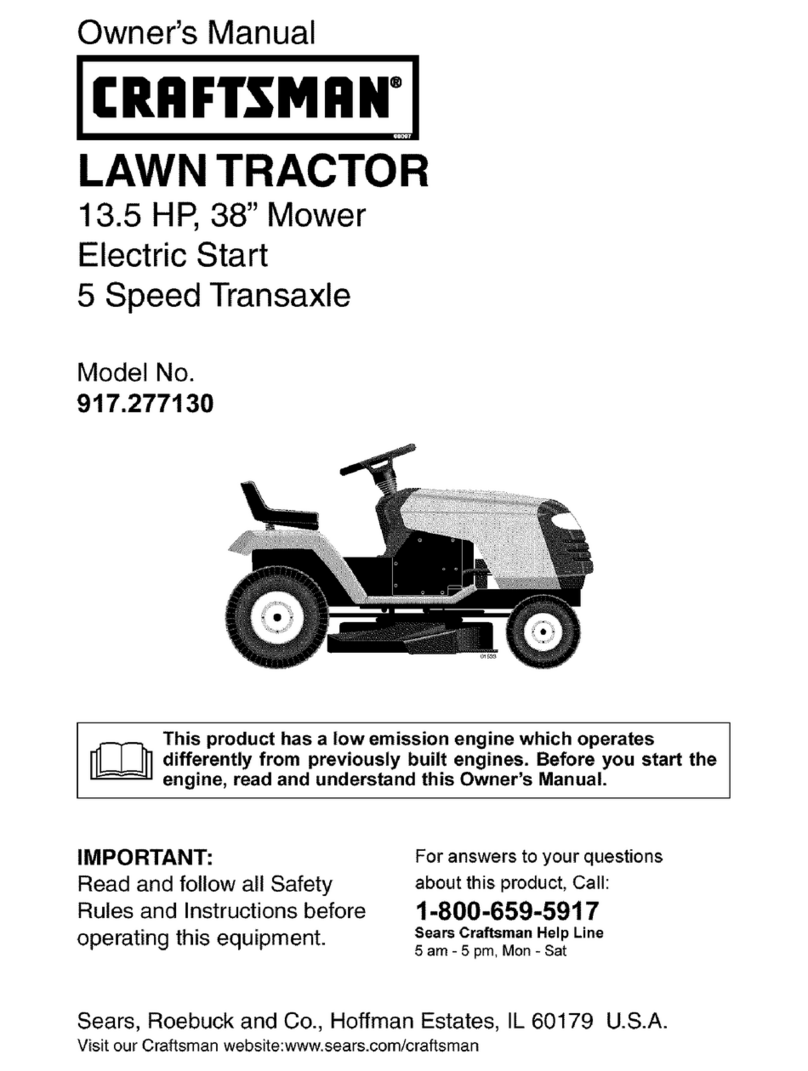

TABLE OF CONTENTS

SAFETY RULES ............................................................ 2

PRODUCT SPECIFICATIONS ...................................... 3

CUSTO MER RESPONSIBtLITIES ..................... 3, 15-19

WARRANTY .................................................................. 3

TABLE OF CONTENTS ................................................ 4

INDEX .......................................................................... ;.4

TRACTOR ACCESSORIES .......................................... 5

ASSEMBLY .............................................................. 7-10

OPERATION .......................................................... 11-14

MAINTENANCE SCHEDULE ...................................... 15

SERVICE AND ADJUSTMENTS ............................ 20-25

STORAGE ................................................................... 26

TROUBLESHOOTING ........................................... 26-27

REPAIR PARTS -TRACTOR ................................ 30-47

REPAIR PARTS - ENGINE .................................... 48-52

PARTS ORDERING/SERVICE .................. BACK PAGE

iNDEX A

Accessories ............................................ 5

Adjustments!

Brake ..................................................22

Carburetor ........................................ 25

Mower:

Front-To-Back ...................... 21

Side-To-Side .........................:.....21

Throttle Control Cable .......................24

Air Filter, Engine .................................... 18

Air Screen, Engine ............................. 18

Assembly .......................................... 7-10

B

Battery:

Charging .................................. 8

Cleaning ........................................ 17

Installation ........................................ 9

Levels .......................................... 8,17

Preparation ....................................... 8

Starting with Weak Battery .......... 23

Storage ...............................................26

Terminals ........................................ 17

Belts:

Motion Drive

Removal/Replacement .......... 22

Mower Blade Drive

RemovaVReplacement ...........22

Biade:

Sharpening ..................................... 16

Replacement ................................... 16

Brake Adjustment ..................................22

C

CarburetorAdjustment ..........................25

Controls, Tractor ..................................... 11

Customer Responsibilities ................15-19

Engine:

Air Filter ........................................18

Air Screen, Engine .......................18

Battery .................................... 17

Cooling Fins, Engine .............. 18

Engine Oil ......................................... 17

Fuel Filter .................................... 19

Spark Plugs ...................................I9

Tractor:

Blades ...................................... 16

Lubdcation Chart ........................15

Maintenance Schedule .............t 5

Tire Care ............................ 8,16,23

Cutting Height, Mower ........................ 12

E

Electrical:

Interlocks and Relays .................... 24

Schematic .........................................29

Wiring Diagram ................................30

Engine:

Air Filter .............................................18

Air Screen ...........................................18

Cooling Fins, Engine ......................... 18

Oil Change ................................... 17

Oil Level ........................................13,17

Oil Type ............................................17

Preparation ..........................................13

Repair Parts .............................. 48-52

Starting ........................................... 14

Storage .......................................... 26

F

Filters:

Air ......................................... 18

Fuel ....................................................19

Fuel:Type ............................................ 13

Storage ...............................................26

Fuse .................................................... 24

G

Gauge Wheels ...................................... 9

H

Hood Removalllnstaliation .........................

L

Leveling Mower Deck ...................... 2l

Lubrication Chart ........................... 15

M

Maintenance Schedule ..........................15

Mower':

Adjustment, Front4o-Back .......... 21

Adjustment, Side-to-Side ............. 21

Blade Sharpening ....................... 16

Blade Replacement .........................16

Cutting Height .............................. 12

Installation .................................. 20

Operation .................................... 13

Removal ...................................... 20

Mowing Tips ..............................................14

Muffler' ........ .............................................. I 9

Spa_k Arrester ......................... 3,40

Mu!cher Plate .............................................10

4

O

Oit: Cold Weather Conditions ...... 13,17

Engine ................................................17

Storage ..........,......................................26

Operation .......................................... 1t -14

Operating Mower ........................................13

Options:

Accessories ...................................... 5

Spark Attester, ................................3,40

P

Parking Brake ....................................11-12

Parts Bag .............................................................6

Parts, Replacement/Repair .............30-47

Product Specifications ........................... 3

R

Repair Parts ........................................30-47

S

Safety Rules .............................................. 2

Seat ............................................................ 8

Service and Adjustments .................20-25

Brake ...................................................22

Carburetor ..........................................25

Fuse ...................................................2,_

Hood RemovaVI nstaliation .............24

Motion Drive Bett

RemovaltReplacement .........22

Mower Blade Drive Belt

Removal/Replacement ..............22

Mower Adjustment:

Front-to-Back ..............................21

Side4o-Side .....................................21

Mower Installation ............................20

Mower Removal ...................................20

Tire Care ....................................8,16,23

Slope Guide Sheet ............................... 55

Spark Plugs ...............................................19

Specifications ............................................ 3

Starting the Engine ..............................13-14

Steering Wheel ......................................7,23

Stopping the Tractor ..................................12

Storage .......................................... 26

T

Throttle Control Cable Adjustment ......24

Tires .....................................................8,16,23

Trouble Shooting Chart ................... 26-27

Transaxle Repair Parts .......................46-47

W

Warranty .............................................. 3

Wiring Diagram ..................................... 30

WMng Schematic ....................................29