4

10.)

Childproof the workshop area by removing all

switch keys from machinery, unplugging all

equipment, or by use of padlocks.

11.) Always remove or unplug machine from

power source before performing any

maintenance or making any adjustments.

12.) Keep all protective guards in place and in

proper working order to avoid potential injury.

13.) Make sure the on/off switch is in the off

position to avoid accidental starting of the

machine when connecting to its power source.

14.) Remove all tools from work area used for

maintenance before turning machine.

15.) Use only recommended or original

accessories. Use of accessories not meant for

this machine can lead to serious injury or even

property damage. Please check the manuals

for accessories to ensure that they can be

safely used with your machine.

16.) Never leave a running machine

unattended. Wait until the machine has come

to a full stop after turning the power switch off

before leaving the area.

17.) Do not stand on tool as it could result in

serious injury or property damage.

18.) Do not store items above or around the

tool or where anyone may try and stand on the

machine to reach the items.

19.) Keep your balance. Never overextend

yourself around the machine. Make sure work

area is free from grease, oil, and other slip

hazards.

20.) Maintain your machine. Always keep

machine clean and in proper working order.

Dress the grinding wheels and replace other

abrasive accessories when worn out.

21.) Before operating machine check for any

damaged parts or accessories. Thoroughly

check all safety guards are operating as they

should and are not damaged. Also check for

the alignment, binding, breaking of moving

parts.

22.) Do not operate machine under the

influence of drugs, alcohol, medication, or

while tired.

23.) Make sure to secure all work using

clamps or jigs to secure the work piece. This is

much safer then attempting to secure the work

piece using your hands.

24.) Pay attention and stay alert while

operating machine. A second of distraction or

inattention can result in serious injury or

property damage.

25.) You should always wear a dust mask

when operating machine to avoid inhaling any

hazardous dust or airborne particulates.

Machine should be operated in a properly

well-ventilated area and in use with dust

collection when available. Long term exposure

to dust may result serious and permanent

respiratory and health conditions such as

silicosis, cancer, and even death. Always use

a NIOSH/OSHA approved respiratory

protection.

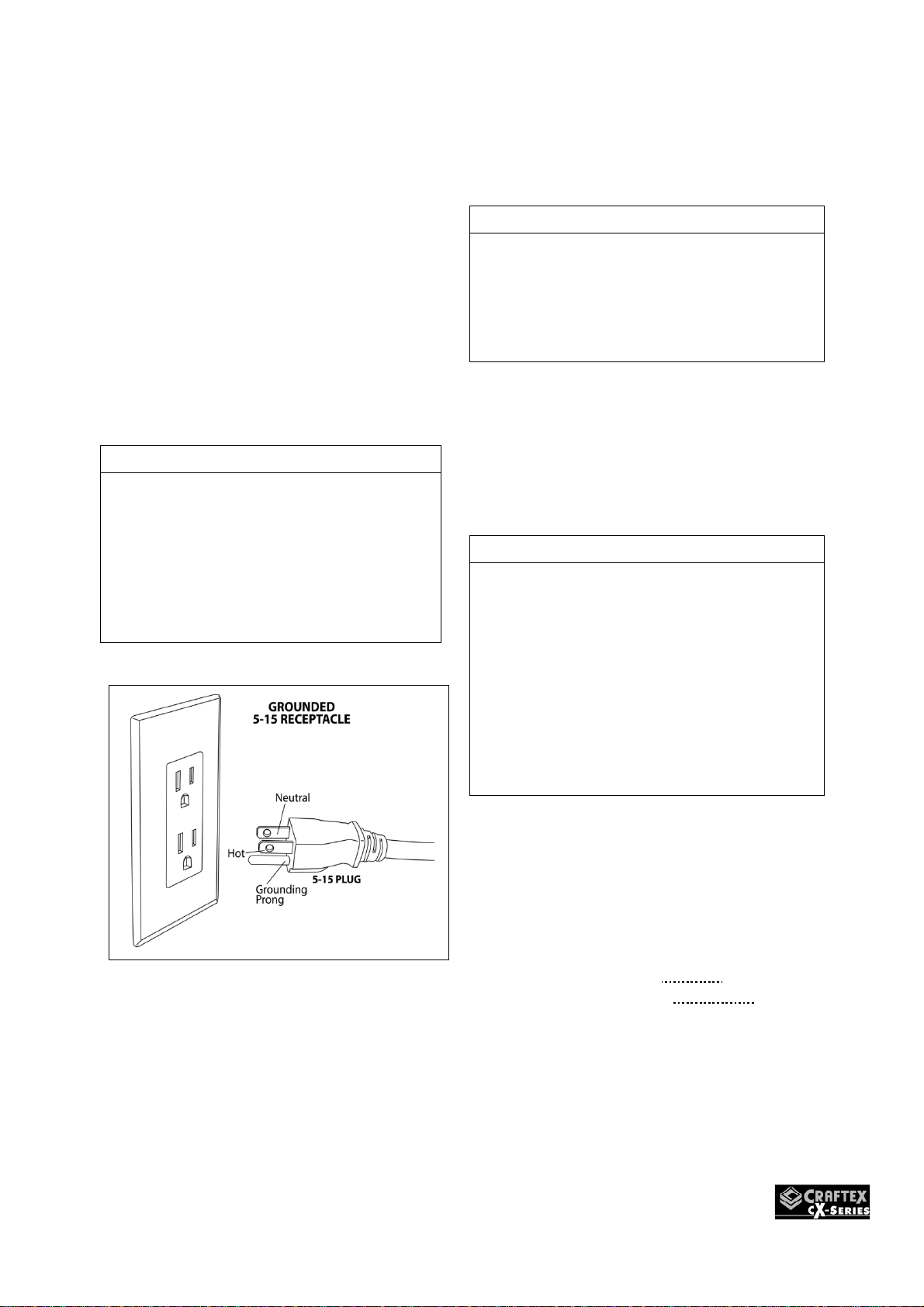

26.) If machine is used in conjunction with an

extension cord it must be heavy enough to

carry the current the machine will draw during

operation. Using a cord with a wire gauge that

is too small or too long can result in voltage

drop causing loss of power and overheating of

the motor. Use only 3 prong extension cords

that have grounding pin.