Operatin9

motor is recommended for light: duty, and a ¾

the base of the motor. If this dimension varies

appr_iably from four inches, it may be necessary

to obtain a belt of a different length° If a 1750

r,p°mo motor is used, a sixdnch motor pul@ and

a longer belt must be purch_ed_ These may be

ordered through any Sears Retail or Mall Order

Store°

The arbor has been made ex_a long to accom-

modate a second pulley to provide for double belt

operation, although the single belt is sufficient to

_rry the loads normally encountered. The extra

motor pulley, arbor pulley, and b,elt may be or-

Caution: und_ no circumstances should a six-

inch motor' pulley be used with a 3450 r.p.mo motor.

_e saw blade speed resulting from such a pulley

ratio would be d_gerous° Do not use a three.lnch

motor p_ley _th a i750 r.p.mo motor° Such a

u_ey ratio will not give sadsfacto_ saw p_-

ormance_

Static Elec:tricity

Occasionally s slight shock may be experienced

upon touching a machine tool, Ti_is is usually due

to a stadc decuicai charge built up by the friction

between moving parts_ such as the V-belt and

pMley. It is not necessarily indicative of a gronnd_

motor or faulty electrical connections, To eliminate

this condition, as well as guard against the effe_

og a grounded motor _ faulty' connections, the

saw should be grounded to a water or steam pipe.

Adjustments

1o All pointers may be readily adjusted to the

zero position by loosening the lock screw, resetting

the pointer and retlghtening the scr_0

2. Both rip fence indicators (part 135, Fig. No.

3) should be adjusted to zero by placing the rip

fence first to the right and then to the left of the

saw blade. The teeth of the saw biade should touch

the rip fence i@tly when the adjustment to zero

is made. Operat_ng_Contro[s

the

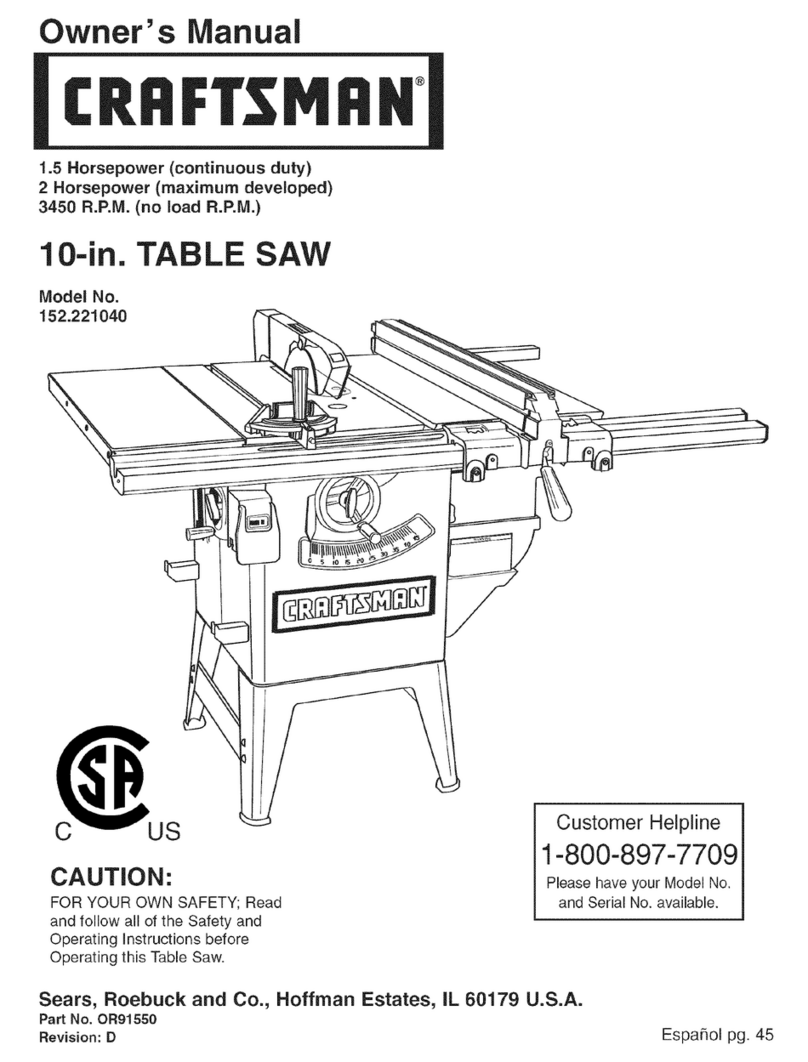

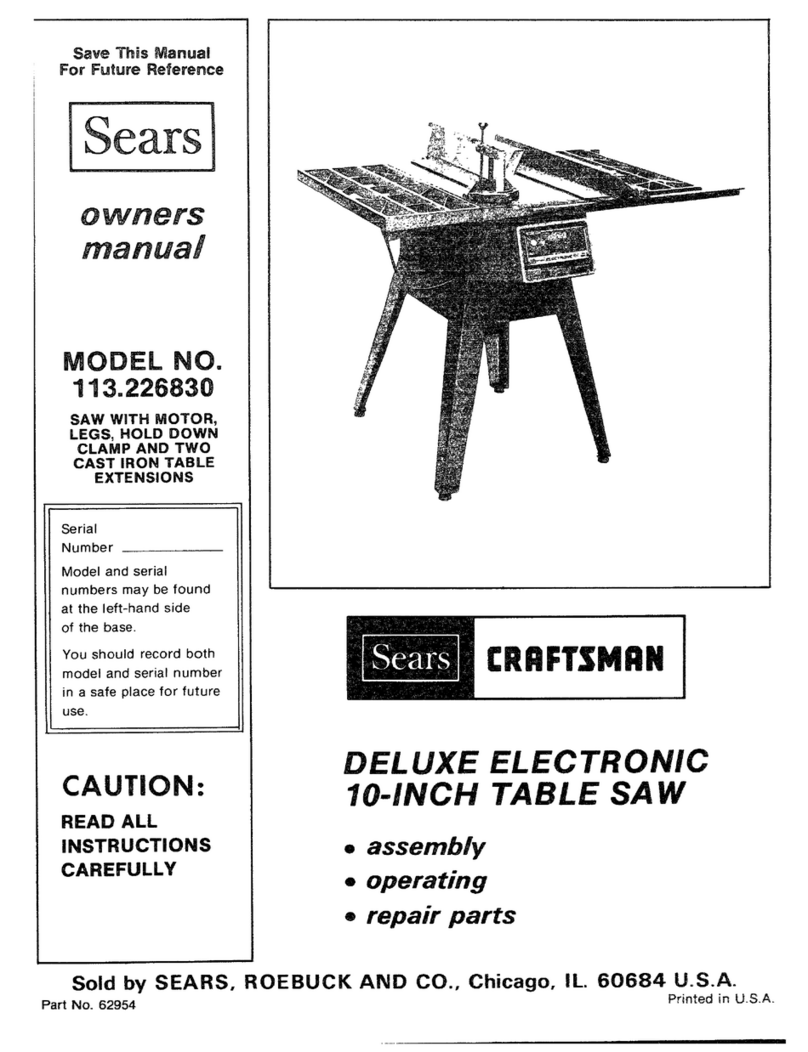

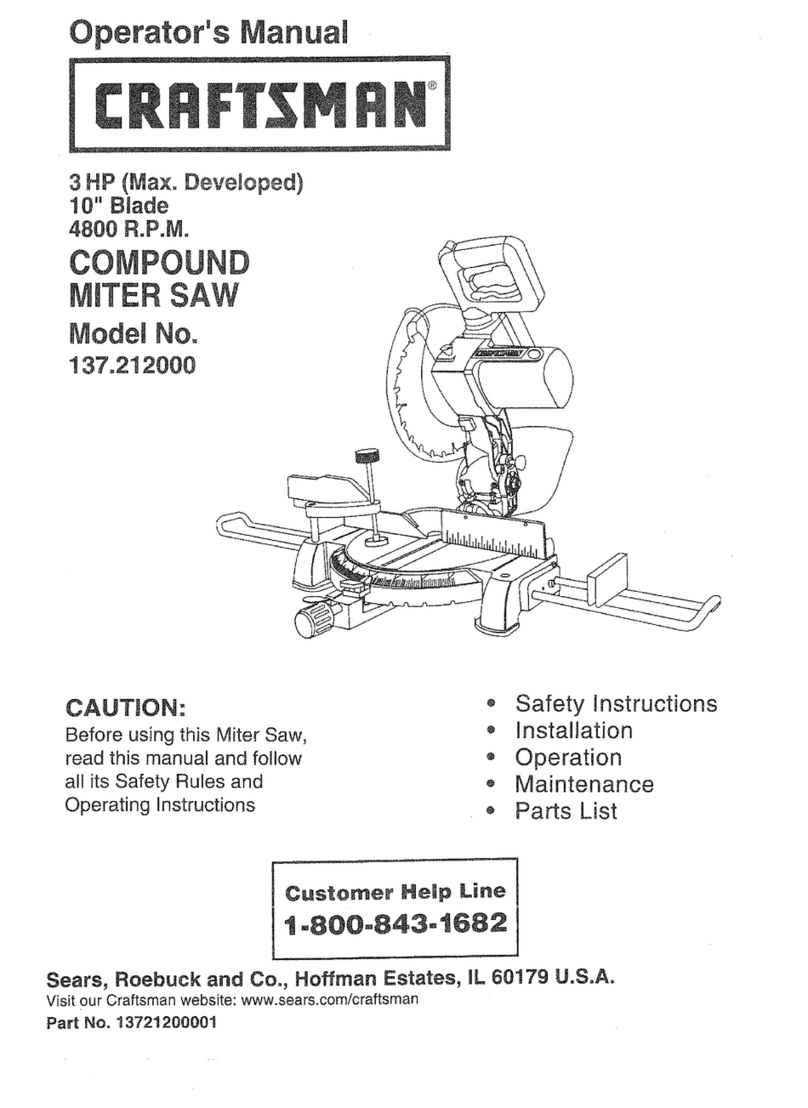

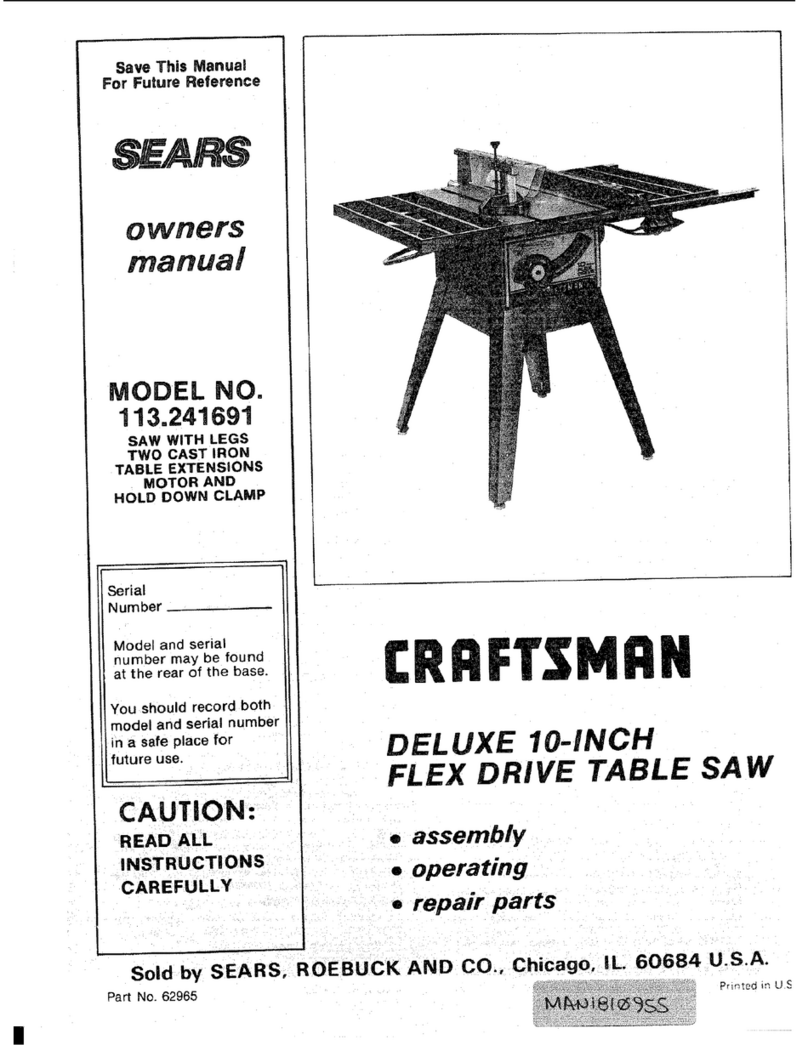

1. Elevation Hand Wheel "A', on the front of

saw, controls devadon of the blade or depth of cut

as indicated on the Depth Dial "B'. The Depth

Dial should read zero_ with the saw' blade just flush

with the surface of the table. Correction of this

setting may be made by sliding the Lift Dial Tape.

This adjustment will be necessary after the blade

_s b_n filed or sharpened, reducing the original

diameter, or when a saw blade of adiameter other

than 8 inches is used. If an extremely accurate

depth of cut is r_uired the height of the saw

blade above the table should be measured or_

preferably, a test cut should be made on, a piece of

scrap and the actual depth of cut measured. Under

no circumstances should a saw blade wi

eter greater than I0 inches be _ed with this saw.

_-_a_ 10-inch saw blade is used_ the pre_nt 3.1neh

motor pulley should be reNa_cxt with a 2½-inch

SiZe.

2. Tilt Hand Wheel "C'_ on the left side of

the saw, controls the angle of tilt. The saw Made

may be tilted from 0 degrees to 45 degrees. _e

angle of tilt is indicated on the Tilt Gage _'D'L

If the angle of the oa_ (tilt) must be extremely

a_urate, the angle of the saw blade sho_x_d be

&eck_ with a protractor or with a board which is

known to be cut at the exact angle required_

3. The tilt mechanlsm may be to&ed in any"

position by means of Clamp Screw Handle "E"

which opiates like a s_ket wrench. The tilt

mechanism should always be locked before starting

work through the saw and should always be un-

locked befor p_ng

4. Rip Pence "F' is operated by pushing in Rip

Fence Knob "G" which engages a pinion gear with

the teeth on Re& _J"o Turning knob _G" after

engagement of the g_r will cause _e Np fence to

move easily across the table° When the pinion gear

is dis_gaged by pulling out knob _G"_ _e rip

fen_ may be moved across the table by hand.

After the rip fence has been adjusted to the post.

don d_ired, it is. clamped in place by pushing down

on Cam Ciamp Lever "H'L if the ciamplng action

is too tight or too loose it may' be adjured by in-

c:reasL,ag or decr_siug the effective length of the

rip fence clamp rod (part 6100, Fig. No. 3). This

is accomplished by loosening the sleeve nut (part

t40, Fig. Non 3) and readjusting the hex nut (part

S-108, Fig. No. 3) on the end of the: clamp rod

at the back of the fence. The sleeve nut, which is

eroployed as a jam nut, should be redghtened after

_e adjustment h_ b_n obtained. A sticky or dirty

table or rip fence may prevent the rip fence from

maintaining proper alignment. Keeping the saw

_ble and rip fence clean and tap#hi the rip fence

lightly* to assist the fence to find its natural position

Mll be found m help maintain the alignment of _e

rip %nee with the saw blade.

_ross Cu#Hn$

Before performing cross cutting operations_ the

alignment of the mitre gage slots wid_ the saw blade

should be checked and corrected, if necessary,

described in paragraph ! under Assembling.

Mitre Gage "K'is graduated in degrees from

the 90 degree position to the 30 degree position,

both left and right. The Mitre Clamp Knob _L"

locks the mitre gage in any position d_ired_ The

Mitre Extension Rods "M" are locked to the mitre

gage by Thumb Screws _'N'+ These rods are pro+

vided for use when it is desired to cut severM pieces

of work to the same length.

To perform accurate work with the mitre gage

the Mitre Gage Pointer (part 6285_ Fig. No. 3) must

be properly adjusted. The mi_e gage should be

set on a _e 90 degree an_e by use of a square

by use of the 90 degree relationship between the

mitre gage Nots and the front table edge, _e mitre