GMP 70605 Troubleshooting guide

Page of 24 General Machine Products (KT), LLC

70605 – USA

SIDEWINDER

Copyright 2017 by General Machine Products (KT), LLC

All rights reserved. No part of this publication may be copied, reproduced or transmitted in any form

whatsoever without the written permission of General Machine Products (KT), LLC

SIDEWINDER

PULL AND ASSIST CAPSTAN WINCH

OPERATION & MAINTENANCE

GMP • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA

TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • WEB: www.gmptools.com

QC Final Inspection by:_________________________ Date:__________________

Unit Serial Number:__________________

Build Date:__________________

July 17 2017 USA Ver 7

Manual P/N 27918

Page 2 of 24 General Machine Products (KT), LLC

REVISION HISTORY:

Rev

No. Date Details Author

01 03-2006 Original issue A Miller

02 05-2007 US Version A Konschak

03 09-2009 Update manual to be consistent with others A Konschak

04 03-2010 Added figure 8 instruction and illustrations A Konschak

05 01-2014 Added new filter information A Konschak

06 09-2016 Updated photos, updated yearly service details A Konschak

07 07/2017 Updated Company Name, warranty information A Konschak

Page 3 of 24 General Machine Products (KT), LLC

CONTENTS

1.0 Introduction

2.0 Safety Instructions

3.0 General Description

4.0 Specification

5.0 Operating Procedure

6.0 Maintenance and Servicing

7.0 Towing Instructions

8.0 Equipment Layout

9.0 Spare Parts

Warranty information can be found at http://www.gmptools.com/warranty

APPENDICES

Appendix 1 Hydraulic Circuit Drawing

Page 4 of 24 General Machine Products (KT), LLC

Founded by engineer George M. Pfundt in 1936, GMP started op-

erations in a downtown Philadelphia building as a specialty ma-

chine shop doing work for the local Bell Telephone company and

for the electric utility company. GMP expanded to a production

shop after landing a contract

with Western Electric Compa-

ny and, subsequently, forming

a close relationship with Bell Telephone Laborato-

ries in Murray Hill, N.J., which enabled it to manu-

facture prototypes of products for experimental

use within the Bell System.

Having outgrown the original factory building, the

company built a 100,000 square foot plant in Tre-

vose, PA (a Philadelphia suburb) and moved there

in 1957. Today GMP is recognized as a premier

worldwide supplier of specialty tools and equip-

ment for the outside plant marketplace. The company's products are known for their

robust design and durability to withstand many years of frequent use.

1.0 INTRODUCTION

Page 5 of 24 General Machine Products (KT), LLC

2.0 SAFETY INSTRUCTIONS

THIS EQUIPMENT MUST ONLY BE USED BY AUTHORIZED PERSONNEL, WHO

HAVE BEEN SUITABLY TRAINED AND COMPETENT TO DO SO.

1. Read and understand the operation and maintenance manual supplied with this

equipment. Keep it in a convenient place for future reference.

2. Keep children and untrained personnel away from this equipment while in operation.

3. Keep all guards and safety devices in place. Do not operate this equipment with

guards removed or damaged.

4. Keep hands, feet and loose clothing away from moving parts.

5. Always stop the machine to carry out lubrication or servicing.

6. Check machine before starting for worn or damaged parts. Check that all nuts and

bolts are tight.

7. If machine is left unattended, ensure that unauthorized use is prevented.

8. Never leave the machine unattended while in use.

9. Consider the use of safety barriers, especially when used in public places.

10. Beware of pinch points involved with rotating components, e.g. rope/cable drums,

capstans, bullwheels, shafts and chain drives.

11. Beware of hot surfaces, especially around the engine, engine exhaust pipe and hy-

draulic oil tank.

12.Some component and assembly parts are in excess of 55lb (25kg) . When lifting

care must be taken, ensure sufficient man power/lifting gear is available, to pre-

vent personal injury and damage to the machine.

13.Beware of exposed electrical contacts especially around the engine. Do not

touch, or allow metal objects to come into contact.

14. Waste engine and hydraulic oils are to be disposed of via an environmental-

ly acceptable method – e.g. passed on for recycling.

15. Wear ear protection when engine is running to prevent ear damage.

16. Machine may cause additional fire hazard if involved in an existing fire due to gaso-

line, diesel, oil and hydraulic oils involved.

17. No personnel are to be in manholes or ducts when the winch is being operated.

18. The machine must be operated on firm ground.

19. Stay clear of cables or lines under tension.

20. Only use the machine for its intended purpose.

21. Do not tamper with pressure relief valves or pressure reducing valves.

22. Rear stabilizing props must be down and on solid surface before use.

THESE INSTRUCTIONS ARE TO BE MADE AVAILABLE TO

OPERATORS OF THIS EQUIPMENT AT ALL TIMES, FAILURE TO

OBSERVE THESE SAFETY INSTRUCTIONS COULD RESULT IN

SERIOUS PERSONAL INJURY AND / OR PROPERTY DAMAGE.

Page 6 of 24 General Machine Products (KT), LLC

3.0 GENERAL DESCRIPTION

The GMP SideWinder is a trailer mounted pull and assist capstan winch,

mounted on a sturdy all-steel fabricated chassis. It is equipped with torsional

suspension axles, stabilizing prop legs, a front telescopic jockey wheel and a

tow bar with a Lunette Ring. The unit is easily pulled by a standard pickup

truck.

The power source is a gasoline engine which drives the fixed displacement

tandem mounted hydraulic pumps. The hydraulic pump is attached to the en-

gine via a bell housing and flexible coupling. One pump powers a hydraulic

motor, through an in-line planetary gearbox, to the capstan. The second pump

drives the rope take-up drum again through a hydraulic motor.

The hydraulic oil tank is fitted with double filtration protection, sight glass and

filler/breather.

Controls are operator friendly and very simple to use. A spring centered lever

controls the direction of rotation of the capstan, while a detented lever engag-

es the take-up drum drive. A control knob is used to limit the rope/cable ten-

sion using the panel mounted tension indicator.

The rope take-up drum is removable and can be split to enable removal of

rope. The capstan can be rotated through 90° on a swivel bracket from the in-

line working position to the transverse transit position when in tow.

When the winch is in the working mode the rear props are extended out of the

chassis to provide greater stability.

Page 7 of 24 General Machine Products (KT), LLC

4.0 SPECIFICATION

Max. Pulling Capacity 1100 lbs (500 kg)

Rope Speed Max. 200 ft/min (60 m/min)

Capstan Diameter 32” (813 mm)

Dimensions: Length: 123” (3124 mm)

Overall Width: 69” (1753 mm)

Height: 57” (1450 mm)

Weight: 1400 lbs. (635 kg)

Track: 60” (1676 mm)

Tire Size: F78-14 205/75D14

Coupling: Lunette Ring (Pintle hook)

Lighting Adapter: 7-Way (others available by request)

Power Supply: Honda GX390 11.7 HP, Recoil Start, Overhead Valve, Cast Iron

Cylinder Sleeve, 1.5 Gallon tank

Load Indication: Calibrated gauge bezel

Main Drive: Fixed displacement tandem pumps to fixed displacement high

torque motors.

Gear Box: In-line planetary gearbox (capstan drive)

Gear Oil Grades: MobileLube HD Plus 85W-140

Refer to the instruction manual supplied with the gearbox for

alternative oil types and grades

Controls: (a) Pay-in / pay-out spring centered control valve.

(see section 8) (b) Detented take-up drum drive control valve.

(c) Tension control knob

(d) Tension indicator

Hydraulic Circuit: Closed circuit system with full filtration and overload protection

Hydraulic Oil Tank Capacity: 16.5 Gal. (63 Liters)

Hydraulic Oil Grade: Tellus T-32

Rear View

Page 8 of 24 General Machine Products (KT), LLC

5.0 OPERATING PROCEDURE

IT IS IMPERATIVE THAT ALL PERSONS USING, OPERATING OR MAINTAINING

THIS WINCH BE FULLY TRAINED AND COMPETENT TO DO SO, AND HAVE

READ THE ENTIRE OPERATING MANUAL.

GMP CANNOT BE HELD RESPONSIBLE FOR MIS-USE OF THIS EQUIPMENT.

5.1 CONTROLS

The operator controls have been designed to be safe and simple to use, with regard to

ergonomic considerations. The operators control station is complete with the following:

(see section 8)

(a) Control lever for winching in and paying out. This provides bi-directional selection of

capstan rotation. The valve spool has a soft start facility allowing for a limited creep

and inching movement.

(b) Control lever for operation of the rear take-up drum. This lever should be in its oper-

ating position before operating the capstan. If the winch is not being used, this lever

should be returned to its non-operating position, thus saving on fuel and preventing

the hydraulic oil from overheating.

(c) Tension control knob. This can be used to limit the actual pulling tension applied to

the capstan.

(d) Pressure gauge which is also an indication of the pulling tension.

5.2 PRE-WINCHING PROCEDURE

Prior to using the winch for any hauling application, it is important to ensure that the

rear prop legs are extended and lowered in order to level the winch, and that the

front jockey wheel is also lowered to a position where the winch is firm and stable.

The winch should be securely anchored to either a suitable vehicle, ground anchors

or other substantial holding point. The winch should be in line with the direction of

pull.

Refer to the pre-winching maintenance checks in section 6.1.

The capstan must be rotated from the “Transverse” transit position to the In-Line

working position. Ensure that the retaining pin and hair-pin are correctly replaced.

It may be necessary to remove the lighting board. This is accomplished by first

un-plugging the connector from the rear jack on the trailer, and then pulling the

spring loaded release pins. The complete lighting board can then be removed

and stored safely.

Page 9 of 24 General Machine Products (KT), LLC

5.3 PAYING OUT ROPE

The rope take-up drum should be de-clutched by removing the lynch pin at the end of

the drum shaft, grasping the drum flange, pulling and then rotating. Once the drum is

free from its drive clutch, it is free to rotate on the shaft and the rope can be pulled

manually from the drum.

5.4 STARTING THE ENGINE

The engine manufacturer’s operating and service manual form an integral part of

this manual. It is recommended that these instructions are read and fully under-

stood by all operating personnel before starting the engine.

Before starting the engine, check the fuel level, engine oil level and oil level in hy-

draulic tank.

5.5 PULLING IN

5.5.1 The rope should be wrapped around the capstan such that:

(a) The rope to take-up drum comes off the top of the capstan and is furthest away

from the operator.

(b) The rope to the fiber cable (load side) comes off the top of the capstan, and near-

est to the operator and gearbox. Approximately four to five complete turns are re-

quired.

Top View

Operator

Page 10 of 24 General Machine Products (KT), LLC

5.5.2 Operate the drum control lever to engage the drum drive. This should be left in its

operating position at all times that the winch is working. At all other times it is advanta-

geous to return the drum control lever to its non-operating position.

5.5.3 Operate the winch control lever by pulling gently towards the operator. The rope

will now be pulled in and be wound onto the rope take-up drum. The speed of pulling

can be increased or decreased by adjusting the engine speed control. The specific

maximum pulling tension is adjusted by the operator by turning the tension control

knob to suit the application.

When winching is completed, move the take-drum operating lever to the “off” position.

5.5.4 When being used as an assist winch, the drum drive is not required and therefore

the operator should ensure that the lever is in the off position. Capstan wrapping of the

cable should ensure that the high tension side should be nearest to the gearbox and

hydraulic motor.

5.6.0 The winch is capable of being used to “figure 8” fiber cable. The capstan should

be rotated to 30° and locked in place by the supplied bolt and nut as shown in photo

below.

From Reel

Page 11 of 24 General Machine Products (KT), LLC

5.6 REMOVING ROPE FROM SPLIT DRUMS

The split drum has been designed to enable removal of the rope in a complete coil. In

order to achieve this, ensure that the drum is fully engaged in its clutch and untie the

rope from the drum.

It is often advantageous at this stage to tie a few wraps of waste string, tie wraps or

tape around the rope coils, ensuring that the string does not pass around one of the

drum spokes. This will help to keep the rope in a nice tight coil when released from the

drum.

To remove the rope from the drum, first remove the retaining pin on the drum’s drive

shaft. Remove the locking bolt from the drum flange-retaining nut. The ears on the nut

can now be used to release the nut by rotating counter-clockwise. Because of the tight-

ness of the rope on the drum, a soft-faced hammer may be used on the retaining nut’s

ears to help with the initial movement. The nut and outer drum flange may then be re-

moved. The rope coil may now be removed. Re-assemble the drum.

5.7 ON COMPLETION OF THE WINCHING OPERATION

The machine should be wiped down and cleaned.

The capstan should be returned and fixed in the transverse transit position.

The lighting board should be re-fitted and the light operation checked.

The winch should be preferably stored in a dry place e.g. garage or workshop.

Page 12 of 24 General Machine Products (KT), LLC

6.0 MAINTENANCE AND SERVICING

It is recommended that this winch is serviced every 12 months, regardless of its con-

dition or the number of operating hours used. This will help to ensure reliable, trouble

free service. It is imperative that any maintenance work is carried out by personnel

suitably trained and qualified to do so.

6.1 PRE-WINCHING MAINTENANCE CHECK

This should be carried out each day prior to the start of winching.

6.1.1

Check the hydraulic oil level. Oil should be visible within the black lines marked on

the hydraulic oil level sight gauge. Replenish if necessary with the correct grade of

hydraulic oil to suit the climatic conditions. (Refer to the section 4 for grades of hy-

draulic oil required).

6.1.2

Check the engine oil level as indicated in the engine manufacturers manual. Replen-

ish if necessary.

6.1.3

Check that there is enough fuel in the tank to complete the planned winching sched-

ule.

6.1.4

Check the condition of the hydraulic hoses, replace if damaged.

6.1.5

Check the condition of the pulling rope, particularly where it joins the drum. Only use

a good condition rope of suitable pulling capacity

6.1.6

Check that all screw fasteners are tight.

6.1.7

Check the hydraulic oil system for leaks, rectify before proceeding.

6.1.8

Clean any dirt or debris from the take-up drum shaft and capstan face.

Page 13 of 24 General Machine Products (KT), LLC

6.2 MONTHLY MAINTENANCE

This should be carried out at intervals not exceeding 4 weeks. These intervals will de-

pend upon the degree of use of the winch.

6.2.1

Carry out all the pre-winching checks as detailed in 6.1

6.2.2

Check the function of all the lighting equipment, this should be more frequent if regular

problems arise.

6.2.3

Check and adjust the tire pressures.

6.2.4

With the engine and drum shaft running, check the return filter condition indicator. This

is a red/green indicator mounted on the hydraulic oil tank return line filter. If the indica-

tor is well over into the red area, replace the filter.

6.2.6

Grease all bearings and grease fittings.

6.2.7

Oil all moving parts to prevent corrosion.

6.2.8

Apply oil to all oilite bushes.

6.2.9

Check the condition of the towing breakaway chain. If damaged, replace immediately.

Page 14 of 24 General Machine Products (KT), LLC

6.3 ANNUAL SERVICING

This should be carried out at approximately 12 monthly intervals by a qualified and

experienced workshop team.

6.3.1

Carry out all the work as specified above in section 6.2

6.3.2

Drain the hydraulic circuit of oil. Clean the filler/breather and replace. Renew the suc-

tion filter element and return line filter element. Refill with fresh oil. Check and reset

all relief valves, (Refer to section 6.4 for further information).

Refer to section 4 for grades of hydraulic oil.

6.5.3

Service the engine as per the engine manufacturers manual supplied with the winch.

6.5.4

Check the condition of the tires, and running gear. Adjust and reset if necessary.

6.5.5

In-line planetary gearbox (capstan drive):

Change the gearbox oil, (refer to section 4 for gear oil grades) refer to the instruction

manual supplied with the gearbox for further details on maintenance and servicing.

6.5.6

Ensure that the support that holds the drive capstan has a liberal amount of grease at

its base where it rotates.

6.5.7

Lubricate the pillow block bearing with a high

quality bearing grease by removing the four re-

taining bolts and lifting off the cover to gain ac-

cess to the grease fitting.

Lubricate with high quality

general purpose grease.

The grease fitting is found

under the plate.

Page 15 of 24 General Machine Products (KT), LLC

6.4 RELIEF VALVE SETTING

Reference should be made to the hydraulic circuit diagram on page 19 of this manual.

There are four relief valves in the circuit and with the exception of item 10, all have been

factory pre-set and should not be adjusted. Item 10 is adjusted by the operator to set a

maximum pulling tension.

If it is necessary to replace or adjust any of the relief valves, the following guidance should

assist.

Item 7 This is a Capstan directional control valve. The relief valve is mounted in the body of

this control valve and is the main system relief valve. With a Dynamometer in the rope load

line, and with 4 complete turns around the capstan, this relief valve should be set to relieve

at 1200 lbs. (550 kg), approx. 1880 psi (130 Bar). Note: Relief valve adjustment is hidden

by a protective cap and sealing washer.

Item 8 This relief valve is situated on the drum directional control valve. This controls the

rope tension between Capstan 10 and Drum when pulling in. The valve should be set to

relieve when the rope tension measures approx. 85-110 lbs. (40-50 kg). This measurement

and adjustment should be made when the rope drum is almost empty. Note: Relief valve

adjustment is hidden by a protective cap and sealing washer.

Item 2 This relief valve is mounted in an aluminum body connected to the drum hydraulic

motor. This valve prevents drum overrun when paying out under power. With the rope drum

almost empty, the relief valve can be set so that a rope tension of approx. 85 lbs. (40 kg)

will cause the drum to rotate.

Item 10 This relief valve is mounted in an aluminum body connected to the capstan hy-

draulic motor. It is intended that the site supervisor will set this relief valve to give maximum

rope tension to suit specific operating conditions. There are two adjustments, limiting for-

ward and reverse.

Item 7 Item 8 Item 2

Item 10

(Forward Capstan)

Item 10

(Reverse Capstan)

Control Panel FrontControl Panel Rear

Page 16 of 24 General Machine Products (KT), LLC

7.0 TOWING INSTRUCTIONS

BEFORE TOWING

A. Check the load is distributed to give a positive hitch weight to ensure stable towing.

Also ensure the hitch weight is within limit of the vehicle.

B. Ensure that the Pintle hook is locked and the safety chains are securely attached to

the tow vehicle.

C. Make sure that the Jockey wheel is rotated up in the driving position and that the

rear prop legs are securely retracted and locked.

D. Make sure all trailer lights are working properly.

E. Check tires for proper inflation.

Page 17 of 24 General Machine Products (KT), LLC

1 CAPSTAN

2 TOW BAR

3 ROPE TAKE-UP DRUM

4 JOCKEY WHEEL

5 REAR PROP LEG

6 CAPSTAN DRIVE GEARBOX

7 ROPE TAKE-UP DRUM HYDRAULIC MOTOR

8 ENGINE

9 HYDRAULIC PUMPS

10 HYDRAULIC OIL TANK

11 HYDRAULIC OIL TANK FILLER / BREATHER

12 RETURN LINE FILTER

13 CONTROL PANEL

14 REAR LIGHTING BOARD

15 AXLE AND WHEELS

16 CAPSTAN HYDRAULIC MOTOR

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

8.0 EQUIPMENT LAYOUT

Page 18 of 24 General Machine Products (KT), LLC

A B C

D

CAPSTAN WINCH CONTROL PANEL

A. WINCH IN / PAYING OUT CONTROL LEVER

B. ROPE TAKE-UP DRUM OPERATION CONTROL LEVER

C. TENSION CONTROL KNOB

D. PRESSURE GAUGE / TENSION INDICATOR

HYDRAULIC OIL TANK SUCTION FILTER

Page 19 of 24 General Machine Products (KT), LLC

For spare parts, call:

General Machine Products (KT), LLC 3111 Old Lincoln Highway Trevose, PA 19053

Tel: +1.215.357.5500 Fax: +1.215.357.6216 Email: info@GMPtools.com

Typical User Replaceble Parts: Part Number:

Oil Tank Filler Breather 32073

Oil Tank Suction Filter 32134

Return Line Filter Element 34565

Sight Level Gauge 32053

Return Line Filter Element Replacement

Replace the Return Line Filter Element when the ar-

row of the clogging indicator is in the red range.

1.Unscrewthereturn

linefiltertopcapusinga

suitablewrench.

2.Removethecloggedele‐

mentandplasccarrier.

Twistandpulltheelement

toseparateitfrom

thecarrier.Installnew

elementincarrierand

dropinfilterhousing.

3.Replacethetopcapmak‐

ingsurenottocrossthe

thread.Checkforleaksaer

9.0 USER REPLACEABLE PARTS

Indicator showing need for filter

element replacement.

34565 Return Line Filter Element

Page 20 of 24 General Machine Products (KT), LLC

Hydraulic Circuit Drawing

Table of contents

Popular Other manuals by other brands

Aqua Medic

Aqua Medic Refill System 2.0 Operation manual

Bavarian Demon

Bavarian Demon 3X instructions

BEAUTY ANGEL

BEAUTY ANGEL CVT 32 operating instructions

Alfalaval

Alfalaval Toftejorg TZ-67 instruction manual

Aqua Medic

Aqua Medic Ozone 25 Operation manual

Aqua Medic

Aqua Medic aquarius plant 60 Operation manual

less care

less care Ultra G Series installation instructions

Aqua Medic

Aqua Medic CO2 reactor M Operation manual

Aqua Medic

Aqua Medic Powerfilter PF 1000 Operation manual

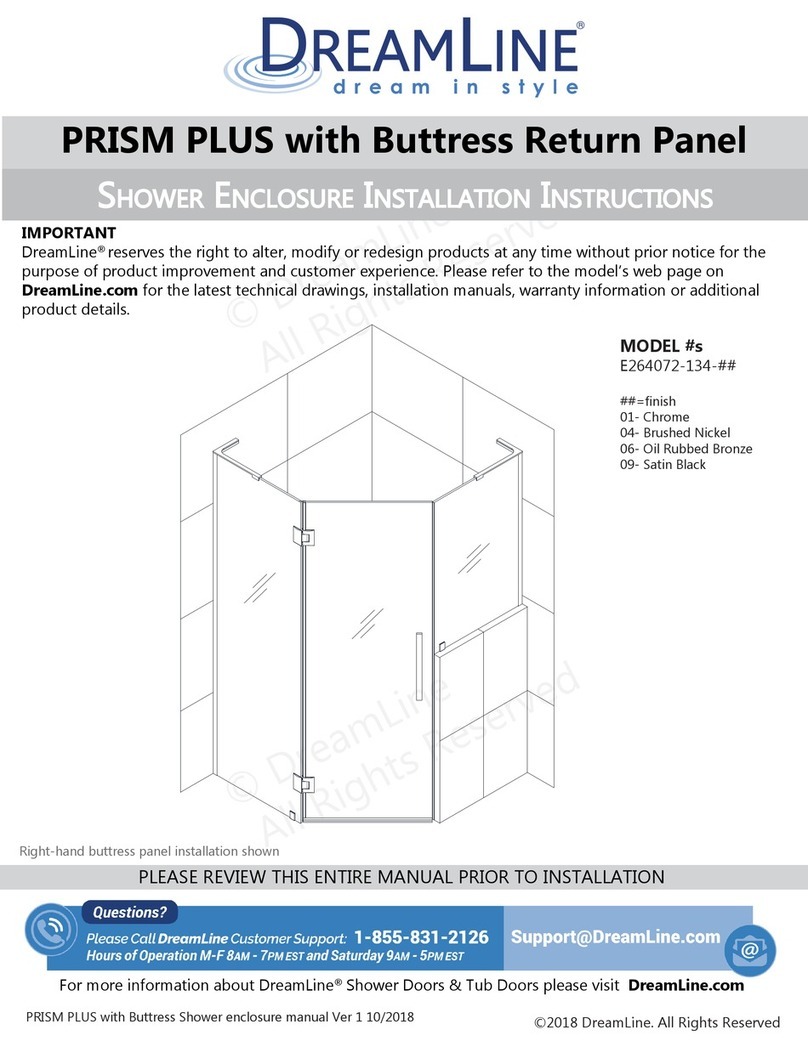

Dreamline

Dreamline PRISM PLUS E264072-134 Series installation instructions

Easy@Home

Easy@Home MD-818 user manual

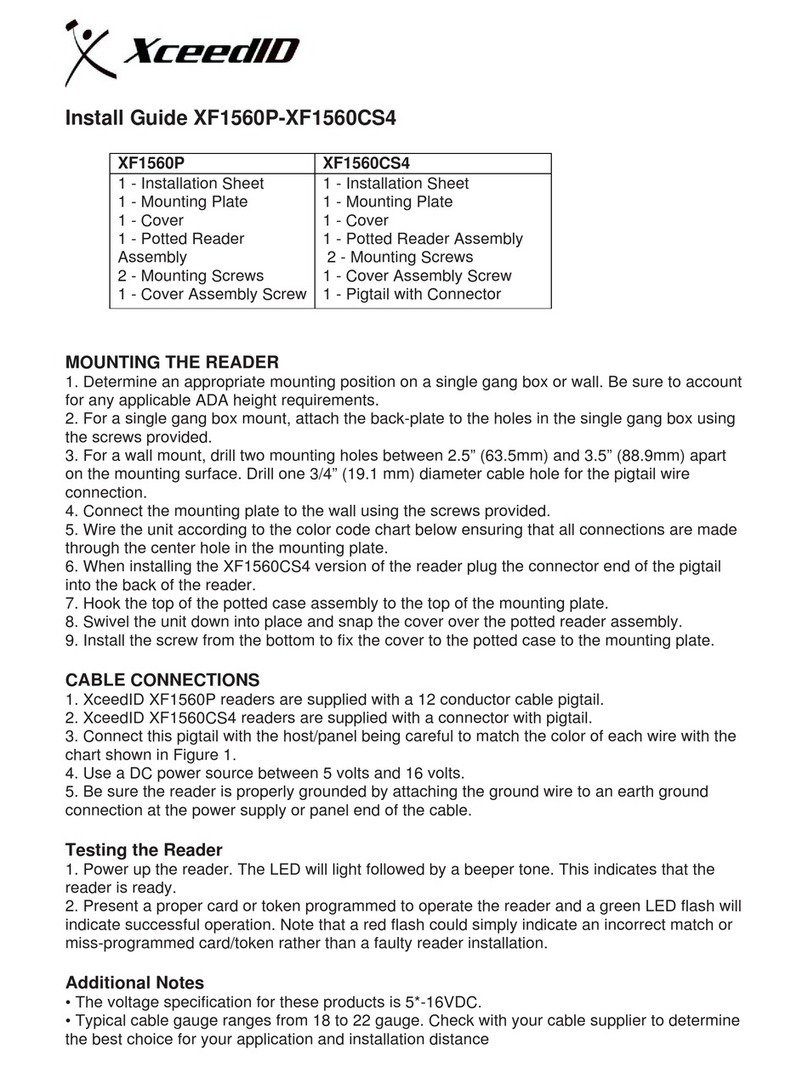

Xceed ID

Xceed ID XF1560P install guide