Sanyo TP 250 User manual

Other Sanyo Turntable manuals

Sanyo

Sanyo TP 1024 User manual

Sanyo

Sanyo TP X2 User manual

Sanyo

Sanyo TP 1400 User manual

Sanyo

Sanyo DVP404U User manual

Sanyo

Sanyo expert TP-1012 User manual

Sanyo

Sanyo TP M15 User manual

Sanyo

Sanyo PLUS Q50 User manual

Sanyo

Sanyo TP220 User manual

Sanyo

Sanyo LC78626KE User manual

Sanyo

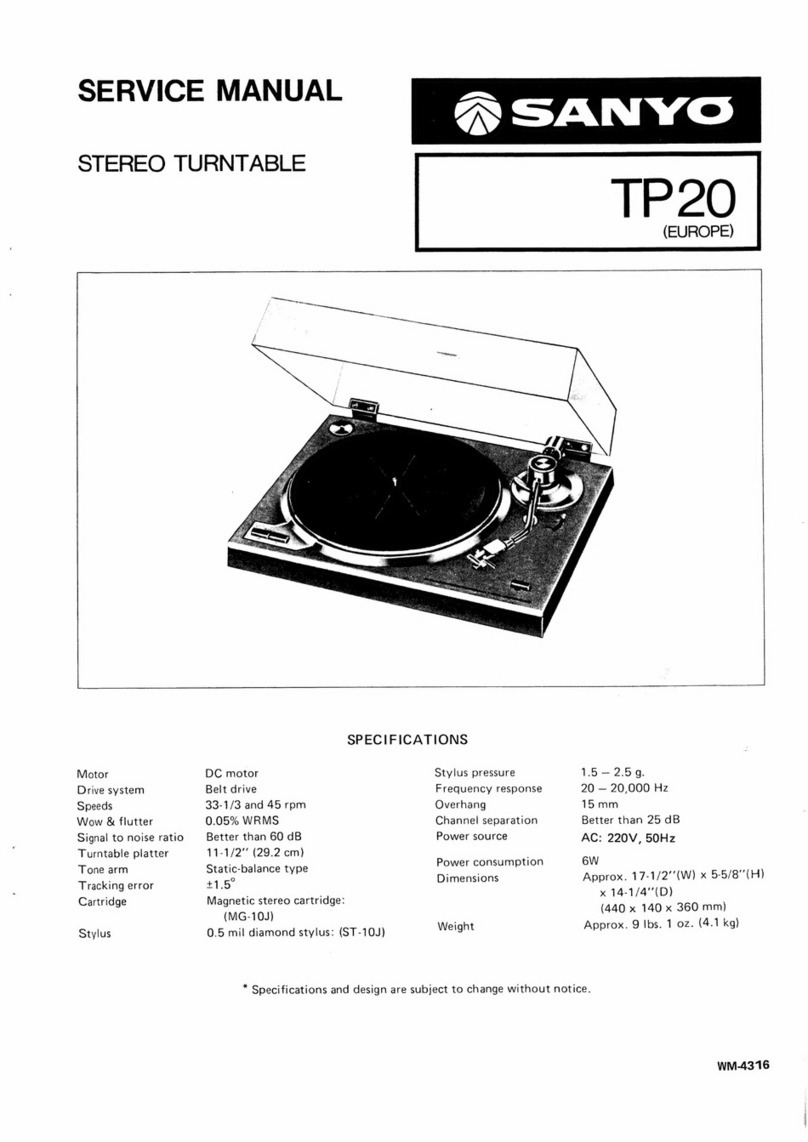

Sanyo TP20 User manual