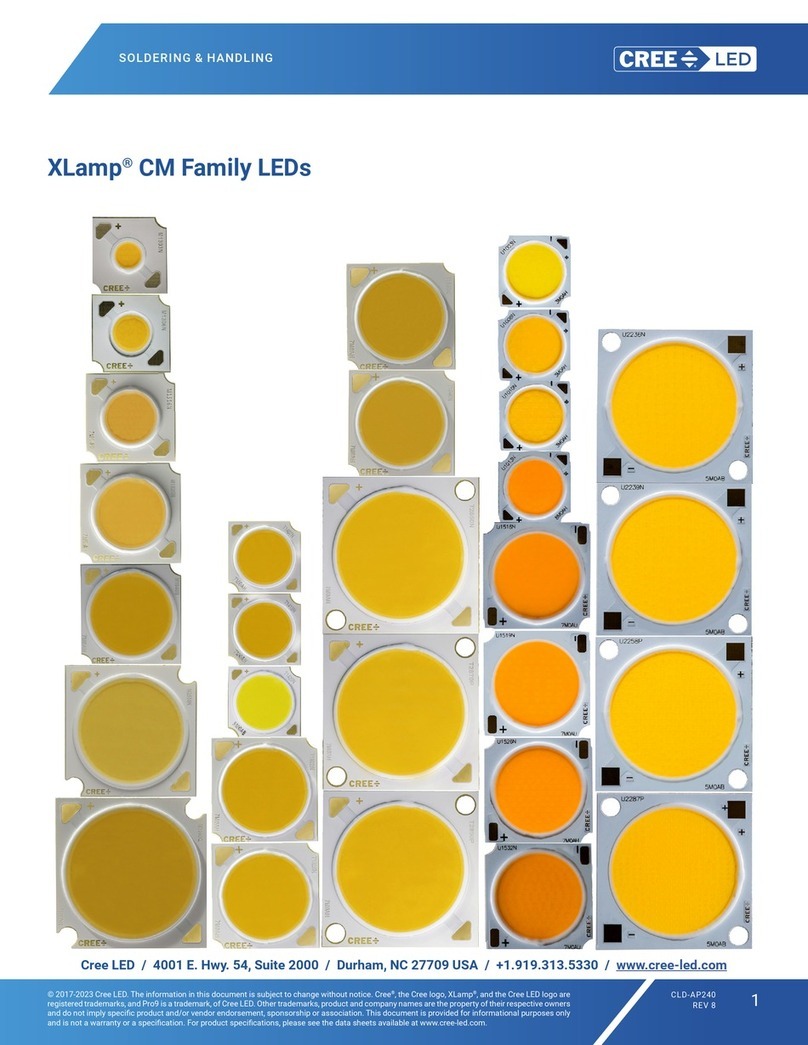

XLAMP®XP FAMILY LED SOLDERING & HANDLING

© 2008-2023 Cree LED. The information in this document is subject to change without notice. Cree®, the Cree logo, the Cree LED logo and XLamp® are

registered trademarks, and Photophyll is a trademark, of Cree LED. Other trademarks, product and company names are the property of their respective

owners and do not imply specic product and/or vendor endorsement, sponsorship or association. This document is provided for informational

purposes only and is not a warranty or a specication. For product specications, please see the data sheets available at www.cree-led.com.

CLD-AP25

REV 26 6

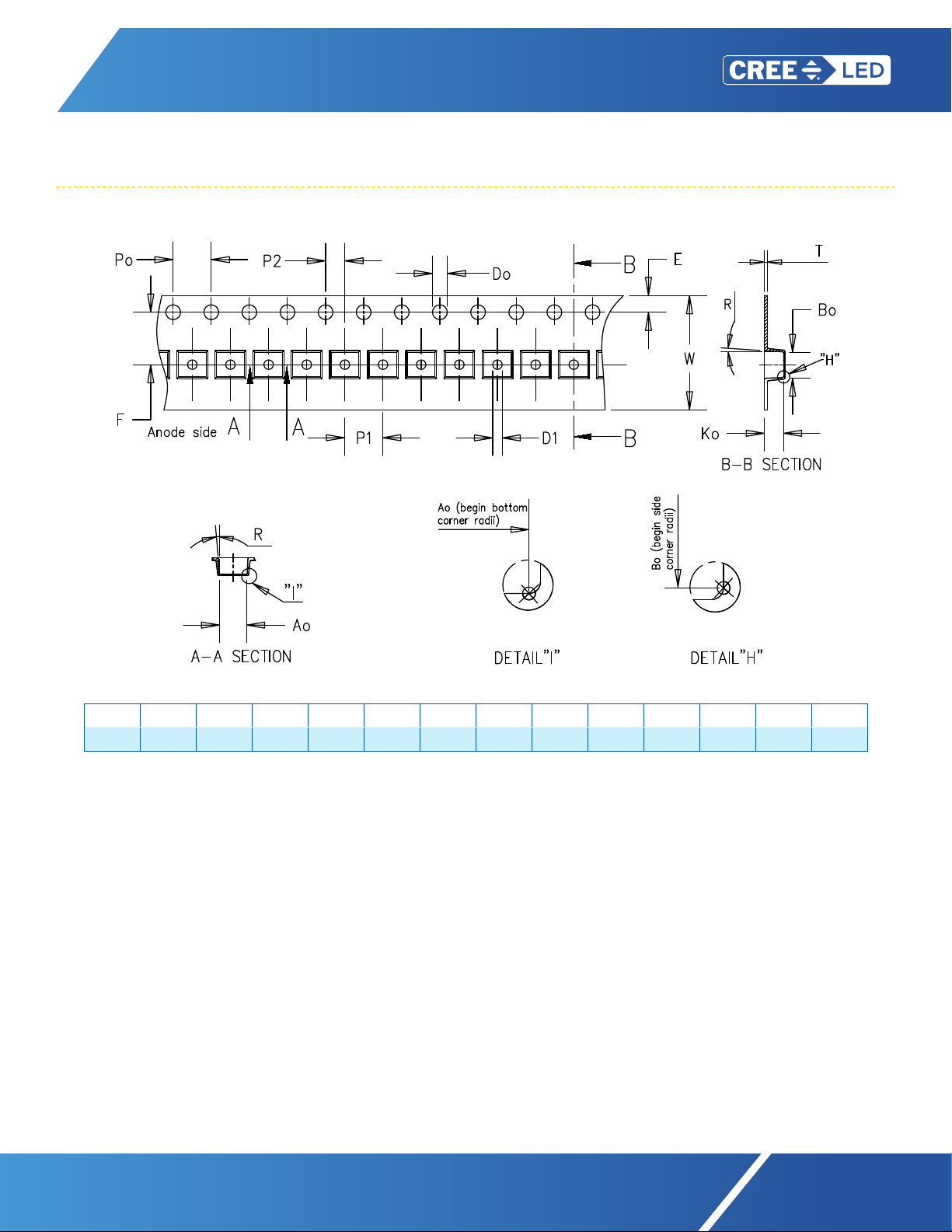

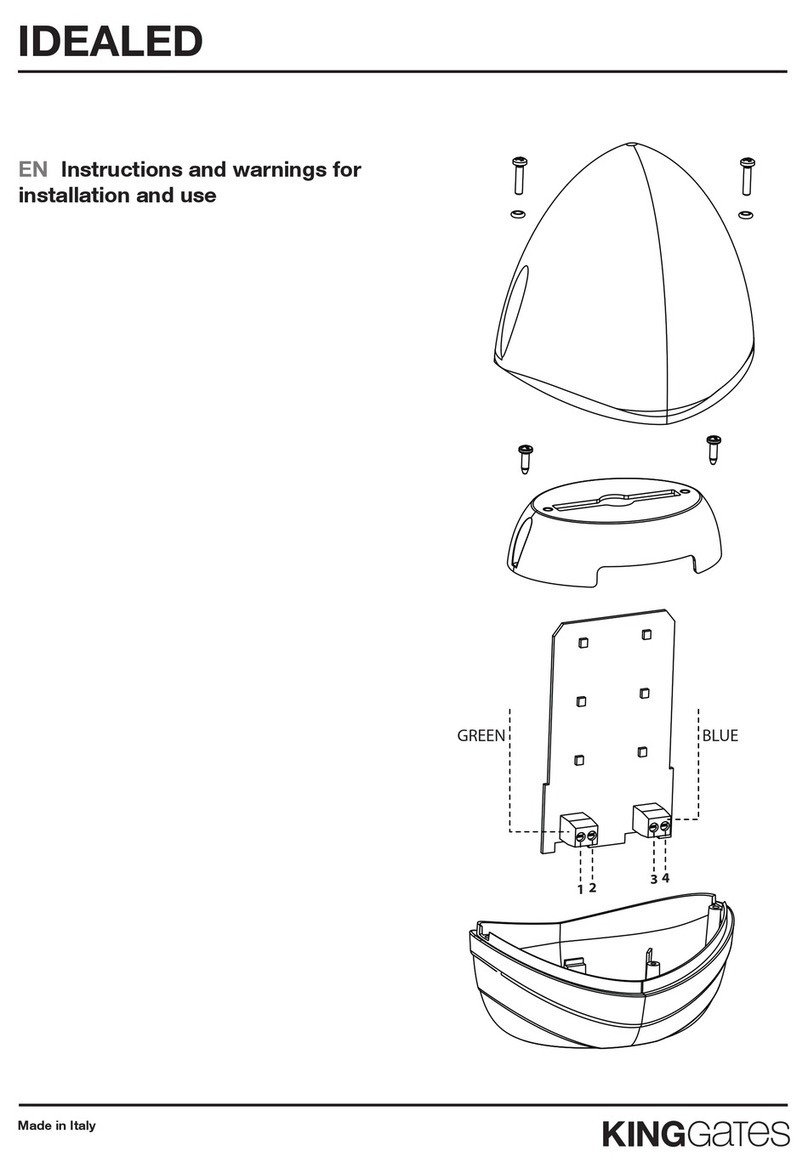

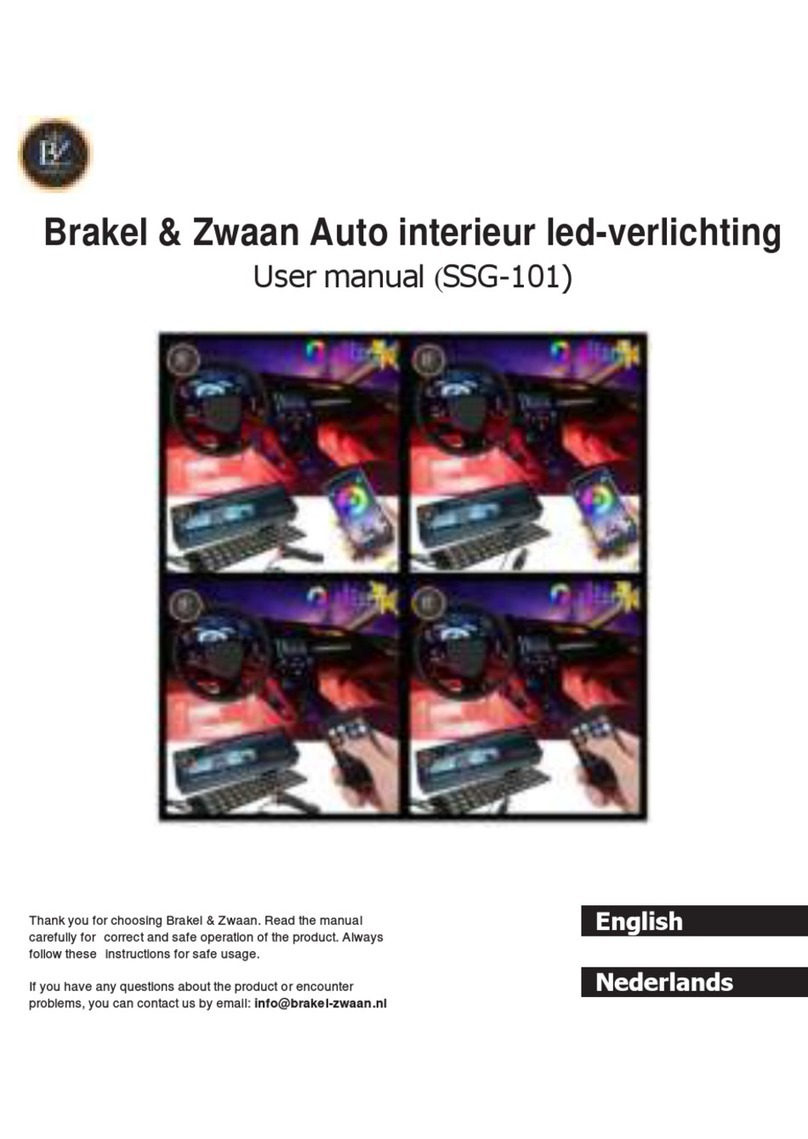

CIRCUIT BOARD PREPARATION & LAYOUTS

Printed circuit boards (PCBs) should be prepared and/or cleaned according to the manufacturer’s specications before placing or

soldering XLamp XP Family LEDs onto the PCB.

The diagrams below show the recommended PCB solder pad layout for XLamp XP Family LEDs.

XP-C, XP-E, XP-G

XP-E2, XP-E2 Torch, XP-G2, XP-G3, XP-G3 Photophyll™ Select, XP-G4, XP-G4 Pro9, XP-L High Density & High Intensity,

XP-L2, XP-P

Notes:

• Cree LED recommends using thermal pad kickouts to maximize component thermal performance.

• Cree LED recommends using white solder mask material to minimize system optical loss.

* This stencil has been tested and optimized for the avoidance of voiding when using ALPHA®LUMET®P30 Maxrel solder paste. For

other solder pastes, a “window pane” design for the thermal pad stencil may result in a lower voiding percentage. Contact your local

Cree LED Field Applications Engineer for consultation regarding your specic application.

Recommended PCB Footprint Recommended Stencil Opening

3.45

3.45

OPTICAL

MODEL ORIGIN

ANODE

SIDE

CATHODE

SIDE

0.73

0.58

2.00

R1.30

OPTICAL

MODEL ORIGIN

3.30

0.50

1.30

2.30

0.50

ANODE

SIDE

CATHODE

SIDE

CENTER PAD

IS ELECTRICALLY

ISOLATED

SOLDERMASK

MAY BE PRESENT

3.30 REF.

3.30 REF.

CENTER PAD

IS ELECTRICALLY

ISOLATED

SOLDERMASK

MAY BE PRESENT

3.30

3.30

0.50

1.30

0.50

3.30

3.30

0.75

0.25

1.01

0.64

2.30

0.28

2.30

ALTERNATE BOTTOM VIEW

BOTTOM VIEW

SIDE VIEW

TOP VIEW

RECOMMENDED STENCIL OPENING

RECOMMENDED PCB FOOTPRINT

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

A

© 2021 CreeLED, Inc. a subsidiary

of SMART Global Holdings, Inc.

THIRD ANGLE PROJECTION

DRAWING FILENAME

20610-350008 XPC XPE XPG

CreeLED, Inc.

4400 SILICON DR

DURHAM, NC 27703

FINISH

A

DRAWING INITIATED

B

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

CREE LED. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT

WRITTEN PERMISSION OF CREE LED

IS PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

REV

DESCRIPTION

APPLICATION

DIMENSIONS ARE IN MILLIMETERS

TOLERANCES:

• ANGULAR: MACH

0.5° BEND

1°

• ONE PLACE DECIMAL

0.5

• TWO PLACE DECIMAL

0.05

• INSIDE BEND RADII EQUAL

MATERIAL

• MACHINE/CASTING RADII 0.50

• RADII AND DIA:

0.10

INTERPRET GEOMETRIC

TOLERANCING PER:

MATERIAL

FINISH

MATERIAL

DRAWN

CHECKED

ENG APPR.

MFG APPR.

Q.A.

DATE

NAME

TITLE:

SIZE

C

DWG. NO.

REV

WEIGHT:

SCALE: 20:1

UNLESS OTHERWISE SPECIFIED:

TLING

24AUG22

XPC

XPE

XPG

SHEET 1 OF 1

350008

2

1

B

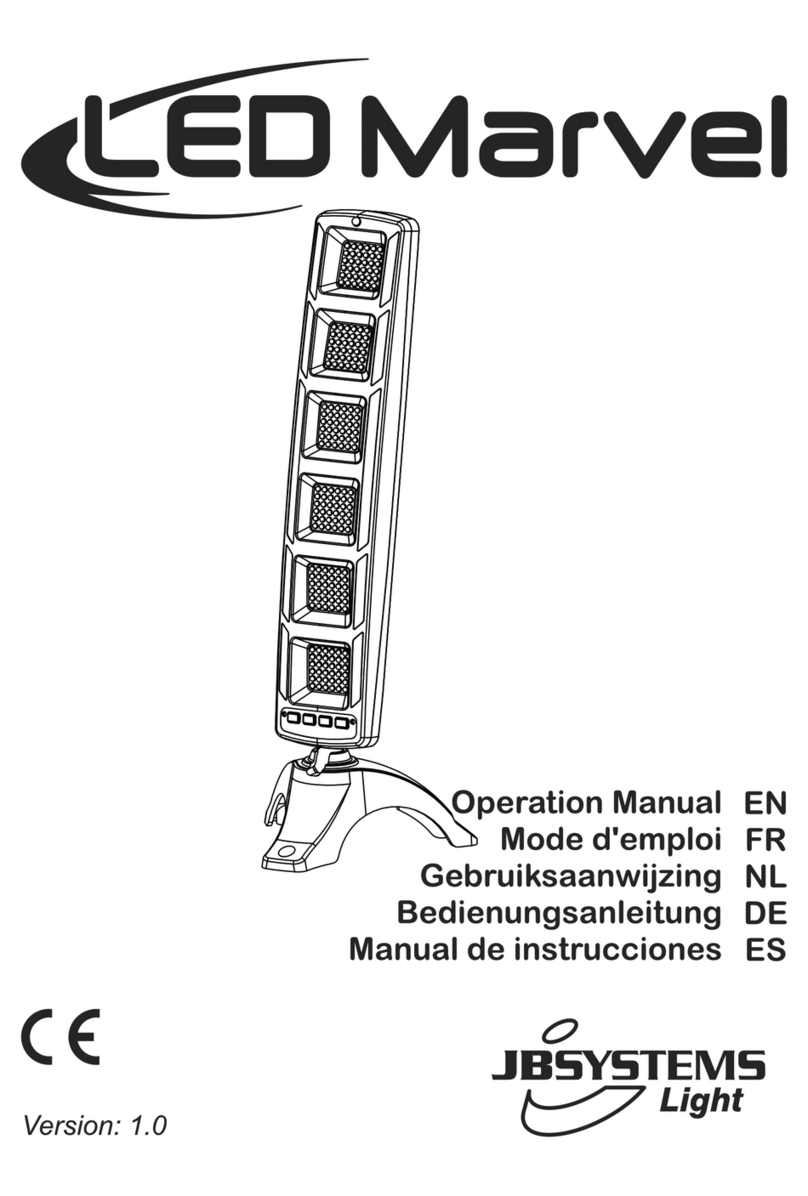

OPTICAL MODEL ORIGIN

Recommended PCB Footprint Recommended Stencil Opening*

3.45

3.45

OPTICAL

MODEL ORIGIN

TOP VIEW

CATHODE

SIDE

ANODE

SIDE

0.58

0.73

2.26

R1.53

OPTICAL

MODEL ORIGIN

3.30

0.50

2.30

0.50

1.30

3.30

CENTER PAD

IS ELECTRICALLY

ISOLATED

SOLDERMASK

MAY BE PRESENT

ANODE

SIDE

CATHODE

SIDE

3.30

3.30

0.50 1.30 0.50

0.50 0.50

0.43

0.29 TYP

0.50 0.56

3.30

0.18 TYP

0.18

0.18

3.30

0.08

0.08

0.83 (2 PLACES)

0.18

0.50

0.56

RECOMMENDED STENCIL OPENING

3.30 REF.

3.30 REF.

CENTER PAD

IS ELECTRICALLY

ISOLATED

SOLDERMASK

MAY BE PRESENT

SIDE VIEW

BOTTOM VIEW

RECOMMENDED PCB FOOTPRINT

ALTERNATE BOTTOM VIEW

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

A

© 2021 CreeLED, Inc. a subsidiary

of SMART Global Holdings, Inc.

THIRD ANGLE PROJECTION

DRAWING FILENAME

2610-350011B

CreeLED, Inc.

4400 SILICON DR

DURHAM, NC 27703

FINISH

A

INITIAL DRAWING RELEASED

B

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

CREE LED. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT

WRITTEN PERMISSION OF CREE LED

IS PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

REV

DESCRIPTION

APPLICATION

DIMENSIONS ARE IN MILLIMETERS

TOLERANCES:

• ANGULAR: MACH

0.5° BEND

1°

• ONE PLACE DECIMAL

0.5

• TWO PLACE DECIMAL

0.05

• INSIDE BEND RADII EQUAL

MATERIAL

• MACHINE/CASTING RADII 0.50

• RADII AND DIA:

0.10

INTERPRET GEOMETRIC

TOLERANCING PER:

MATERIAL

FINISH

MATERIAL

DRAWN

CHECKED

ENG APPR.

MFG APPR.

Q.A.

DATE

NAME

TITLE:

SIZE

C

DWG. NO.

REV

WEIGHT:

SCALE 20:1

UNLESS OTHERWISE SPECIFIED:

TLING

24AUG22

XPEB

XPEB TORCH

XPEB PLUS

XPG2

SHEET 1 OF 1

2

1

350011

B

UPDATED OPTICAL MODEL ORIGIN