2

1. To Secure machine to existing work bench use three (3) 3/8”

bolts or lag screws of suitable length.

2. Attach the Stitching Handle to

the BOSS. Slide the Stitching Handle

onto the shaft & secure the handle in

position with bolt (AR-73 & 73-1)

3. Attach the Thread Stand.

1) Insert the bolt through the

bottom of the thread stand and the

thread stand post (AR-18)

2) Insert the bolt through the

thread guide and thread stand

plate and carefully start it into

the provided hole on the top of

the sewing machine. Position the

thread guide to allow the thread

to feed into thread guide B un-

obstructed and tighten the bolt to

secure.

CAUTION: Always keep your free

hand clear of presser foot and

needle foot during operation - in-

cluding during the following tests.

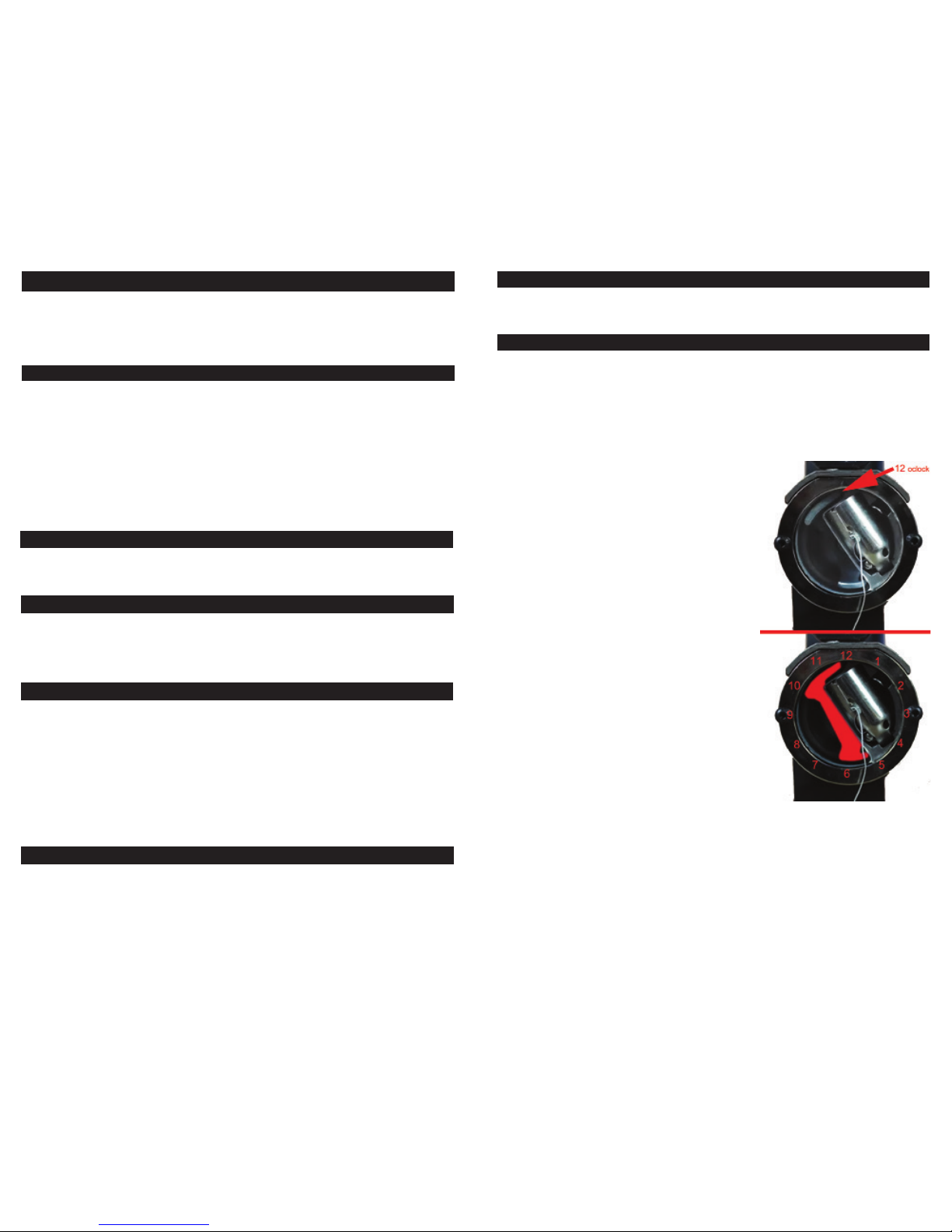

• To Check* the Presser Foot Lift:

(*Always be sure the presser foot path

is clear of hands, tools etc.)

With machine secured to a stable work

bench, lift the Presser Foot by

squeezing the Presser Foot Lifting Handle.

The Presser Foot should lift approximately 7/8 inch.

• To Check* the Stitching Handle:

(*Always be sure needle foot path is clear of hands, tools etc.)

With machine secured to a stable work bench, cycle the needle foot,

by pulling the Stitch Handle completely down and then return it com-

pletely to the upright position.

3

This Tippmann “BOSS®” hand stitcher sewing machine is surrendered by Tippmann Industrial

Products, Inc., with the understanding that the purchaser assumes all liability resulting from unsafe

operation. Tippmann Industrial Products, Inc., shall not be liable for personal injury resulting from

the use of this machine under any circumstances.

All information in this manual is subject to change without notice and in no way represents a com-

mitment on the part of Tippmann Industrial Products, Inc. We reserve the right to make changes

and improvements to products without incurring any obligation to incorporate such improvements in

products previously sold.

The ownership of this machine places upon you the total responsibility of its safe operation. You must

observe the same safety precautions as you would any piece of equipment to assure the safety of

not only yourself but everyone around you.

Outlined here are some general precautions to be aware of: the operator should at all times use

common sense when using this machine and be sure others who may operate are also familiarized,

responsible and safety conscious. Do not attempt to operate this machine until you have read and

are familiar with this manual. Common sense includes reading, reviewing and understanding these

written instructions before operating or setting up this machine including but not limited to:

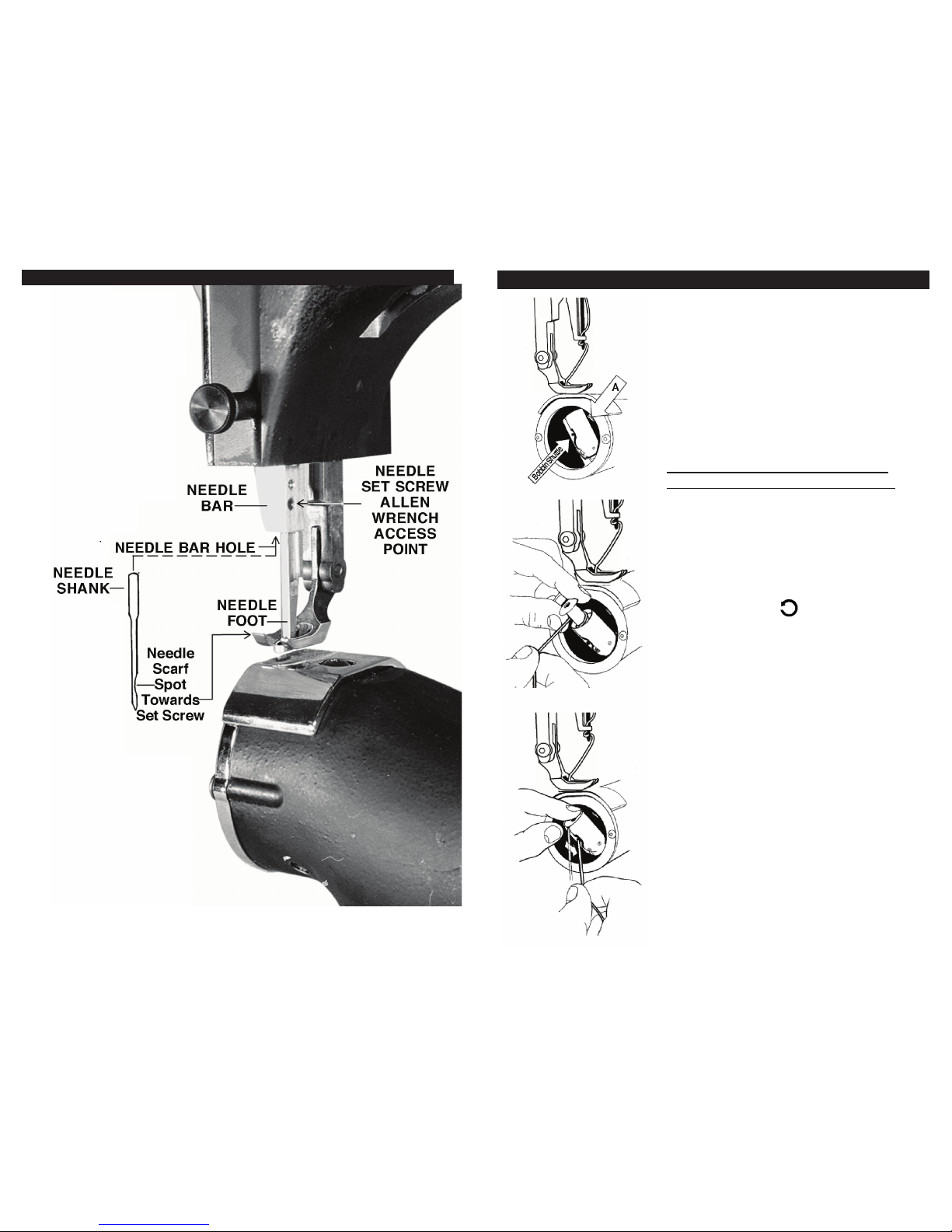

• Before changing needles.

• Before threading needles.

• Before changing bobbin.

• Before disassembly of machine. • Before moving machine.

• Do not attempt to operate this machine until it is securely fastened to a sturdy

work surface.

• Do not operate this machine when parts have been removed as damage to the

machine and/or injury to operator may result.

• Keep hands clear of presser foot and needle at all times.

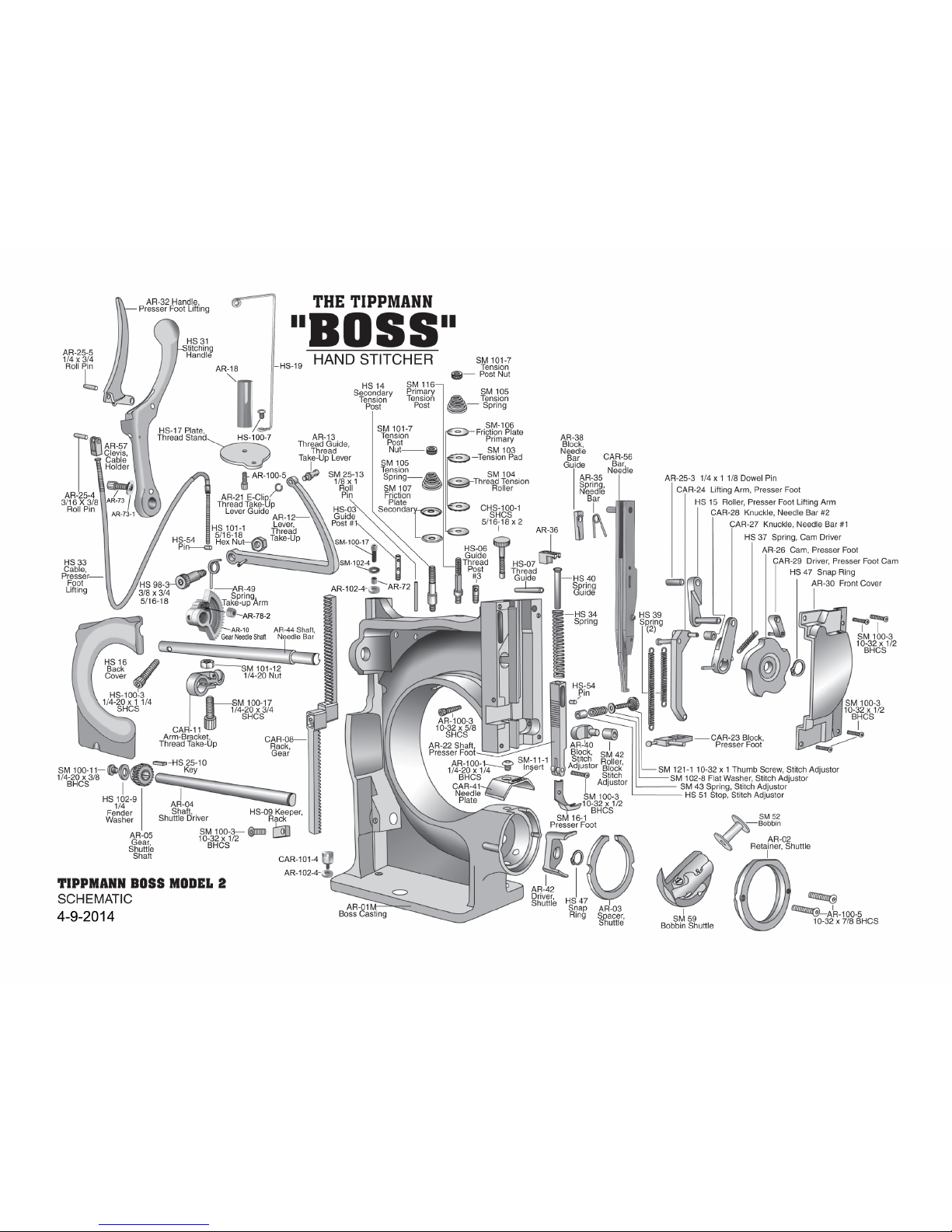

Make .................................................................................................................. TIPPMANN

Model ......................................................................................................................“BOSS 2”

Type Feed .......................................................................Needle Feed/Lower Needle Guide

Type Stitch .......................................................................................................... Lock Stitch

Type Bed .................................................................................................... 3 “ Cylinder Bed

Throat Depth ...................................................................................................................6.5”

Stitch Cycle Rate .................................. Variable - 1 to 100 Stitches (1” to 15”+ per minute)

Presser Foot Clearance............................................................................................ 7/8 inch

Maximum Sewable Thickness ................................................................................. 3/4 inch

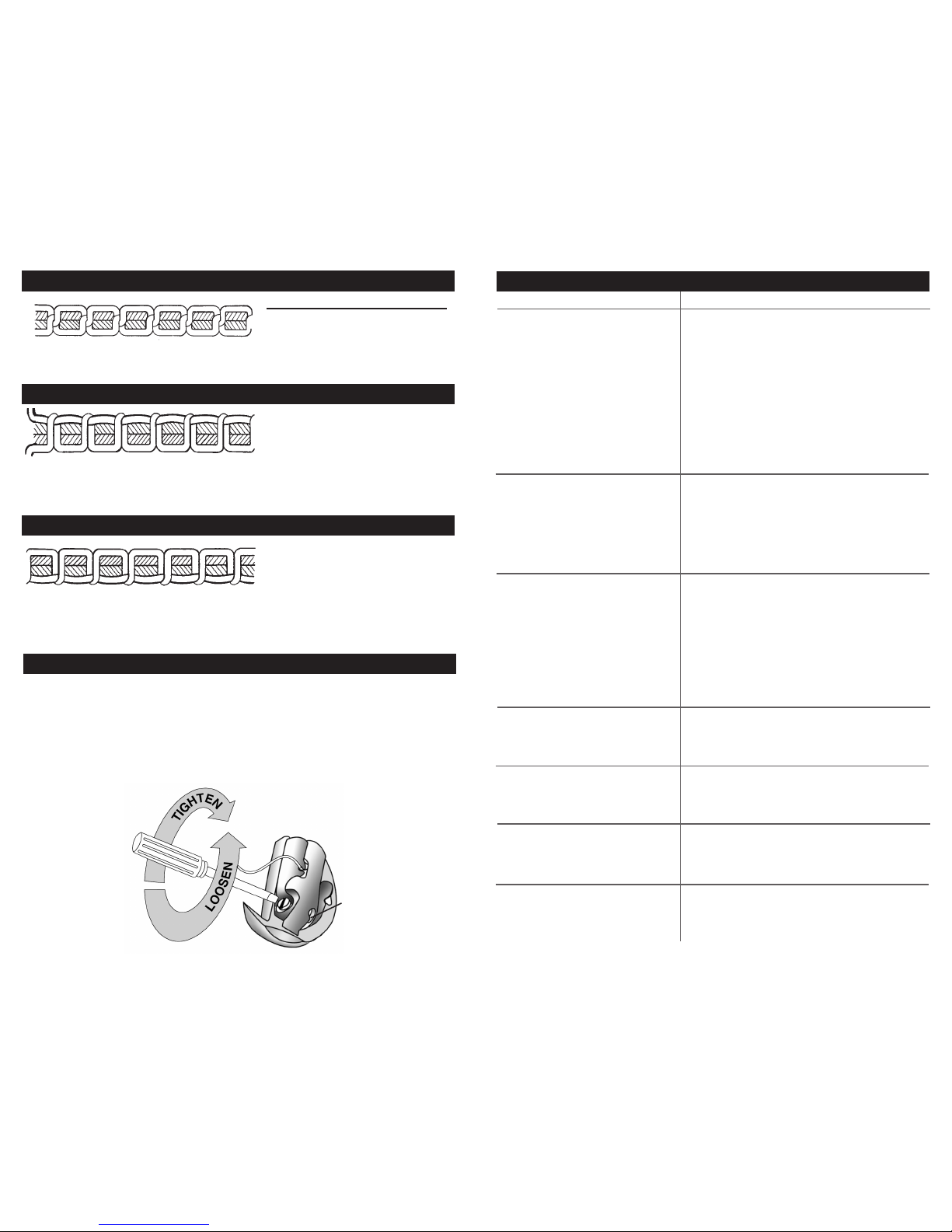

Needle System ........................................................................................794 Series & 7 x 3

Thread Sizes ......................................................................................................... 69 to 415

Stitch Length Adjuster..................................................................... 4 per inch to 16 per inch

Machine Weight ..................................................................................................23 Pounds

The Tippmann “BOSS” hand stitcher sewing machine is a needle-feed, lock-stitch machine. The

“BOSS” is designed and built to achieve precision quality stitching, extreme durability of the machine

itself and maximum owner satisfaction for many years.

SPECIFICATIONS

GENERAL DESCRIPTION

SAFETY IS YOUR RESPONSIBILITY!

WARNING / LIABILITY STATEMENT SETUP INSTRUCTIONS

AR-73

AR-73-1

LOCK WASHER