Anypowerequipmentcancauseinjuryifoperatedimproperlyoriftheuserdoesnotunderstandhowtooperate

theequipment.Exercisecautionatall times,whenusingpowerequipment.

• Readthisowner'smanualcarefullyandknowhow

tooperateyoursnowthrowerandhowtostopthe

unitanddisengagethecontrolsquickly.

• Neverallowchildrentooperatetheequipment.

• Neverallowadultstooperatetheequipment

withoutproperinstruction.

• Keeptheareaofoperationclearof allpersons,

especiallysmallchildren,andpets.

• Thoroughlyinspecttheareawheretheequipment

istobeusedandremovealldoormats,sleds,

boards,wiresandotherforeignobjects.

• Disengageallclutchesandshiftintoneutralbefore

startingengine.

• Donotoperateequipmentwithoutwearingad-

equatewinteroutergarments.

• Wearsubstantialfootwearwhichwillprotectfeet

andimprovefootingonslipperysurfaces.

• Checkfuelbeforestartingtheengine.Donot

removethefuelcaporfillthefueltankwhilethe

engineis runningorhot.Donotfill thefueltank

indoors.Gasolineisanextremelyflammablefuel.

• Makesurethesnowthrowerheightisadjustedto

clearthetypesurfaceit willbeusedon.

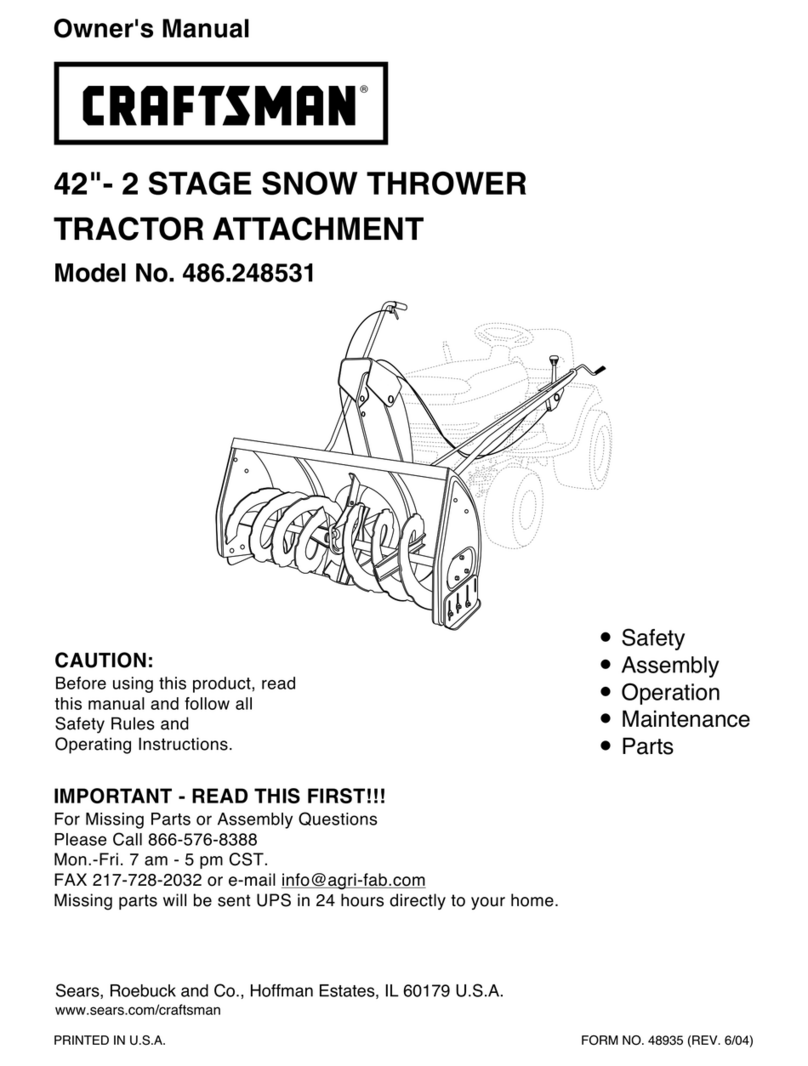

• Donotusethesnowthrowerwithouttherear

weightattachedtothetractor.

• Nevermakeanyadjustmentswhiletheengineis

running.

• Alwayswearsafetyglassesoreyeshieldduring

operationorwhileperformingandadjustmentor

repair.

• Donotplacehandor feetnearrotatingparts.Keep

clearofthedischargeopeningatalltimes.

• Useextremecautionwhenoperatingonorcrossing

gravelsurfaces.

• Donotcarrypassengers.

• Afterstrikingaforeignobject,stoptheengine,

removethewirefromthesparkplugandthen

thoroughlyinspectthesnowthrowerfordamage.

Repairanydamagebeforerestartingandoperating

thesnowthrower.

• Ifthesnowthrowerstartstovibrateabnormally,

stoptheengineimmediatelyandcheckforthe

cause.Vibrationisgenerallyawarningoftrouble.

• Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingthesnowthroweror

makinganyadjustmentsorinspections.

• Takeallpossibleprecautionswhenleavingtheunit

unattended.Disengagetheattachmentclutchlever

orswitch,lowerthesnowthrower,shiftintoneutral,

settheparkingbrake,stoptheengineandremove

thekey.

• Whencleaning,repairingorinspecting,make

certainallmovingpartshavestopped.Disconnect

thesparkplugwireandkeepitawayfromtheplug

topreventaccidentalstarting.

• Donotrunengineindoorsexceptwhentransport-

ingthesnowthrowerinoroutofthebuilding.Open

theoutsidedoors.Exhaustfumesaredangerous.

• Donotclearsnowacrossthefaceofslopes.

Exerciseextremecautionwhenchangingdirection

onslopes.Donotattempttoclearsteepslopes.

Refertotheslopeguideonpage27ofthismanual.

• Neveroperatethesnowthrowerwithoutguards,

platesorothersafetyprotectiondevicesinplace.

• Neveroperatethesnowthrowernearglassenclo-

sures,automobiles,windowwells,dropoffsetc.

withoutproperadjustmentofthesnowthrower

dischargeangle.

• Neverdirectdischargeatbystandersorallow

anyoneinfrontofthesnowthrower.

• Neverrunthesnowthrowerintomaterialathigh

speeds.

• Donotoverloadthemachinecapacitybyattempt-

ingtoclearsnowattoofastarate.

• Neveroperatethemachineathightransportspeed

onslipperysurfaces.Lookbehindandusecare

whenbacking.

• Watchfortrafficandstayalertwhencrossingor

operatingnearroadways.

• Disengagepowertothesnowthrowerwhentrans-

portingorwhennotinuse.

• Useonlyattachmentsandaccessoriesapprovedby

themanufacturerofthesnowthrower(suchas

wheelweights,counterweights,cabsetc.)

• Neveroperatethesnowthrowerwithoutgood

visibilityor light.

,_ Look for this symbol to point out important safety precautions. It mean--Attention!!

Become alert!! Your safety is involved.

3