[F]

Barrierephoto-electrique N°,5506 C

..

Equipement fourni

. BoTte å relais

. Cellulephotoelectrique

.Cåble

.Plaque de fixation

.Jeu de montage

råcepteur et emitteur

3 x 0,25 mm2,8 m de long

pour montage sur le railde la porte,

speciale pour portails Crawford

et rondellespour la plaque de fixation;

viset ehevillespour la boite å relais

visde fixation,åctrous

plans electrique et de montage

.Instruetions de montage

.Etiqyettes de protection

Instructions de montage

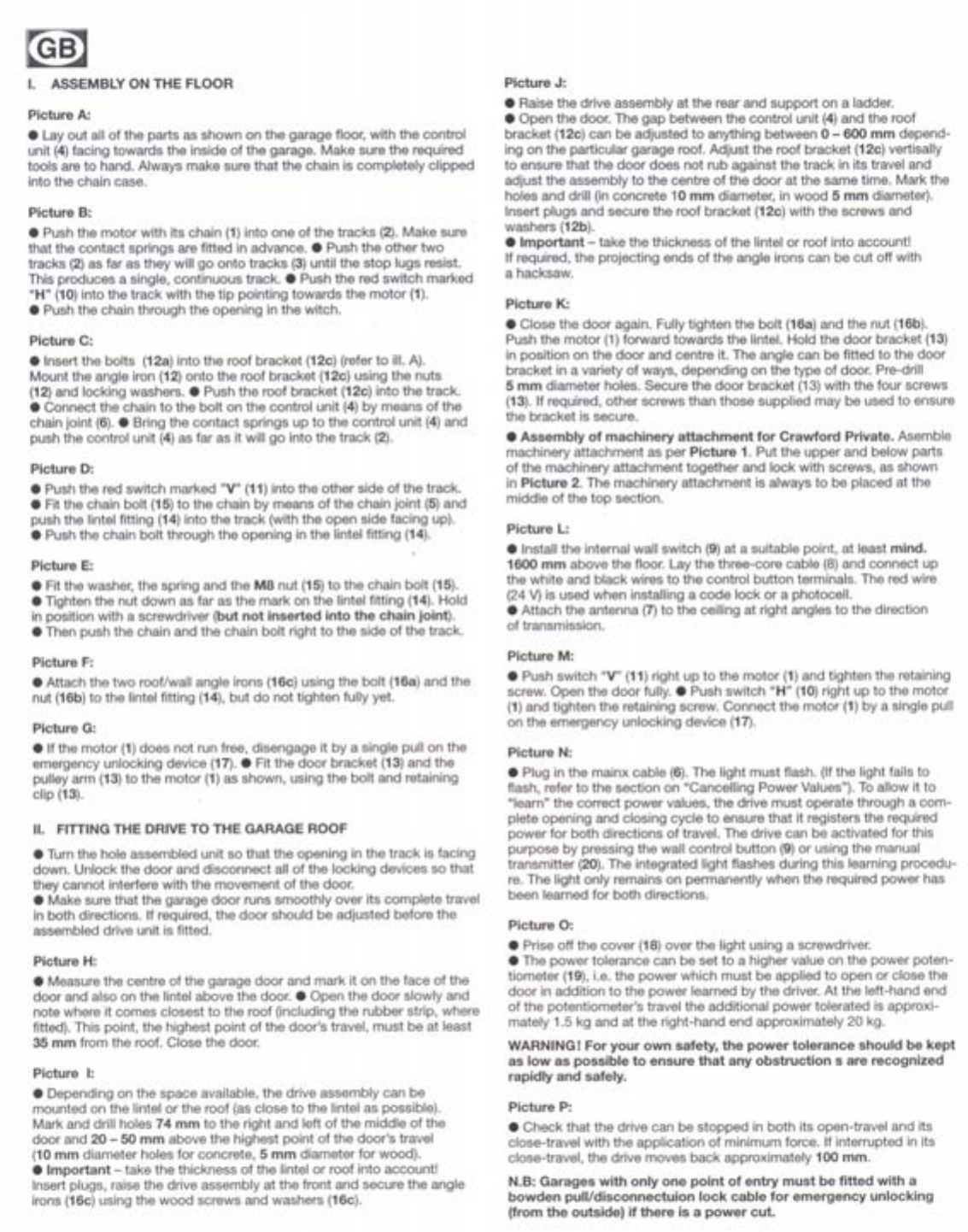

Botteå relais:

.Plaeer la boTte å relais sur le linteau de la porte, au-dessus ou å eate

de I'extremite du rail;se refererau sehema des eonnexions.

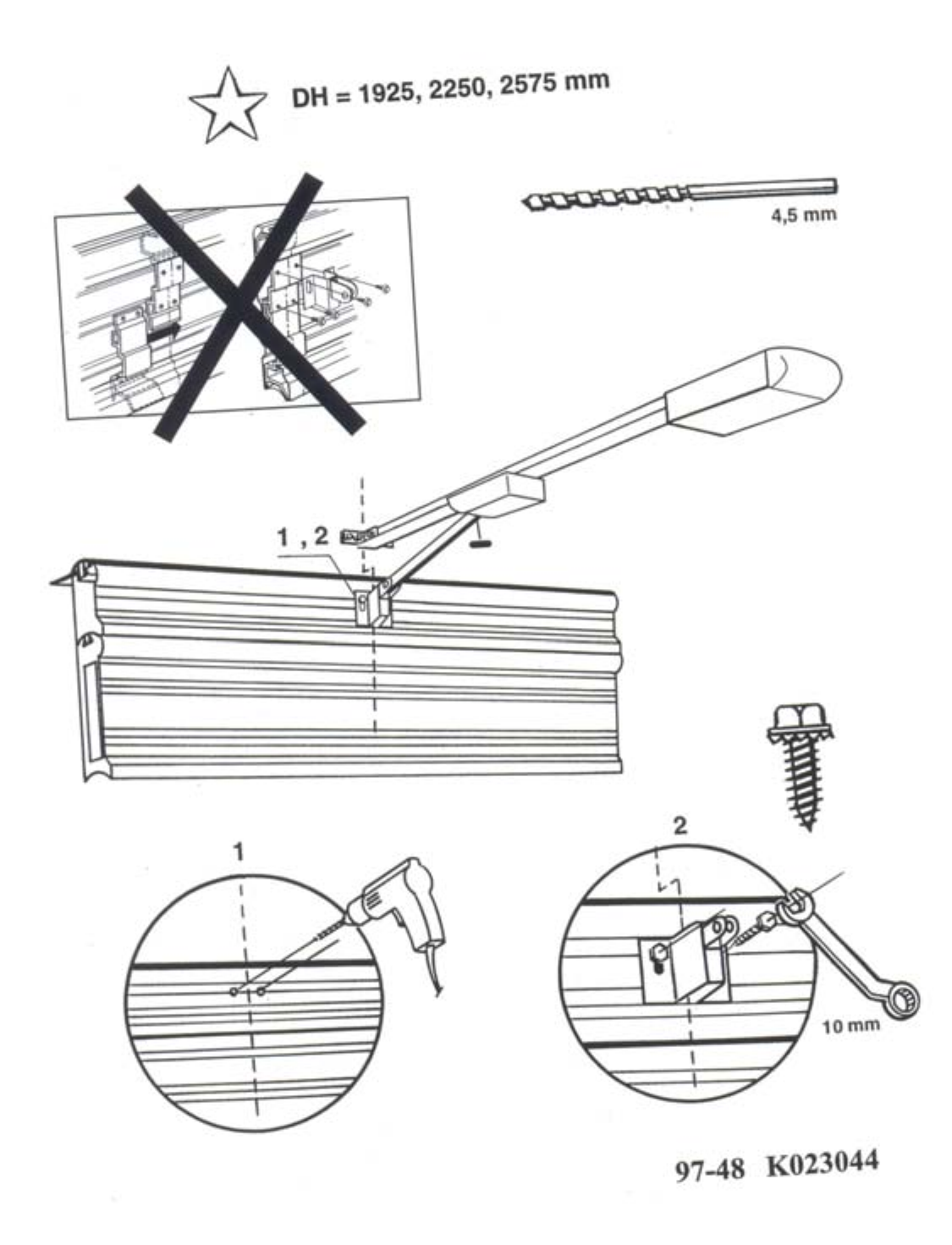

Plaques de fixation:

.Dans ehaque rail de porte, pereer deux trous (ø 6,5 mm)

eorrespondant aux trous de la plaque de fixation.

.ATTENTION! Les plaques de fixation dolivent etre placees de

fayon opposee, å la meme hauteur et avec I'arete superieure il

150 mm, au maximu, au-dessus du niveau du sol. Si on n'utilise

pas de plaques de fixation,on peut utiliserles quatre trous dans la

partie inferieuredu boitierpour lafixationau mur.

.Monterla plaque de fixationsur le railmural,la tete de visdirigee

vers I'interieur.

.Pour les portails Crawford de type PRIVAT,la plaque de fixation doit

etre plaeee å I'exterieursur le eapot du bomier.Veillerå inserer deux

rondelles par trou de fixationentre lecapot du borneier et la plaque

de fixation.

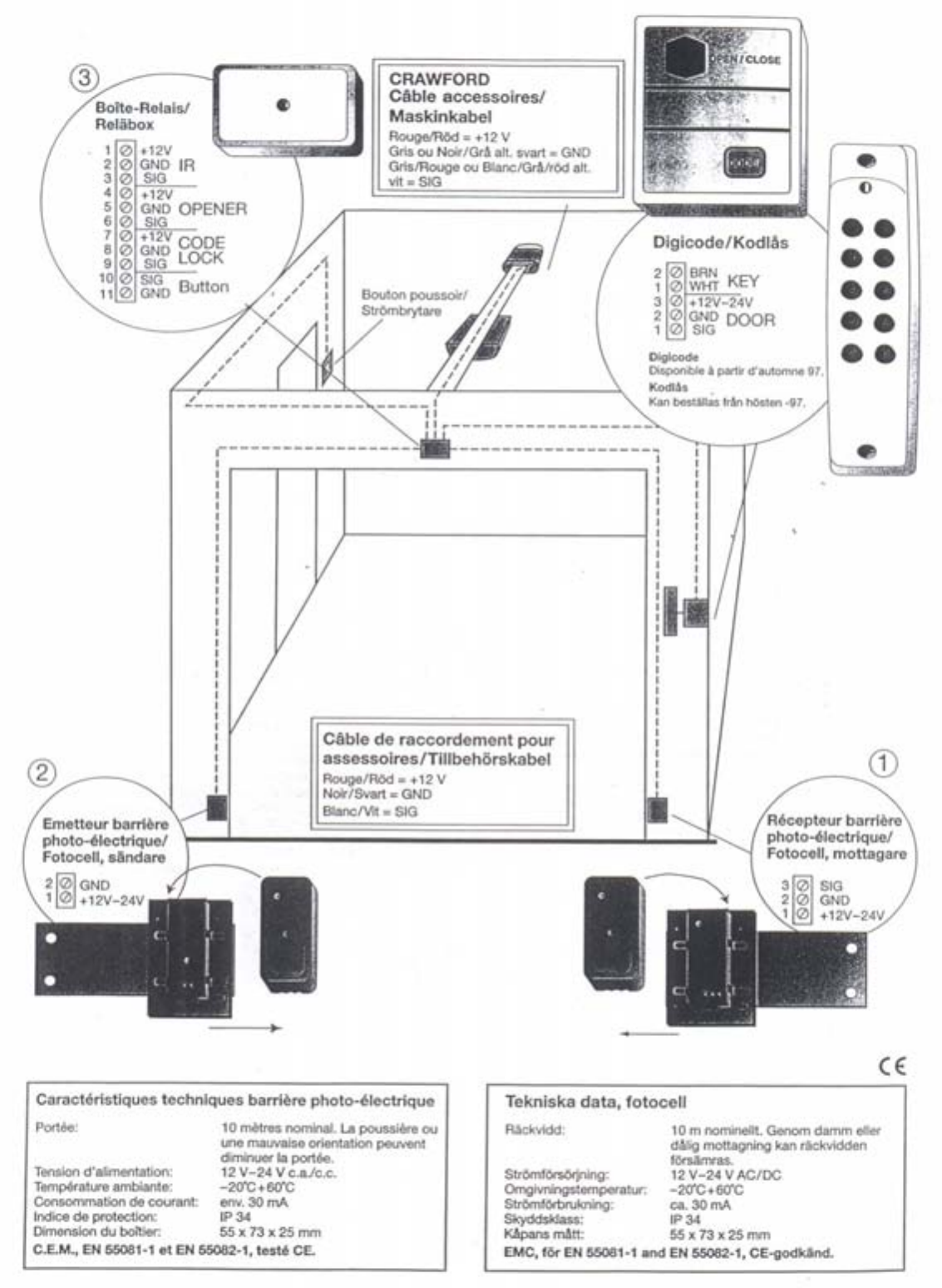

Installation et connexions

.ATTENTION! Si I'ouvre-porte de garage a dejil ete utilise,

dåsenficher le connecteur du reseau.

.Poser le cåble relieau bouton-poussoir de I'ouvre-porte au-dessus

du rail vers I'avant en direction de la boTte å relais.

.Couper le cåble å la longueur appropriee, et le connecter aux bornes

(Aparto)conformement au schåma des connexions @.

.Poser le cåble å trois conducteurs (fournQde la boTte å relais vers

le råcepteur (receiver) et I'emetteur (transmitter) de la barriere

photoelectrique.

.Connecter les deux extremies de cåble de I'emetteur et du recepteur

aux bornes IRde la boTteå relais, comme indique sur le schema des

connexions@. Les bornes GND(terre)et 12 Vrecoivent chacune

deux conducteurs.

.Connecter le råcepteur comme indique sur le schåma des con-

nexions (D, et I'emetteur, n'utiliser que les couleurs de conducteur

rouge (12 V)et noire (GND (terre»),et isoler le conducteur blanc avec

du rubanIsolant. .

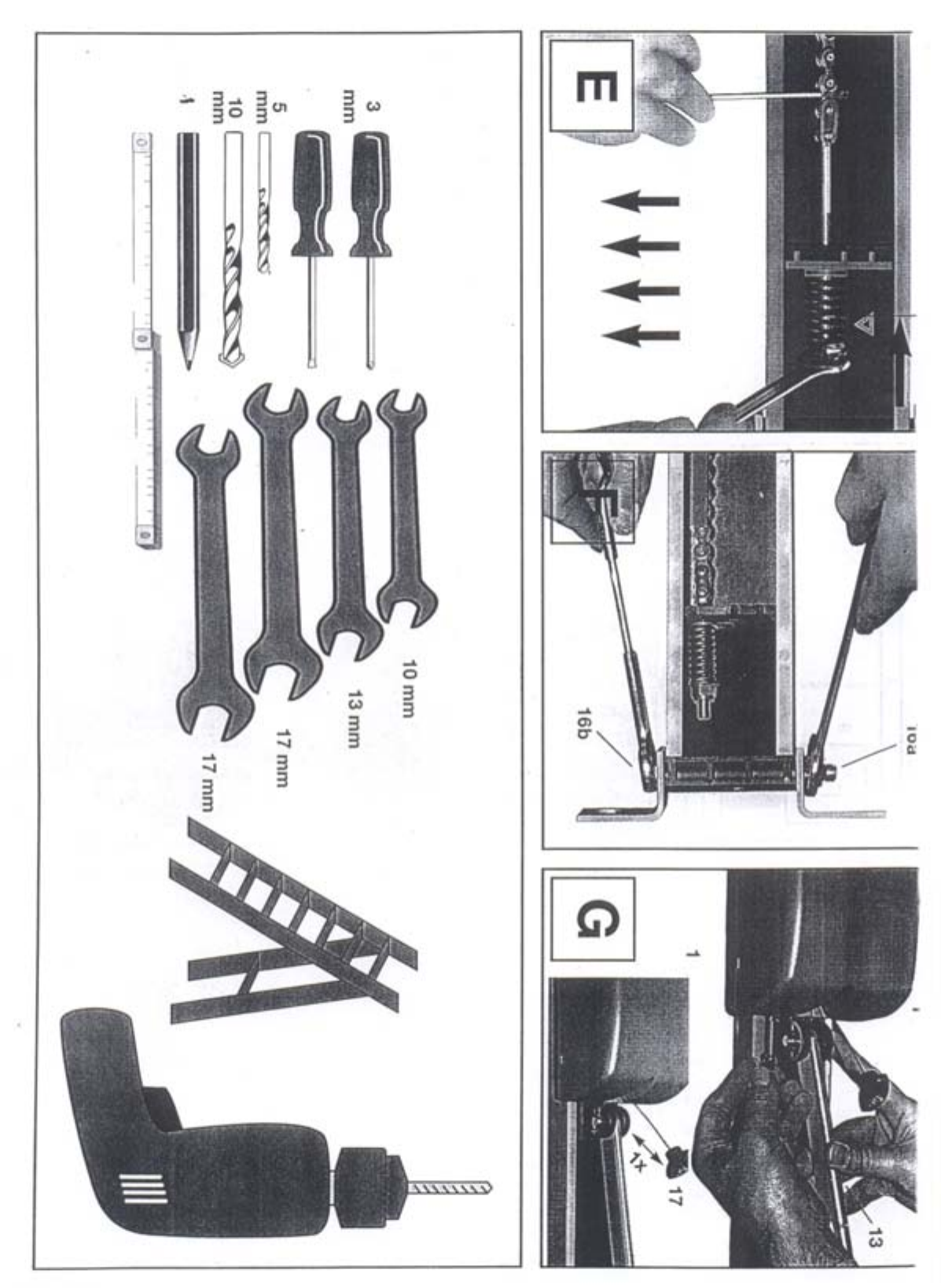

.Placer les parties inferieuresdes boitiersde I'emetteur et du

råcepteur de la barriere photoelectrique sur les plaques de fixation

ou, en cas de montage mural,les visser dans les trous.

. Collerles etiqyettes de protection (fournies)sur chayun des marqua-

ges de couvercle de boitier.

.Poser le couvercle de la barrierephotoelectrique en appuyant

fortement jusqu'å ce qu'iIs'encliquette de fayon audible.

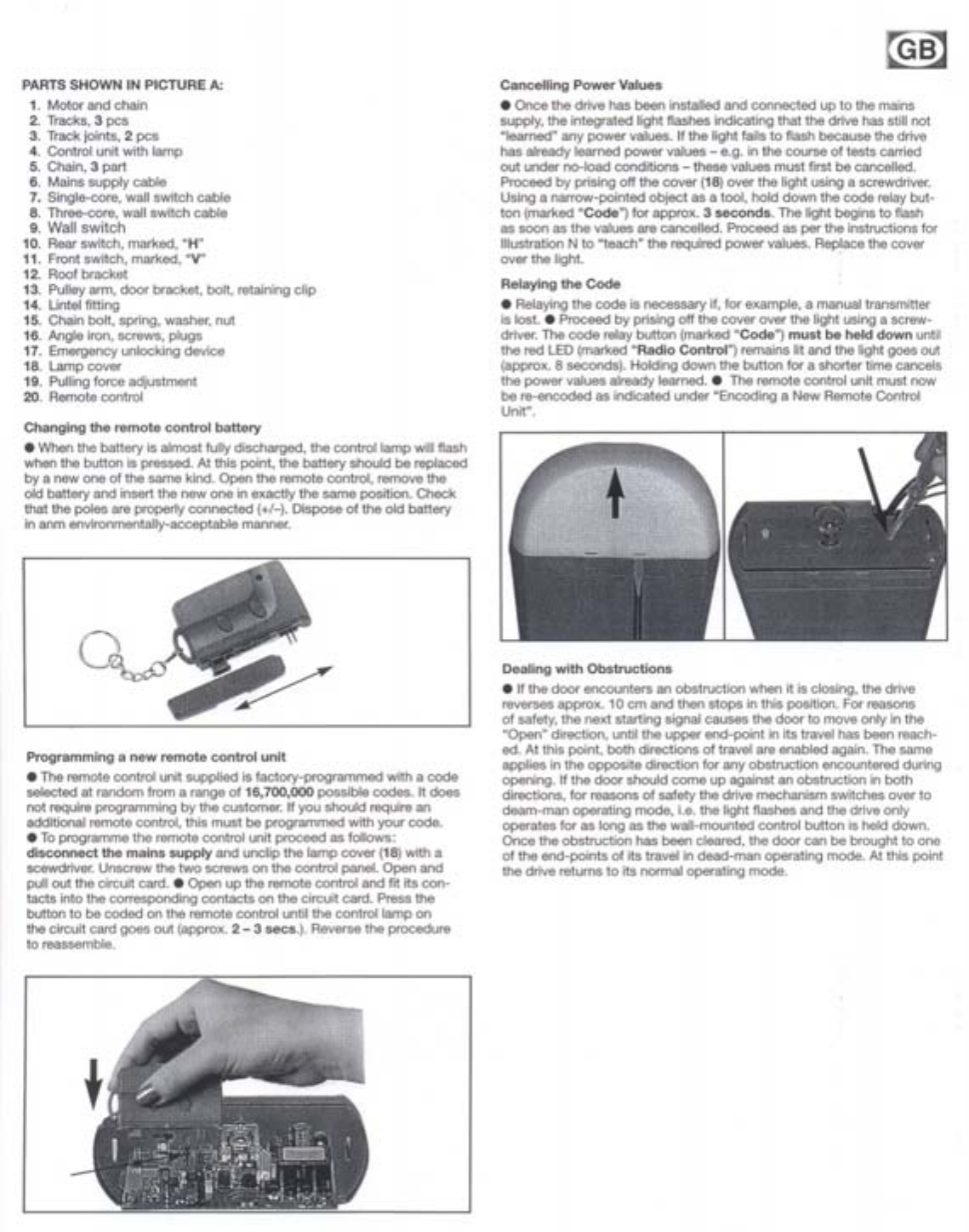

Alignement et controle

.Enficherle cåble de raceordement de I'ouvre-porte de garage au

reseau.

.Si la diode electroluminescente rouge clignote å I'enfichage, bien

que le faisceau lumineuxne soit pas interrompu, aligner I'emetteur et

le råcepteur jusqu'å ce que la diode electroluminescente s'eteigne.

.Contraler le bon fonctionnement de J'installation en interropmpant å

plusieurs reprises le faisceau lumineuxinfrarouge. Cela peut se faire

en passant la mainjuste devant I'undes deux dispositifs

photoelectriques. Si I'installationfonctionne correctement, on peryoit

une legere emission sonore et fa diode electroluminescente rouge de

I'emetteur s'allume.

.Activer "ouvre-porte de garage au moyen de I'emetteur portatif our

du bouton-poussoir interieur.

.Lars de la course d'ouverture de la porte, la barriere photoelectrique

est inactive. Par contre, lorsde la course de fermeture, I'ouvre-porte

s'arrete instantanement et revienten arrieresur environ 10 cm en

cas d'interruption du faisceau lumineux.Si le faisceau lumineux est

interrompu, "ouvre-porte ne demarre pas, niavec le bouton-

poussoir, niavec I'emetteur portatif.

[s)

Sakerhetspaket, 5506 C

Forpackningen innehåller:

. Relabox

. FotocelJ

.Kabel

. Fastplatta

. Montage-set

Mottagare och Sandare

3 x 0,25 mm2, langd 8 m

for montage på portskenor, speciell for Crawford

garageportar

Fastskruvar, muttrar och under1aggsbrickor

for fastplatta, skruvar och plugg for Relabox

Kopplings- och placeringsschema

.Montageanvisning

.Skyddsetiketter

Montage

Relabox:

.Placera och fast relaboxen på vaggen ovanfor elJervidsidan av

lopskenan, se placeringsschema.

Fastplattor:

.Borra2 st 6,5 mm hål ivarderavaggskena enligt fastplattornas

hålbild.

.OBS!Placera fastplattorna med ovankant max 150 mm från

golvet. Vidmontage av fotocellernapå vagg anvandes de tyra

skruvhålen i plastboxens underdel.

.Montera fastplattorna i vaggskenorna med skruvhuvudet från insid an

av skenan.

.For Crawford Privat monteras fastplattorna utanpå klammskydden.

Placera 2 st under1aggsskivor per skruv mellan klammskydd och

fastplatta. .

Installation/Kabeldragning

OBS!Dragurnatkontaktentil!dingarageportsoppnare.

.Fast maskinens treledande strombrytarekabel ovanpå lopskenan

fram til!relaboxen.

.Anpassa kabellangden och anslut till relaboxens kopplingsplint

enligt placeringsschema @.

.For1agg den medlevererade 3-led. kabel n från relaboxen till

mottagare och såndare.

.Anslutde båda kabelandarna frånmottagare och sandare enligt

placeringsschema @ i relaboxens kopplingsplint IR. Anslut både

såndare och mottagarens kabelandar til!GND och +12 V.

OBS! Isåndaren anvandes endast rott +12 Voch svart GND.

Den friavita kabeln skall isoleras med isoleringstape.

.Anslut mottagare eD och sandarE~ @.

OBS! Isåndaren anvandes endast rott +12 Voch svart GND.

Den fria vita kabeln skall isoleras med isoleringstape.

.Skjut på mottagare och såndare på fastplattorna så långt att den

linjerariytterkant av fastplattorna alt. vaggmontera enheterna med

skruvfastsåttning.

.De båda medlevererade skyddsetiketterna appliceras vid markering

på lockens framsidor.

.Tryckfast locken på plats.

Centrering och provning

.Anslut nåtkontakten til!din garageportsoppnare.

.Skullevidnatanslutningdenrodalysdiodenpå mottagarenIysa

fastanIjusstråleinteårbrutenmåstesandareoch mottagarejusteras

for korrekt centrering så att lampan slocknar.

.Kontrollerainstallationengenom att med t.ex. handen fleragånger

bryta Ijusstrålen. Ett klickande Ijud hOrs från relåboxen nar relaet

aktiveras, och den rOda ledlampan i mottagaren lyser.

.Aktivera garageportoppnaren via handsandare eller vaggstrom-

brytare.

.I uppåtgående rorelse har fotocellen ej någon funktion. I nedåtgå-

ende rorelse stoppar maskinen direktoch går c:a 10 cm tillbakaså

lange Ijusstrålenar bruten. Meden bruten Ijusstråle kan maskineriet

med vaggstrombrytare eller handsåndare ej startas. '"

..

~

o

'"

ti

~

E

li

\2

tt

~.

<

~

J!

.

'"

2

!

!j