Credo 900 Series User manual

INSTALLATION GUIDE

Electric Drums &

Hydraulic Disc or Drum

Please return to customer once install completed

Read instructions before installation

NZ: 3500KG GVM | AU: 4500KG GVM

2

AU Freephone 1300 538 598

E sales@trailparts.com.au

www.trailparts.com.au

Index

Page 7

Page 5

Page 4

Page 6

Page 12/13

Page 14

Page 15

Page 10/11

Page 9

Page 8

Recoding In Cab Controller

Warranty - T&C - Maintenance

Serial Number Locations

Troubleshooting

Hydraulic Pre-Assembled Wiring Diagram (Serial: 900-4499)

Hydraulic Pre-Assembled Instructions (Serial: 900-4499)

Hydraulic Wiring Diagram (Serial: 900-4499)

Hydraulic Instructions (Serial: 900-4499)

Electric Wiring Diagram (Serial: 900-4499)

Electric Instructions (Serial: 900-4499)

Page 3 Orientation Guide

Note: Check serial number to find correct instructions

Note: This instruction Book is

for Credo units with a serial

number btween 900 - 4500

3

NZ Freephone 0800 487 245

E sales@trailparts.co.nz

www.trailparts.co.nz

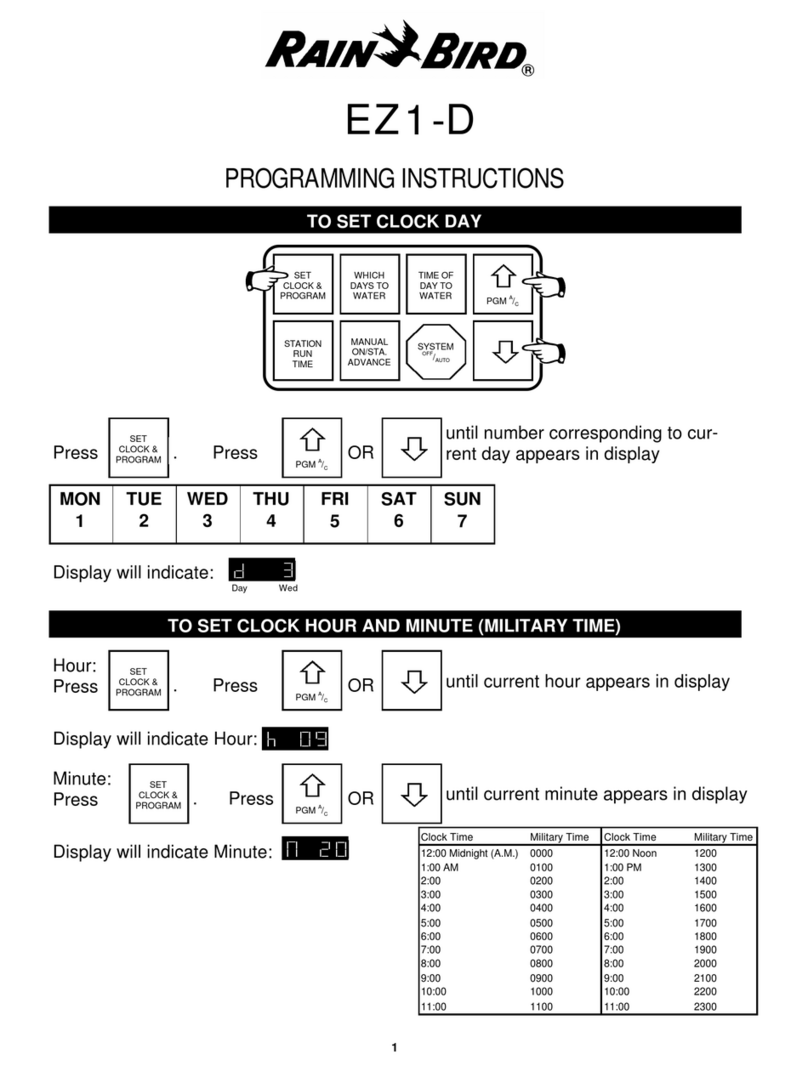

Orientation Guide

SIDE

Direction of Travel

SIDE

Back can be up to

70 Degrees Up

Back can be up to

20 Degrees Down

20

o

70

o

OR

TOP

TOP

Direction of Travel

Must be mounted straight longitudinally, i.e. parallel to direction of travel

INCORRECT

CORRECT

90

o

FRONT

FRONT

Unit Must Be Level

Laterally

INCORRECT

CORRECT

90

o

Direction

of travel

Must be

mounted

straight

longitudinally,

i.e. parallel to

the direction of

travel

FRONT

FRONT

Unit Must Be Level

Laterally

INCORRECT

CORRECT

90o

Unit must be

level laterally

Direction of travel

Back can be up

to 70 degrees up

Back can be up to

20 degrees down

4

AU Freephone 1300 538 598

E sales@trailparts.com.au

www.trailparts.com.au

Credo General Installation Instructions

(Applies to Serial # 900 - 4499)

Credo Electric Installation Instructions

Mount the brake controller according to the mounting orientation instructions on page 3.

Wire the brake controller according to the instructions on page 9.

It is important that trailers fitted with the Credo™ braking system are also fitted with 12/24 volt

LED lights, not voltage specific incandescent or LED lights.

Maximum of 2 tail lights and 4 marker lights to be connected to the unit.

If more are required please phone us for installation support.

Controller must be mounted to a metal surface which is mounted to the main chassis.

The controller is capable of running trailers with up to 4 wheels braked with

electric drum brakes.

The earth from the trailer brakes and the trailer battery must only connect to the brake

controller output earths as shown in the diagram. They cannot be connected to a common

chassis earth.

Cable gauge should be suicient size to avoid voltage drop. For electric drum brakes a

minimum of 15 amp cable should be used and a separate feed should be run per two wheels

that are fitted with brakes.

Magnet wires can be used interchangeably, for brakes positive and earth.

5

NZ Freephone 0800 487 245

E sales@trailparts.co.nz

www.trailparts.co.nz

Credo General Installation Instructions

(Applies to Serial # 900 - 4499)

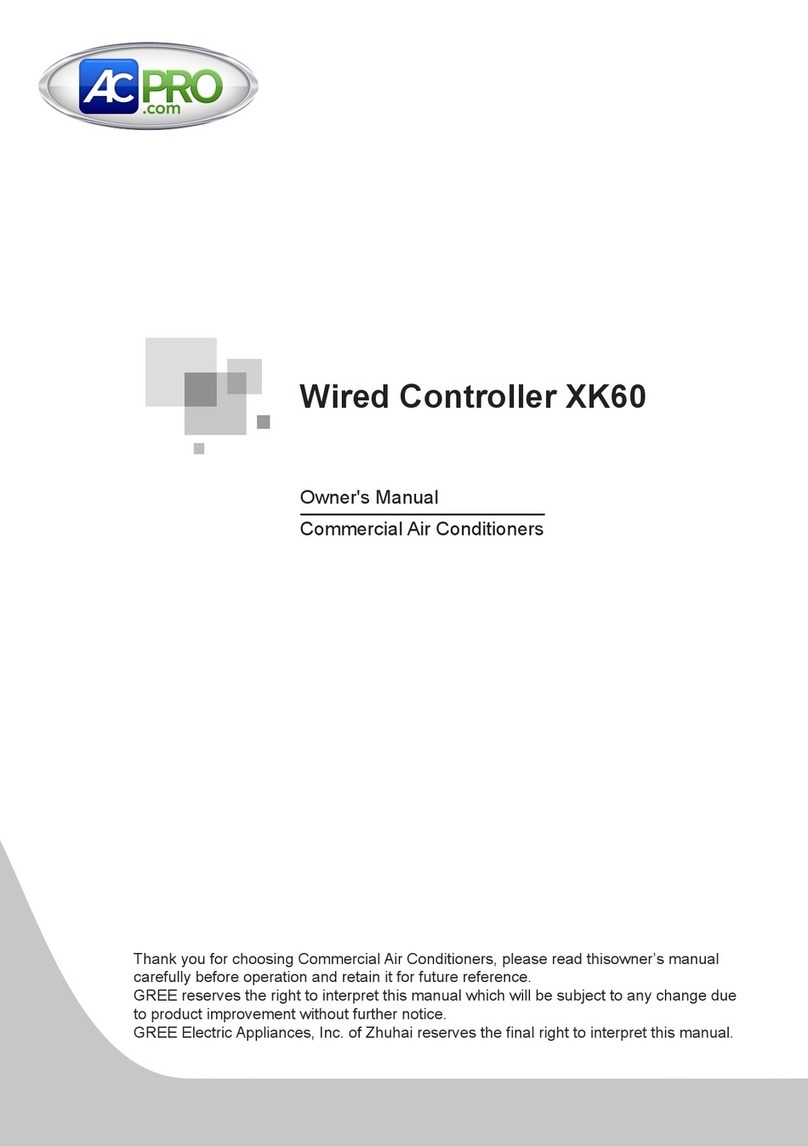

Connect one grey to each side

of the breakaway switch

Green - Right Indicator

Brown - Tail light

White - Earth

Red - Stop light

Yellow - Left Indicator

Connect trailer lights to

5 core output

One 5 Amp/hr battery

must be fitted with the

battery supplied.

Do not use brake system battery

to power any other systems.

There should be no more

than 2.5 metres of cable

between the controller and

the trailer plug to avoid

voltage drop.

Pink not used

May also be

green/yellow

Battery Requirements:

Electric: 1x5Ah or bigger

Hydraulic: 2x5Ah or 1x12Ah

or bigger

30 amp blade fuse

required on orange wire

Must only be used for

credo connection

Elecrtic Drum magnet

wires are interchangeable

Electric Drum

White to Magnet

Blue to Magnet

Orange Not Used

Wiring diagram below applies to CredoTM

Brake Controller with electric drums only.

Credo Electric Drum Wiring Diagram

Applies to units in serial

range 900 - 4499

All unused wires must be isolated.

6

AU Freephone 1300 538 598

E sales@trailparts.com.au

www.trailparts.com.au

Credo Hydraulic Installation Instructions

The earth from the BrakeRite actuator and the trailer battery must only connect to the brake

controller output earths as shown in the diagram. They cannot be connected to a common

chassis earth.

Cable gauge should be of suicient size to avoid voltage drop. The main power feeds to the

actuator from the brake controller should be minimum 20amp.

Mount the actuator in a protected position. Orientation is not important for this, but filler caps

should be level and upright.

Do not run the actuator without fluid as this will damage the pump.

Use new DOT 3 or DOT 4 brake fluid.

Bleed the brakes by activating the breakaway switch. However, do not run the actuator

continuously for more than 1 minute every 5 minutes. All air must be removed from the system

for the brakes to work correctly. Ensure that the fluid level does not drop below 20mm from the

filler cap opening to avoid more air being pumped into the system.

Credo General Installation Instructions

Credo Hydraulic Instructions

(Applies to Serial # 900-4499)

Mount the brake controller according to the mounting orientation instructions on page 11.

Wire the brake controller according to the instructions on page 11.

It is important that trailers fitted with the Credo™ braking system are also fitted with 12/24 volt

LED lights, not voltage specific incandescent or LED lights.

Maximum of 2 tail lights and 4 marker lights to be connected to the unit. If more are required

please phone us for installation support.

Controller must be mounted to a metal surface which is mounted to the main chassis.

7

NZ Freephone 0800 487 245

E sales@trailparts.co.nz

www.trailparts.co.nz

All unused wires must be isolated.

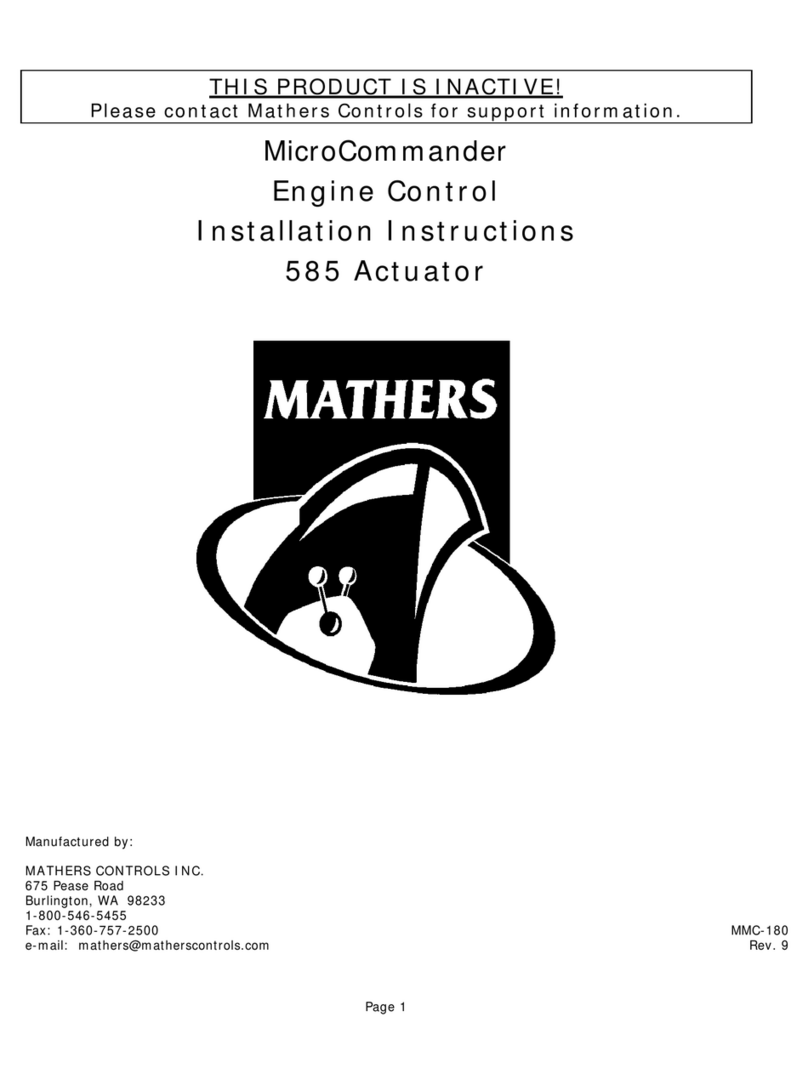

Credo Hydraulic Disc / Drum Wiring Diagram

Wiring diagram below applies to CredoTM

Brake Controller with hydraulic brakes only.

Actuator must have Trailparts™ isolator fitted.

Connect one grey to each side

of the breakaway switch

Green - Right Indicator

Brown - Tail light

White - Earth

Red - Stop light

Yellow - Left Indicator

Connect trailer lights to

5 core output

One 5 Amp/hr battery

must be fitted with the

battery supplied.

Do not use brake system battery

to power any other systems.

There should be no more

than 2.5 metres of cable

between the controller and

the trailer plug to avoid

voltage drop.

Battery Requirements:

Electric: 1x5Ah or bigger

Hydraulic: 2x5Ah or 1x12Ah

or bigger

30 amp blade fuse

required on orange wire

Must only be used for

credo connection

White to Pump

Blue to Pump

Orange Not Used

Pink to Brown

Hydraulic Pump

Credo Hydraulic Instructions

(Applies to Serial # 900-4499)

Applies to units in serial

range 900 - 4499

8

AU Freephone 1300 538 598

E sales@trailparts.com.au

www.trailparts.com.au

Credo Pre-assembled Hydraulic Installation

Instructions

Do not run the actuator without fluid as this will damage the pump.

Use new DOT 3 or DOT 4 brake fluid.

Bleed the brakes by activating the breakaway switch. However, do not run the actuator

continuously for more than 1 minute every 5 minutes. All air must be removed from the system

for the brakes to work correctly. Ensure that the fluid level does not drop below 20mm from the

filler cap opening to avoid more air being pumped into the system.

The multi core cable marked "7 pin plug" must be wired directly to the trailer plug, and it is

important that the earth wire from that cable must only be earthed using the trailer plug earth

pin, i.e. it cannot be connected to a common chassis earth.

The twin core cable joins to the breakaway switch cables.

Connect the cable marked "trailer lights" from the on-trailer module to the trailer tail camp

circuit. DO NOT bypass this directly to the trailer plug.

The on-trailer module assembly can be mounted o centre side to side, but MUST BE, A)

parallel with the front-rear centre line of the trailer, and B) mounted level on the trailer in its

loaded state.

Credo Hydraulic Pre-assembled Instructions

(Applies to Serial # 900-4499)

Mount the on-trailer module according to the mounting orientation instructions on page 3.

Wire the on-trailer module according to the instructions on page 7.

It is important that trailers fitted with the Credo™ braking system are also fitted with 12/24 volt

LED lights, not voltage specific incandescent or LED lights.

Maximum of 2 tail lights and 4 marker lights to be connected to the unit. If more are required

please phone us for installation support.

9

NZ Freephone 0800 487 245

E sales@trailparts.co.nz

www.trailparts.co.nz

Credo Hydraulic Pre-assembled Instructions

(Applies to Serial # 900-4499)

FRONT

REAR

Wiring diagram above applies to Credo™ pre-assembled

Brake Controller with hydraulic brakes only.

Credo Hydraulic Pre-assembled Wiring Diagram

Connect front wire tails to trailer

7 pin plug

Connect wire tails from rear to

trailer tail-lamps

Connect brake line to brake

actuator port

Connect 2-core cable to

breakaway switch

Green - Right Indicator

Brown - Tail Light

White - Earth

Red - Stop Light

Yellow - Left Indicator

Applies to units in serial

range 900 - 4499

All unused wires must be isolated.

Actuator must have Trailparts™ isolator fitted.

10

AU Freephone 1300 538 598

E sales@trailparts.com.au

www.trailparts.com.au

Troubleshooting

Fault Possible Causes Repairs/Checks

In-cab controller shows

‘Low Trailer Battery’

warning (old style In-cab

Controller shows Eb Error)

Or

No tail lights / tail lights

go out when brakes are

applied.

In-cab controller shows

‘Please Drive with Your

Headlights On’ message,

even though the headlights

are on

(old style In-cab shows Ec

Error).

Battery is excessively

discharged.

Bad connection between

trailer mounted brake

controller and battery.

Blown battery fuse.

Poor connection on battery

terminals.

Serial number mismatch

between Controller and

Trailer.

Faulty trailer plug

In-cab controller cannot

communicate with the

trailer mounted controller

due to interference

Incorrect wiring by-passes

controller.

Poor connection on battery

terminals.

Check battery is over 12.5V when

disconnected. If lower replace the

battery.

Check if battery is charging by

disconnecting the battery leads,

connect to vehicle and switch

lights on. Then check for 14V on

the end of the battery leads. A

measurement of 14V means the

charger is working – if no voltage

then a replacement or repaired

controller is required.

Check leads, fuse holder and any

connections between the battery

and controller for

poor / corroded connections. Any

high resistance joins will cause

excessive voltage drop to the

controller under braking resulting

in the ‘Low Battery’ error.

Obtain serial number: Refer to

page 19

If they do not match then follow

instructions on page 16/17.

Check trailer plug pins are not

corroded or crushed in, and either

spread the pins, remove corrosion

or replace the plug.

Check the controller to In-cab

connection by taking the in-cab

unit back to beside the trailer

mounted controller, if still error is

still present controller needs to be

replaced or repaired.

Check the vehicle connection

goes to only the trailer mounted

controller and all tail and marker

lights from the controller lights

output.

11

NZ Freephone 0800 487 245

E sales@trailparts.co.nz

www.trailparts.co.nz

Fault Possible Causes Repairs/Checks

Brakes randomly come on

and lock up.

Braking output on In-cab

controller stays at ‘-‘ on the

screen when brakes are

applied.

In-cab Controller shows ‘0’

or higher numbers when

brakes applied but no

braking happens.

Faulty Break-away switch.

Faulty Break-away wiring.

In-cab controller has

‘emergency stop’ button

pressed.

Faulty trailer plug / vehicle

connection.

Incorrect wiring bypasses

controller.

On electric drums – Faulty

wiring or magnets.

On hydraulic actuator driven

brakes – Faulty wiring or

isolator if fitted

Check breakaway switch and

wiring for a short circuit. Replace

any faulty components or wiring.

Make sure In-cab controller is

securely mounted on vent holder

and emergency stop button not

inadvertently pressed.

Check and repair trailer plug and

vehicle socket and associated

wiring – replace any faulty parts.

Check vehicle connection goes

directly to the controller and does

not bypass the controller.

On electrics check wiring

and drum magnets for faulty

connections. Normal magnet

resistance is 5 Ohms. 2 Magnets

together is 2.5Ohms and 4 is 1.25

Ohms.

On Hydraulic the Blue signal wire

should be checked for voltage

when the emergency stop being

is pressed. If there is some voltage

and there is no brakes then call for

assistance.

12

AU Freephone 1300 538 598

E sales@trailparts.com.au

www.trailparts.com.au

-

-

EMERGENCY

STOP

LESS MORE ADJ.

+

GAIN SENS.

ZzP

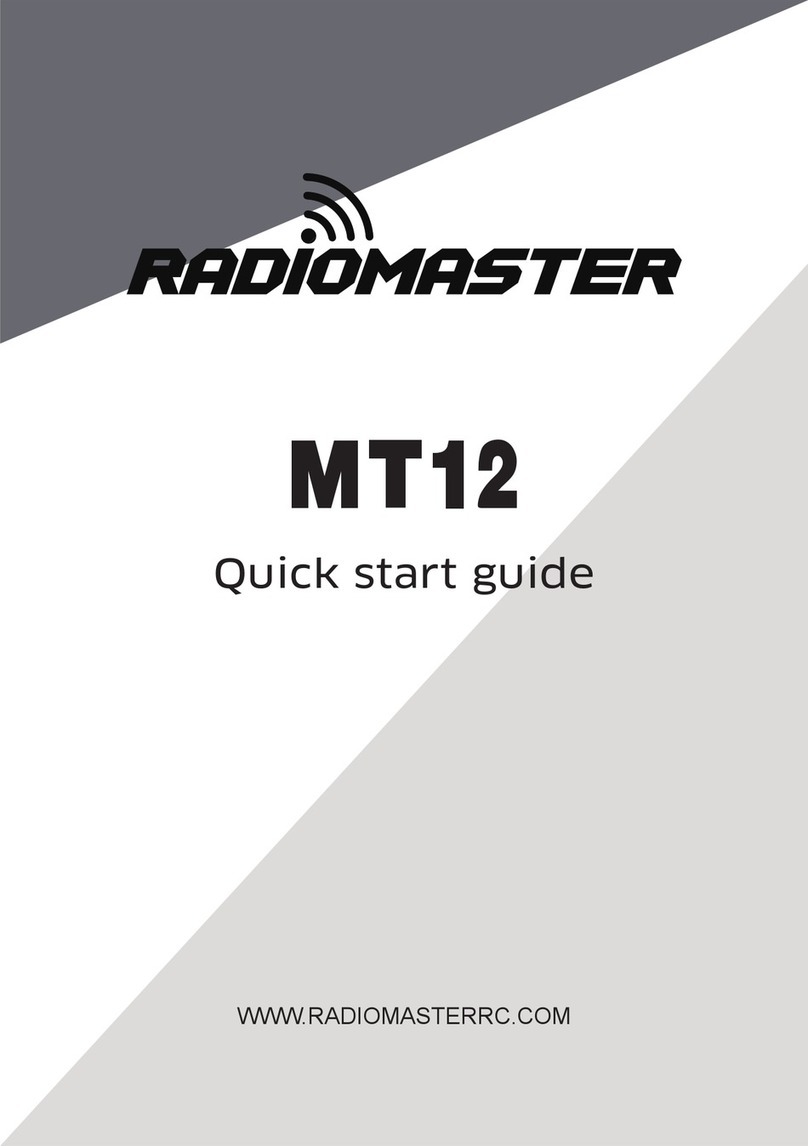

Recoding of Touch-Screen In-cab Controller

1Power up In-cab controller on the USB

cable and leave plugged in for the

duration of coding the controller.

2Wait till the screen displays the gain and

sensitivity control buttons.

3Press and hold the battery symbol for 5

seconds ignoring the screen flashing

any messages.

4The In-cab controller will do a single

beep and display 2 buttons ‘SET’ and

‘ESC’, and a 4 digit number. This number

is the number serial number of the

matching trailer mounted controller.

5Change the number by tapping each

digit to increment the digit by one.

To reach 0 increment the digit till it

reaches 9 and then the next tap brings

it back to 0. (Tip: tap lower on the

numbers to avoid bumping ESC or

SET).

-

-

EMERGENCY

STOP

LESS MORE ADJ.

+

GAIN SENS.

ZzP

1000

EMERGENCY

STOP

SET

ZzP

ESC

Refer to step 4

Refer to step 3

Refer to step 2

13

NZ Freephone 0800 487 245

E sales@trailparts.co.nz

www.trailparts.co.nz

6Once you have the serial number of

your trailer mounted controller showing

press ‘SET’ to lock the In-cab controller

to that serial number.

7The In-cab controller will after a pause

emit 3 beeps and return to the normal

operation screen.

8Connect the trailer to vehicle and turn

on the headlights – check the head light

symbol loses the red cross to prove it is

connected to the trailer and functioning

as normal.

9If red cross doesn't go away, unplug

In-cab controller and select immediate

sleep if this screen appears.

Leave unplugged for approx 5 seconds.

Plug in the In-cab controller and if the

serial number on the fourth start up

screen does not match the number on

the trailer, start recoding process again.

-

-

EMERGENCY

STOP

LESS MORE ADJ.

+

GAIN SENS.

ZzP

4350

EMERGENCY

STOP

SET

ZzP

ESC

4352

EMERGENCY

STOP

SET

ZzP

ESC

Fourth start up screen Refer to step 8

Refer to step 6

Refer to step 5

VERSION 1.9

SERIAL 1000

EMERGENCY

STOP

ZzP

14

AU Freephone 1300 538 598

E sales@trailparts.com.au

www.trailparts.com.au

Warranty Terms and Conditions

LIMITED EIGHTEEN MONTH WARRANTY CONDITIONS

Trailequip Ltd warrants that the mechanical and

electrical components of the TRAILPARTS/CREDO

products as listed below will be free of defects in

material and workmanship for a period of eighteen

months from the original date of purchase.

Whilst we take every eort to ensure compatibility

with all known vehicles we cannot guarantee 100%

compatibility for all vehicles.

To obtain any warranty service, you must provide

Trailequip Ltd with proof of purchase, such as a copy of

your tax invoice or purchase receipt, which will include

a purchase date and the serial number of your product.

This warranty does not cover the removal or re-fitting

of the product.

TRAILPARTS/CREDO will, at its discretion, repair,

replace or refund the purchase price of a defective

product or component, provided you return the

defective product or component during the warranty

period, freight charges prepaid, to Trailequip Ltd or to

an authorized TRAILPARTS/CREDO dealer or stockist.

Attach your name, address, email address, telephone

number, a description of the problem, and a copy of

the tax invoice or purchase receipt listing the date of

purchase and the TRAILPARTS/CREDO serial number

of the defective product.

This warranty does not apply if the product has been

damaged by misuse, overloading, impact, modification,

improper installation. This warranty is void if any

TRAILPARTS/CREDO serial number has been removed,

altered, or defaced.

Please contact the below for

warranty service or support:

TRAILPARTS/CREDO

C/ Trailequip Ltd

2 Tuna Street

Dargaville 0310

New Zealand

International Phone: +649 439 5508

Australia Phone: 1300 538 598

Check battery is keeping well charged. A well charged battery should be at or above 13 volts.

This is particularly important if the trailer is left parked for extended periods of time. If the trailer

is not used for extended periods the battery should be removed every 2 months and charged to

ensure it does not become damaged. This can happen if the battery charge drops below

10.5 volts.

Check the trailer plug and vehicle socket to ensure they are not damaged and they give a

sound electrical connection. An intermittent or faulty connection could mean the brakes do not

function correctly.

If fitted with a hydraulic actuator make sure the fluid level remains suicient. The fluid should be

changed in line with general trailer service intervals.

If fitted with electric drums make sure they are kept properly adjusted and that the magnets and

linings are not excessively worn and are replaced in line with general trailer service intervals.

Maintenance and checks

15

NZ Freephone 0800 487 245

E sales@trailparts.co.nz

www.trailparts.co.nz

Incab Controller:

For serial numbers 1-2700 the serial number is located on the grey base of the controller or at the

bottom of the black plate on the back if it is a touch screen controller.

Serial numbers 2701- when the touch screen controller is first connected to power the serial number

is shown on the 4th screen that displays on start up.

Trailer Mount Controller:

Either engraved/stamped into the alloy base plate or etched into the front face of the trailer

mount controller.

Serial Number Locations

AU Freephone 1300 538 598

E sales@trailparts.com.au

www.trailparts.com.au

NZ Freephone 0800 487 245

E sales@trailparts.co.nz

www.trailparts.co.nz

This manual suits for next models

1

Table of contents