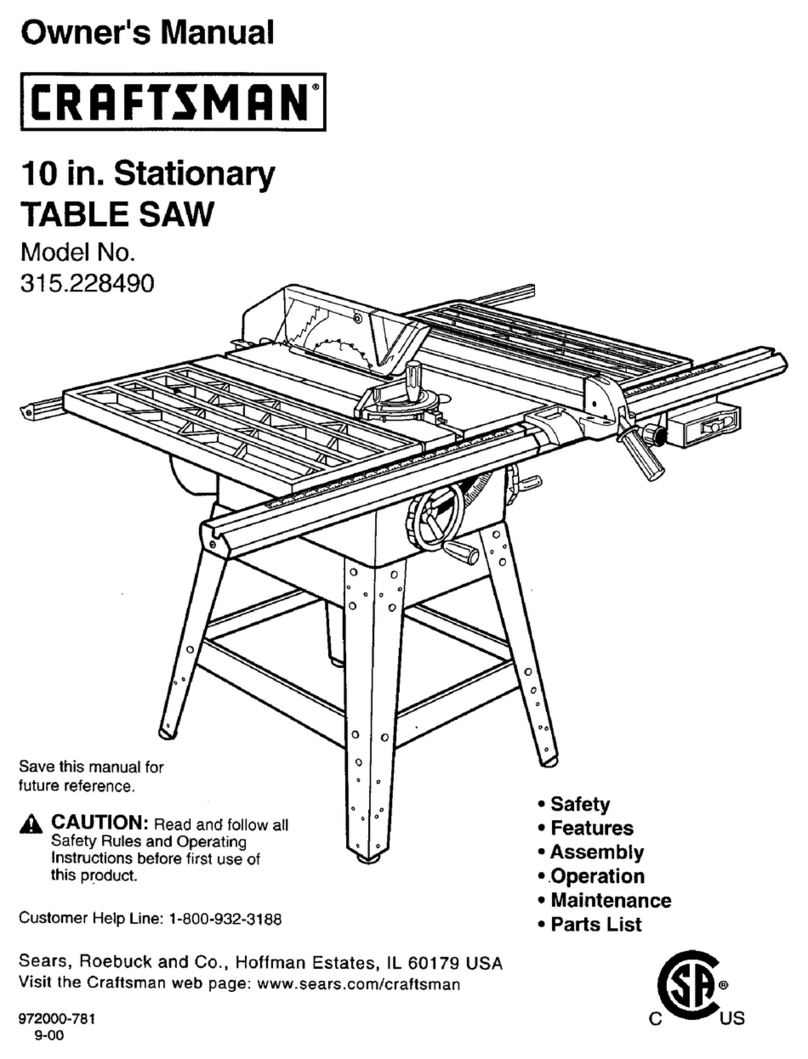

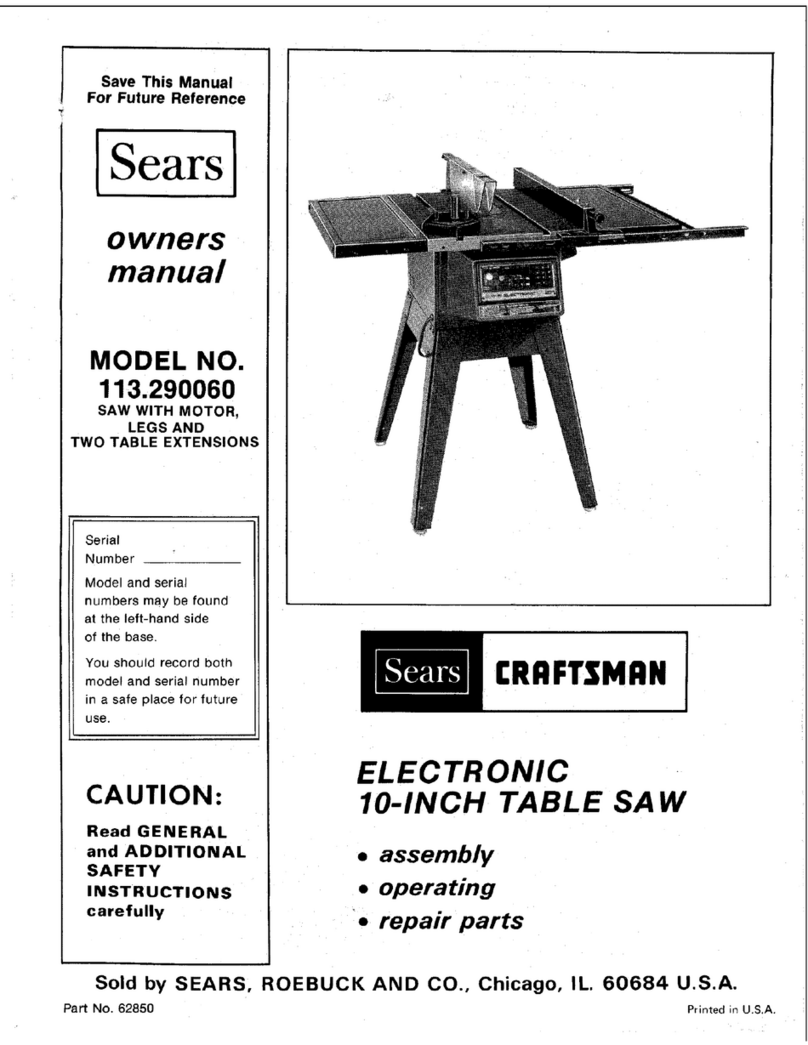

.The Table Leveling Screw should stop the table

at right angles to the blade. See figure 3. Check

with an accurate square. If the table is not square

adjustment of the leveling screw

necessary. Tighten the lock nut securely

after turning the screw.

~45 ° STOP

SCREW

TABLE TILT

PROTRACTOR

FIGURE 3.

4. The 45 ° Stop Screw should stop the table at an

angle of 45 ° to the blade. See figure 3. Check

carefully, if adjustment is necessary, tighten the

lock nut securely after turning the screw. It may

be necessary to reset the pointer to indicate the

proper angle on the tilt scale.

5. The Miter Protractor must be square with the bar

when the pointer shows 90 ° on the protractor

scale. Check with an accurate square and reset

the pointer if necessary.

6. The Table Insert should be flush with the table

surface. To-adjust, loosen the two slotted head

screws (X-532) which you can see from the top

of the insert. You will find four small set screws

(X115) coming up through from the bottom of

the table, two against the front and two against

the rear of the insert. By turning these four

screws slightly, the insert may be leveled and

brought flush with the table surface.

CARE OF THE BLADE:

The blade supplied with this bench saw will give

many hours of efficient cutting service in the average

home workshop without requiring sharpening. When

the teeth become blunted and dull, and adefinite de-

crease in cutting efficiency is noted, the blade may be

put hack in good condition again as follows:

1. Raise the table until an oilstone laid on the table

surface will just touch the teeth of the blade. Turn

the blade backwards by hand until the ends of

all the small cutting teeth have been touched and

are the same length.

2. With an 8 inch round edge mill file, file the gullets

(space between the teeth) of all teeth of the same

shape to auniform depth and width. Maintain

the original shape, bevels, and dimensions. Avoid

sharp corners and nicks in the gullets.

.The top one-quarter of each cutting tooth should

be set at an angle of approximately 10 degrees.

set should be uniform and should alternate

!lt to right on successive teeth. T_he large

require no set--they should be kept

bapproximately 1/64 inch shorter than the cutting

teeth.

File the bevel of each cutting tooth--I 5 to 20

degrees bevel on the inside front face of each

tooth. Maintain the original bevel angle and be

careful not to shorten the teeth,

Blade Wobble is often noticed at slow speeds

starting or stopping the saw. If this does not

at full speed, check the saw blade and

amp washers for dirt or saw dust on the clamping

'rfaces.

Gummy residue can generally be removed with

'ERATION:

provided with this saw may be used for

both cross-cutting and ripping. However, if continu-

ous ripping or continuous cross cutting is planned,

a rip blade or cross cut blade will operate much more

efficiently.

For proper chip clearance and best general results,

the blade should project through the work-piece

approximately I_ inch.

Saw warped stock with the concave or hollow face

do'*v'n.

Support long work as it leaves the rear of the table.

Avoid back tracking on a cut.

Do not force material into the blade too fast. Use

astraight, direct, steady feed which does not over-

tax the cutting capacity of the blade.

SAFETY:

While the bench saw is one of the most widely used

woodshop power tools, it is by nature of its general

design, one of the most dangerous in the hands of

inexperienced or careless operators. The bench saw

is not, however, an unsafe tool when used with com-

mon sense and good judgment.

Use a push block rather than letting the hands get

closer than 3inches to the blade on narrow cuts.

Keep the splitter in place whenever possible. Never

hold the hands over the blade when making blind

groove type cuts. Stand to one side when completing

a cut. A loose piece caught by the blade can fly

back with surprising force.

Always stop the saw when removing waste stock

from near the blade, when making adjustments, or

when changing settings.

Do not wear dangling neck ties, loose baggy

sleeves, etc., while operating power tools.

The guard is supplied with this saw for your safety

--use it to its best advantagel

ACCESSORIES for this saw will be listed in your

catalog or can be obtained from your nearest Sears

Retail Store. An interesting and instructive booklet

entitled "The Circular Saw" is also .available. It

explains many handy special operations which may

be performed on your bench saw.