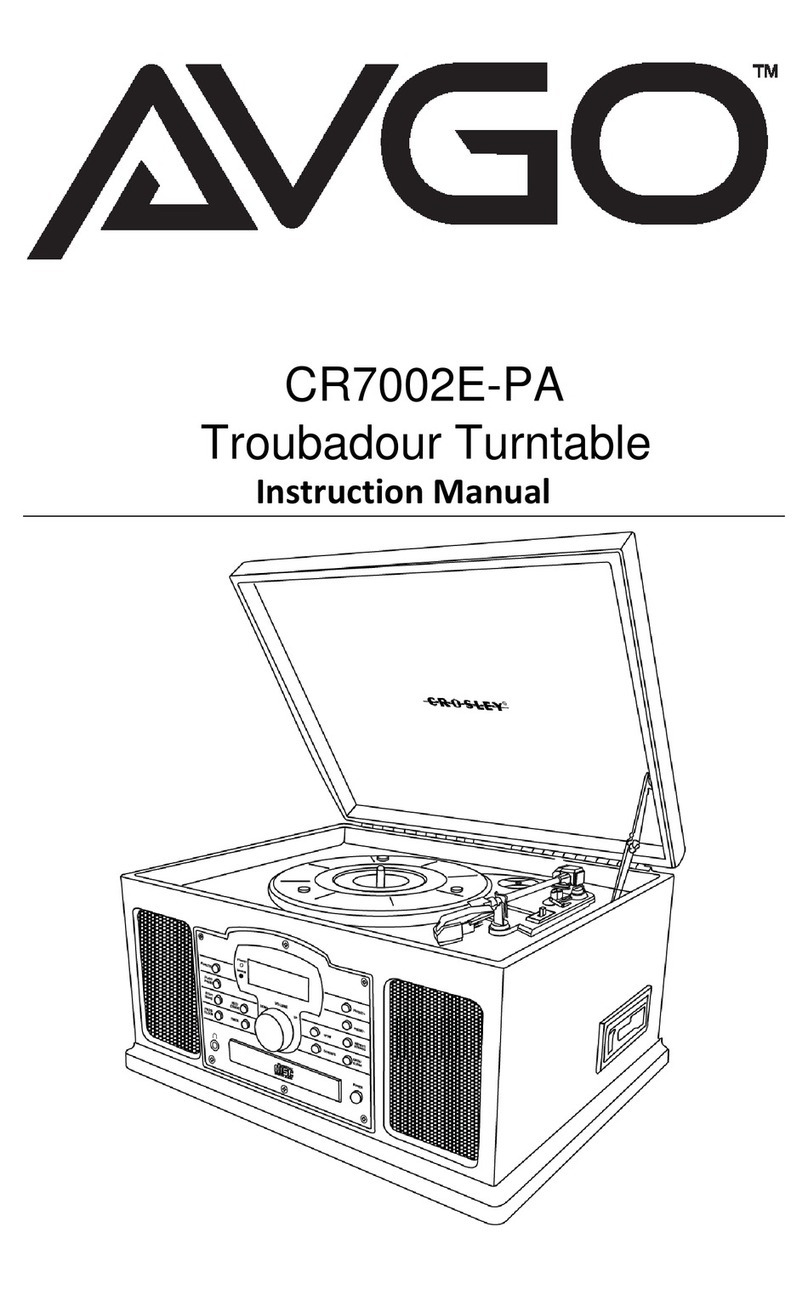

Creek Audio Wyndsor User manual

Wyndsor Turntable

Assembly Instructions

Contents of the Packing Case

Platter

Base, with 3 adjustable feet already fitted

Motor, with pulley fitted and power cable

Speed controller

Creek OBH-Uni power supply

Spike washers

2 alternative size arm mounting adjustment rings - 24mm and 25mm

Spare oil

Bearing

Weighted clamp

Acrylic cover

White gloves

Tools

Stroboscope

It is possible that a tonearm will be supplied to order

Page Two

Contents

¢Packaging Contents

¢History

¢Overview

¢Assembly and Operation

¢Specification

History

Thank you for purchasing our Wyndsor turntable.

This turntable is manufactured to the highest engineering standards and should give you

years of trouble free use and musical enjoyment.

Please take time to read this manual thoroughly before assembling your turntable, as

incorrect assembly could result in damage.

The Wyndsor turntable and LP1 speed controller have been designed by Mike Creek to

celebrate 25 years as a manufacturer of hi-fi equipment.

In honour of his father’s electronics business, where Mike served his apprenticeship from

1970-1975, the turntable reflects the family business name, Wyndsor Recording Company

Ltd.

Bob Creek, Mike’s father, manufactured reel to reel tape recorders in London from 1948-1970

and, among other consumer products, turntables from 1970-1978.

Those products were sold under the brand name Wyndsor Recording Company.

Page Three

Overview

The Creek Wyndsor turntable shipped

from the factory without arm - its

versatility allows it to be fitted with the

arm of your choice.

For photographic purposes we have

chosen to use the Rega RB300 and

Goldring MM cartridge.

The turntable is mounted on the Creek

AR4 rack, which not only supports the

turntable but also isolates the vibrations

that cause feedback.

The two products complement each other as similar parts are used on both. The

adjustable feet and damping rings are identical.

Assembly Instructions

To avoid marking the acrylic parts, please be sure to complete the assembly wearing

the white gloves provided.

The black acrylic base is already fitted with the three adjustable

silver feet and spikes. Be very careful not to damage anything with

the pointed spikes while assembling the table.

Remove the base from the plastic bag and place it on the surface

where you intend to use it.

Take the bearing and separate the two halves by unscrewing the

large bolt at one end. There is oil covering the ceramic spindle -

take care not to allow the oil to get on the other parts. If by chance it

does, then simply wipe it clean.

Place the bottom section of the bearing through the centre hole in the black base and

then tighten the bolt and cup to the underside to hold it tightly in place. It should be a

tight fit so some effort may be required to force it into place. Use the Allen key provided

to tighten the bolt, just enough to stop it from coming loose. Do not over-tighten it.

Add a small amount of oil to the inside of the top section of the bearing and place it onto

the ceramic shaft.

Page Four

Assembly Instructions Cont’d.

Next, lift the base away and place the motor and pulley on the

flat surface where you wish to use the turntable.

Then lower the base back onto the surface so that the motor fits

inside the hole made for it in the base.

It can be adjusted later after everything is in place.

(The belts are fitted at a later stage).

The Wyndsor turntable accepts many different tonearms. The adjustment ring fitted is

23mm - however two different sizes are included - 24mm and 25mm. Be sure to use

the correct one for your tonearm.

Fit the tonearm you choose to use. Unscrew the knurled ring around the outside of the

mounting hole. This is the VTA - the vertical tracking adjustment ring. It should be in its

uppermost position, exposing two grub screws that intersect the hole. These screws

should allow the arm boss to drop through the hole, while they are unscrewed.

Pass the plugs and earth wire through the mounting hole. When the boss is sitting on

the VTA adjuster, line the arm up with the front of the turntable and tighten the fixing

screws to hold it in place. Do not over-tighten them.

Place the platter ring on top of the bearing and make sure it is fully inserted and flat.

Spin the platter to check it spins freely.

Fit your preferred cartridge according to the manufacturer’s instructions. A specially

made alignment protractor is provided, printed inside the white and black stroboscope.

It is advisable to obtain a good quality set of scales, made for weighing the cartridge,

and a small spirit level for levelling the base and tone arm.

Remove the cover from the stylus and place it on the edge of a record after the arm

weight has been set up. Use your eye or, better still, a small level to check that the arm is

level. Adjust the VTA ring carefully at the base of the arm to make it level.

Make sure that you do not make any adjustments unless the arm is returned to its

resting position.

Page Five

Assembly Instructions Cont’d.

With the set-up near to completion, lift the feet up individually and place the small metal

washer under each spike. This is optional, depending on the surface. Certain surfaces,

like the glass one shown, could let the spikes slip. A very small piece of Blu-Tack or

other sticky material will help to secure the position of the washers.

When the washers are all in place, use the level to check for adjustments. Loosen the

middle locking rings of the feet and adjust the spikes up or down to level the base, both

side to side and back to front. When you are happy, tighten the locking nuts, while being

careful that the spikes don’t also turn.

Move the motor round to place the pulley as far from the platter as possible and centre it

in the gap so that it does not touch the base anywhere.

One by one, fit the three belts provided to the motor pulley, starting at the bottom and

working up. Stretch the belt away from the pulley with two hands so that it goes around

the platter. Release it and turn the platter gently to allow the belt to turn into its preferred

place.

Some may prefer to do this the other way by placing the belt around the platter first and

then finding the right level on the pulley. It is not an exact science. It is possible to run

the turntable with only one or two belts. It is however, more stable with all three belts.

When all the belts are set, make sure the lowest one is not too close to the bottom of the

platter, or it may fall off in use.

Page Six

Assembly Instructions Cont’d.

Place the LP1 motor speed

controller on a shelf within range of

the motor cable.

Plug the 4-pin power plug into the

back of the LP1 speed controller, in

the appropriate socket.

Once it is plugged in, tighten the

locking ring around it.

Plug the appropriate mains plug

onto the OBH-Uni power supply

adaptor for your country of use.

The Universal power supply (OBH-Uni) provides 24V DC at 625 mA - 15 Watts in total. It

can operate in any region, with mains voltages ranging from 85 - 265V AC/50 Hz - 60 Hz

Plug the 2.3mm DC jack plug into the back of the LP1 speed controller.

The switch on the motor can over-ride the speed controller, so it should normally be in

the ON position (1) and then the power can be applied from the power switch on the left

hand side of the speed controller.

Select either 45 or 33.3 RPM from the buttons on the front of the speed controller. Use

the stroboscope to set the absolute speed.

Place it on the platter and run the turntable at the desired speed. Adjust the appropriate

control knob on the front panel to set the speed.

The lines on the stroboscope should appear to stop moving when the right speed has

been reached.

When playing a record, place the heavy

clamp on top of the spindle to flatten the

record and stop resonances or vibration from

affecting the performance.

It will be necessary to plug the RCA plugs

from the tone arm into an appropriate

amplifier fitted with a Phono pre-amp, set for

either MM or MC cartridge matching.

Creek Audio manufactures both moving magnet

and moving coil phono pre-amplifiers.

Page Seven

Wyndsor Turntable Specification

Construction Acrylic Base and Acrylic platter

Speed 331/3 RPM and 45 RPM

Drive Unit Low voltage AC synchronous motor

Platter Bearing Inverted ceramic shaft with polished ball

Drive Belts Custom made silicon belts, available from Creek Audio

Warranty 5 years

Creek Audio Limited

12 Avebury Court Mark Road Hemel Hempstead HP2 7TA England

Tel: +44 (0) 1442 260146

E-mail: [email protected]

Internet: www.creekaudio.com