J

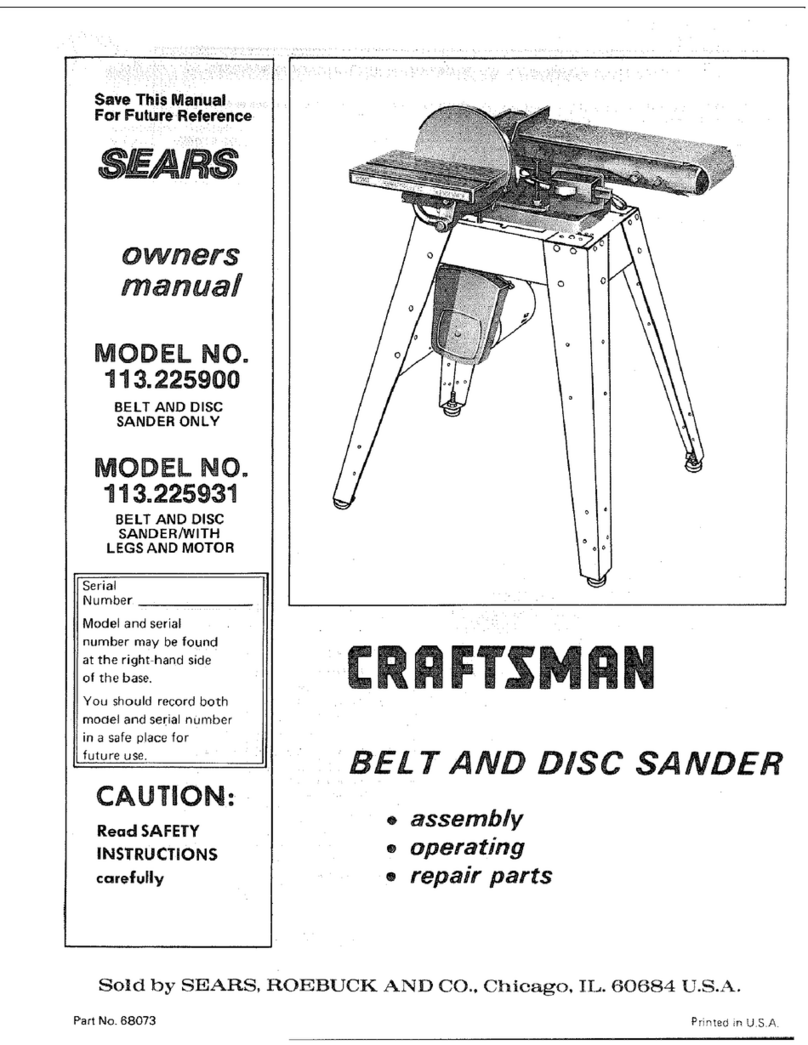

Fig. 1

This sander has been designed so that it may be

driven from behind or below the belt table, The

direction of rotation of the sanding belt must be from

the idler pulley to the drive pulley across the top of

the machine.

Bolt the sander securely to its stand. This is import-

ant because of the considerable pull exerted by the

motor when the sander is operated at maximum

capacity.

Do not run this sander until oil reservoirs on all

bearings have been filled with a good grade of

machine oil similar to S.A.E No. 20. To fill oil reser-

voirs easily and completely, use an oil can with a

small spout, or a pressure oil can in order to displace

air in reservoirs.

Always keep oil reservoirs filled with oil.

This tool is equipped with new type bronze bear-

ings which meter filtered oil to the moving parts.

These bearings have invisible pores that become

saturated with oil. The heat generated by the turning

oI the shaft causes the lubricant in the reservoir to

automatically flow through these bronze bearings,

thus lubricating the moving shaft. When the shaft is

at rest, the oil is absorbed by the bearing.

Do not drill holes through the bearings to feed oil

to the shaft, as it is not necessary.

CONTROLS

A micrometer adjustment of the work table is ob-

tained with the knurled knob. (A in Fig. 1). The wing

nuts (B) lock the work table support arms at the an-

gle chosen. The screw (C) in the work table support

is adjustable and supports the work table when set at

45 °. The bolts (D) lock the belt table at any angle up

to 90°. After setting the fence square -with the belt

table clamp with the bolt (E) The knurled lock stud

assembly (F) holds the tension which is set with the

lever on the opposite side. The knobs (G) adjust the

tension independently on [he bearings on either side

of the idler pulley. The bolts (H) lock the tensioning

screws when the belt has been made to track pro-

perly. The screws (J) are adjustable to keep the idler

pulley shaft parallel with the drive shaft.

ADJUSTMENTS

Belt Tension

When replacing the sanding belt loosen the lock

stud (E in Fig. 2) and move the tensioner lever to

position (A). This will pull the idler pulley in to posi-

tion (B). Slip on the belt and move lever to position

(C). This will force idler pulley to position (D) thus

tightening the belt. The belt should be set at just

enough tension to give the belt the slack shown in the

lower half of Fig. 2.

CAUTION: DO NOT RUN THE SANDER WITH

TIGHT SANDING BELTS.

If moving the lever does not give enough travel on

the idler pulley, check the set screw in the idler pulley

bracket beneath the belt table. Tighten the square

head set screw on the tenmoner rack with only _,"

of the rack extending out of the casting.

Any additional tension changes required can be

obtained by moving the adjusting knobs (G in Fig. 1)

the same distance on both sides.

Adjustment of Belt

After the belt has been given the proper amount of

tension, start the sander with the motor. The belt must

track in the center of-both the idler and drive pulleys_

If belt tends to creep to either side loosen the lock

screws (H in Fig. 1) and tighten the knob (G) on the

side toward which the belt is moving. When belt

tracks properly tighten Both bolts (H).

Belt Table

The belt table may be varied from its normal hori-

zontal position to a vertical position by loosening the