130 Left

Frame

Side

(Small

Hole)

A990885 Hardware

16

Screwsand4 Washers

5990887 GuideBushing

1Pr (4

Pr Req'd.)

6445132 Frame

Cover.

Lower

7990874 Connecting

Link

(Complete)

8990764 Bow

Arm

I990765 BowArm w/WristPin

10 445063 Spring

11 990877 SwitchAssembly

445129 Right FrameSide (Large

Hole)

'13 990878 BowPivotScrew

.10-32

x 1-3/4LocalHdwe.

(4)

14 990884 MotorMountScrews

(2Lower,1 Upper)

'15 445073 Base w/o Feet

Code

No. Parl

No. Description

.16 990880 Suction

Cups

Long& 2 Screws

17 99088

1Suction

CupsShort

& 2 Screws

1B 990883 Housing

Extension&Screws

19 404038 Cord

20 9901

49 TableSlide

Bracket

Assemblv

445030 Table

w/Ouadrant

22 990185 MotorComplete

w/Housing& Cord

23 990888 Screw

#10Sheet

Metal

5/8Long

LocalHdwe.

(5)

4211 Adapter

Assembly

Ior 4" Pad

25 4214 4" RubberBacking

Pad

(Use

with

4211)

to 26877 3 in.Pin

Type

(Fine)

Blade

26878 3in.

PinType

(Coarse)

Blade

3801

23 Owners

Manual

(not

illustrated)

27 284000 CableClamp

28 445044 Cord Strain Reliel

29 445131 Frame

Cover,

Upper

5

owners

manual

MODEL

NO.

572.247202

Sears

SERVICE

is at

YOUR

SEFVICE

How to ORDERRepair Parts

TheModel

Numberwillbe

found

on

a

plate

attached

to

your

Saw

at

therear

of

thebase.

Alwaysmentionthe

ModelNumber

when

requestingserviceor repair

parts.

All parts listedhereinmay be ordered

throughSEARS,

ROEBUCK

AND

CO.

Whenordering

parts

by

mail,selling

prices

willbefurnishedonrequest

or

parts

willbeshipped

at

prevailing

prices

and

you

willbebilledaccordingly.

WHENORDERING

REPAIR

PARTS,ALWAYS

GIVE

THEFOL-

LOWINGINFORMATION

AS

SHOWN

IN

THISLIST,

ThePART

NUMBER

ThePARTDESCRIPTION

The

MODEL

NUMBER572.247202

TheNAMEOF

ITEM-SCROLLSAW/SANDER

1.

2.

3.

4. v

FULL

ONE

YEARWARRANTY

ON

CRAFTSMAN

SCROLL-SAWSANDER

lf thisCraftsman

Scroll-Saw/Sanderfailsto give

completesatistactionwithinone

year

fromthe

dateofpurchase,

return

ittothenearestSearsstorethroughoutthe Unit€dStates,andSearswill

replace

it,free of charge.

lfihisScroll-Saw/Sanderis

usedforcommercialorrental

purposes,

thiswarrantyappliesforonly

90daysfrom the dateot purchase.

Thiswarranty

givesyouspecificlegalrights,and

youmayalsohave

other

rightswhichvaryfrom

state to state.

Sears,

Roebuck

andCo.

BSC41-3

SearsTower

Chicago,lL 60684

Your

Sears

merchandisehasaddedvalue

when

you

consider

that Sears has serviceunits nationwidestaffedwith Sears

trained

technicians . professional

techniciansspecifically

trained on Sears Products, having the parts, tools and

equipment

to insurethatwe meet

our pledge

to you. . . .we

service

whatwe

sell.

Sears,Roebuckand

Co.,Chicago,Ill. 60684U.S.A.

Made inU.S.A.

6

ERRFTS}IRJI.

IMPOKTANT

MAINTDNANCE INFOKMATION

Your Craftsman@

ScrollSaw/Sander

was thor-

oughlyinspected

torigid

standards

priorto

leaving

the manufacturer's

factory

and should

give

you

many

years

ofsatisfactory

service.

Occasionally,

when

the

Craftsman@

Scroll

Saw/

Sanderis removed

fromits

carton

andthetable

attached,

the

userwill

notice

that

the

blade

does

not

appear

to

be

perpendicular

tothe

table

surface

(Figure

1).

Before

attempting

to correct

this

condition,

first

checktoseethat

the

tableis

inits

horizontal

orzero

degree

(0")

position.

Useasquare

orotherright

an-

gle

device

(apiece

ofpaper

wilt

suffice)

tocheck

the

blade

position

relative

tothe

table

surface

(Figure

2).

lfthe

bladeis

not

perpendicular

tothe

table,

simply

push

the

upperarm

ofthe

sawframe

in

the

direction

thatwill

correct

the

bladealignment(Figure

3).

Handling

the

saw

byholding

the

upper

arm

ofthe

sawframe

(Figure

4)can

also

causethe

saw

blade

to

tiltfromthe

truevertical

position.

This

is

not

an

unu-

sual

conditionand

canbe

easily

corrected

by,again,

applyingslight

pressure

tothe

upper

arm

of

the

saw

frameinthe

direction

that

willcorrect

thealignment

(Figure

3).

lftheuseravoids

the

natural

tendency

to use

the

upperarmof the

frame

asa handle

when

lifting

or

moving

the

saw,there

should

benofurther

need

to

realign

the

blade.Figure

5shows

the

proper

way

to

pick

upthe

Scroll

Saw.

Before

deciding

on anyadjustment,

it is recom-

mended

that

you operate

thesaw

andmake

some

trial

cutsso that

youcan

experience

scroll

cutting.

Besureto check

themounting

of the

sawblade

in

theblade

holder

prior

tocutting.

Generally

the

blade

ismounted

sothat

the

teeth

arefacing

front.

How-

ever,

thebladecan

bemounted

with

the

teeth

facing

the side.Alwayshave

the saw teethoriented

to a

downward

cut.

i'l

li i

Figure

1Figure

2

Figure

3

Form No. 380226 21-11/83-ZO

Figure

4Figure

5

Table of contents

Popular Sander manuals by other brands

USAG

USAG 920 AN1 instruction manual

Triton

Triton TSP S450 Operating and safety instructions

MIRKA

MIRKA ros650cv operating instructions

Ingersoll-Rand

Ingersoll-Rand R025A Series Installation and maintenance information

Black & Decker

Black & Decker 7461 owner's manual

Alpha tools

Alpha tools BBS 720 Original operating instructions