Cress E1814 User manual

ELECTRONIC KILNS

OWNER'S MANUAL

2

CONGRATULATIONS !

Congratulations on being the owner of a Cress electronic kiln! Besides having the safety and reli-

ability that has long been associated with the Cress name, the kiln you have selected is equipped

with the best electronic control on the market. We are pleased to offer a control with a wider

range of automatic firing speeds which will do almost any firing job without the need for custom

programming. This control also includes a short temperature soak at the end of each firing cycle

to ensure greater temperature uniformity with uneven loads. There is considerably more insula-

tion between the heat and the electronics to ensure high reliability, and a safety master switch is

included to protect against power surges when the kiln is not in use.

We are proud of our products and gratified that you have joined the many thousands of ceramic

enthusiasts who have compared and chosen Cress firing equipment. We sincerely wish you many

years of creative and rewarding use of your Cress kiln.

UNPACK SHIPMENT IMMEDIATELY

When this shipment was given to the carrier, neither the crating nor contents were damaged, In case of

damage or loss (either obvious or concealed) save all packing material. Concealed damage or loss discov-

ered by the consignee, which was not noted at time of delivery, must be reported to the delivering carrier

immediately upon discovery. At that time, an inspection of the merchandise by the carrier’s representative

should be requested. Failure to report such a damage or loss within 15 days places the burden of proof

upon the claimant to show this damage or loss was caused while in the carrier’s possession.

3

4

IMPORTANT SAFEGUARDS!

Please read and observe the following safety warnings before operating your kiln:

1. Install kiln 18" or more from any wall or combustibles.

2. Fire only on stand or legs furnished.

3. Never fire hotter than cone 10 or 2350 oF.

4. Do not fire hotter than the manufacturer’s recommendation for your clay, glazes, or decals, or per-

manent damage may result to your kiln or ware.

5. Do not open lid until kiln has cooled.

6. Before opening lid, turn off all switches, then carefully open lid and test that lid brace is securely

engaged before allowing lid to stand freely.

7. Do not leave kiln unattended while firing.

8. Never use an extension cord.

9. Operate kiln only in a well ventilated room.

10. Unplug kiln before servicing or cleaning.

11. Dangerous Voltage - Do not touch heating elements with anything.

12. Do not touch hot sides of kiln or hot lid. Burns may result.

14. Never store anything under kiln; never lean objects against kiln.

15. Do not store or use flammable liquids or sprays in the same room with your kiln.

16. Do not store or use your kiln outside; keep rain and moisture away from kiln.

17 Do not use kiln if cord is damaged.

18 Wall receptacle must not be corroded.

19. Use kiln only with adequate electrical supply and with the correct voltage, amperage and correct

fuse size (not too large or small). Be sure the wire size is large enough (avoid aluminum wiring). Do

not use a 208 volt kiln on 220 volts.

20. Kiln must be grounded properly.

21. Wear goggles when looking thorough peephole.

22. Wear protective gloves when handling hot peephole plugs.

23. When firing objects to be used with food and drink, use only supplies tested and labeled “safe” for

such purposes.

It is imperative that you read all instructions before operating the kiln.

5 WD = wired direct - no cord. A licensed electriction must follow all local and federal codes.

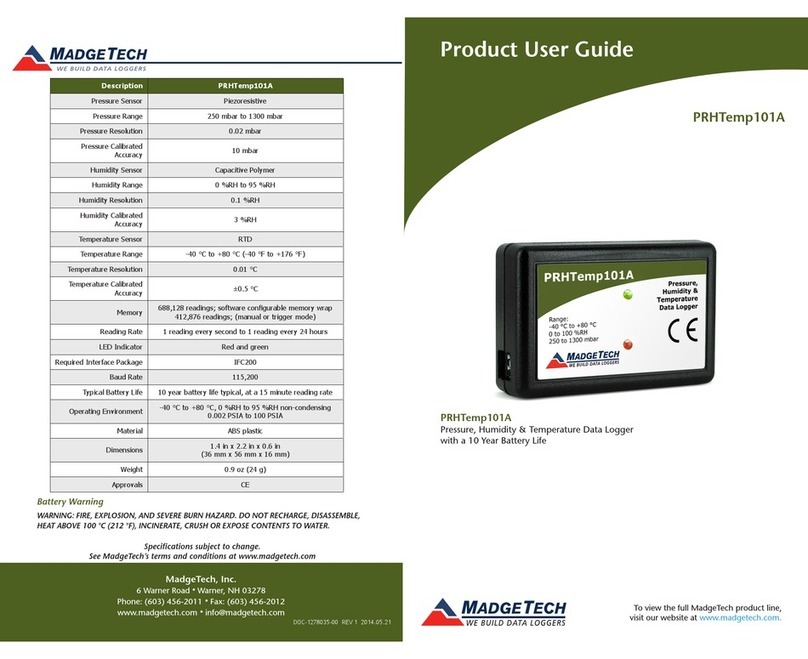

Maximum Chamber Inside Outside Outside Dimensions Fuse Wire

Model Amps Volts Cone Temp. Opening Depth Cu.Ft. Depth Width Height Size

Size

E1814 24 220 10 2350 14"Hep. 18 1.84 21 25.5 31 25 8

25.5 208 10 2350 14"Hep. 18 1.84 21 25.5 31 30 8

E18 25 220 10 2350 17.5" Oct. 18 2.60 22.5 27 31 30 8

26.5 208 10 2350 17.5" Oct. 18 2.60 22.5 27 31 30 8

E23 36 240 10 2350 17.5" Oct. 22.5 3.30 22.5 27 35.5 50 6

32 208 10 2350 17.5" Oct. 22.5 3.30 22.5 27 35.5 40 6

ET23 36 240 10 2350 17.5" Oct. 22.5 3.30 23.5 28 36.5 50 6

32 208 10 2350 17.5" Oct. 22.5 3.30 23.5 28 36.5 40 6

E27 44 220 10 2350 23.38" Dec 27 7.00 29.5 34 40 60WD 4

54 208 10 2350 23.38" Dec 27 7.00 29.5 34 40 60WD 4

ET27 44 220 10 2350 23.38" Dec 27 7.00 30.5 35 41 60WD 4

55 208 10 2350 23.38" Dec 27 7.00 30.5 35 41 60WD 4

ET28 48 240 8 2300 28.13 “ RD 27 9.92 35.5 40 41 60WD 4

KILN PLACEMENT AND INSTALLATION

All kilns should be located in an area free from flammable materials such as drapes, boxes, paper, spray

cans, paint, gasoline, etc. All kilns must be located a minimum of 18 inches from every vertical surface. Do not

place any kiln under any overhead obstruction such as cabinets, shelf, drapes, hanging plastic, etc., and never lean

anything against your kiln. Do not store anything between the kiln and a wall or under your kiln; keep these areas

clear at all times. Keep material off the top of your kiln; do not use the lid as a shelf.

Recommended floor surfaces include cement, ceramic tile with cement grout, brick, or stone. If it is

necessary to put your kiln on a synthetic or wooden floor, use a sheet of fireproof material underneath your kiln

and extending 24" beyond the kiln in all directions. A layer of hard firebrick is also acceptable for this purpose.

Floor coloration may be sensitive to heat.

Good housekeeping must be maintained at all times in the kiln area for safety.

Your kiln must be fired on the metal stand provided; it has been designed specifically for the height and

weight of your kiln. Do not use any other stand. Be sure to center the kiln on the stand so that it is stable, and posi-

tion it so that the cord does not touch the sides of the kiln, which will be hot during firing. It is also important that

the stand and kiln be level (use a bubble level for this purpose), otherwise there is a possibility of pieces of ware

falling during firing. Screw the stand to the kiln with the screws provided.

Use your kiln only in a well ventilated room. Vapors containing poisonous gases are possible when firing

certain materials. Do not breath fumes from kiln when firing.

ELECTRICAL SPECIFICATIONS

Proper electrical wiring is necessary to safely and efficiently operate a kiln. Even though the

voltage is a full 120 volts or 234 volts at the meter, the voltage on which the kiln operates will be somewhat lower

at the kiln location. Make sure your electrical outlet has the correct electrical capacity and voltage to handle your

kiln. It is necessary to measure the voltage at the location of the kiln with the kiln turned on. Voltage drops occur

on all wiring. Proper electrical wiring will provide an adequate operation voltage and current at the kiln without

significant voltage drop. (Voltage may be temporarily low during brownouts especially on a hot day in the summer

when all your neighbors have their air conditioning turned on and during peak electrical usage periods in your area).

If the wire coming from your power source to the kiln is too small or too long the kiln will not operate properly,

even if the wire meets national electrical safety codes. If the voltage is low, the kiln may not reach the maximum

desired temperature or will fire too slowly. This may reduce element life. 230 volt and 240 volt kilns may be used

with 220 volt to 245 volt power.

Do not attempt to change the receptacle on an existing line without using the services of a licensed

electrician. The electrician will know whether the wire size is correct. It is advisable to use a larger wire size than

absolutely necessary to prevent voltage drop, especially if the run to the meter is long. The increase in cost is usu-

ally very small compared to the long term savings in firing times and line loss (voltage loss). Never cut the plug

off and replace it. If the plug becomes damaged, change the entire cord with a CRESS factory supplied cord which

will meet temperature as well as electrical requirements. The outlet must be in good condition or heating of the

cord and plug cap will occur. Do not use an extension cord at any time.

Temperature rating specifications as well as the electrical rating requirements for your kiln are listed on a

decal on the kiln. Your electrician must make sure all local codes are met with your house wiring. Your licensed

electrician is responsible for meeting the requirements for the local and national codes.

Copper

6

THE CRESS ELECTRONIC CONTROL

The Cress Electronic Control is easy to use and includes advanced features which give great flexibility in firing schedules.

It displays the internal kiln temperature throughout the firing and cooling process, so you can easily monitor the progress of

your firing.

The control is a microprocessor based programmable ramping control which will run either preprogrammed firing

profiles, or your own user designed custom profiles. It has five preprogrammed firing speed profiles, an optional user selected

alarm setting, program preview, pyrometric cone-temperature equivalent file, and an LED display that can be selected for

either °F (Fahrenheit) or °C (Celsius) temperature read out and operation.

This control also has self diagnostics that help safeguard the equipment as well as the ware being fired. It will alert

you to problems and help in failure diagnosis with the use of error codes that are displayed in the LED window.

There are two basic modes of operation; The CONE FIRE mode, which uses preprogrammed firing profiles, and

the RAMP HOLD mode, which allows you to create and use custom firing profiles.

CONTROL KEYS OVERVIEW

The following is a list of the control operating keys on the control touch pad along with a brief explanation of their

functions.

10 KEY TOUCH PAD WITH ENTER KEY - used to input user selected program variables.

START KEY - used to start a firing profile.

STOP KEY - used to stop a firing profile.

PREVIEW KEY - used to display program or firing information. (varies with mode of operation)

°F or °C SELECT KEY - used to select the temperature scale the control operates in.

CONE TABLE KEY - used to look up the temperature equivalent of a pyrometric cone.

RAMP HOLD KEY - used to select or to create a custom firing profile.

CONE FIRE KEY - used to select a preprogrammed firing profile.

FAST KEY - used to select the fast CONE FIRE profile.

MED-FAST KEY - used to select the medium fast CONE FIRE profile.

MED KEY - used to select the medium CONE FIRE profile.

MED SLOW KEY - used to select the medium slow CONE FIRE profile.

SLOW KEY - used to select the slow CONE FIRE profile.

ALARM KEY - used to insert a user selected alarm point. ( temperature )

SETUP, INFORMATION & OPTION KEYS

°F or °C SELECT

To change the temperature units the control is operating in press the °F or °C SELECT key. The display will read

CHG°. Pressing the ENTER key will toggle the setting between Fahrenheit and Celsius.

CONE TABLE

The cone table is a list of pyrometric cone temperature equivalents. To look up a cone temperature, press the CONE

TABLE key. The display will flash CONE and a number. Use the key pad to select the desired cone number (cone # 022

through cone # 10), then press the ENTER key. The display will flash the cone temperature then return to the IdLE condi-

tion.

PREVIEW

The PREVIEW key is used to review the parameters of the program that is currently in memory (the program that will

be running if the START key is pressed ). Simply press the PREVIEW key and the display will scroll through the program

7

ALARM

The alarm function simply turns on an audible signal (a beeping sound) at a predetermined temperature setting.

To set an alarm press the ALARM key; the display will flash ALAR. Enter the desired temperature then press the ENTER

key. To silence the alarm during operation, press the ALARM key.

BASIC CONTROL OPERATION

CONE FIRE MODE (SIMPLE AUTOMATIC FIRING)

In the CONE FIRE mode, optimal firing patterns for each cone number have already been programmed into the

control. Only three pieces of information need to be provided:

1) The cone number required for the type of ware being fired.

2) The desired firing speed.

3) The hold time, if one is desired. Hold time is optional and is not needed under most firing conditions.

If no hold time is desired enter zero. The display now reads IdLE and the control is ready to execute the

firing.

* IMPORTANT: THE ZEROES IN A PYROMETRIC CONE NUMBER ARE A NECESSARY PART OF THE NUM-

BER. OMITTING THESE ZEROES WILL RESULT IN A SERIOUS OVERFIRE.

( CONE O6 IS MUCH COLDER THAN CONE 6 !)

SETTING UP A CONE FIRE MODE PROGRAM:

1) Turn on the master power switch located below the control on the front of the kiln panel.

2) Press the CONE FIRE key; the display prompts you to enter a cone number. Use the 10 digit

key pad to select the appropriate cone number (be sure to include the zeroes), then press the ENTER key.

3)The display now prompts you for a speed. Press the appropriate speed key located below the

CONE FIRE key, then press the ENTER key.

4) The display now prompts you for a hold time (if needed). Use the 10 digit key pad to enter the desired

amount of time, hours first (left of the decimal point), then minutes (right of the decimal point), then press the

ENTER key. (see example below)

To set hold time of 1 hour and 25 minutes you would do the following steps:

Press 1 display shows 00.01

Press 2 display shows 00.12

Press 5 display shows 01.25

8

The following is an example of entering a CONE FIRE program for a firing at cone 06 at medium speed with no hold time.

STEP PRESS ACTION DISPLAY / PROMPT

1 CONE FIRE Selects CONE FIRE mode ConE

2 06 Selects desired cone number 06

3 ENTER Inputs (stores) new cone number Spd

4 MED Selects desired speed MED

5 ENTER Inputs (stores) new speed HOLd

6 0 Selects desired hold time 0

7 ENTER Inputs (stores) new hold time IdLE

8 START STARTS FIRING -ON- then temperature

OPTIONS

ALARM

Before starting kiln program, to set an optional alarm setpoint press the ALARM key, then use the 10 digit key pad

to select the desired temperature. Then press the ENTER key and the control will return to the IdLE condition. After starting

a kiln program, your can program ALARM, then the kiln will return to temperature instead of IdLE after a few seconds.

PREVIEW

To review the program, press the PREVIEW key. The display will scroll through the parameters of the program

then return to the IDLE condition.

CONE TEMPERATURE OFFSET

The CONE FIRE mode target temperature may be adjusted up or down by as much as 50°F. This may be used to

affect the bend of the pyrometric cones if needed.

Each of the cone numbers (cone # 022 through cone # 10) may be independently adjusted for an increase or a de-

crease in target temperature.

To do so press the CONE FIRE key (when displaying IdLE), select 999 as the cone number, then press the ENTER

key. Select the cone number to offset then press ENTER. The display will read °F or °C OS and the current offset value.

To raise the temperature enter 00, then the number of degrees of change (1-50) and press ENTER. To lower the tem-

perature enter 90, then the number of degrees, and press ENTER. Then finish the remainder of the CONE FIRE profile.

The offset value will remain in memory and will not need to be reentered

STARTING THE PROGRAM:

Press the START key and the control will run the program. The display will first read ON, then will display the kiln

temperature. At the end of the firing the display will flash CPLt and the run time. Pressing the STOP key will display the

kiln temperature; pressing either the PREVIEW, CONE FIRE or the RAMP HOLD keys will return the display to the IdLE

DELAY START: Warning; delay start should only be used for convenience while someone is present. It should not be

used to start the kiln at a time after the kiln operator leaves the area. Press F/C key. Then press the number 3. The control

will flash "DELA". Enter Hrs.:Min. Press the "ENTER" key. Then the kiln goes to IDLE. When you start your pro-

gram by pressing the" START" key, the kiln will start after the delay time that was input. The optional exhaust fan starts

when the program starts and works during the delay start period.

9

STOPPING THE PROGRAM

If it is necessary to stop a program while it is running simply press the STOP key. To correct an entered number,

clear the display by entering all zeros, then reenter the desired value and press ENTER.

CONE FIRE PREPROGRAMMED FIRING PROFILES

The following are the firing profiles for the five speed options in the CONE FIRE mode.

FAST (cone 06 example)

570°F per hour temperature rise until the kiln reaches 200°F below end setpoint (selected cone temperature), then

200°F per hour rise until the setpoint is reached. (Do not use this firing speed for firing above cone 05)

The segment profile chart for FAST is:

SEGMENT RATE TEMPERATURE HOLD

1 570 °F 200 °F below setpoint 0

2 200 °F setpoint 0

The firing time varies depending on the load and the cone selected. Because it takes time for moisture to evaporate

from the ware and for chemical changes to occur, FAST is not recommended for thick hand made pieces.

MED-FAST (cone 06 example)

500°F per hour temperature rise until the kiln reaches 1100°F, then 400°F per hour until the kiln reaches

the final 250°F of the firing, then 175°F per hour until the setpoint is reached. (Do not use this firing speed for firing above

cone 05). The segment profile chart for MED-FAST is:

SEGMENT RATE TEMPERATURE HOLD TIME (HH:MM)

1 500 °F 1100 °F 0

2 400 °F 250 °F below setpoint 0

3 175 °F setpoint

Firing time varies according to load density and cone selected.

MED (cone 06 example)

500°F per hour temperature rise until the kiln reaches 1000°F, then 200°F per hour until the kiln reaches 1100°F,

then 400°F per hour until the final 250°F of the firing, then 120°F per hour until the setpoint is reached.

The segment profile chart for MED is:

SEGMENT RATE TEMPERATURE HOLD TIME (HH:MM)

1 500 °F 1000 °F 0

2 200 °F 1100 °F 0

3 400 °F 250 °F below setpoint 0

4 120 °F setpoint

Firing time varies according to density of load and cone selected. Examples of the type of ware most often fired at this speed

would be low fire glazes, thick greenware, or cast earthenware.

MED-SLOW (cone 06 example)

400°F per hour temperature rise until the kiln reaches 1000°F, then 100°F per hour until the kiln reaches

1100°F, then 400°F per hour until the final 250°F of the firing, then 108°F per hour until the setpoint is reached.

The segment profile chart for MED-SLOW is:

SEGMENT RATE TEMPERATURE HOLD TIME (HH:MM)

1 400 °F 1000 °F 0

2 100 °F 1100 °F 0

3 400 °F 250 °F below setpoint 0

4 108 °F setpoint

Firing time varies according to load density and cone selected.

10

11

SLOW (cone 06 example)

80°F per hour temperature rise until the kiln reaches 250°F, then 250°F per hour until the

kiln reaches 1000°F, then 100°F per hour until the kiln reaches 1100°F, then 250°F per hour until the final 250°F of the fir-

ing, then 80°F per hour until the setpoint is reached.

The segment profile chart for SLOW is:

SEGMENT RATE TEMPERATURE HOLD

1 80 °F 250 °F 0

2 250 °F 1000 °F 0

3 100 °F 1100 °F 0

4 250 °F 250 °F below setpoint 0

5 80 °F setpoint

Firing time will vary according to the load density and cone selected. Thicker pieces, hand built, or hand thrown pottery,

stoneware, and porcelain are examples of ware which would be fired at this speed.

RAMP HOLD MODE

The RAMP HOLD mode is used to create custom firing profiles. If the end firing temperature is to correspond to a

pyrometric cone firing, that temperature can be retrieved from the cone table file or from the cone / temperature chart on page

26 of this manual. Keep in mind, however, that the temperature at which a given cone will bend varies according to the rate

of temperature rise and the length of hold time as well as the absolute temperature. More on the nature and use of pyrometric

cones may be found on the section on cones. It is essential to have an understanding of the properties of cones before creating

custom programs based on temperature / cone setpoints. (The firing profiles in the CONE-FIRE mode are already prepro-

grammed for optimal firing curves for each cone.)

Since it takes time for heat to soak into a piece of ceramic ware, the faster the rate of temperature rise the more the

internal temperature of the ware will lag behind the temperature in the kiln. For this reason, the last segment of a firing should

approach the desired setpoint relatively slowly (no greater than 108 °F per hour) to allow the ware to absorb the heat and to

prevent overfiring. ( An analogy which might be helpful is to think of cooking a roast. If you roast it for a short time at high

heat, it will be seared on the outside, but “ rare” on the inside. If you roast it at a low heat for a longer time, it will be cooked

uniformly throughout. Since ceramic ware needs to be fired uniformly throughout the piece, we must approach the final tem-

perature slowly enough to allow the heat to penetrate the ware without overshooting.)

12

In RAMP HOLD mode there are six user files available. Each file holds one custom program in permanent

memory. Each program may contain up to eight segments, and each segment has its own firing rate (degrees per

hour of temperature rise), its own temperature setpoint, and an optional hold time.

Temperature rate is the number of degrees per hour you wish the temperature in the kiln to rise in an hour.

Although the control will accept temperature rates from zero to 9999 degrees per hour, the kiln is limited by power

available, voltage, element condition, and the load. The kiln can not heat at a faster rate just because you set the

control to a rate exceeding its limitations. If you set the control for a rate faster than the kiln is able to heat, you will

cause an overfire because the cone table in the control will set the temperature unrealistically high for a fast rate

that is unachievable. A fast firing may have a temperature rise setting of 500 °F per hour for the initial segment, but

the final segment should not be set higher than 108 °F per hour, or 80 °F per hour if firing to a temperature above

cone 6.

Temperature is the number of degrees you wish to reach in that segment before either holding (“soaking”)

for a specified time or continuing on to the next segment. You may not exceed 2350 °F without damage to your

kiln.

Hold is the amount of time you wish to “soak” the load at a given temperature before continuing on to

the next segment. If no hold time is desired, program in 0. The highest possible hold time is 99 hours 99 minutes.

In the display, numbers to the left of the decimal point represent hours; numbers to the right of the decimal point

represent minutes.

CREATING A CUSTOM PROGRAM

1) To create a custom program, from IDLE press the RAMP HOLD key. The display flashes

USEr and a number; select a user file number ( 1-6 ) to hold the program, then press the ENTER key.

2) The display flashes SEGS. Select the required number of segments ( 1-8 ), then press ENTER.

3) The display flashes RA 1. Select the heat up rate for segment #1 (measured in degrees per hour),

then press the ENTER key.

4) The display flashes °F (or °C) 1; select the end temperature for segment #1 (maximum

temperature is 2400°F), then press the ENTER key.

5) The display flashes HLd 1; select the hold time for segment #1(if necessary). Hold is an option.

Leaving the time at 00.00 means that there is no hold time; a time setting of 99.99 means that the

hold time is set to 99 hours and 99 minutes.

6) Repeat steps 3 through 5 for each additional segment.

7) The alarm function is also an option. Leaving the setting at 9999 means no alarm is set; otherwise se-

lect the desired temperature at which the alarm should sound. To silence the alarm, press the ALARM

key.

To review the new program, press the PREVIEW key. To start the new program, simply press the START key.

STARTING AN EXISTING CUSTOM PROGRAM

To start an existing (previously programmed) custom program, from IDLE press the RAMP HOLD key.

The display reads USEr. Select the file user number of the program to run, then press ENTER. The display reads

The following is an example of a custom firing profile. To fire at a 300 °F rise per hour up to 1600 °F; at 108 °F rise per

hour up to 1900 °F with a five minute hold time and an alarm to sound at 1800 °F, use these steps:

STEP PRESS ACTION DISPLAY / PROMPT

1 RAMP HOLD Enters RAMP HOLD mode USEr

2 Number (1-6) Selects desired user file number 1

3 ENTER Inputs user file number SEGS

4 Number (1-8) Selects number of firing segments 2

5 ENTER Inputs number of segments rA 1

6 Temperature (1-9999) 300 Selects temperature rate of rise 300

per hour for first segment

7 ENTER Inputs rate of rise °F 1

8 Temperature (1-2350) 1600 Selects end temperature for first segment 1600

9 ENTER Inputs end temperature for first segment HLd 1

10 Time in hours and minutes 00.00 Selects hold time at end of first segment 00.00

11 ENTER Inputs hold time for segment 1 rA 2

(zero for this example)

12 Temperature (1-9999) 108 Selects temperature rise rate (2nd segment) 108

13 ENTER Inputs rate of rise °F 2

14 Temperature (1-2350) 1900 Selects end temperature for segment 2 1900

15 ENTER Inputs end temperature for segment 2 HLd 2

16 Time in hours and minutes 00.05 Selects hold time at end of second segment 00:05

(five minutes for this example)

17 ENTER Inputs hold time of five minutes ALAr

for second segment

18 Temperature (1-9999) 1800 Selects temperature that alarm will sound 1800

19 ENTER Inputs alarm temperature CPLt

20 START Starts the program in action

Before entering your custom program, create a chart to show the three components of each segment you wish to use. You

may have up to eight segments in your program, though you may choose to use fewer segments.

13

SEGMENT RATE in degrees per hour TEMPERATURE HOLD TIME (hh:mm)

1

2

3

4

5

6

7

8

Segments of custom programs may be used to ramp the temperature down and cool the kiln more slowly, if desired,

than it would if the kiln were turned off at the highest setpoint.

To change one value in a complicated RAMP HOLD profile without having to reenter the entire program simply

press ENTER to move through each value you wish to keep the same until you reach the one you wish to change. Then

enter the desired value, press ENTER, and continue.

To change a firing profile while the firing is in progress, press STOP. Use either CONE FIRE or RAMP HOLD to

enter new instructions for the remainder of the firing profile. Then press START to continue.

ERROR CODES

The following are error codes that may appear in the display window if the controller diagnoses a problem. If this

occurs, please reset the control by turning the power off, then on. If the problem continues call your dealer or Cress tech

support line at 702-884-4397.

ERROR #.

1 The program is ramping up and the rate of rise is 0 degrees per hour. The rate of rise is

checked every 7.5 minutes. Slow rate must persist for 22.5 minutes before the error is triggered.

2 The program is in hold and the temperature is 50 degrees or more above the hold

temperature. The error must persist for 18 seconds before the error is triggered.

3 The program is in hold and the temperature is 50 degrees or more below the hold

temperature. The error must persist for 18 seconds before the error is triggered.

4 The program is ramping down and the temperature is more than 50 degrees above the

last hold temperature. The error must persist for 18 seconds before the error is triggered.

5 The program is ramping down and the temperature is more than 50 degrees below the

local setpoint. The error must persist for 18 seconds before the error is triggered.

6 A negative temperature reading is detected. The thermocouple must be installed with

the polarity reversed.

7 The program is ramping up and the temperature is 50 degrees above the local setpoint.

The error must persist for 18 seconds before the error is triggered.

8 In CONE FIRE mode, the temperature is falling in the last segment instead of

increasing.

FAIL..... Open thermocouple.

PF...........Power failure

14

ERRP....Power failure. Press "cone Fire" to restart.

15

DISPLAY WINDOW MESSAGES Some of the readouts look odd at first since the control is unable to produce certain

letters or capital letters. You will soon get used to the meaning. The following are the display messages and their meanings:

DISPLAY DESCRIPTION

CHG° Displays after pressing °F or °C SELECT key.

ConE The control is waiting for you to input a cone number between 022 and 10.

CPLt The control is waiting for you to turn the power switch off after completing a firing

profile. The control displays the current internal temperature.

Err See table on errors, a software error has occured.

FAIL The thermocouple is not properly connected to the control or the thermocouple needs to

be replaced. Replace the thermocouple if the connections are OK.

FA5T Fast firing profile

HLd (1 -6) The control is waiting for the user to enter a hold time in hours and minutes.

IdLE Control is awake but awaiting instructions.

nn-5 Medium slow speed firing profile (nn equals m, 5 equals S)

nnEd Medium speed firing profile

nn-F Medium fast firing profile

PF The control is saying there was a power failure for more than 2 minutes or that the kiln

was turned off for more than two minutes.

rA (1-6) For each segment, the control is waiting for the user to enter a temperature rate of rise in

°F per hour or °C per hour.

SEGS (IT’S NOT SE65) The control is waiting for the user to enter the number of segments in

the profile being programmed.

SlO Slow speed firing profile

Spd The control is waiting for the user to enter the speed for this firing - SLOW, MED-SLOW,

MED, MED-FAST, or FAST.

°F (1-6) The control is waiting for the user to enter an end temperature in °F for a segment of the

firing profile in RAMP HOLD mode.

°C (1-6) The control is waiting for the user to enter an end temperature in °C for a segment of

the firing profile in RAMP HOLD mode.

Flashing Temp The element power is off and the kiln is cooling. The display shows the current temperature .

Flashing Time Indicates the kiln is in the hold stage during a RAMP HOLD firing profile. The time

remaining in the hold segment is displayed alternately with the temperature.

Temperature (not flashing) Current kiln temperature during a firing.

12.34 (or other) Shows hours and minutes. In this example 12 hours and 34 minutes.

(Note: period separates hours and minutes in the display.)

16

PREPARATION FOR FIRING

Before loading the kiln, there are several things you should do to prepare for a firing:

Remove all dust and chips that may have resulted from shipping (or previous firing). A small vacuum cleaner is very

useful in keeping your kiln clean. Dust in the kiln could cause imperfections in glazed ware.

Prepare a small amount of kiln wash. Kiln wash is a refractory material that prevents glazed pieces from sticking to

shelves. It is usually purchased as a dry powder and is then mixed with water to the consistency of skim milk. Use only high

fire kiln wash. Clean all your new shelves, then kiln wash only the top side of each shelf and the floor of the kiln, applying

with a paint brush. This will seal the dust and prevent glazes from adhering to these surfaces. Apply a paper thin coat, or it

may chip off. When the kiln wash wears off, bare spots only should be recoated keeping the kiln wash thin but the top of the

shelves covered. If glaze has dripped onto shelves, chip it off, smooth and re-apply kiln wash to these areas. Sandpaper may be

used to smooth these small areas before reapplying kiln wash. CAUTION: Do not coat the sidewalls, lid or bottom of shelves.

Take care to keep kiln wash off of the elements to avoid burning them out.

Plug the kiln in, making sure that the cord does not touch the kiln case which will become hot during firing.

KILN BREAK -IN

The purpose of the first (break in) firing is to get rid of any moisture in the kiln, and to burn off the protective coating

on the elements. (This will produce some smoke) Be sure to read all safeguards (page 2) and study directions on firing before

you test fire your kiln. We recommend firing the kiln with the shelves and posts but empty of ware to cone 05.

This firing will produce a good oxide coating on the elements which will help protect them and increase element life.

We do not recommend firing ware in the first kiln firing (the fumes could be hard on the unprotected elements). The

first firing will test the shelves, a very small percentage of which may crack on the first firing. (Test firing shelves is a wise

precaution for any new shelves.)

LOADING

Careful loading of ware in the kiln is important for satisfactory results. You need to plan the placement and distribu-

tion of the items to be fired. Careless, hurried loading might result in mishaps which could ruin hours of work. Also be sure

your hands are clean since dirt or oil may contaminate colors or affect the finish of your ware.

Remember that the insulating firebrick used in ceramic kilns is soft and fragile. Care should be taken to avoid dam-

aging the liner when loading (or unloading) the kiln. After several firings the brick may show fine cracks, particularly if the

kiln is fired to high temperatures (such as cone 6). This is normal and will not effect the function or structural integrity of your

kiln.

The lid brace locks the lid in the open position for loading and unloading the kiln. Pull the lid up until the lid brace

engages the slot on the arm, then lower until the lid is solidly braced before letting go. To unlock, pull the lid brace arm up

while raising the lid a few inches, then lower the lid past the locking slot and gently close the lid. Do not drop the lid, as the

firebrick is fragile.

Make sure that any ware you put into your kiln is bone dry (not cold to the touch). If pieces are hand molded make

sure that no air pockets remain in the clay. This causes small “explosions” when fired, since the air expands and the moisture

turns to steam. Hollow out the solid pieces whenever possible. Thick solid pieces can be fired safely only at very slow heating

and cooling rates. Solid pieces tend to crack and break more easily during firing than hollowed pieces.

Your kiln is designed to provide as uniform a heat as possible throughout the firing chamber. The kiln should be

loaded in a balanced manner; mix heavy pieces and light pieces. When firing in the same load, light and heavy ware should

be alternated on the same shelf and distributed throughout the kiln to help the kiln heat evenly. This will assure that all pieces

17

Your ware will fire more evenly if you allow for sufficient air circulation around pieces. If it is necessary to place pieces on

the floor of the kiln, it is recommended that you stilt them to allow for air circulation underneath. It is best to fire with a shelf

at least 1/2" off the floor of the kiln.

Never place ware closer than 1/2" from the elements in the kiln. One inch is preferable. Place large, flat pieces that

take up the full width of the kiln so that their edges are between element grooves. This will prevent the edges from heating

up before the center of the piece, causing possible damage by cracking from uneven expansion. To prevent unstable objects

from falling during firing use stilts to make sure they do not wobble. Take care that stilts will not strain rims and other delicate

areas.

It is important to always place shelves so that there is at least one element groove between shelves or between a

shelf and the lid. This will allow each compartment to heat evenly up to the proper temperature. WHEN PLACING POSTS,

LINE THEM UP SO THAT EACH POST IS DIRECTLY ABOVE THE POST BELOW TO PREVENT STRESSING AND

POSSIBLE WARPING OF SHELVES. POSTS MUST RUN IN COLUMNS THROUGHOUT THE KILN.

Remember when loading to place a large (witness) cone behind each of the peepholes for each firing so that you

can monitor the progress of that firing. For an accurate reading, cones should be placed 2" to 3" behind peepholes to avoid a

cooling draft. For more information on cones and their use, see the section on pyrometric cones.

There are variations in loading techniques depending upon the type of ware being fired. The following are recom-

mendations for loading different kinds of ware.

Loading Bisque

Low fire ceramic greenware pieces will not adhere to each other when fired, therefore they may touch one another.

They may be stacked and set directly on shelves without sticking. In some cases they may be nested or placed on top of one

another, if the weight is evenly distributed on the piece below. Do not, however, place a heavy piece upon a small piece or

the weight may cause the lower piece to warp or crack. Tile and large flat pieces should be fired flat on a shelf so they do not

warp. Slow firing is required in such cases because the shelf mass effects the temperature uniformity across the flat piece.

Strain on any delicate portion of a piece could result in distortion. Fire bisque items with their lids in place to assure a good

fit. Remember that although low fire greenware pieces may be touching there must still be enough room for sufficient air

circulation around pieces for even firing results.

Loading for glaze firing

Glaze is finely ground glass suspended in a liquid. Two glazed pieces, if allowed to touch each other will adhere

to one another when the glazes melt and re-solidify. Glaze will also adhere to the kiln or kiln shelf. Therefore stilts are used

when firing most glazed pieces. Stilts are small ceramic or pointed metal supports; a wide variety is available. In some cases

a piece may be dry footed (the base left unglazed). Be sure that the glaze is not applied too heavily, or it may “run” and stick

to the shelf or the bottom of the kiln.

Remember to prepare the kiln with kiln wash, as described earlier, especially when firing a glaze to prevent any

glaze from permanently adhering to the kiln bottom or shelves.

Glazed pieces should not be placed closer than 1/2" to one another since glaze bubbles before it smoothes to its

final surface. Bubbles and fumes from this process will contaminate adjacent pieces if spacing is not at least 1/2". We do not

recommend that glazed pieces and bisque be fired in the same load, since they are normally fired at different temperatures

and since this could cause discoloration. Bisque is normally fired one cone hotter than the same piece when glazed fired.

Do not stack or nest glazed pieces. Do not fire glazed pieces requiring lids with the lids in place as they will stick

together permanently.

Loading Overglaze, China Paint, Lusters, and Gold

Loading for overglaze pieces is the same as for your glazed ware, except that lusters should be spaced at least 1"

18

Loading stoneware and porcelain

It is necessary to fire stoneware and porcelain at a much higher temperature than that used

for low fire ware or glaze. At this heat the ware becomes much softer than ceramic bisque. For this

reason it may stick to other pieces and so should not be stacked or nested. It will also tend to distort in

shape unless the maximum temperature is accurately controlled and the piece is properly supported.

Hollow greenware pillars made of the same material as the ware are often used for support so that the

expansion and shrinkage of the support is the same as that of the ware. Do not support high-fire ware

on ordinary stilts. Often simpler shapes are supported by a reusable “setter” shaped for a particular

piece. Do not place ware closer than 3/4" from the elements to avoid uneven heating and distortion of

the piece.

Glazed porcelain and stoneware pieces, because of the high temperatures used, are always

dry-footed to prevent them adhering to the shelves.

Use high fire kiln wash. Some prefer to load stoneware unto surfaces sprinkled with silicaflour,

sometimes called “flint”. Keep “flint” away from the elements - it will cause them to burn out.

Loading glass

Do not fire small thin pieces of glass and large thick pieces in the same load. Glass sagging

is very sensitive to variation in temperature. Load only one or two shelves; keep the bottom shelf 3"

or more off the kiln floor and keep glass pieces at least 3" or more from the kiln top. Do not crowd

pieces at any time. Terra cotta molds, dusted with whiting (calcium carbonate) to prevent the glass

from adhering to the mold, are used in sagging sheet glass to shape. Do not use ceramic bisque molds

for sagging glass.

PYROMETRIC CONES

The most widely used method for monitoring the temperature achieved inside a kiln is the

pyrometric cone. A cone is a small elongated pyramid shaped indicator made of ceramic material which

is formulated to melt when subjected to a sufficient amount of heat. It does not indicate temperature

per se but the effects of temperature over a period of time. Cones react very similarly to the ceramic

ware, since they are similar in composition. They deform as a result of the influence of heat, time, and

kiln atmosphere, revealing what is happening in the kiln and when the proper firing temperature has

been reached.

A whole series of cones is available (see cone number - temperatures chart), made to melt at

different temperatures. Cones are available in two sizes. The large (senior or witness) cones may be

used at any location in the kiln to check temperature uniformity and firing progress. Small (junior)

cones are used specifically in kilns equipped with Kiln SitterR mechanical shutoff devices.

It is a good idea to make use of witness cones during firing, especially if exact temperatures are

critical. They are helpful both during the firing, allowing you to check on how the firing is progressing

and enabling you to turn the kiln off should maturity be reached before the kiln shuts off, and after the

firing, when you can make notes of the results to use in adjusting the programming and increasing the

accuracy of future firings. Witness cones also monitor the accuracy of the thermocouple, which may

degrade over time and eventually need replacing.

Always use a large cone of the number corresponding to the maximum desired temperature

behind each peephole during every firing in order to monitor firing progress and check the operation

of the control. Place the cone 2" to 3" behind the peephole to avoid cooling drafts and obtain an ac-

curate indication. Do not unplug the lower peepholes for more than a few seconds to avoid creating a

convection draft which can cool the cones and shock the ware. Do not place the cone too close to the

elements. Be sure to position it so that you will be able to see the tip when it bends and so that it will

not contact any ware when it bends. At high temperatures it is difficult to see the cones; using dark

19

It is important always to stand pyrometric cones at the pre-cut angle provided by the base of each cone; this

should be approximately 8 degrees away from vertical in the direction the cone is expected to bend. Setting the

cones consistently at this angle assures that each cone (of the same number) will bend at uniformly the same

temperature. Cone plaques or wire cone holders are commercially available. Holders may also be made from

brick or clay. Holders made from fire brick are generally reusable and trouble free. Standard cones may also

be purchased with wider self-supporting bases.

Periodically view the witness cones during firings. The kiln should shut off at about the time the cones

bend to a 90 degree angle. This cone will continue to bend a little after the kiln is shut off as the cooling is

slow. This effect is more dominant at lower cone numbers.

Placing at least one cone (more if you wish to check temperature uniformity) in each firing, even if

not visible from a peephole, is a good idea since noting its condition when you unload the kiln will confirm

that the load was properly fired.

An excellent way to check the temperature on any shelf in any location in the kiln is to use a cone

plaque containing three large cones. One is for the desired maximum firing temperature. The other two should

be numbered above and below the firing cone. For example, if firing to cone 06, use a cone 05, 06, and 07.

These are often referred to as the guide cone, firing cone, and guard cone. The lower temperature (guide) cone

bends as a warning that the desired temperature will soon be reached. The firing cone should bend until the tip

is at a 90 degree angle, and the guard cone, if bent too far, signals overfiring.

Be sure to keep pyrometric cones bone dry so that they will not crack in the kiln. Once dropped, roughly

handled or exposed to moisture, cones develop small cracks which tend to make them bend prematurely and

give an inaccurate temperature indication.

The cones generally used in firing clays and glazes in pottery work are numbered ranging from 07 to

04. A very common one which works satisfactorily in most cases is 06. Cones used to fire china paint, gold,

and decals range from 015 to 019. Cone 4 to cone 6 is used for porcelain. Stoneware may be fired to cone 8 or

cone 10. All clay and glaze manufacturer’s recommend the correct heat treatment for their products. Clays and

glazes do vary, so check labels or ask your local ceramic supply dealer for advice on the proper cones to use,

since he knows the characteristics of the clays and glazes he handles.

FIRING

A kiln is designed to produce the extremely high temperatures necessary to chemically alter ceramic

materials. Use caution and common sense to avoid burns when the kiln is in operation, since the kiln surfaces

will be hot. It is therefore imperative that you read and observe all safety precautions.

Safety cautions

Do not leave the kiln unattended, such as firing over night. Even though your kiln has an electronic

control, it is advisable to use a large cone visible through the peephole to check firing progress. Check witness

cones at (1) hour intervals through firing, at the expected shutoff time and every half hour thereafter until the

cone is properly bent or the control has turned off. Always check to see that the control has operated correctly.

Always monitor the progress of each firing.

Never open the lid while the kiln is firing. This could cause serious burns as well as damage to the

ware and kiln. After firing always allow the kiln to cool with the lid closed until it is cool enough for you to

unload it with your bare hands.

A two position lid prop is provided. The highest lid prop position is used for normal venting at the

beginning of the firing cycle. It operated simply by rotating a prop to engage the catch mounted on the lid.

After the kiln reaches 1000 degrees F, release the prop by raising the lid by the handle (use protective glove)

so that the prop swings out of the way, and gently lower the lid. The lowest lid prop position is used for the

later portion of the firing cycle for china, lusters, and gold firing to obtain the best results.

The peepholes, as the name implies, allow you to look into the kiln and, along with witness cones

placed on the shelves, to monitor firing progress. In most instances, the kiln is fired with the lower peephole

plugs in place and the top most peephole open.

20

Firing Speed

The main consideration for firing speed is that you should not fire faster than the ware will absorb heat, and

you should not cool faster than the ware will release heat. A specified amount of heat over a certain amount of time

is necessary to produce the chemical changes that result in a finished piece. Firing and cooling rapidly will result in

stressing and even cracking or crazing the ware due to uneven expansion. Very thick pieces, such as hand molded

sculptures, require very slow heating and cooling. Slow heating also allows moisture to escape without damaging the

ware, and slow cooling allows glazes, which may bubble when gases escape during the vitrification process, to return

to a smooth finish.

The maximum degree of heat and the length of time necessary vary widely according to many factors such as

the type of ware (porcelain, earthenware, stoneware, etc.) or glaze, paint or decal, the thickness of the piece, the size

of the load being fired, the voltage available and the condition of the elements.

Remember that during firing you will not endanger your ware by turning the kiln off before maturity. If you

ever hear pieces cracking or falling, or if your kiln has been jarred, turn the kiln off. Wait until it is cool, then open and

check for problems that may have developed. Replace all cones with new ones before firing again.

Element life varies depending upon the frequency and temperature of firings. They will last for many firings

if treated properly. Keep the element grooves free of debris of any sort which will eat through the element and cause

it to burn out. Also keep in mind that after repeated firings elements become brittle and will break if struck or scraped.

Do not fire your kiln hotter than the temperature for which it is rated.

Venting

Conventional venting consists of propping the lid during the first part of the firing cycle and firing with the

top peephole unplugged to allow fumes to escape. The optional Cress Fanfare kiln exhaust system is an excellent way

to provide ventilation and has many advantages. Besides removing fumes coming off the ware from the kiln room and

eliminating the need to prop and then lower the lid during firing, the Fanfare increases temperature uniformity, provides

for less cross contamination of colors during glaze firings, and achieves the clearest, brightest and purest colors pos-

sible.

Firing Glass

Glass is very sensitive to variations in temperature of only a few degrees. Glass must be allowed to pass through

the lower temperatures slowly to prevent shattering, then it may be fired rapidly up to temperature (firing rapidly at this

point helps preserve colors). Glass softens quickly once the critical temperature is reached and sagging begins (usually

approximately 1500 OF for glass slumping); it is wise to check it often at this point (at 10 minute intervals) and when it

has slumped properly, turn off all switches, crack the lid at the lower lid prop position for up to ten minutes to prevent

over softening of the glass, then close the lid and allow to cool completely.

Glass is slumped onto terra cotta molds dusted with whiting (calcium carbonate) to prevent sticking. Be sure

to the glass loading section.

Firing charts

It is a valuable practice to keep a written record of each firing, noting the settings (even the degree of deforma-

tion of witness cones and their locations.) This firing chart allows you to repeat good results and successful firings and

avoid repeating less than satisfactory firing results.

AFTER FIRING

When the firing cycle has been completed, the display will read CPLt. If you need to monitor the tem-

perature as the kiln is cooling, press "stop", then turn the power switch off at the end of the cooling. Otherwise turn

power switch off when the display reads CPLt.. Allow the kiln to cool naturally, and do not open the peepholes or

prop the lid (unless working with glass, metallics, or lusters in which case some special venting techniques may

be necessary) until the kiln has cooled to at least 130 OF and you can unload it using your bare hands. If the kiln is

opened prematurely, the ware and even the kiln could be damaged. You should expect the cooling period to take at

least twice as long as the firing cycle took to complete.

This manual suits for next models

6

Table of contents

Popular Other manuals by other brands

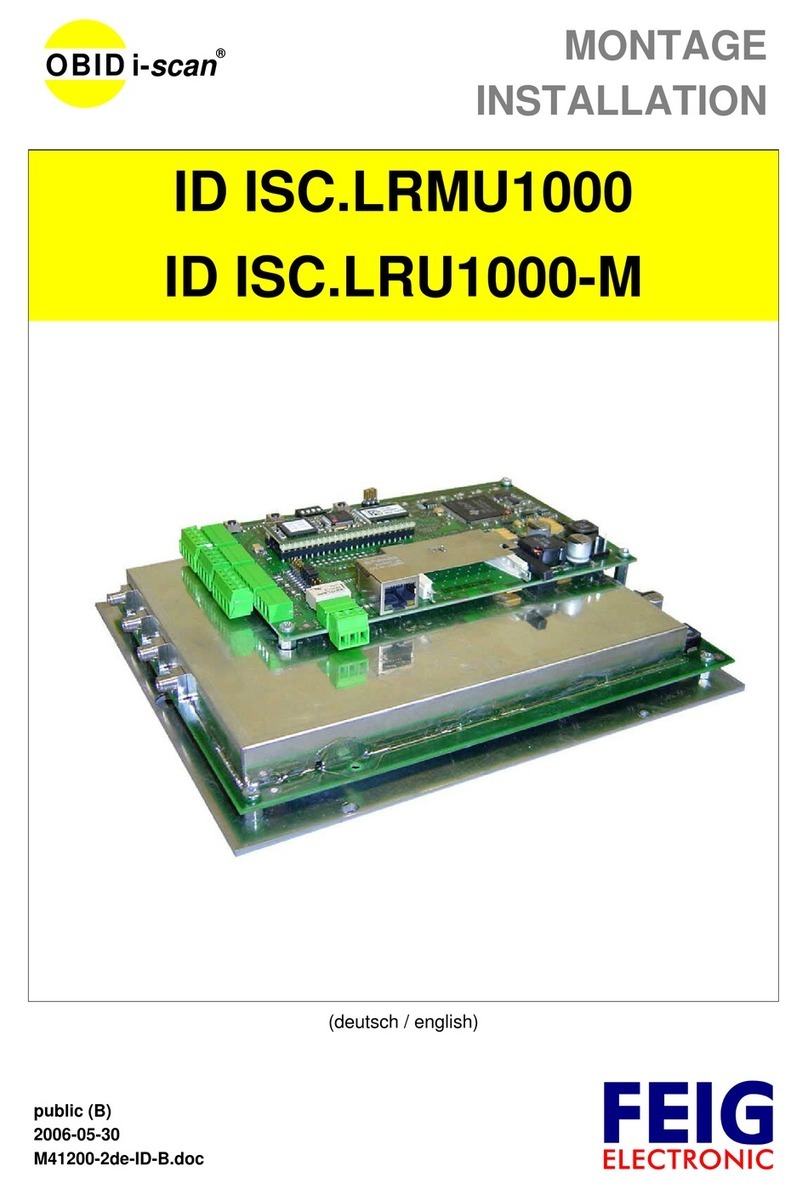

Feig Electronic

Feig Electronic OBID i-scan ID ISC.LRMU1000 installation manual

Feig Electronic

Feig Electronic OBID ID ISC.ANT340/240-A Mounting instruction

weBoost

weBoost Drive 3G-Flex 470013 user guide

GMP

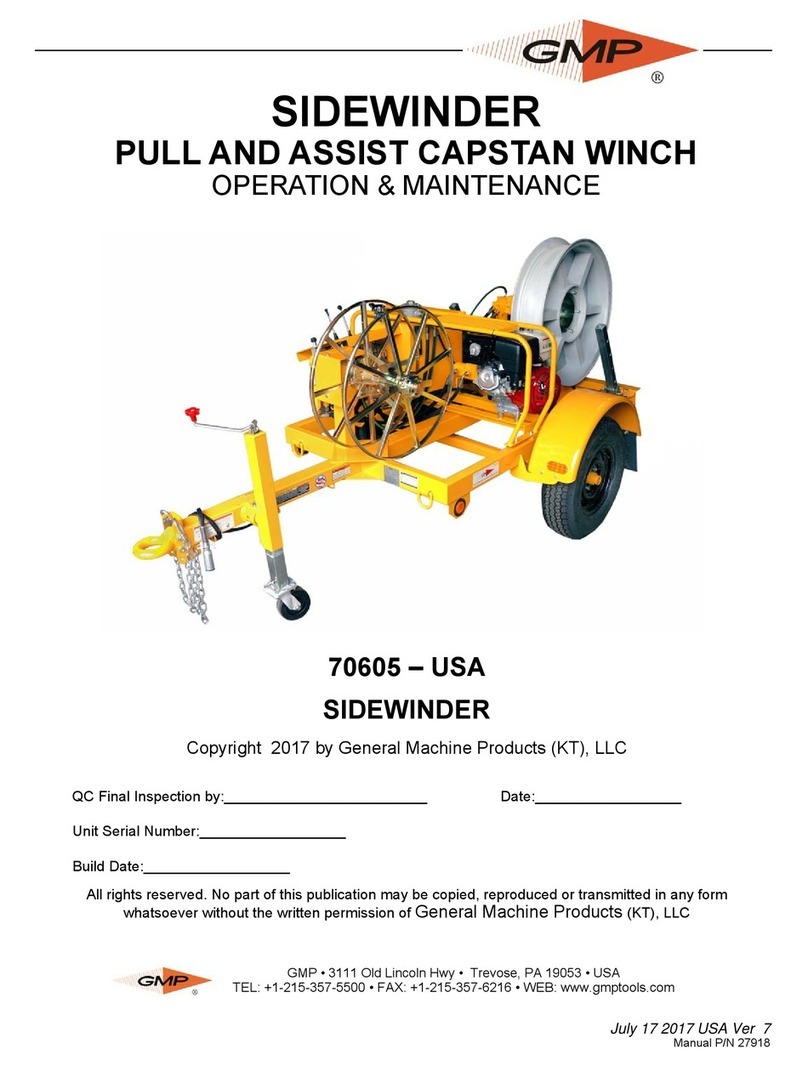

GMP 70605 operation & maintenance

SNOWJOE

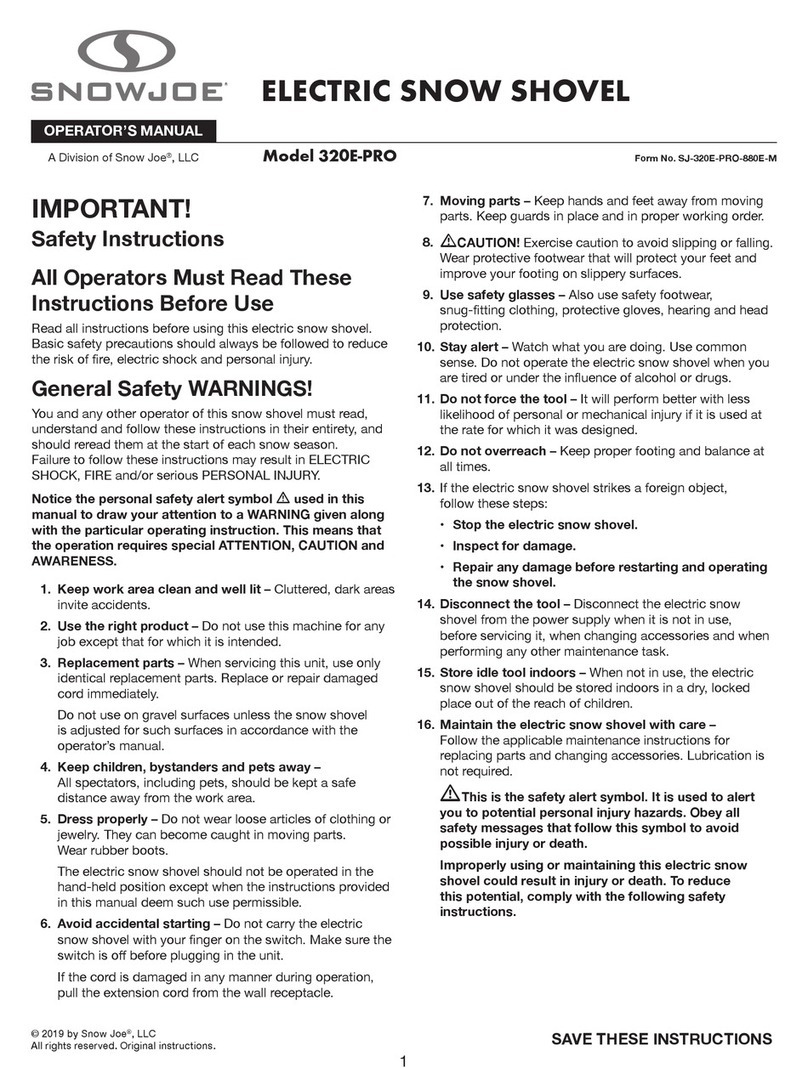

SNOWJOE 320E-PRO Operator's manual

Roller

Roller Multi-Control SL operating instructions