CREE-LED XLamp CM Series User manual

SOLDERING & HANDLING

Cree LED / 4001 E. Hwy. 54, Suite 2000 / Durham, NC 27709 USA / +1.919.313.5330 / www.cree-led.com

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 1

XLamp®CM Family LEDs

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 2

TABLE OF CONTENTS

Introduction ............................................................................................................................................................................................................ 3

Handling XLamp®CM Family LEDs ...................................................................................................................................................................... 3

Heat Sink, Layout, Thermal Interface.................................................................................................................................................................... 4

Case Temperature Measurement Point................................................................................................................................................................ 5

Light-Emitting Surface Temperature Measurement ............................................................................................................................................ 5

Notes on Soldering XLamp®CM Family LEDs ..................................................................................................................................................... 6

Low Temperature Operation.................................................................................................................................................................................. 7

Notes on CM Family LED Connectors .................................................................................................................................................................. 7

Chemicals & Conformal Coatings......................................................................................................................................................................... 8

Handling ................................................................................................................................................................................................................. 9

Packaging............................................................................................................................................................................................................. 10

2D Barcode Format.............................................................................................................................................................................................. 23

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 3

INTRODUCTION

This application note applies to XLamp®CM family LEDs, which have order codes in the following format:

CMxxxxx-xxxx-xxxxxxxxx

This application note explains how XLamp CM family LEDs and assemblies containing these LEDs should be handled during manufacturing.

Please read this entire document to understand how to properly handle XLamp CM family LEDs.

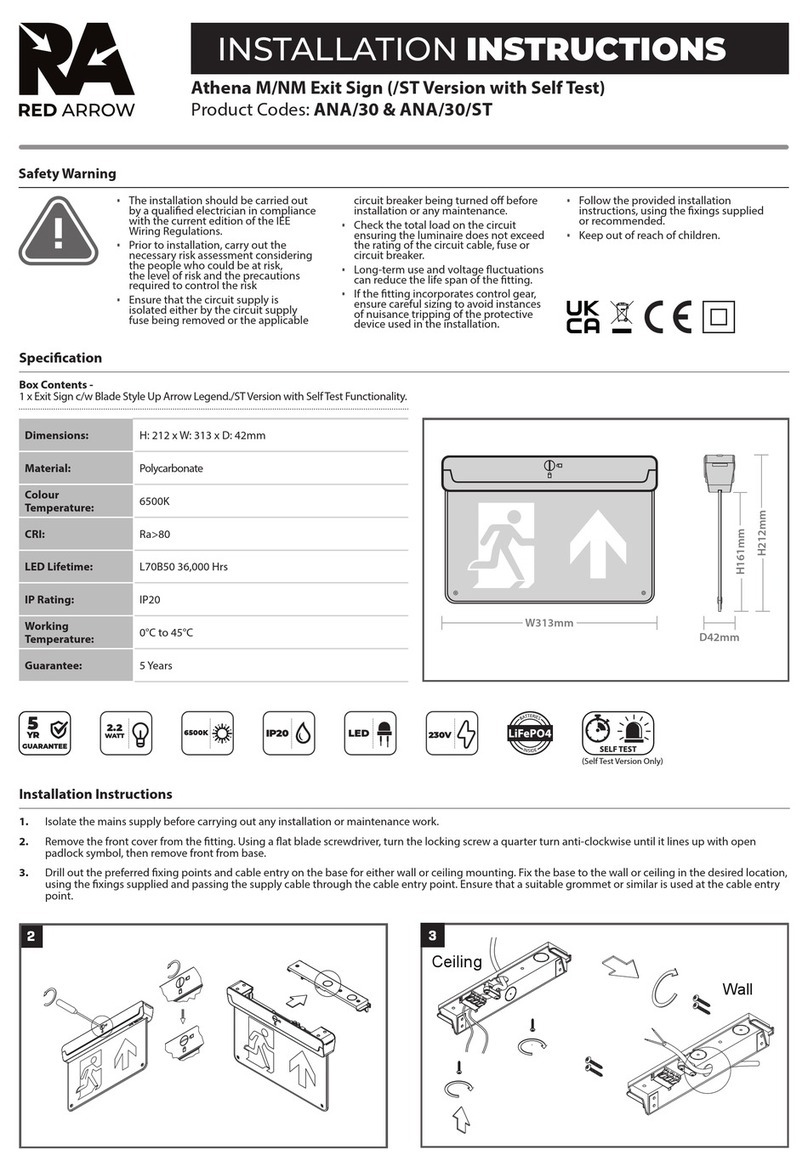

HANDLING XLAMP®CM FAMILY LEDS

In general, CM family LEDs are attached directly to a heat sink via screws or a connector and discrete wires are used to deliver power to

the LED, as illustrated below. A thermal interface material (TIM) must be applied between the CM family LED and the heat sink to properly

maintain thermal performance.

Cree LED recommends the following at all times when handling XLamp CM family LEDs or assemblies containing XLamp CM family LEDs:

• Avoid putting mechanical stress on the LED.

• Never touch the optical surface with ngers or sharp objects. The LED surface could be soiled or damaged, which could affect the

optical performance of the LED

• Cree LED recommends always handling CM family LEDs with appropriate ESD grounding.

• Cree LED recommends handling CM family LEDs wearing clean, lint-free gloves.

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 4

Manual Handling

Do not touch the lens with ngers. Do not push on the lens.

When using tweezers to handle XLamp CM family LEDs, do not touch the lens with the tweezers.

HEAT SINK, LAYOUT, THERMAL INTERFACE

To insure effective thermal management for CM family LEDs, Cree LED recommends the CM family LED be attached to an appropriately

sized heat sink, depending on drive current and intended operating environment. Refer to the CM family LED data sheet for the maximum

case to ambient temperature thermal resistance that must be observed to ensure the CM family LED operates at or below its maximum

rated case temperature (Tc).

Attaching a CM family LED to a heat sink is most often accomplished by inserting a pad of TIM, thermally conductive epoxy, or thermal

grease between the CM family LED and heat sink and is strongly recommended. For best thermal results, the TIM thickness should be

kept to a minimum while assuring there are no voids. Good thermal conductivity is an important ingredient in a successful LED-based

lamp or luminaire and is ignored at one’s peril. The following formula shows how the factors that inuence thermal resistance (Rth) are

related.

Rth = Thickness / (Conductivity * Area)

P

CORRECT

X

WRONG

X

WRONG

P

CORRECT

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 5

Cree LED has used Arctic Silver®adhesive and Timtronics Silver Ice thermal grease in reference designs with good results. There are a

number of TIMs available; some are listed in the Thermal Management of XLamp LEDs application note. There are a number of factors

in the decision to use a particular TIM including, but not limited to, cost, availability, ease of use and manufacturing techniques, and

recommending a specic TIM for any lighting application is out of the scope of this document.

Cree LED recommends securing CM family LEDs to a heat sink using the structure of the lamp or luminaire, thermally conductive epoxy,

which is discussed previously in this section, or an LED holder, which is discussed in the LED Connectors section. Regardless of attachment

method, Cree LED recommends following the manufacturer’s directions for application to achieve maximum thermal performance. Use

caution when securing CM family LEDs over relatively thick TIMs, such as thermal pads, to avoid catastrophic mechanical damage to the

LED.

CM family LEDs and thermal interface materials are secured either by screws through the pair of diagonally opposite screw holes or

by the use of an LED holder (see the section on LED Connectors). When using the screw holes to secure CM family LEDs, Cree LED

recommends #4 (/40) or M2.5 screws. Excessive torque may result in damage to the LED array. Factors that determine the appropriate

screw torque are the thickness, size and type of thermal interface material and the planarity of these materials as well as that of the heat

sink. Refer to the illustration on page 2 for the proper mounting method. The amount of torque that can safely be applied to mounting

screws is approximately 45newton‑centimeters (4inch‑pounds). To prevent loosening of screws during vibration or thermal cycles, Cree

LED recommends non-conductive lock washers or self-locking fasteners. Cree LED DOES NOT RECOMMEND the use of chemical thread

lockers to secure CM family LEDs as several of these compounds have been shown to be chemically incompatible with LEDs.

CASE TEMPERATURE MEASUREMENT POINT

XLamp CM family LED case temperature can be measured at either solder pad. Cree LED recommends attaching the thermocouple with

conductive epoxy.

LIGHT-EMITTING SURFACE TEMPERATURE MEASUREMENT

The light‑emitting surface (LES) of XLamp CM family LEDs is dened as the central region of the LED, which contains the encapsulated

chip array as shown below.

LES temperatures are measured using an infrared (IR) thermal imaging camera. IR cameras detect the infrared wavelength thermal

emission from an object’s surface, which is correlated to the surface temperature using the surface’s thermal emissivity. CM family LES

thermal emissivity is 0.98. Please consult the IR camera’s operating instructions for proper measurement settings and guidelines. Factors

that can affect the accuracy of IR thermal measurement include the distance to the object’s surface, image focus and ambient conditions.

LES

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 6

Making accurate LES temperature measurements requires the IR camera to have

a direct line‑of‑sight view of the LES. Remove all lenses, diffusers and bafes

that cover the LES before making a measurement. Measure LES temperatures

when the LED has reached thermal equilibrium under steady-state operation. An

example IR thermal image of a CM family LED in a luminaire is shown at the right.

The LES temperature at the position of the crosshairs is reported in the upper left

corner of the image.

Cree LED recommends a maximum LES temperature of 140°C to ensure optimal

LED lifetime.

NOTES ON SOLDERING XLAMP®CM FAMILY LEDS

XLamp CM family LEDs are designed for electrical connection using wire-attach soldering or a connector. Cree LED recommends the use

of a connector to help ensure proper clamping force is applied to the CM family LED and to help prevent damage that can occur during

wire-attach soldering.

Cree LED makes the following recommendations to get the maximum benet from wire‑attach soldering:

• Do not pre-heat CM family LEDs before soldering.

• Use “no clean” lead-free solder.

• Use a temperature‑controlled soldering iron having a minimum 60W of power to help ensure the temperature of the tip remains

stable during soldering.

• Use a solder tip with a width of 2.6mm (0.1in) or greater.

• Ensure that solder tip temperature measures and does not exceed 380°C.

• Perform soldering (including pre-tinning) on a thermally non-conductive surface.

• Ensure a contact time with bond pads of 3 seconds or less.

• Return CM family LEDs to room temperature after each soldering step. It is imperative that this recommendation be followed. Cree

LED recommends placing the CM family LED on a thermally conductive surface such as an aluminum block for at least 10 seconds

to return the LED to room temperature.

The following example hand-soldering steps are based on the above recommendations.

1. Start from ambient temperature conditions.

2. Pre‑tin the rst bond pad on a thermally non‑conductive surface, allowing no more than a 3‑second maximum contact time.

3. Let the LED return to room temperature.

4. Pre-tin the second bond pad on a thermally non-conductive surface, allowing no more than a 3-second maximum contact time.

5. Let the LED return to room temperature.

6. Pre‑tin the rst wire.

7. Pre-tin the second wire.

8. Solder the rst wire to the rst bond pad, allowing no more than a 3‑second maximum contact time.

9. Let the LED return to room temperature.

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 7

10. Solder the second wire to the second bond pad, allowing no more than a 3-second maximum contact time.

11. Let the LED return to room temperature before subsequent handling.

Use caution when soldering and handling CM family LEDs to avoid damaging the LEDs. Solder reworking should be kept to a minimum

because of the potential for solder-pad lifting and damage to the LED from multiple applications of high heat from a soldering iron.

Additionally, repetitive soldering introduces potential for solder ux to build up around the solder pads, which can cause long‑term

degradation if not properly removed.

Solder Type

Cree LED strongly recommends using “no clean” solder with XLamp CM family LEDs so that cleaning the PCB after soldering is not

required.

Cree LED recommends the following solder compositions: SnAgCu (tin/silver/copper) and SnAg (tin/silver).

LOW TEMPERATURE OPERATION

The minimum operating temperature of these XLamp LED components is ‑40°C. To maximize lifetime, Cree LED recommends avoiding

applications where the lamps are cycled on and off more than 10,000 cycles at temperatures below 0°C.

NOTES ON CM FAMILY LED CONNECTORS

A number of rms have developed connectors to simplify the mechanical and electrical attachment of CM family LEDs. CM family LEDs

have been designed to be compatible with existing holders for CX family of LEDs. Cree LED has found all sampled CX family connectors

tested to be compatible with CM family LEDs. Customers are encouraged to perform electrical and thermal tests to verify compatibility

with connectors.

If CM family LEDs are to be attached with wired leads, the horizontal and vertical pull force of the attached solder leads should not exceed

1000g.

P

CORRECT

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 8

CHEMICALS & CONFORMAL COATINGS

Below are representative lists of chemicals and materials to be used or avoided in LED manufacturing activities. For a complete and current

list of recommended chemicals, conformal coatings and harmful chemicals consult Cree LED’s Chemical Compatibility Application Note.

For assistance with the process for testing the compatibility of chemicals and materials with LEDs, consult your regional Cree LED Field

Applications Engineer.

Recommended Chemicals

In testing, Cree LED has found the following chemicals to be safe to use with XLamp CM Family LEDs.

• Water

• Isopropyl alcohol (IPA)

Chemicals Tested as Harmful

In general, subject to the specics in Cree LED’s Chemical Compatibility Application Note, Cree LED has found certain chemicals to be

harmful to XLamp CM Family LEDs. Cree LED recommends not using these chemicals anywhere in an LED system containing XLamp CM

Family LEDs. The fumes from even small amounts of the chemicals may damage the LEDs.

• Chemicals that might outgas aromatic hydrocarbons (e.g., toluene, benzene, xylene)

• Methyl acetate or ethyl acetate (i.e., nail polish remover)

• Cyanoacrylates (i.e., “Superglue”)

• Glycol ethers (including Radio Shack®Precision Electronics Cleaner - dipropylene glycol monomethyl ether)

• Formaldehyde or butadiene (including Ashland®PLIOBOND®adhesive)

Hermetically Sealing Luminaires

For proper LED operation and to avoid potential lumen depreciation and/or color shift, LEDs of all types must operate in an environment

that contains oxygen. Simply allowing the LEDs to ventilate to air is sufcient; no extraordinary measures are required. Hermetically

sealing LEDs in an enclosed space is not recommended.

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 9

HANDLING

Do not stack assemblies containing XLamp CM family LEDs so that anything rests on the LED lens. Force applied to the LED lens may

result in the lens being damaged. Assemblies containing XLamp CM family LEDs should be stacked in a way to allow at least 2-cm

clearance above the LED.

Do not use bubble wrap directly on top of the XLamp CM family LEDs. Force transferred through the bubble wrap can potentially damage

the LED.

P

CORRECT

X

WRONG

X

WRONG

P

CORRECT

PACKAGING

Drawing dimensions are in inches.

Tolerance: ±.13mm

CMA1303, CMA1306, CMA1306 Pro9™

CMA1516, CMA1516 Pro9

SIZE

TITLE

OF

REV.

SHEET

C

DRAWING NO.

DATE

DATE

DATE

CHECK

FINAL PROTECTIVE FINISH

MATERIAL

APPROVED

DRAWN BY

THIRD ANGLE PROJECTION

SCALE

A

B

C

D

123456

6 5 4 3 2 1

A

B

C

D

Phone (919) 313-5300

Fax (919) 313-5558

4600 Silicon Drive

Durham, N.C 27703

UNAUTHORIZED PERSON WITHOUT

THE WRITTEN CONSENT

MAY NOT BE COPIED, REPRODUCED OR DISCLOSED TO ANY

CONFIDENTIAL INFORMATION OF CREE, INC. THIS PLOT

CONTAINED WITHIN ARE THE PROPRIETARY AND

CREE CONFIDENTIAL. THIS PLOT AND THE INFORMATION

OF CREE INC.

NOTICE

X .5

.XXX .25

.XX .75

.X 1.5

FOR SHEET METAL PARTS ONLY

.XX

.25

.XXX .125

X .5

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN

MILLIMETERS AND AFTER FINISH.

TOLERANCE UNLESS SPECIFIED:

SURFACE FINISH:

1.6

5.875

5.875

.875

.875

R.375

2/28.000

A

2610-00119

CMT1420 MARKETING SPEC

05/08/12D. CRONIN

REVISONS

REV DESCRIPTION BY DATE APP'D

LABEL WITH CREE BIN

CODE, QUANTITY, LOT #

BAG

PATENT LABEL IS LOCATED

ON UNDERSIDE

OF COVER

LABEL WITH CREE BIN

CODE, QUANTITY, LOT #

LABEL WITH CREE BIN

CODE, QUANTITY, LOT #

LABEL WITH CREE BIN CODE,

QUANTITY, LOT #

.875

.875

R.375

5.875

5.875

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 10

PACKAGING - CONTINUED

CMA1825, CMA1825 Pro9, CMA1840, CMA1840 Pro9

CMA2550, CMA2550 Pro9

LABEL WITH CREE BIN CODE,

QUANTITY, LOT #

1.063

1.125

R.375

7.125

7.625

LABEL WITH CREE BIN CODE,

QUANTITY, LOT #

1.188

1.188

R.375

7.125

7.625

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 11

PACKAGING - CONTINUED

CMA3090, CMA3090 Pro9

LABEL WITH CREE BIN CODE,

QUANTITY, LOT #

1.313

1.313

7.500

8.125

R.375

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 12

Dimensions are in mm.

Tolerances: ± 0.5mm

CMB1304, CMB1304 Pro9, CMB1306, CMB1306 Pro9

Load Tray

Upper Tray

PACKAGING - CONTINUED

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 13

CMB1507, CMB1507 Pro9, CMB1510, CMB1510 Pro9, CMB1516, CMB1516 Pro9

Load Tray

Upper Tray

CMB1-09-XXXX-12XXCA0 CMB1507/CMB1510/CMB1516

CMB1-09-XXXX-12XXCA0 CMB1507/CMB1510/CMB1516

CMB1-09-XXXX-12XXCA0 CMB1507/CMB1510/CMB1516

CMB1-09-XXXX-12XXCA0 CMB1507/CMB1510/CMB1516

PACKAGING - CONTINUED

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 14

CMB1818, CMB1818 Pro9, CMB1825, CMB1825 Pro9, CMB1840, CMB1840 Pro9

Load Tray

Upper Tray

CMB1-12/14-XXXX-12XXCA0 CMB1818/CMB1825/CMB1840

CMB1-12/14-XXXX-12XXCA0 CMB1818/CMB1825/CMB1840

CMB1-12/14-XXXX-12XXCA0 CMB1818/CMB1825/CMB1840

CMB1-12/14-XXXX-12XXCA0 CMB1818/CMB1825/CMB1840

PACKAGING - CONTINUED

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 15

CMB2550, CMB2550 Pro9

Load Tray

Upper Tray

CMB1-19-XXXX-1212BA0 CMB2550

CMB1-19-XXXX-1212BA0 CMB2550

CMB1-19-XXXX-1212BA0 CMB2550

CMB1-19-XXXX-1212BA0 CMB2550

PACKAGING - CONTINUED

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 16

CMB3090, CMB3090 Pro9

Load Tray

Upper Tray

CMB1-23-XXXX-1516BA0 CMB3090

CMB1-23-XXXX-1516BA0 CMB3090

CMB1-23-XXXX-1516BA0 CMB3090

CMB1-23-XXXX-1516BA0 CMB3090

PACKAGING - CONTINUED

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 17

CMT1407, CMT1412, CMT1420

CMT1922, CMT1925, CMT1930, CMT1945

LABEL WITH CREE BIN CODE,

QUANTITY, LOT #

.875

5.875

5.875

.875

R.375

LABEL WITH CREE BIN CODE,

QUANTITY, LOT # 1.063

7.125

7.625

1.125

R.375

PACKAGING - CONTINUED

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 18

CMT2850, CMT2870, CMT2890

R.375

7.500

8.125

1.313

1.313

LABEL WITH CREE BIN CODE,

QUANTITY, LOT #

PACKAGING - CONTINUED

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 19

PACKAGING - CONTINUED

Dimensions are in mm.

Tolerances: ± 0.5mm

CMU1003, CMU1003 Pro9, CMU1006, CMU1006 Pro9, CMU1010, CMU1010 Pro9, CMU1013, CMU1013 Pro9

Load Tray

Upper Tray

XLAMP®CM FAMILY LED SOLDERING & HANDLING

© 2017-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, XLamp®, and the Cree LED logo are

registered trademarks, and Pro9 is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective owners

and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational purposes only

and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP240

REV 8 20

This manual suits for next models

40

Table of contents

Other CREE-LED Lighting Equipment manuals