9

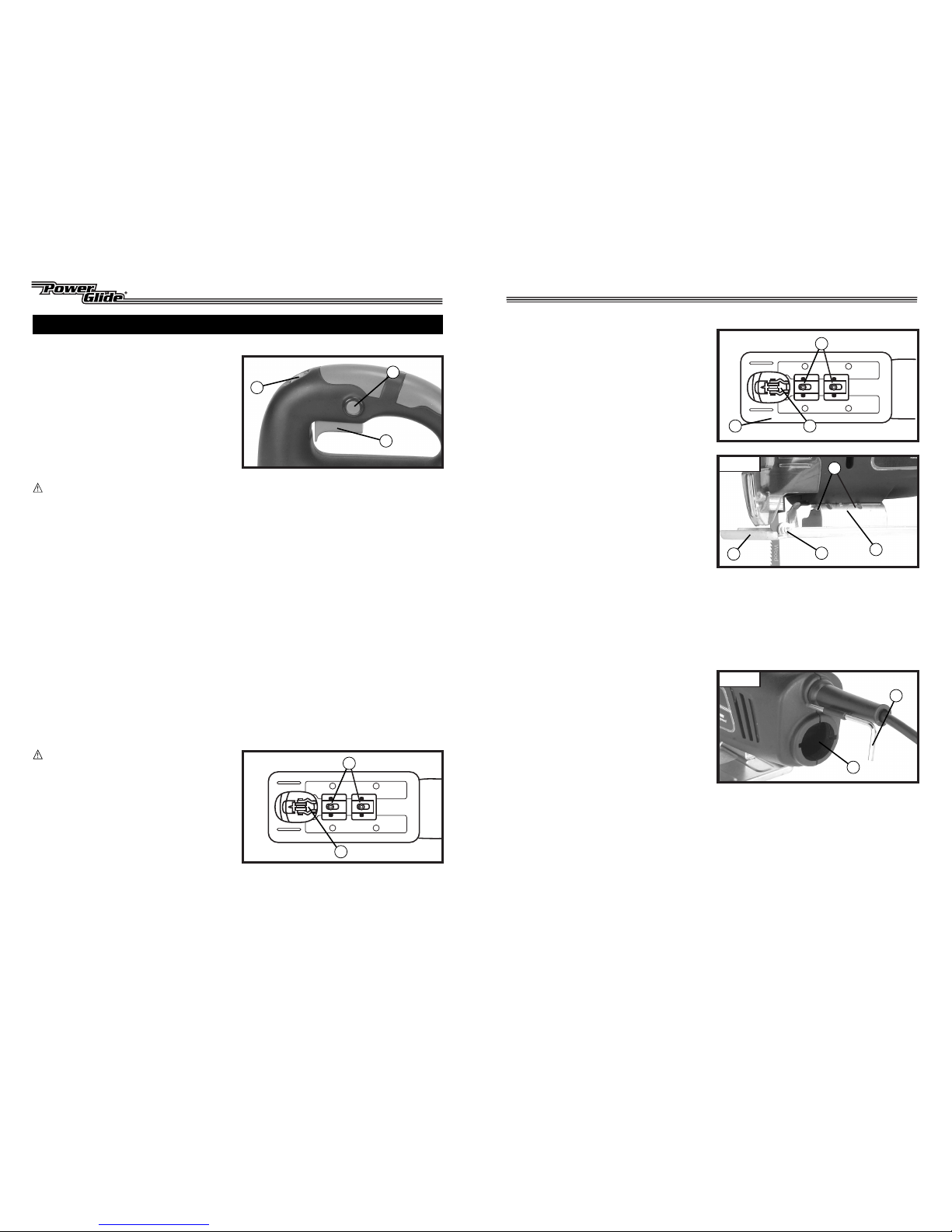

CONNECTION TO THE POWER SUPPLY

Electrical Safety

1. Double Insulated tools are equipped with a polarized plug (one blade is wider than the other.)

This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a qualified electrician to install a polarized

outlet. Do not change the plug in any way. Double insulation eliminates the need for the three

wire grounded power cord and grounded power supply system.

2. Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electrical shock if your body is grounded.

3. Don't expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electrical shock.

4. Do not abuse the cord. Never use the cord to carry the tools or pull the plug from the outlet.

Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electrical shock.

Extension Cords

1. Make sure your extension cord is in good condition. When using an extension cord, be sure to

use one heavy enough to carry the current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and overheating. Table 1 shows the

correct size to use depending on cord length and nameplate Ampere rating. If in doubt, use

the next heavier gauge. The smaller the gauge number, the heavier the cord.

2. When operating a power tool outside, use an outdoor extension cord marked "W-A" or "W".

These cords are rated for outdoor use and reduce the risk of electrical shock.

3. Use only UL listed extension cords. Inspect extension cord before use and never use damaged

or altered extension cords. Follow extension cord manufacturer safety instruction.

4. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electrical shock.

Amp Volts

25 ft. 50ft 100ft 150 ft

1-5 120V 18 16 16 14

6-10 120V 16 16 14 12

11-12 120V 14 14 14 12

12-16 120V 14 12 Not Recommended

Table 1.

Minimum Gage For Power Cord

Total Length of cord in feet

Rating

AWG

4

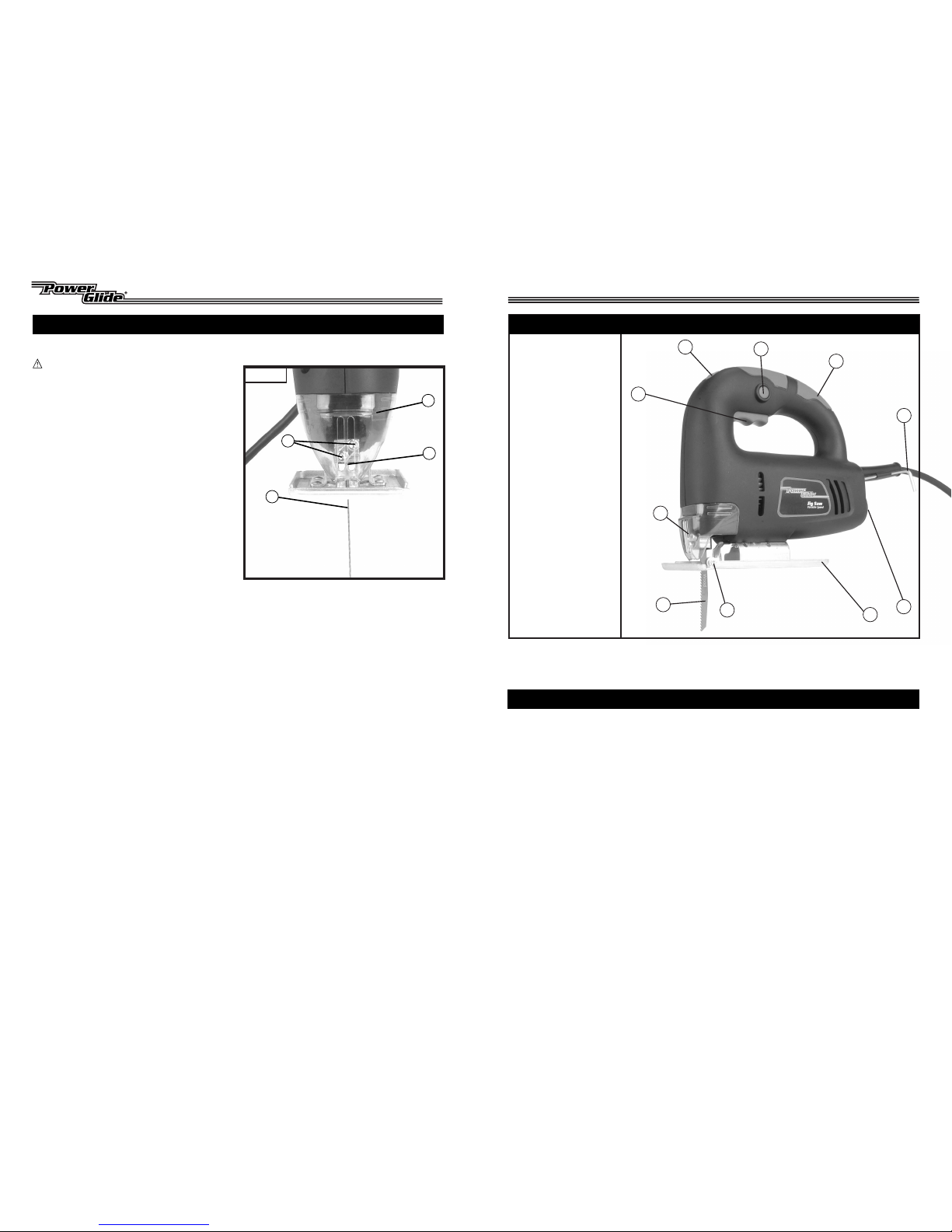

Basic Operation

WARNING:

• RISK OF INJURY - Always keep hands and body away from saw blade at all times

during operation

• RISK OF ELECTRICAL SHOCK - Do not expose the tool to rain or water. Do not use in damp

locations. Do note use tool to cut pipe or conduit containing water.

• RISK OF EXPLOSION - Do not operate the tool in explosive atmospheres or in presence of

flammable liquids or gases.

• Never touch the saw blade while it is moving. Do not touch the saw blade after operation, it

will be very hot.

• Never hold workpiece in your hand. Any workpiece that is not adequately clamped in place

may come loose and cause serious injury

CAUTION: Remove all nails, staples, fasteners, foreign objects or other debris before sawing.

Make sure there is enough space under and behind the work piece for the saw blade.

1. (SEE FIGURE 8) Adjust base plate (1) to the

desired bevel angle.

NOTE: Use a protractor or square to check

the bevel angle between the blade and the

base. Make a test cut in a scrap piece of

material and measure the bevel angle.

2. Adjust the variable speed control knob (2)

to the desired setting.

3. Clearly mark the desired cut-line (3) on

the workpiece

4. Secure workpiece for the cut: Hold smaller

workpieces with a vise. Clamp larger

workpiece to a workbench or table.

5. Hold the tool firmly by the grip (4) during

start-up and while in use.

6. Place the front of the saw base (5) against

the workpiece and align the cutting edge of

the blade with the cut-line on the work-

piece. Start the saw and allow it to reach

full speed.

7. Apply enough downward pressure to keep the base plate flush with the workpiece. Slowly

move the saw forward to start the cut. Work slowly, do not force the tool, allow the saw blade

to do the work.

NOTE: Uneven base contact with the workpiece can cause excessive vibration, blade

damage or breakage. Whenever possible, keep the base in firm contact with the workpiece.

8. When sawing curves, proceed slowly and do not use excessive twisting or side-to-side

pressure - blade damage will occur.

9. Never cut material thicker than the retracted length of the blade.

10. Starter holes are recommended for all inside edge cutting.

OPERATING INSTRUCTIONS

Figure 8

1

2

3

4

5