Crane Merchandising Systems ICON User manual

Part Number: PR15937000 Issue: A - 09/2017

Technical Manual

II COTI / ICON

EC Declaraon of Conformity

We Crane Merchandising Systems (UK),

Of Pipsmore Park, Bumpers Farm Industrial Estate, Chippenham, Wiltshire, UK,

SN14 6NQ

Declare that:

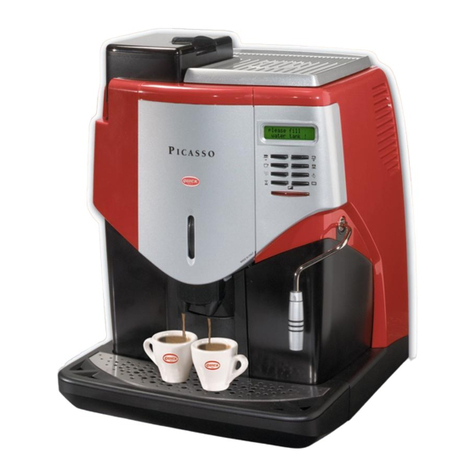

Type of Equipment: Beverage Vending Machine

Model Name: COTI / ICON

Has been designed and manufactured to comply with all essenal requirements of the

following Regulaons/Direcves:

2006/95/EEC The Low Voltage Direcve and its amending direcves

2004/108/EEC The Electromagnec Compability Direcve and its

amending direcves

on materials and arcles intended to come into contact

with food relang to plasc materials and arcles intended

to come into contact with food stus

The Essenal Requirements of the European regulaons for CE marking applicaon are:

1. Mechanical resistance and stability

2. Safety in case of re

3. Hygiene, health and the environment

4. Safety in use

5. Protecon against noise

6. Energy economy and heat retenon

Tests have been performed by accredited cercaon bodies in accordance to the

following specicaons:

Low Voltage Direcve: EN 60335-1:2002+A1:2004+A11:2004+A12:2006+A2:2006+

A13:2008

EN 60335-2-75:2004+A1:2005+A11:2006+A2:2008+

A12:2010

EMC Direcve: EN 55014-1:2006+EN55014+A1:2009+A2:2011

EN 55014-2:1997+A120

EN 61000-3-2:2006+A1/A2:200 EN 61000-3-3:2008

EN 61000-4-2:2009 EN 61000-4-3:2012 EN 61000-4-4:2004

EN 61000-4-5:2006 EN 61000-4-11:2010

With regard to hygiene for foodstus in locaon, the operator must comply with

852/2004/EEC which lays out the general and specic hygiene rules to ensure a high level

of consumer protecon with regard to food safety.

Gillian White

Vice President, General Manager Global Coee

Date: 01/07/2017:

REG. (EC) 1935/2004

REG. (EC) 10/2011

Technical Manual III

Introducon / Important Informaon

The following Symbol is used throughout this Manual:

Safety First! Take care, risk of personal injury.

Crane Merchandising Systems accepts no responsibility for damage caused to the

equipment through misinterpretaon or misuse of the informaon contained in this

manual.

© Copyright 2017 Crane Merchandising Systems

Introducon

This manual provides you with guidance on the installaon, daily operaon and basic

maintenance of your COTI/ICON freestanding vending machine. Crane Merchandising

Systems always recommend that a trained technician service its equipment.

Crane Merchandising Systems is commied to connuous product improvement. This

means that the informaon within this document although correct at me of publicaon,

is for guidance only and may be subject to change without prior noce.

Important Safeguards

Always follow these basic safety precauons when

operang or maintaining your machine:

1. Ensure that you and anyone who operates or

maintains your machine have this manual available

for quick and easy reference, read all instrucons

carefully before commencing work.

2. Beware of Electricity Certain maintenance

operaons require your machine to remain

connected and switched on. Only trained personnel

should carry out these rounes, and independently

of all other operaons. Observaon of safe working

pracces in accordance with current regulaons is

necessary at all mes.

Important! Unless otherwise specied always

disconnect your machine from the electricity supply

before commencing work.

IV COTI / ICON

Introducon / Important Informaon

3. Servicing the Heater Tank/Espresso pressurised water

system

Important! Water in this machine can exceed 99°C.

Water at this temperature can cause severe injury.

Espresso machines may be ed with a pressurised

water system, under no circumstance should this be

dismantled other than by a fully trained engineer.

4. Do not operate your machine if any part is damaged

unl a service technician has carried out necessary

repairs and ensured that it is safe.

5. Beware of moving components when servicing the

machine.

6. Allow your machine to cool before handling or

moving.

7. Never immerse your machine in water or any other

liquid and never clean it with a water jet.

8. If your machine should freeze up, call a service

technician before switching it back on.

9. In machines ed with carbonator units the CO2

bole is lled with gas at up to 800psi and MUST be

secured in an upright posion. In the event of a leak,

venlate the area in the vicinity

10.Ensure that you are familiar and adhere to the most

recent Health and Safety at Work and Electricity at

Work Regulaons.

Technical Manual V

Introducon / Important Informaon

Important! This appliance is not intended for use by

persons (including children under 8 years old and the

inrm) with reduced physical, sensory or mental

capabilies or lack of experience and knowledge.

Unless they have been given supervision or instrucon

concerning use of the appliance by a person

responsible for their safety and they fully understand

the hazards involved.

Children should be supervised to ensure that they do

not play with the appliance.

Children must not carry out any cleaning of

maintenance of the machine.

Your COTI/ICON machine is for indoor use only and

because it is a beverage machine should be sited in a

clean and hygienic area.

VI COTI / ICON

Table of Contents

Table of Contents

Secon 1 - Machine Specicaons ...................................................................... 1

1.1 Specicaons - COTI .......................................................................... 1

1.2 Specicaons - ICON.......................................................................... 2

1.3 Water Filter ....................................................................................... 2

1.4 External Features - COTI .................................................................... 3

1.5 External Features - ICON.................................................................... 4

1.6 Internal Features - COTI..................................................................... 5

1.7 Internal Features - ICON .................................................................... 6

Secon 2 - Installaon .......................................................................................... 7

2.1 Sing Your Machine .......................................................................... 7

2.2 Connecng the Water Supply ........................................................... 8

2.3 Connecng the Electrical Supply ...................................................... 9

2.4 Commissioning Procedure ................................................................ 10

2.5 Seng Up the Carbonator Unit (Where Fied) ............................... 14

2.6 Cup Drop Unit Set Up ........................................................................ 16

2.7 Sck Srrer Adjustment (Where Fied) ........................................... 17

2.8 Warranty Card ................................................................................... 18

Secon 3 - Navigaon and Programming Mode ................................................. 19

3.1 Navigaon - COTI .............................................................................. 19

3.2 Navigaon - ICON .............................................................................. 20

3.3 Program Entry ................................................................................... 21

3.4 Navigang through the Menu Display ............................................. 21

3.5 Accessing the Programming Mode ................................................... 22

3.6 Entering or Updang Parameters ..................................................... 22

Secon 4 - Customising the User Interface ......................................................... 24

4.1 Images ................................................................................................ 24

4.2 Image Locaons - COTI ..................................................................... 25

4.3 Image Locaons - ICON ..................................................................... 27

4.4 USB Sck Contents ............................................................................ 29

4.5 Copy USB Sck Contents ................................................................... 29

4.6 Select the Image for Display.............................................................. 31

4.7 Remove Content from Machine........................................................ 33

4.8 Edit the Product Name and Descripon ........................................... 34

Technical Manual VII

Table of Contents

4.9 Congure Generic Content ............................................................... 35

4.10 Standby Screen ............................................................................... 36

4.11 Allergens .......................................................................................... 41

4.12 Nutrion Info ................................................................................... 42

4.13 Operator Manuals ........................................................................... 45

4.14 ADA Mode (COTI machine only) ..................................................... 45

4.15 Addional User Interface Opons .................................................. 45

Secon 5 - Engineer’s Program ............................................................................ 47

5.1 Menu Structure Overview ................................................................ 47

5.2 Main Menu ........................................................................................ 52

5.3 Data Recall ......................................................................................... 52

5.4 Diagnoscs ........................................................................................ 55

5.5 Test .................................................................................................... 56

5.6 Price ................................................................................................... 61

5.7 Product Conguraon ....................................................................... 63

5.8 Menu Setup ....................................................................................... 73

5.9 Free Vend .......................................................................................... 74

5.10 Money ............................................................................................. 74

5.11 System Sengs ............................................................................... 78

5.12 Security Codes ................................................................................. 84

5.13 Timed Events ................................................................................... 85

5.14 Leave Service Applicaon ............................................................... 88

5.15 Machine Reboot .............................................................................. 88

Secon 6—Service Keypad Funcons .................................................................. 89

Secon 7 - Technical Informaon ........................................................................ 92

7.1 Water Services .................................................................................. 92

7.2 Hot Water System ............................................................................. 92

7.3 Ingredient Dispense .......................................................................... 92

7.4 Mixing System ................................................................................... 93

7.5 Moving Dispense Head ..................................................................... 93

7.6 Cup Dispense Unit ............................................................................. 93

7.7 Waste Level Probes ........................................................................... 94

7.8 CoEx Brewer (Espresso Machines) ................................................... 94

7.9 Oltre Brewer ...................................................................................... 94

7.10 Power Supply Units ......................................................................... 95

VIII COTI / ICON

Table of Contents

7.11 Mains Filter ...................................................................................... 96

7.12 Coin Mechanism Transformer (Oponal Extra) ............................. 96

7.13 Coin and Card/Key Systems ............................................................ 96

7.14 Change Giver ................................................................................... 96

7.15 Card/Key System ............................................................................. 96

Secon 8– Espresso System ................................................................................. 98

8.1 Example Vend .................................................................................... 98

8.2 System Overview ............................................................................... 98

Secon 9- Dispense Pipe Lengths ........................................................................ 102

9.1 To Replace Pipes ............................................................................... 102

Secon 10 - Diagnoscs and Maintenance Procedures ...................................... 104

10.1 Diagnoscs ...................................................................................... 104

10.2 Heater Tank De-Scale Procedure .................................................... 110

10.3 System Drain Down - Espresso Machines Only ............................. 111

10.4 CoEx Brewer/Bean Grinder Maintenance - Espresso Machines ... 113

Secon 11- Electrical/Electronics Informaon .................................................... 118

11.1 Touch Screen—COTI ........................................................................ 118

11.2 Touch Screen - ICON ........................................................................ 119

11.3 Control Board—Atlas H Board......................................................... 120

11.4 Control Board Connecons—Atlas H Board ................................... 121

11.5 Input/Output Board......................................................................... 123

11.6 Input Circuit 1................................................................................... 124

11.7 Input Circuit 2................................................................................... 125

11.8 Output Circuit 1................................................................................ 126

11.9 Output Circuit 2................................................................................ 127

11.10 Power Circuit—Instant & Freshbrew Machines ........................... 128

11.11 Power Circuit—Espresso Machines............................................... 129

11.12 Heater Circuit ................................................................................. 130

Technical Manual IX

Table of Contents

1COTI / ICON

Secon 1 - Machine Specicaons

Secon 1 - Machine Specicaons

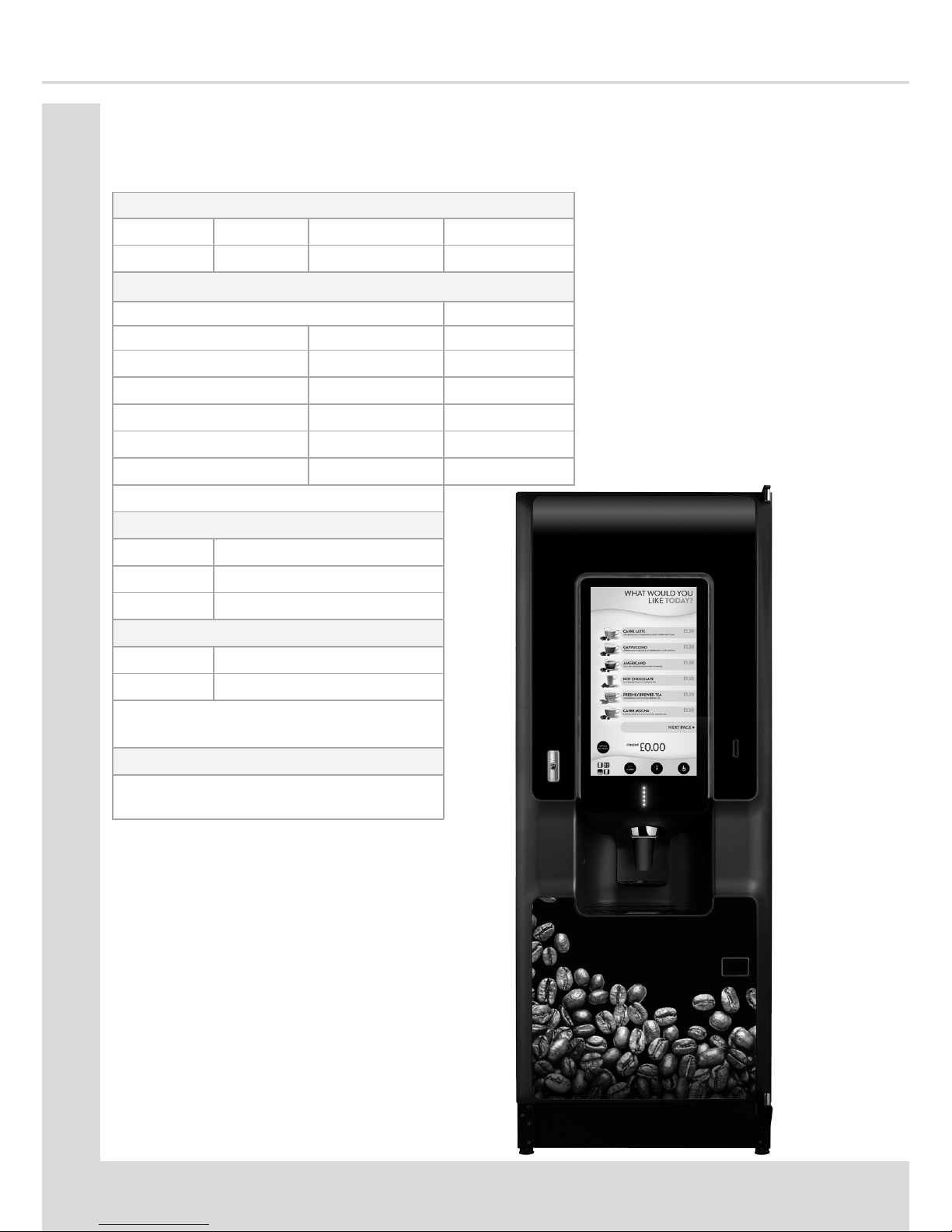

1.1 Specicaons - COTI

General

Height 1830 mm Depth 785 mm

Width 700 mm Weight 184 kg

Cup Capacity

Cup Type Cup Capacity #

150ml plasc squat 7oz plasc squat 800

150ml plasc tall 7oz plasc tall 750

150ml paper tall 7oz paper tall 665

180ml plasc 9oz plasc 650

180ml paper 9oz paper 575

250ml paper 12oz paper 400

*Approximate and are for guidance only.

Electrical Services

Voltage 220 - 240 Volts

AC Current 13 Amp Fused

Frequency 50/60 Hz

Water Services

Pressure 200 kPa (2 Bar) - 600 kPa (6 Bar)

Stopcock 15 mm BSP from rising main

All weights and dimensions are approximate

and are for guidance only.

Sound Levels

A-weighted sound pressure level is below

70dB.

Technical Manual 2

Secon 1 - Machine Specicaons

1.2 Specicaons - ICON

1.3 Water Filter

If your machine is ed with a CoEx® Espresso and/or

Oltre Freshbrew brewer, then it must be connected to

the water supply via a scale inhibing water lter.

Crane Merchandising Systems recommend and supply

the Brita and Cuno ranges of water lters.

General

Height 1830 mm Depth 790 mm

Width 700 mm Weight 193 kg

Cup Capacity

Cup Type Cup Capacity #

150ml plasc squat 7oz plasc squat 800

150ml plasc tall 7oz plasc tall 750

150ml paper tall 7oz paper tall 665

180ml plasc 9oz plasc 650

180ml paper 9oz paper 575

250ml paper 12oz paper 400

*Approximate and are for guidance only.

Electrical Services

Voltage 220 - 240 Volts

AC Current 13 Amp Fused

Frequency 50/60 Hz

Water Services

Pressure 200 kPa (2 Bar) - 600 kPa (6 Bar)

Stopcock 15 mm BSP from rising main

All weights and dimensions are approximate

and are for guidance only.

Sound Levels

A-weighted sound pressure level is below

70dB.

3COTI / ICON

Secon 1 - Machine Specicaons

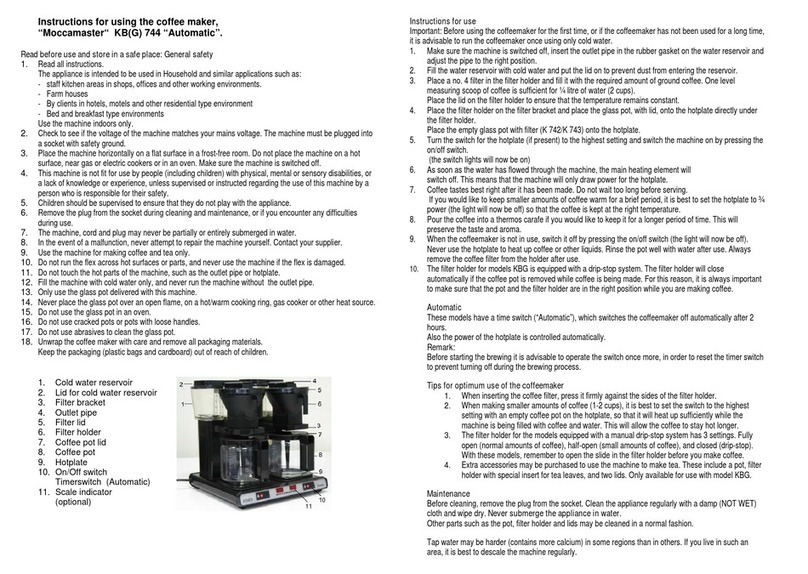

1.4 External Features - COTI

Key:

1Door 6Drip Tray

2Touch Screen 7Adjustable Foot

3Door Lock 8Coin Entry

4Cup Staon 9Cup Stand

5SureVend™ Sensor 10 Coin Return Cup

Technical Manual 4

Secon 1 - Machine Specicaons

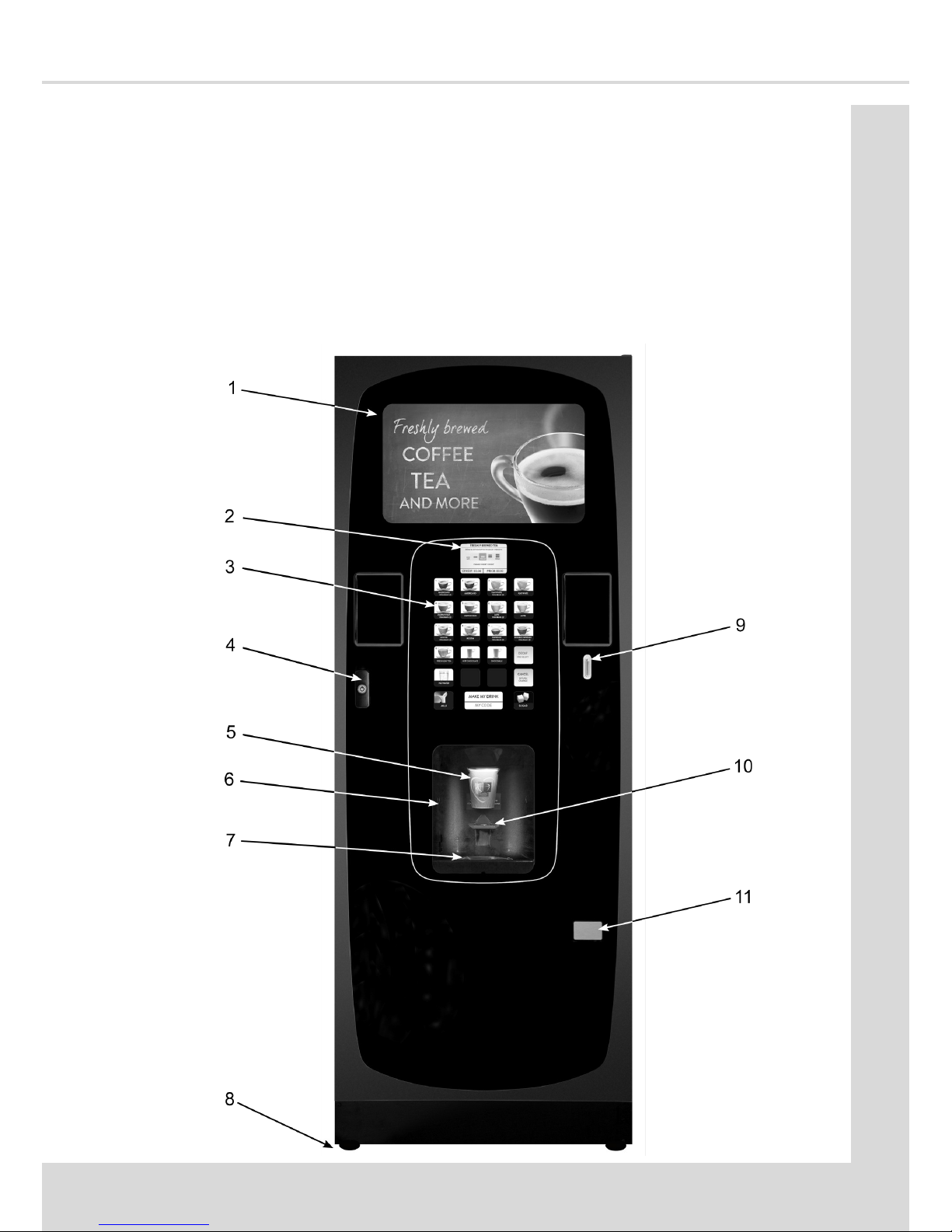

1.5 External Features - ICON

Key:

1Door 6SureVend™ Sensor

2Display Screen 7Drip Tray

3Drink Selecon Menu 8Adjustable Foot

4Door Lock 9Coin Entry

5Cup Staon 10 Cup Stand

11 Coin Return Cup

5COTI / ICON

Secon 1 - Machine Specicaons

1.6 Internal Features - COTI

Key:

1Main Switch 10 Kick Plate

2Service Keypad 11 Waste Bucket (liquids)

3Cup Turret 12 Waste Bucket (solids)

4Cup Dispense Unit 13 Dispense Head

5Door Locking Mechanism 14 Brewer

6Cup Catcher 15 Mixer

7SurevendTM Sensor 16 CoEx Brewer

8Drip Tray 17 Ingredient Canisters

9Drip Catcher

Technical Manual 6

Secon 1 - Machine Specicaons

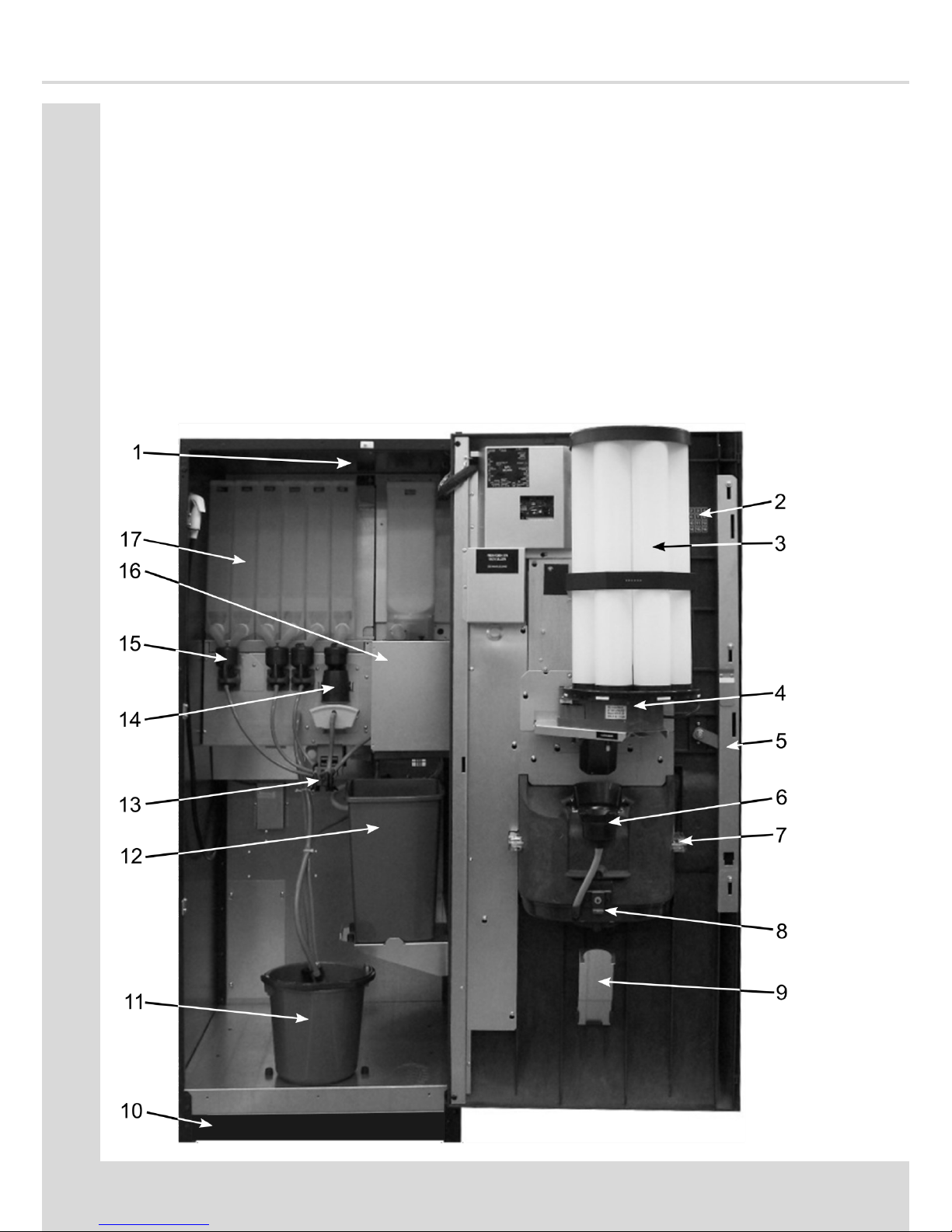

1.7 Internal Features - ICON

Key:

1Main Switch 10 Kick Plate

2Cup Turret 11 Waste Bucket (liquids)

3Service Keypad 12 Waste Bucket (solids)

4Cup Dispense Unit 13 Dispense Head

5Door Locking Mechanism 14 Brewer

6Cup Catcher 15 Mixer

7SurevendTM Sensor 16 CoEx Brewer

8Drip Tray 17 Ingredient Canisters

9Drip Catcher

7COTI / ICON

Secon 2 - Installaon

Secon 2 - Installaon

Important! It is essenal that the personnel

responsible for installing and servicing your machine,

understand the following:

1. The installaon and commissioning of your machine

should only be carried out by a trained and

authorised service technician.

2. All water and electrical services must be correctly and

safely connected in compliance with naonal and

local regulaons.

3. All covers must be replaced correctly and securely

and your machine le in a safe condion.

2.1 Sing your Machine

1. Your machine is only suitable for indoor use. We

recommend that it be situated in an area with an

ambient temperature not below 10º C and not

exceeding 30º C. Your machine should be located

near the appropriate water and electrical services,

refer to Secon 1.1 Specicaons.

2. It must also not be sited in an area where a water jet

could be used.

3. Prior to placing your machine in its nal locaon,

ensure that there is sucient access space available

via passageways, stairs, lis, etc.

4. Ensure that access to the machine is restricted to

personnel who have knowledge and praccal

experience of the appliance, in parcular as far as

safety and hygiene are concerned.

Technical Manual 8

Secon 2 - Installaon

5. To ensure adequate venlaon, 100 - 150 mm (4 - 6

inches) clearance must be allowed between the back

of the cabinet and the wall.

6. Open the door using the key provided. Remove

transit packing and installaon kit. Check for visual

signs of damage which may have occurred during

transit. If your machine is damaged or any parts are

missing, you must contact the supplier immediately.

7. Level your machine in both the front-to-back and

side-to-side planes by adjusng the feet. Ensure that

the door opens and closes easily and the lock

operates correctly.

2.2 Connecng the Water Supply

1. Your machine should be situated within 1 metre of a

drinking water supply from a rising main, terminang

with a W.R.C. approved 15mm compression stop-tap.

N.B. The water supply should comply with both local

and naonal regulaons.

Dynamic water pressure at the stop-tap must be

within the limits 200—600 kPa (2—6Bar).

2. Freshbrew & Espresso Machines: COTI/ICON

machines ed with a Oltre freshbrew brewer or

CoEx® brewer must be connected to the water supply

via a water lter. This lter must be of food grade

quality and able to remove temporary hardness

(scale), heavy metals (lead, copper, iron, cadmium),

chlorine and any organic pollutant’s/discolouraon.

9COTI / ICON

Secon 2 - Installaon

Warning! If your Freshbrew or Espresso machine is

connected to a water supply and used without a

water lter as specied above, your warranty will be

void.

3. Connect the exi-hose supplied with your machine to

the stopcock. Flush the water supply before

connecng the machine.

N.B. When connecng your machine to a water

supply always use the new exi-hose as supplied with

the machine. Never re-use an exisng hose.

4. Connect the hose to the inlet located on the rear of

your machine. Ensure that the seal is correctly ed.

Ensure that all water supply ngs are ght.

5. Turn on the water supply at the stop tap and check

for leaks.

2.3 Connecng the Electrical Supply

Safety First!

The electrical safety of this appliance can only be

guaranteed if it is correctly earthed. The manufacturer

declines all liability for damage resulng from a system

which has not been earthed. On no account should it be

earthed only to the water supply pipe.

The appliance must be connected to a 200—230V

50/60Hz 13 amp fused switched socket outlet. Installed to

the latest edion of the IEE regulaons, using a 3 pin BS

approved 13 amp fused plug for UK and in compliance

with Naonal and European regulaons on electrical

safety in other countries.

Technical Manual 10

Secon 2 - Installaon

Important: If any internal fuses become damaged or

fail in any way they must be replaced by the correct

fuse available from the manufacturer quong the

informaon wrien on the label adjacent to the

relevant fuse-holder.

Important: If the mains lead becomes damaged in

any way it must be replaced by a lead available from

the manufacturer.

2.4 Commissioning Procedure

A trained installaon engineer must carry out the

following procedure before the machine can be used for

the rst me. Ensure that the electrical and water

services to the machine are connected correctly. Check

for leaks in the water supply.

1. Open the front door of your machine.

2. Ensure that the waste bucket is ed correctly. Clip

the level probe and overow pipes correctly onto the

rim of the bucket.

3. Cup Turret. Unbox the cup tubes and lid and t in

place, then ll with the correct size cups for the cup

catcher ed to the machine. Allow the cups to drop

into the tubes directly from the packaging. DO NOT

touch the cups with your hands .

Important: Do not ll the tube directly above the cup

dispense posion. Allow the cup turret motor to

rotate a full tube to the cup dispense posion.

Rotang the cup turret by hand will damage the

mechanism.

11 COTI / ICON

Secon 2 - Installaon

Note: If you are using paper cups, rst inspect each

sleeve for damage to the cup rims. Damaged cups

must not be used.

4. The cup turret mechanism will index the rst

available cups to the dispense posion and drop the

cup stack into the cup drop mechanism. Fill the

remaining empty cup stack with cups and replace the

lid.

5. All Models: The water inlet valve will open and the

heater tank will start to ll. As the water heats,

ensure that no water overows from the heater tank

overow pipe into the waste bucket. Check the

system for leaks.

6. Instant & Freshbrew Machines: As heater tank lls

and heats, ensure that no water overows from

overow pipe into the waste tray.

7. Espresso Models: The machine will pump

approximately 400ml of water through the system

which will be heated to operang temperature.

Note: The machine has a safety cut-out which will

only allow the heater tank to ll for a maximum of

two minutes. If aer soware power-up the heater

tank has not lled within this me, the mains power

supply should be switched o and then on again to

reset the heater tank me-out.

Important: Should the machine fail to ll correctly or

leak, turn o the stopcock and the power to the

machine before invesgang the fault.

This manual suits for next models

1

Table of contents

Popular Coffee Maker manuals by other brands

Mr. Coffee

Mr. Coffee BVMC-KG6 user manual

Mr. Coffee

Mr. Coffee 403 Series Installation and operating instructions

Magic Chef

Magic Chef MCSCM12TB instruction manual

Magic Chef

Magic Chef MCCM1NB12 manual

Quickmill

Quickmill Michelangelo 07000 operating instructions

MACCHIAVALLEY

MACCHIAVALLEY JAVA Installation & maintenance