3

IQWrench2 Opta

CONTENTS PAGE

SECTION 1 Introduction ..................................................................................................... 4

How to use this manual ........................................................................................... 4

Packing List ............................................................................................................. 4

Care and Storage .................................................................................................... 4

Overview .................................................................................................................. 5

Batteries .................................................................................................................. 7

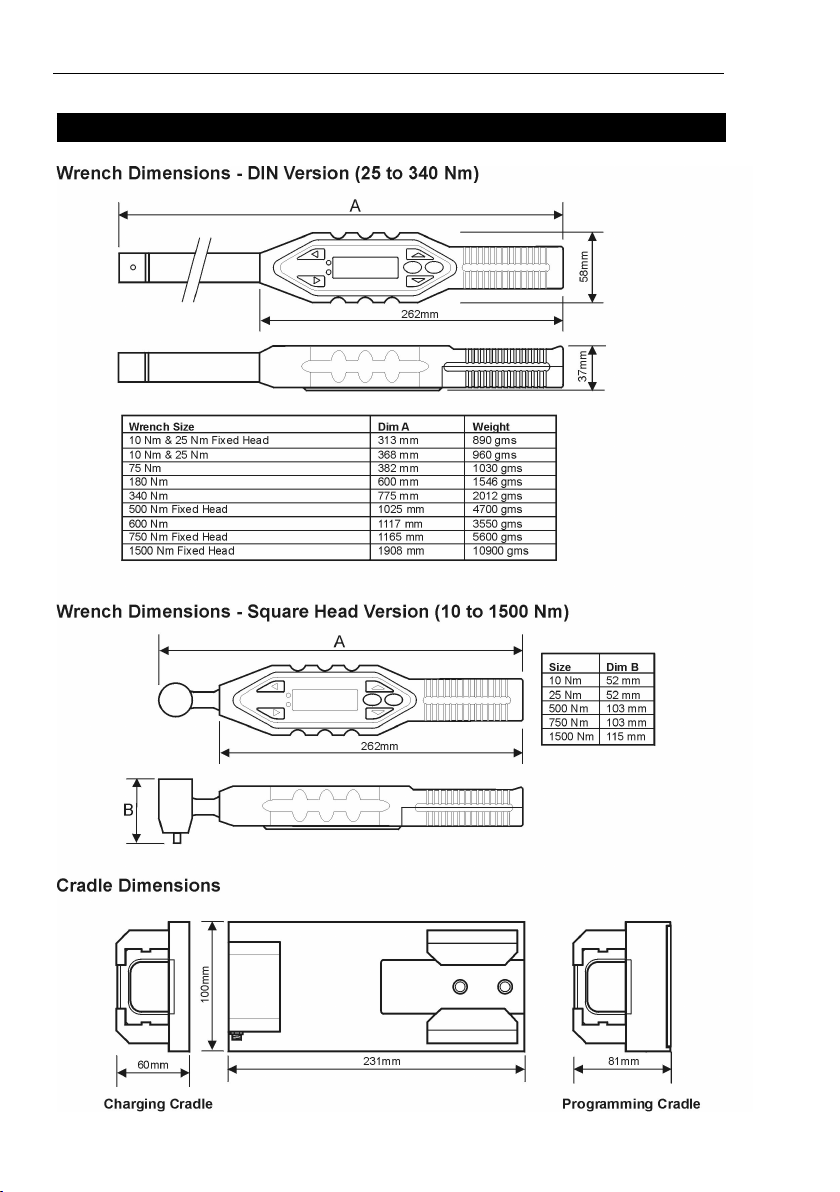

Dimensions .............................................................................................................. 8

Specifications ........................................................................................................... 9

Accessories ............................................................................................................. 9

SECTION 2 Controls ......................................................................................................... 10

Removing & Attaching Drive Adaptors ................................................................... 10

Control Panel ......................................................................................................... 11

Charging/Comms Cradle ....................................................................................... 12

SECTION 3 Operating Instructions .................................................................................. 13

Charging the Wrench ............................................................................................. 13

Basic Operation ..................................................................................................... 14

Powering On .......................................................................................................... 14

Auto Power Off...................................................................................................... 14

Hardware Reset ..................................................................................................... 14

Attaching a PC ....................................................................................................... 14

Basic Operating principles ..................................................................................... 15

Basic Menu Structure ............................................................................................. 17

Getting Started - Using for the first time ................................................................. 18

Changing the Time and Date and Date Format ..................................................... 18

Changing the Language ........................................................................................ 18

Taking a Reading - Quick Read Mode ................................................................... 19

Taking a Reading - Quick Store Mode ................................................................... 22

Quick Read setup Menu ....................................................................................... 28

Quick Store Setup Menu ........................................................................................ 29

Main Setup Menu ................................................................................................... 32

Power Settings Menu ............................................................................................. 33

Battery Charge Indicator ........................................................................................ 34

Advanced Operation ......................................................................................................... 35

Features (Advanced Mode) ................................................................................... 35

Using with Opta Comms ........................................................................................ 36

Working with Jobs ................................................................................................. 36

Working with Rounds ............................................................................................. 40

Remote Setup ........................................................................................................ 41

Comms Setup ........................................................................................................ 41

Flash Program ....................................................................................................... 41

Software Reset ...................................................................................................... 41

Trace Duration ....................................................................................................... 44

Verification and Adjustment ................................................................................... 44

Zero Gyro ............................................................................................................... 44

Section 4 Additional information and features ............................................................... 45

Gyro ....................................................................................................................... 45

Cycle End Time ..................................................................................................... 45

LEDs ...................................................................................................................... 46

Regional Settings .................................................................................................. 46

Buzzer ................................................................................................................... 47

Remote Setup ........................................................................................................ 47

Remote Protocol .................................................................................................... 48

Status Bar .............................................................................................................. 48

Power .................................................................................................................... 49

Wireless ................................................................................................................ 51

Change Rv ID ........................................................................................................ 51

Retry Function ....................................................................................................... 52

Users ..................................................................................................................... 53

ID Adapter .............................................................................................................. 54

Calibration Date ..................................................................................................... 54

Measurement Modes ............................................................................................. 55

Job Measurement Icons ........................................................................................ 56

Yield Function ........................................................................................................ 57

Specialist Job Function .......................................................................................... 60

Downloading Jobs ................................................................................................. 61

Glossary of Terms .................................................................................................. 62