CREE-LED XLamp XQ Series User manual

SOLDERING & HANDLING

Cree LED / 4001 E. Hwy. 54, Suite 2000 / Durham, NC 27709 USA / +1.919.313.5330 / www.cree-led.com

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 1

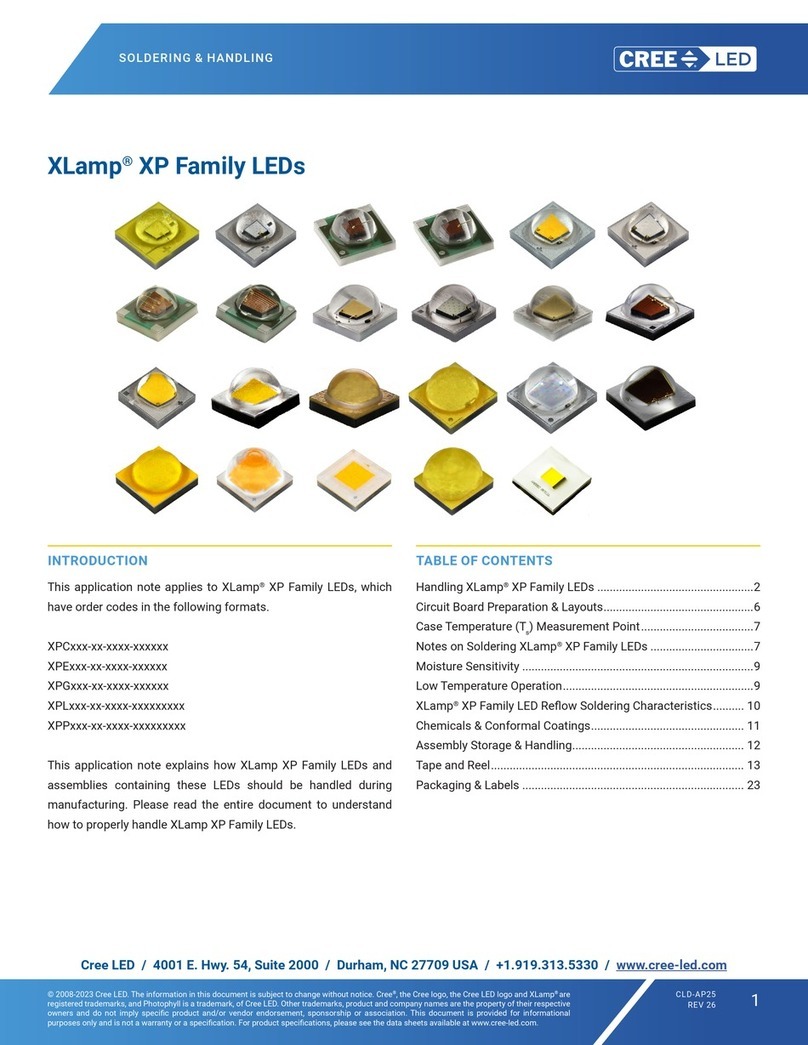

INTRODUCTION

This application note applies to XLamp®XQ Family LEDs, which

have order codes in the following format.

XQxxxx-xx-xxxx-xxxxxxxxx

This application note explains how XLamp XQ Family LEDs and

assemblies containing these LEDs should be handled during

manufacturing. Please read the entire document to understand

how to properly handle XLamp XQ Family LEDs.

TABLE OF CONTENTS

Handling XLamp®XQ Family LEDs ..................................................2

Circuit Board Preparation & Layouts................................................4

Case Temperature (Ts) Measurement Point....................................4

Notes on Soldering XLamp®XQ Family LEDs .................................5

Moisture Sensitivity ..........................................................................6

ESD.....................................................................................................6

XLamp® XQ Family LED Reow Soldering Characteristics.............7

Chemicals & Conformal Coatings....................................................8

Assembly Storage & Handling..........................................................9

Tape and Reel................................................................................. 10

Packaging & Labels ....................................................................... 13

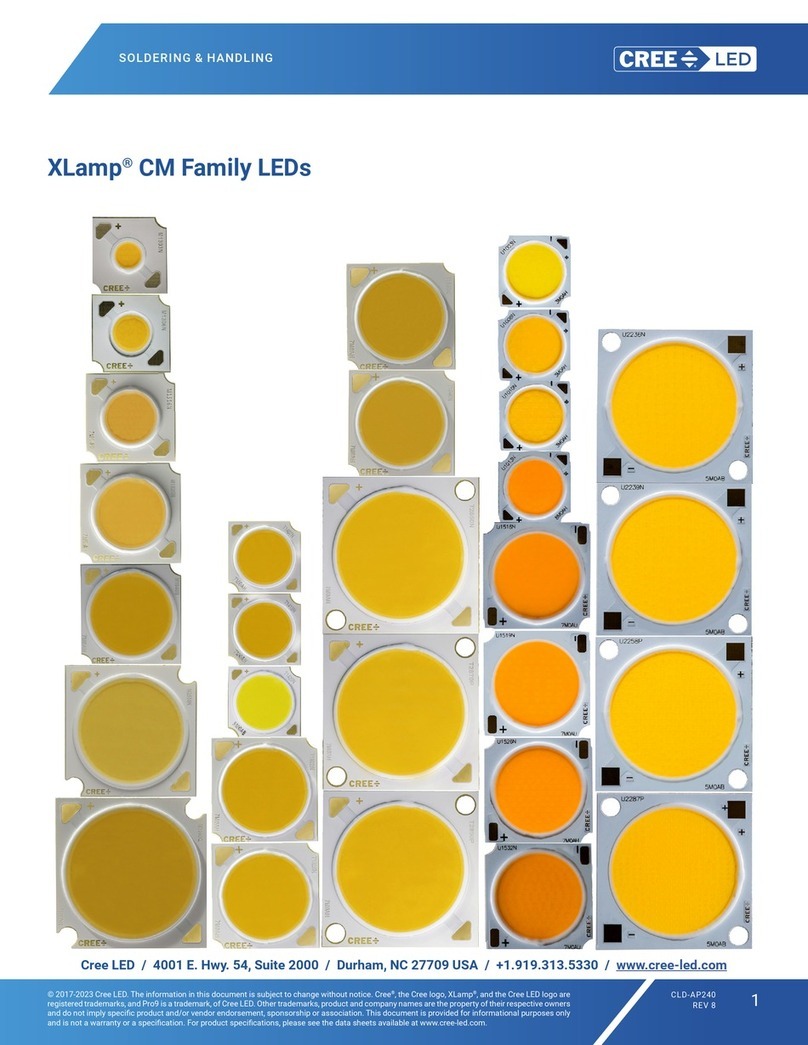

XLamp®XQ Family LEDs

XLAMP®XQ FAMILY LED SOLDERING & HANDLING

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 2

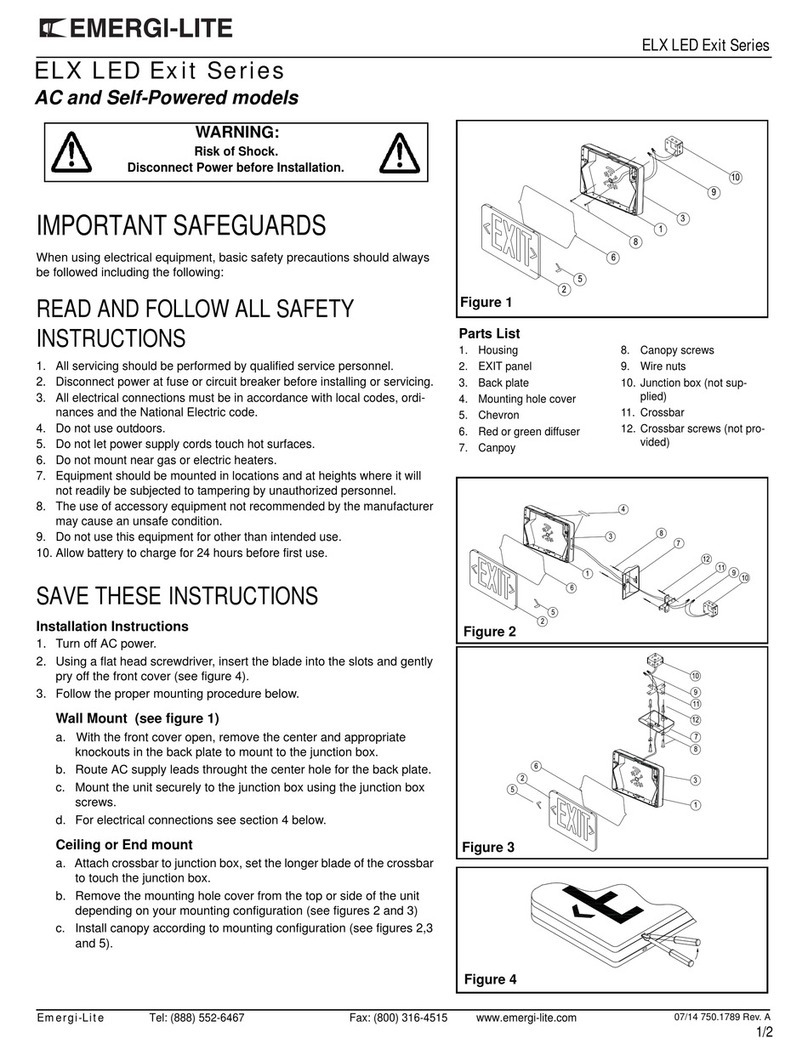

HANDLING XLAMP®XQ FAMILY LEDS

Manual Handling

Use tweezers to grab XLamp XQ Family LEDs at the base. Do not touch the lens with the tweezers. Do not touch the lens with ngers. Do

not push on the lens.

Do not apply more than 600g of shear force onto the lens. Excessive force on the lens could damage the LED.

Cree LED recommends the following at all times when handling XLamp XQ Family LEDs or assemblies containing these LEDs:

• Avoid putting excessive mechanical stress on the LED lens.

• Never touch the optical surface with ngers or sharp objects. The LED lens surface could be soiled or damaged, which would affect

the optical performance of the LED.

• Cree LED recommends always handling XQ family LEDs with appropriate ESD grounding.

• Cree LED recommends handling XQ family LEDs wearing clean, lint-free gloves.

Whenever possible, Cree LED recommends the use of a pick & place tool to remove XLamp XQ Family LEDs from the factory tape & reel

packaging.

P

CORRECT

X

WRONG

XLAMP®XQ FAMILY LED SOLDERING & HANDLING

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 3

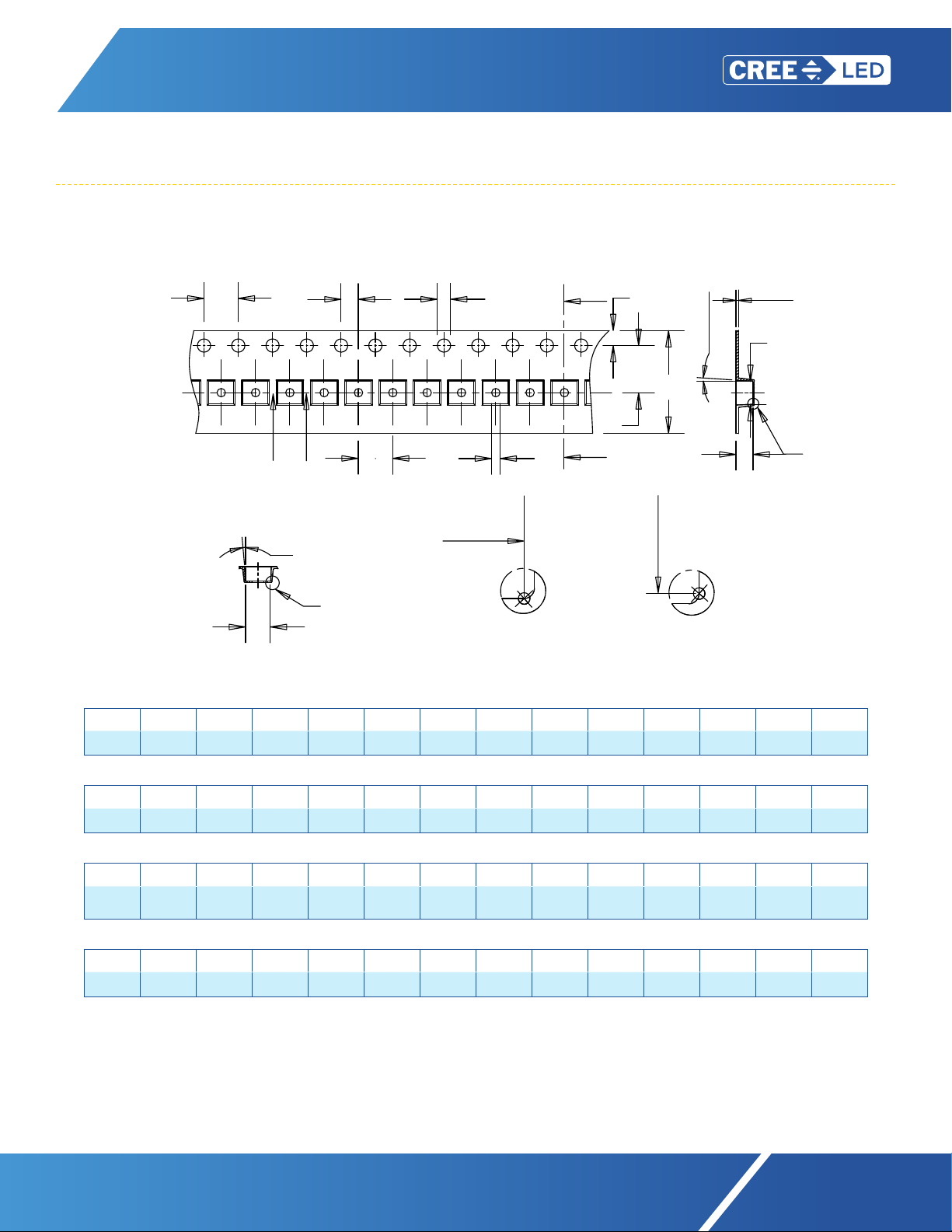

Pick & Place Nozzle

For pick and place nozzles coming into contact with silicone-covered LED components, Cree LED recommends nozzles be constructed

of non-metallic materials. Cree LED and several of Cree LED’s customers have had good success using nozzles fabricated from 95a

urethane. The following pick & place tools are specic to the XQ Family LEDs.

All dimensions in mm.

Measurement tolerances: .xxx = .001mm

2.700

.200

Ø .800

Ø 1.000

1.016

Ø0.0400

0.787

Ø0.0310

30°

J. Lancaster

A

B

C

D

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

SCALE

SIZE

CAD FILE:

DWG. NO.

A

SHEET

OF

REV.

DATE

APPROVALS

DRAWN

CHECKED

RESP ENG

MFG ENG

QUAL ENG

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

DECIMALS ANGLES

XX =

.002

XXX =

.001

MATERIAL

FINISH

32

DO NOT SCALE DRAWING

ITEM

NO.

PART OR

IDENTIFYING NO.

NOMENCLATURE

OR DESCRIPTION

MATERIAL

SPECIFICATION

QTY

REQD

PARTS LIST

1

2

3

4

5

6

7

8

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF

COUNT ON TOOLS, INC. ANY REPRODUCTION IN PART OR WHOLE WITHOUT

THE WRITTEN PERMISSION OF COUNT ON TOOLS, INC. IS PROHIBITED.

A

B

C

D

1

2

3

4

5

6

7

8

XXXX =

.0002

1/2

REVISIONS

Rev.

DESCRIPTION

DATE

APPROVED

A

PRINT RELEASE

JDL

11/6/2014

2013-1565 Cree XQ LED tip

11/6/2014

Thursday, November 06, 2014 2:52:10 PM

1.016

Ø0.0400

0.787

Ø0.0310

30°

J. Lancaster

A

B

C

D

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

SCALE

SIZE

CAD FILE:

DWG. NO.

A

SHEET

OF

REV.

DATE

APPROVALS

DRAWN

CHECKED

RESP ENG

MFG ENG

QUAL ENG

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

DECIMALS ANGLES

XX =

.002

XXX =

.001

MATERIAL

FINISH

32

DO NOT SCALE DRAWING

ITEM

NO.

PART OR

IDENTIFYING NO.

NOMENCLATURE

OR DESCRIPTION

MATERIAL

SPECIFICATION

QTY

REQD

PARTS LIST

1

2

3

4

5

6

7

8

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF

COUNT ON TOOLS, INC. ANY REPRODUCTION IN PART OR WHOLE WITHOUT

THE WRITTEN PERMISSION OF COUNT ON TOOLS, INC. IS PROHIBITED.

A

B

C

D

1

2

3

4

5

6

7

8

XXXX =

.0002

1/2

REVISIONS

Rev.

DESCRIPTION

DATE

APPROVED

A

PRINT RELEASE

JDL

11/6/2014

2013-1565 Cree XQ LED tip

11/6/2014

Thursday, November 06, 2014 2:52:10 PM

1.016

Ø0.0400

0.787

Ø0.0310

30°

J. Lancaster

A

B

C

D

CAD GENERATED DRAWING,

DO NOT MANUALLY UPDATE

SCALE

SIZE

CAD FILE:

DWG. NO.

A

SHEET

OF

REV.

DATE

APPROVALS

DRAWN

CHECKED

RESP ENG

MFG ENG

QUAL ENG

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

DECIMALS ANGLES

XX =

.002

XXX =

.001

MATERIAL

FINISH

32

DO NOT SCALE DRAWING

ITEM

NO.

PART OR

IDENTIFYING NO.

NOMENCLATURE

OR DESCRIPTION

MATERIAL

SPECIFICATION

QTY

REQD

PARTS LIST

1

2

3

4

5

6

7

8

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF

COUNT ON TOOLS, INC. ANY REPRODUCTION IN PART OR WHOLE WITHOUT

THE WRITTEN PERMISSION OF COUNT ON TOOLS, INC. IS PROHIBITED.

A

B

C

D

1

2

3

4

5

6

7

8

XXXX =

.0002

1/2

REVISIONS

Rev.

DESCRIPTION

DATE

APPROVED

A

PRINT RELEASE

JDL

11/6/2014

2013-1565 Cree XQ LED tip

11/6/2014

Thursday, November 06, 2014 2:52:10 PM

XLAMP®XQ FAMILY LED SOLDERING & HANDLING

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 4

CIRCUIT BOARD PREPARATION & LAYOUTS

Printed circuit boards (PCBs) should be prepared and/or cleaned according to the manufacturer’s specications before placing or

soldering XLamp XQ Family LEDs onto the PCB.

The diagram below shows the recommended PCB solder pad layout for XLamp XQ Family LEDs.

All dimensions in mm.

Measurement tolerance: .xx = .±13mm

High Density & High Intensity

CASE TEMPERATURE (TS) MEASUREMENT POINT

XLamp XQ Family LED case temperature (Ts) should be measured on the PCB surface, as close to the LED’s base as possible. This

measurement point is shown in the pictures below. Connect the thermocouple at a point where the voltage potential is below the rating

for the meter. XQ Family LEDs do not have an isolated thermal pad and care should be exercised to avoid bridging the anode and cathode

together, which may occur if the thermocouple bead is large. Cree LED recommends using a 36 AWG (0.01267mm2) thermocouple wire

for Ts measurements.

XQ-A XQ-E High Density XQ-E High Intensity

It is not required to use a solder footprint for the thermal pad that is larger than the XLamp XQ Family LED itself. In testing, Cree LED has

found such a solder pad to have insignicant impact on the resulting Ts measurement.

1.60

1.60

OPTICAL MODEL ORIGIN

OPTICAL MODEL ORIGIN

0.38

1.60

R0.936

1.50

0.60 0.60

0.30

1.50

ANODE

SIDE

CATHODE

SIDE

1.50

1.50

0.60

0.30

1.20

0.50

0.40

1.40

RECOMMENDED STENCIL OPENING

RECOMMENDED PCB FOOTPRINT

BOTTOM VIEW

SIDE VIEW

TOP VIEW

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

A

© 2021 CreeLED, Inc. a subsidiary

of SMART Global Holdings, Inc.

THIRD ANGLE PROJECTION

DRAWING FILENAME

2610-160003A XQE XQA HD

CreeLED, Inc.

4400 SILICON DR

DURHAM, NC 27703

FINISH

A

INITIAL DRAWING RELEASED

B

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

CREE LED. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT

WRITTEN PERMISSION OF CREE LED

IS PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

REV

DESCRIPTION

APPLICATION

DIMENSIONS ARE IN MILLIMETERS

TOLERANCES:

• ANGULAR: MACH

0.5° BEND

1°

• ONE PLACE DECIMAL

0.5

• TWO PLACE DECIMAL

0.05

• INSIDE BEND RADII EQUAL

MATERIAL

• MACHINE/CASTING RADII 0.50

• RADII AND DIA:

0.10

INTERPRET GEOMETRIC

TOLERANCING PER:

MATERIAL

FINISH

MATERIAL

DRAWN

CHECKED

ENG APPR.

MFG APPR.

Q.A.

DATE

NAME

TITLE:

SIZE

C

DWG. NO.

REV

WEIGHT:

SCALE: 50:1

UNLESS OTHERWISE SPECIFIED:

TLING

24NOV21

2610-160003

XQE XQAHD

SHEET 1 OF 1

2

1

UPDATE TO OPTICAL MODEL ORIGIN

B

Recommended PCB Footprint Recommended Stencil Opening

XLAMP®XQ FAMILY LED SOLDERING & HANDLING

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 5

NOTES ON SOLDERING XLAMP®XQ FAMILY LEDS

XLamp XQ Family LEDs are designed to be reow soldered to a PCB. Reow soldering may be done by a reow oven or by placing the PCB

on a hotplate and following the reow soldering prole listed on page 7.

Do not wave solder XLamp XQ Family LEDs. Do not hand solder XLamp XQ Family LEDs.

Solder Paste Type

Cree LED strongly recommends using “no clean” solder paste with XLamp XQ Family LEDs so that cleaning the PCB after reow soldering

is not required. Cree LED uses Kester®R276 solder paste internally.

Cree LED recommends the following solder paste compositions: SnAgCu (tin/silver/copper) and SnAg (tin/silver).

Solder Paste Thickness

The choice of solder and the application method will dictate the specic amount of solder. For the most consistent results, an automated

dispensing system or a solder stencil printer is recommended. Cree LED has seen positive results using solder thickness that results in a

4-mil (102-μm) bond line, i.e., the solder joint thickness after reow soldering.

X

WRONG

P

CORRECT

P

CORRECT

P

CORRECT

X

WRONG

XLAMP®XQ FAMILY LED SOLDERING & HANDLING

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 6

After Soldering

After soldering, allow XLamp XQ Family LEDs to return to room temperature before subsequent handling. Handling of the device, especially

around the lens, before cooling could result in damage to the LED.

Cree LED recommends verifying the solder process by checking the consistency of the solder bond of several trial PCBs after reow. This

can be done by X-ray or by shearing selected devices from the circuit board. The solder should appear completely re-owed (no solder

grains evident). The solder areas should show minimum evidence of voids on the backside of the package and the PCB.

Cleaning PCBs After Soldering

Cree LED recommends using “no clean” solder paste so that ux cleaning is not necessary after reow soldering. If PCB cleaning is

necessary, Cree LED recommends the use of isopropyl alcohol (IPA).

Do not use ultrasonic cleaning.

MOISTURE SENSITIVITY

Cree LED recommends keeping XLamp LEDs in the provided, resealable moisture-barrier packaging (MBP) until immediately prior to

soldering.

Unopened MBPs that contain XLamp LEDs do not need special storage for moisture sensitivity. Bare XLamp LEDs have a storage

temperature range of -40°C to 100°C. However, the MBP, reel, tape and box have a more limited storage temperature range.

Once the MBP is opened, XLamp XQ Family LEDs may be stored as MSL 1 per JEDEC J-STD-033, meaning they have unlimited oor life in

conditions of ≤ 30 ºC/85% relative humidity (RH). Regardless of storage condition, Cree LED recommends sealing any unsoldered LEDs

in the

original MBP.

ESD

XQ-A LEDs have an ESD class rating of 1. Cree LED recommends following the JESD 625 standard, “Requirements for Handling

Electrostatic-Discharge-Sensitive (ESDS) Devices,” when handling XQ-A LEDs or any LED component. Passing a static charge through an

electrostatic-discharge-sensitive device can result in performance degradation or catastrophic failure of the device.

XLAMP®XQ FAMILY LED SOLDERING & HANDLING

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 7

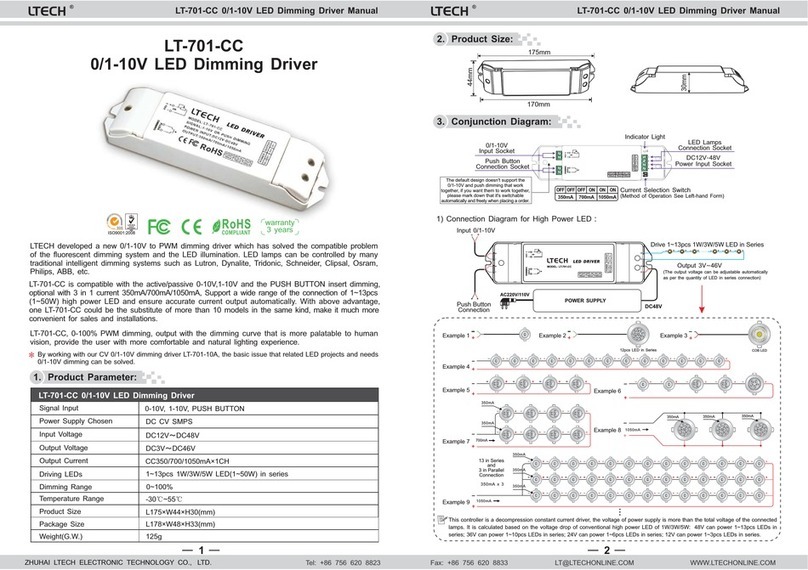

XLAMP®XQ FAMILY LED REFLOW SOLDERING CHARACTERISTICS

In testing, Cree LED has found XLamp XQ Family LEDs to be compatible with JEDEC J-STD-020C, using the parameters listed below. As

a general guideline, Cree LED recommends that users follow the recommended soldering prole provided by the manufacturer of the

solder paste used, and therefore it is the lamp or luminaire manufacturer’s responsibility to determine applicable soldering requirements.

Note that this general guideline may not apply to all PCB designs and congurations of reow soldering equipment.

Prole Feature Lead-Free Solder

Average Ramp-Up Rate (Tsmax to Tp)1.2°C/second

Preheat: Temperature Min (Tsmin) 120 °C

Preheat: Temperature Max (Tsmax)170 °C

Preheat: Time (tsmin to tsmax) 65-150 seconds

Time Maintained Above: Temperature (TL)217 °C

Time Maintained Above: Time (tL) 45-90 seconds

Peak/Classication Temperature (Tp) 235 - 245 °C

Time Within 5°C of Actual Peak Temperature (tp) 20-40 seconds

Ramp-Down Rate 1 - 6 °C/second

Time 25 °C to Peak Temperature 4 minutes max.

Note: All temperatures refer to topside of the package, measured on the package body surface.

IPC/JEDEC J-STD-020C

TP

TL

Temperature

Time

t 25˚C to Peak

Preheat

ts

tL

tP

25

Ramp-down

Ramp-up

Critical Zone

TL to TP

Tsmax

Tsmin

XLAMP®XQ FAMILY LED SOLDERING & HANDLING

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 8

CHEMICALS & CONFORMAL COATINGS

Below are representative lists of chemicals and materials to be used or avoided in LED manufacturing activities. For a complete and current

list of recommended chemicals, conformal coatings and harmful chemicals consult Cree LED’s Chemical Compatibility Application Note.

The video at www.youtube.com/watch?v=t24bf9D_1SA illustrates the process Cree LED has developed for testing the compatibility of

chemicals and materials with LEDs. You should also consult your regional Cree LED Field Applications Engineer.

Recommended Chemicals

In testing, Cree LED has found the following chemicals to be safe to use with XLamp XQ Family LEDs.

• Water

• Isopropyl alcohol (IPA)

Chemicals Tested as Harmful

In general, subject to the specics in Cree LED’s Chemical Compatibility Application Note, Cree LED has found certain chemicals to be

harmful to XLamp XQ Family LEDs. Cree LED recommends not using these chemicals anywhere in an LED system containing XLamp XQ

Family LEDs. The fumes from even small amounts of the chemicals may damage the LEDs.

• Chemicals that might outgas aromatic hydrocarbons (e.g., toluene, benzene, xylene)

• Methyl acetate or ethyl acetate (i.e., nail polish remover)

• Cyanoacrylates (i.e., “Superglue”)

• Glycol ethers (including Radio Shack®Precision Electronics Cleaner - dipropylene glycol monomethyl ether)

• Formaldehyde or butadiene (including Ashland®PLIOBOND®adhesive)

Hermetically Sealing Luminaires

For proper LED operation and to avoid potential lumen depreciation and/or color shift, LEDs of all types must operate in an environment

that contains oxygen. Simply allowing the LEDs to ventilate to air is sufcient; no extraordinary measures are required. Hermetically

sealing LEDs in an enclosed space is not recommended.

XLAMP®XQ FAMILY LED SOLDERING & HANDLING

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 9

ASSEMBLY STORAGE & HANDLING

Do not stack PCBs or assemblies containing XLamp XQ Family LEDs so that anything rests on the LED lens. Force applied to the LED lens

may result in the lens being knocked off. PCBs or assemblies containing XLamp XQ Family LEDs should be stacked in a way to allow at

least 1cm clearance above the LED lens.

Do not use bubble wrap directly on top of XLamp XQ Family LEDs. Force from the bubble wrap can potentially damage the LED.

X

WRONG

P

CORRECT

P

CORRECT

XLAMP®XQ FAMILY LED SOLDERING & HANDLING

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 10

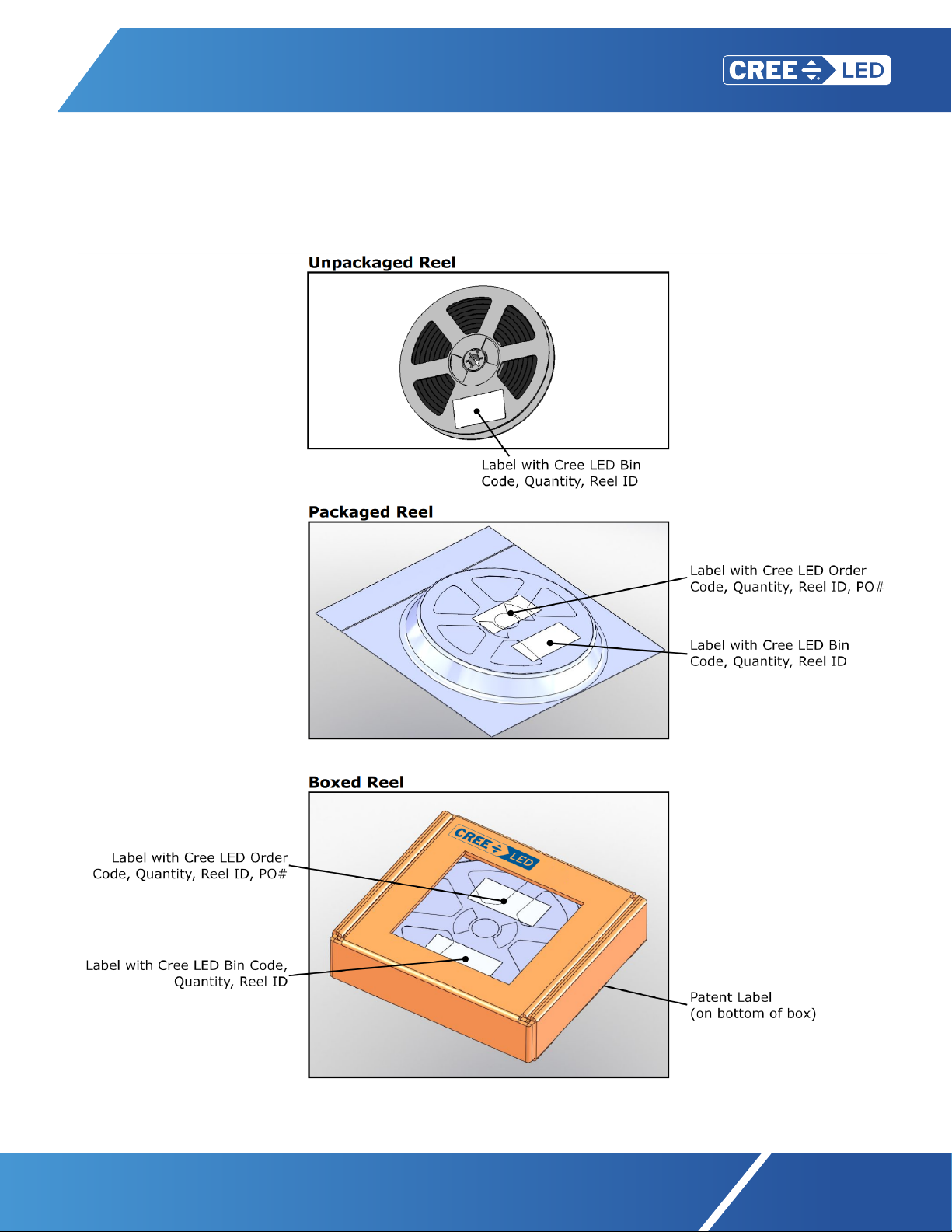

TAPE AND REEL

All Cree LED carrier tapes conform to EIA-481D, Automated Component Handling Systems Standard.

Except as noted, all dimensions in mm [in].

Measurement tolerances unless indicated otherwise: .xx = ±.15 mm

XQ-A High Density White and Colors

Item Ao Bo Ko Po P1 P2 T E F Do D1 W R

Dim. 1.75 1.75 1.60 4.00 4.00 2.00 0.30 1.75 3.50 1.50 0.70 8.00 5°

XQ-E High Density White and Colors (except PC Amber)

Item Ao Bo Ko Po P1 P2 T E F Do D1 W R

Dim. 1.85 1.85 1.65 4.00 4.00 2.00 0.30 1.75 3.50 1.50 1.00 8.00 3°

XQ-E High Density PC Amber

Item Ao Bo Ko Po P1 P2 T E F Do D1 W 10Po

Dim. 1.85 1.85 1.9 4.00 4.00 2.00 0.30 1.75 3.50 1.50 1.00 8.00 40.0

±0.20

XQ-E High Intensity

Item Ao Bo Ko Po P1 P2 T E F Do D1 W R

Dim. 1.85 1.85 1.20 4.00 4.00 2.00 0.30 1.75 3.50 1.50 1.00 8.00 3°

D1

Ao

P1

P2

Po Do

Bo

Ko

W

F

E

1) All Cree LED carrier tapes conform to EIA-481D, Automated Component handling Systems Standard

NOTICE

ITEM

Dim.

FDo

Ao

A-A SECTION

ITEM

Dim.

Bo

D1 W

DETAIL"I"

Ko Po

R

"I"

A

A

DETAIL"H"

P2

P1 TE

B

B-B SECTION

"H"

T

Ao (on a place in the

bottom of the corner

radii)

Bo (on a place in the

bottom of the corner

radii)

R

R

Anode side

2) Measurement tolerances unless indicated otherwise: .xx = ±.15 mm

2402-M022 XML3

5.40 5.40 3.35 4.00 8.00 2.00 0.36 1.75

5.50 1.50 1.50 12.00 3deg

XLAMP®XQ FAMILY LED SOLDERING & HANDLING

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 11

TAPE AND REEL - CONTINUED

XQ-A & XQ-E High Density

7”

13 mm

Cover Tape

Pocket Tape

END START

Feed Direction

Feed Direction

Trailer

Min. 160 mm empty pockets

sealed with tape

Loaded Pockets

2000 Lamps

Leader

Min. 400 mm empty pockets

with min. 100 mm sealed

XLAMP®XQ FAMILY LED SOLDERING & HANDLING

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 12

TAPE AND REEL - CONTINUED

XQ-E High Intensity

7”

13 mm

Cover Tape

Pocket Tape

END START

Feed Direction

Feed Direction

Trailer

Min. 160 mm empty pockets

sealed with tape

Loaded Pockets

3000 Lamps

Leader

Min. 400 mm empty pockets

with min. 100 mm sealed

XLAMP®XQ FAMILY LED SOLDERING & HANDLING

© 2013-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®and the Cree LED logo

are registered trademarks of Cree LED. Other trademarks, product and company names are the property of their respective owners and do not imply

specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only and is not a

warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP115

REV 7 13

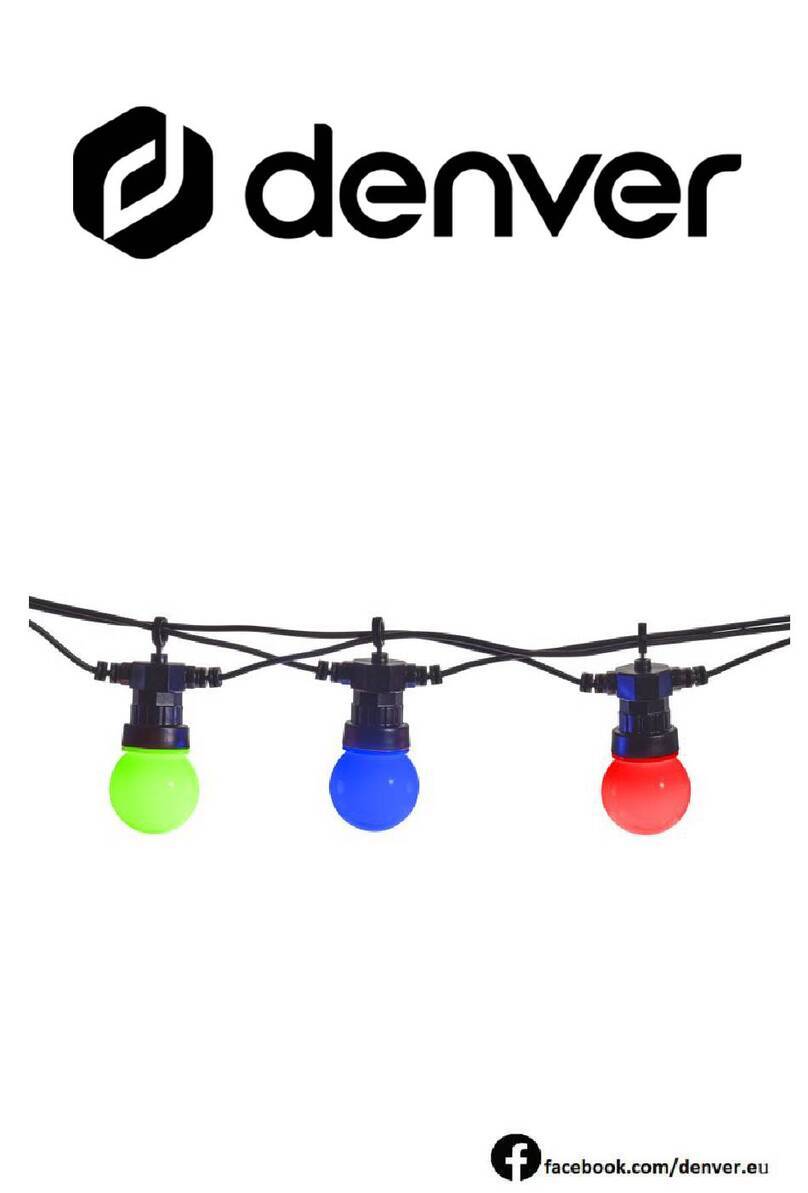

PACKAGING & LABELS

The diagrams below show the packaging and labels Cree LED uses to ship XLamp XQ Family LEDs. XLamp XQ Family LEDs are shipped

in tape loaded on a reel. Each box contains only one reel in a moisture barrier bag.

Table of contents

Other CREE-LED Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Magnum

Magnum MLT3060K operating manual

Denver

Denver SLP-515 user manual

Prilux

Prilux ACTIVA CALPE quick start guide

Cooper Lighting

Cooper Lighting SURE-LITES HR87 Series installation instructions

Larson Electronics

Larson Electronics EPL-DL-12-25-1523 instruction manual

RPS Studio

RPS Studio RS-SP300 instructions