Crestwood CP-201 User manual

PHoToFAcr- FolJ"* CRESTWOOD

moDEt cP-201

oo

oq

Od.

}Y

hE

6g

3*

Hq

rq

;{

po

leO

9e

Figure 1

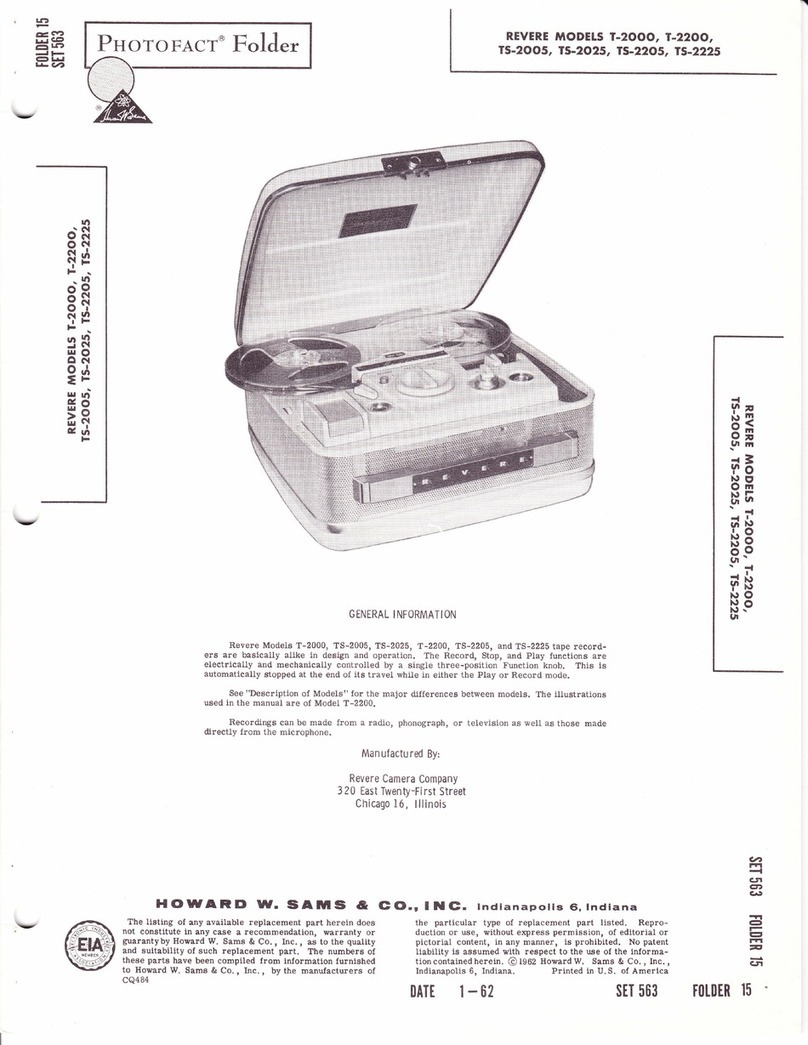

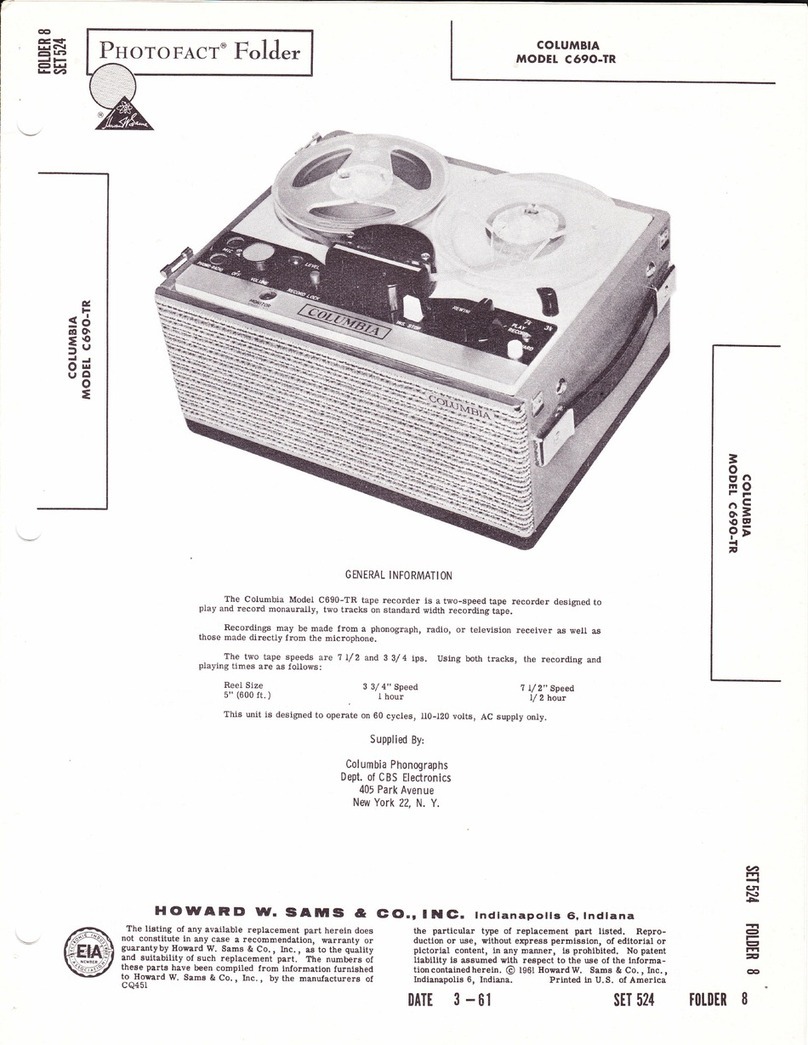

GENERAL INFORMATION

The Crestwood Tape Recorder, Model CP-201, is designed to magnetically record

on a standard ?-inch reel of" lf{" wide tape, two tracks instead of one, which

doubles the playing time with no loss in frequency response or quality.

Erasing, in the Model CP-201, is obtained by a 35 KC frequency at approximately

1?5 volts through the erase head coil. The erase head is so placed on the recorder

that the tape passes through it before the recording head. Erasure takes place

automatically as recording occurs, so that no special step is necessary.

Power supply is from 105-120 volts, 60 cyclesAC. Do not connect the unit to

DC power source.

Manufactured by:

Crestwood Recorder Corporation

218 South Wabash Avenue

Chicago 4, Illinois

Fhis molerial compiled and published by

& co., lNc., INDIANAPO

0ut t2_50

o ALL N,IGHTS RESERVED

Lls,

sff il8 lNDIANA

t0rDtn 4

HOWARD w. sAil 5

OPERATING INSTRUC TIONS

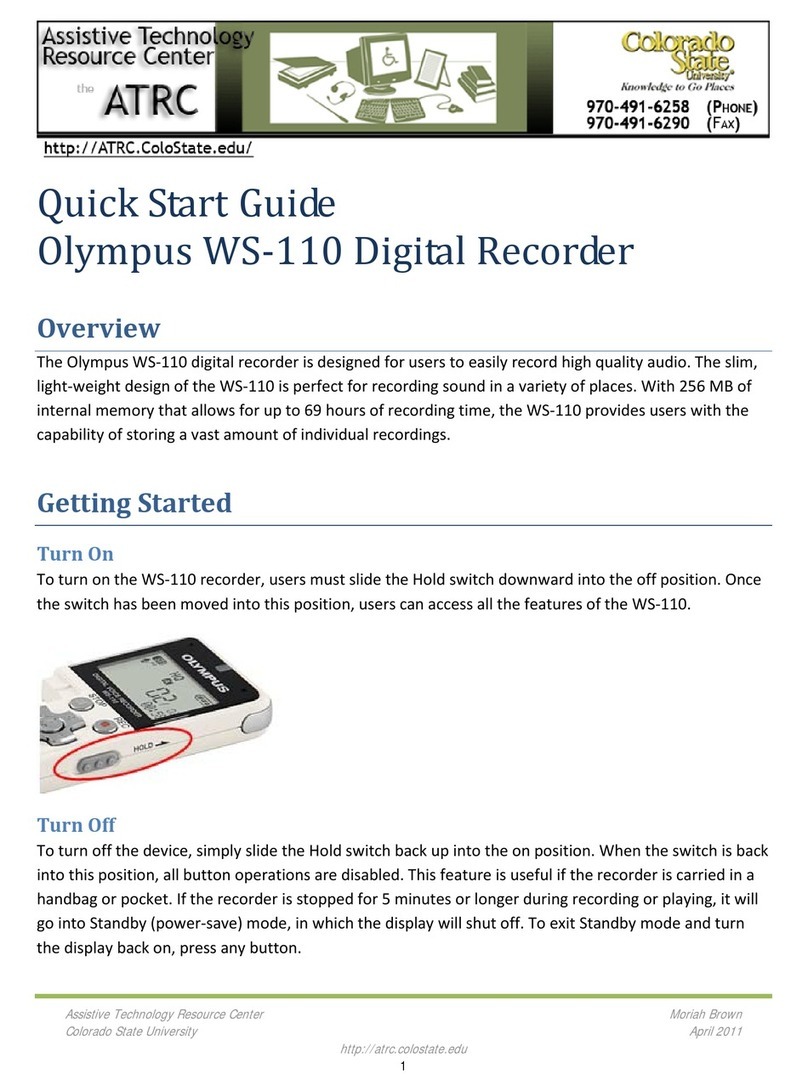

Preparing the Crestwood for Recording -

1. Insert line cord in a convenient wall recep-

tacle of the proper rating.

2. Turn the volume control knob to the right -

pilot light will light up;

3. Place a full reel of tape on the right hand

spindle (11). Make sure the magnetic coating (dull

side) is on the right spindle (11). Make sure the

magnetic coating (dull side) is on the outside of the

reel.

4. Place an empty reel on the left-hand

spindle (22), and feed the end of the tape in the slot

located between the two reels and then through one of

the radial slots in the empty reel. HoId the end of

the tape and rotate the reel, in a clockwise direction,

four or five revolutions. The tape shoutd now be

firmly fastened to the takeup reel. The dull side of

the tape should face outward on the supply reel and

on the takeup reel.

5. Turn the ('Record-Play,'knob to the

"Record" position.

6. If a microphone recording is to be made,

connect the microphone to the ,.Mike, jack.

?. If a recording from a radio is desired, it is

recommended that the connector cord be connected

to the speaker voice coil, by means of the alligator

clips, and the other end of the cord plugged into the

microphone jack. It is also possible to make a con-

nection to the plate side of the detector tube.

This kind of connection may be desirable in some

cases, because any circuit deficiencies in the ampli-

fier of the radio will not be included in the recording.

B. Adjustthe volume control so the neon

light level indic ator flashes intermittenily. Care

should be taken to adjust the input signal to such a

level that, with a setting of 4 on the volume control,

the neon level indicating light will flash intermittent-

ly. If the volume control setting for intermittent

flashing of the neon light is 3, or below, the input

signal level to the microphone jack is too low. A too

high level inpnrt signal will cause an overload in the

lzAxl amplifier tube, and, when played back, the re-

cording will be distorted. (Setting of the tone control

is immaterial. It is not in the circuit on ,,Record.r,)

9. Turn the control knob (1) to the ,,Forward,,

position. This engages the drive mechanism and

begins the recording.

10. To stop the recording, turn the control

knob (1) to the "Stop" position.

The Crestwood is designed for two-channel record-

ings; therefore, when the full reel has been recorded,

the two reels should then be interchanged, without

rewinding, and the procedure, as outlined in steps B

to 10, repeated.

To Rewind -

To rewind a recording, merely turn the control knob

(1) to the "Rewind" position.

Page 2

To Play a Recording -

1. Insert the line cord plug into a convenient

wall receptacle of the proper rating.

2. Turn the ,,Vplume', control knob to the

right - pilot light will tight up.

3. Place the full reel of the tape on the right-

hand spindle (11). Make sure the dull-coated side is

on the outside of the reel.

4. Place an empty reel on the left-hand spindle

(22) and feed the end of the tape in the slot located

between the two reels and then through one of the

radial slots in the empty reel. Hold the end of ttre

tape and rotate the reel, in a clockwise direction,

four or five revolutions. The tape should now be

firmly fastened to the takeup reel. The dull side of

the tape should face outward on the supply reel and

the takeup reel.

5. Turn the '(Record-Play" switch to the

"Play" position.

6. Turn the control knob (1) to t'Forurard"

position. This engages the drive mechanism and

begins the play-back.

7. Adjust the Volume and Tone controls to

suit.

AD JUS TM E NTS

An open Record Head (10A) or Erase Head (10) must

be replaced completely; however, a worn-out, or

damaged Record Head or Erase Head lamination can

be replaced as follows:

Remove entire head and bracket assembly (15) with-

out disturbing the individual heads. On record head

(10A), remove record head laminations by prying out

with a screw driver. Press in new laminations with

your fingers until laminations are seated in the yoke.

The erase head lamination can be replaced in the

same way.

Identification of th6 laminations follows:

Record Head Lamination - Small Gap (.0005" )

ffibrassstrip.

Erase Head Lamination -Wide Gap (.010")

ffibrassstrip.

Overall width on Erase Head (10) is greater

than Record Head. Since the Crestwood is a

two-channel machine, it is important to replace

Iaminations with the steel sections uppermost

in the Tape Guide.

Motor. Power and Erase Switch -

The motor power switch (42) is set with the motor

in the "Stop" position so that the contacts are open

by the brazing action of the switch blade against the

bakelite pin in the motor swing plate.

The Erase "Safety" switch (43) is mounted in the

neutral "Stop" position so that the contacts are open

and a gap of approximately 1/16" appears between

motor mounting assembly (51) and the insulating

bushing on the switch. The switch is so adjusted that

Figure 2

it makes a firm contact when the control knob is set

in the "Forward" position. (ffris switch prevents

accidental erasure while rewinding.)

The Forward Stop Lug -

The forward stop Iug (5?), Figure 3, should be set so

the motor mounting assembly (51) comes to a rest

position against it as soon as the drive roller (56)

makes firm contact with the flywheel (39). Excessive

pressure against the flywheel will prevent the motor

from starting when the control lever is pressed

quickly into the "Forward" position. Insufficient

pressure will result in a slippage and "Wow." The

best setting is to adjust the forward stop lug (57),

Figure 3, lf 16" from the edge of the swing plate (51)

at the point when the drive roller begins to touch the

flywheel.

There is no rewind stop 'adjustment; however, the

rewind drive pulley is located in a hanger whose

position is adjusted by bending the stop lug (a6A)

against the swing plate bushing in a manner that will

allow a clearance between the drive roller (56) and

the rewind pulley (a7) in the (Stop" position. This

will also allow the drive roller to engage the drive

pulley in the "Rewind" position. In this position, the

rewind drive pulley hanger (46) is away from the

stop, pressing the drive roller by means of the

torsion spring that needs no adjustment.

Pressgre Lever and Arm Adjusting Plte -

Set the pressure Iever (16) so that it is vertical when

the control knob is in the ('Forward" or ((Record-

trIayback" position. A I s o adjust the arm adjusting

plate (58), Figure 2, so it will clear the pressure arm

(16) by l/64" when in this position. With normal

adjustments, the tape guide (9) witl move very

slightly, or not at all, when the control is turned from

the "Off" to the "Rewind" position.

Brake Spring -

The brake spring (29) should be adjusted so that the

brake (26) clears the takeup pulley (44) and allows it

to turn freely in either the "Forward" or "Rewind"

position. The pressure in the "Off" or "Stop" pos-

ition should be sufficient to prevent "coasting" of

the reel. If the brake clearance is not equal in the

t'Forward" and fuRewind" positions, then the ad-

justment on the motor transf er Iever (49) is

incorrect.

Transfer Lever -

The transfer lever (49) should be adjusted when the

control is in the c'Off" or "Stop" position. Move

the transfer lever (49) slightly and tightenthe set

screws of the transf er lever (49) when the drive

roller (56) is midway between the rewind drive pulley

(47) and the flywheel (39).

Head Pressure -

The head pressure is ad justed by means of two

screws in the slotted holes in the head bracket (15).

Both the Record Head (10A) and the Erase Head (10)

should be adjusted into the'tape guide block until the

pressure pads on the reverse side show a movement

of slightly less than Lf32'" . This adjustment gives

the necessary 30 grams head pressure against the

shoe for each head. "Wowt' will result if too much

pressure is used at this point.

Head Alignment -

The lateral movement of each head is done by moving

the heads in the required direction by means of the

screws in the slotted holes that hold the heads to the

head bracket (15). The position should be such that

there is no hanging up of the tape pressure guide

when the control lever is turnedtothe "stop"

position.

The Record Head (11A) should be adjusted so that

the air gap in the lamination is at right angles to the

direction of the tape travel.

TROUBLES

Irregular Qpeed "Wow" -

1. FeIt pressure pads in tape guide assembly

(9) worn.

2. Oil or grease on drive roller (56) or pres-

sure roller (20).

3. Head pressure too great (see adjustment on

head pressure). Be careful not to disturb the head

alignment.

Es

Hq

rr!

;{

!o

bo

oe

Page 3

Figure 3

4. Insufficient pressure on pressure roller

(20). Tighten spring (1?) or replace roller (20).

5. Drive roller (56) or pressure roller (26)

eccentric. Allow mechanism to run for 20 minutes.

If after this time the rollers are still eccentric, re-

place with new rollers.

6. Motor shaft binding. Motor shaft should

turn freely when the control knob is in the ,,Off,

position. If necessary, realign bearings by tapping

motor lightly with wooden mallet.

Motor Runs but Mechanism WiIl not errelg -

1. Motor Stop is adjusted incorrecily (see

adjustment on "Pressure Lever and Arm Adjusting

Plate").

2. Drive roller (56) defective. Replace.

1. Check rewind belt (45) or take-up belt (21)

for being broken or loose. Replace.

2. Motor Stop not adjusted properly (see ad-

justment on ('Pressure Lever and Arm Adjusting

Plate").

3. Pressure roller (20) interferes with panel

in rewind position.. Remove pressure roller (20) and

chamfer bottom edge of roller l/16,, x 4bo.

Control Knob Turns but Motor Assembly

-

1. Motor transfer lever (49) set screws loose.

Tighten the set screws with the mechanism in the

"Stop" or "Neutralt' position.

2. Transfer lever (49) Ioose at hub. Replace.

No Positive Detent Position for Motor Assembly -

1. Detent lever (48) loose. Tighten set screws.

2. Check detent lever (48) to see if it is loose

at the hub. If so, replace.

Slow Speed -

1. Low-operating temperature.

Page 4

2. Pressure arm spring (1?).

3. Head pressure too great (see adjustment on

t(Head Pressure").

4. Flywheel (39) shaf t binding. Checkto see

that the s c r e w s holding front and rear plates are

tight and that plates are not warped.

5. Motor shaft binding. Realign bearings by

tapping lightly on the motor.

Machine Will Play Back

bfDoefiA R;Eord=*

1. Defective microphone.

2. Microphone plugged in speaker outlet.

3. Defective amplifier.

High Background Noise (Hiss) -

1. Defective bias oscillator tube or circuit.

2. Defective tape.

3. Defective Record-Playback Head.

4. Record head magnetized. Demagnetize

with 60-cycle AC air core coil.

Incomplete Erase -

1. Erase Voltage po\trer too low.

2. Defective 6C4 oscillator.

3. Erase head open. Replace.

4. Poor contact on Record-play switch.

Poor Recording -

1. Head g a p not at right angles to tape (see

adjustment on "Head Alignment").

2. Overloading.

3. Defective, or damaged, head.

4. Head lamination damaged or worn.

5. Poor contact of head to tape caused by worn

felt pressure pad.

Mechanism Runs Forward but Will not Rewind,

@F- ffi

@# m

ffi

A PHOTOFACT ''EXPLODED'' VIEW

O Howord W. Soms & Co., lnc. 1949

ts

HU

rr rl

;{

PO

l$O

9E

Page 5

f;$

{i[

.L5j

;w;

*-$tu;

g'l {rtt @(Lt r.'.t:g.l)

Figure 5

Figure 4

Figure 6

Page 6

ts

Hffi

FEE

;€

po

*rO

gs

ot

E

Glo

6

E

A

c!

€

A

€

c

a

ld

o

{

F

!.t

c

o. +F

rt

.9

L

et

s

cs

c{

.E

ts I

t

L

c

s

c\

+I+

3

.o

!

o;

r

E

oa, {lo

gg

+rc{

oo

+)P

o. o.

1J +J

Oo i

oo

&l{

$rt}{

d.(J

oo

t< tr

02to

(dd

d)d)

EI

U

tr

=

tl,

I

us'

'nX

7

OP

Sd

bu

Zod

6E

&,O

6

z3

i, ox

b)

ir O

<:

b()

o

I

o

U'

o

z

6

d

a

u

(,

z

n

6

E

d

Hu'

n

r{h H

la

/a.I

\€?z ar ut

L*g

ho

lrl

6

tr

LJ

|,-@Fll''

@+f a

I \:y

@

A

€l

o

L

9>

H,',

a

ei

ils ft.

lJr lr'-

o

Olr.

tlX

J}Fil,,

t

g

4

o

o

o

€

(

o

h

{{}

r-\

\y

o

l&

o

--t

(9) r

Ol|.

Yq>

o urE

N /h\

inr9\g'

n

(a) q

>flHl,'

tlnl

Page 7

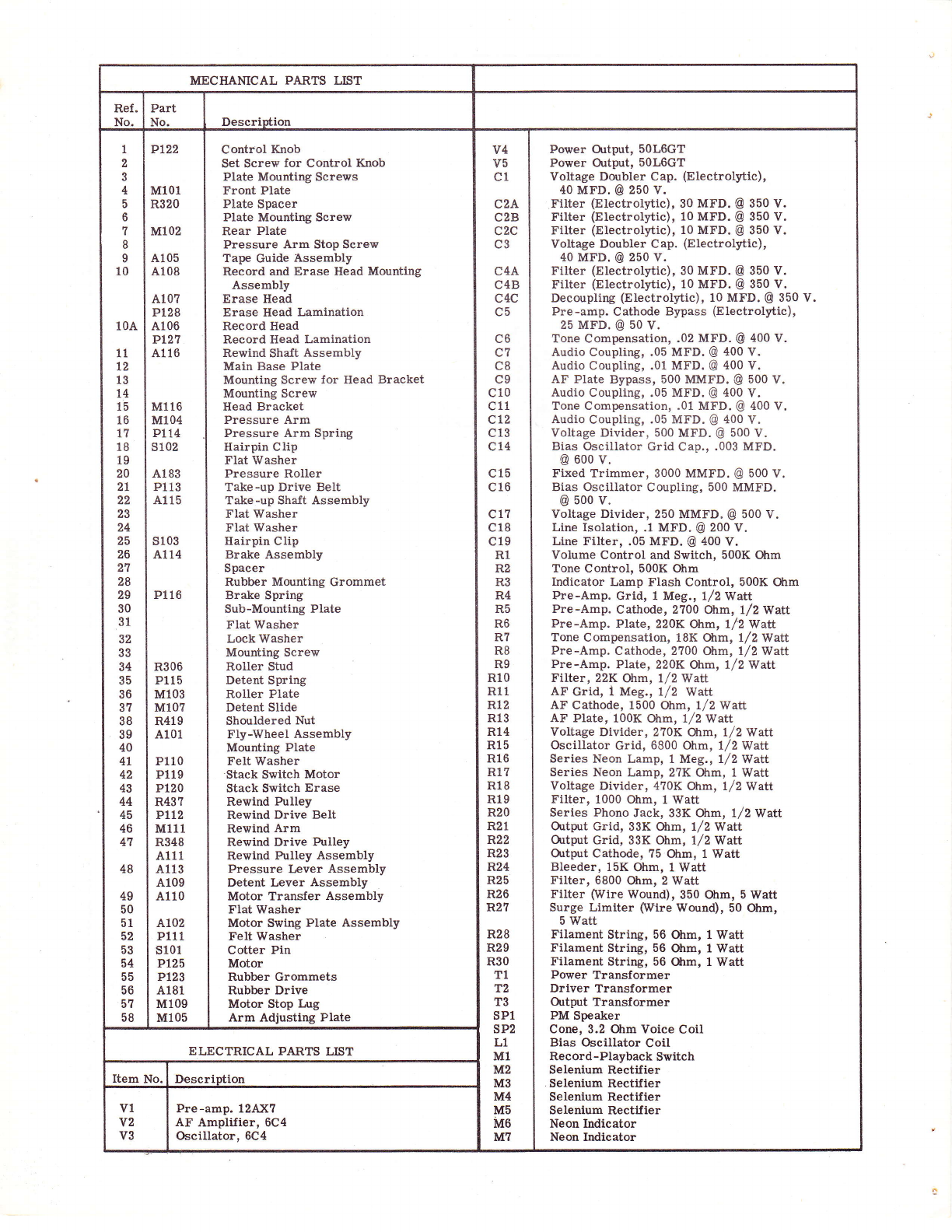

MECHAMCAL PARTS Lr;T

Ref.

N^ Part

N^ Descriution

I

2

3

4

5

6

7

I

I

10

10A

11

12

13

14

15

16

1?

18

19

20

2t

22

23

24

25

26

21

28

29

30

31

32

33

34

35

36

37

38

39

40

4L

42

43

44

45

46

41

48

49

50

51

52

53

54

55

56

51

58

Pl22

M101

R320

M102

A105

A108

A10?

p128

A106

PI2'I

A116

M116

M104

P114

s102

A183

Pl13

A115

s103

A114

P116

R306

Pl15

Ml03

Ml07

R419

A101

P110

Pl19

Pl20

R43?

Pttz

Ml11

R348

A111

A113

A109

A110

A102

Pl11

s101

P125

Pl23

A181

M109

Ml05

Control Knob

Set Screw for Control Knob

Plate Mountlng Screws

Front Plate

Plate Spacer

Plate Mounting Screw

Rear Plate

Fressure Arm Stop Screw

Tape Guide Assembly

Record and Erase Head Mounting

Assembly

Erase Head

Erase Head Lamination

Record Head

Record Head Lamination

Rewlnd Shaft Assembly

Main Base Plate

Mounting Screw for Head Bracket

Mounting Screw

Head Bracket

Pressure Arm

Pressure Arm Spring

Hairpin Clip

FIat Washer

Pressure Roller

Take-up Drive Belt

Take-up Shaft Assembly

Flat Washer

Flat Washer

Hairpin Clip

Brake Assembly

Spacer

Rubber Mounting Grommet

Brake Spring

Sub-Mounting Plate

Flat Washer

Lock Washer

Mounting Screw

Roller Stud

Detent Spring

Roller Plate

Detent Slide

Shouldered Nut

Fly-\{heel Assembly

Mounting Plate

Felt Washer

'Stack Switch Motor

Stack Switch Erase

Rewind Pulley

Rewind Drive Belt

Rewind Arm

Rewind Drive Pulley

Rewind Pulley Assembly

Pressure Lever Assembly

Detent Lever Assembly

Motor Transfer Assembly

Flat Washer

Motor Swing Plate Assembly

Felt Washer

Cotter Pin

Motor

Rubber Grommets

Rubber Drive

Motor Stop Lug

Arm Adjusting Plate

v4

v5

c1

c2A

c2B

c2c

c3

c4A

c4B

c4c

c5

C6

c1

c8

c9

c10

c11

c12

c13

c14

c15

c16

c1?

c18

c19

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

Rt2

R13

R14

R15

R16

R1?

Rl8

Rl9

R20

R21

F"22

R23

F"24

R25

R26

R27

R28

R29

R30

T1

T2

T3

sP1

sP2

L1

M1

M2

M3

M4

M5

MO

M7

Power Ortput, 50L6GT

Power Ortput, 5OLOGT

Voltage Doubler Cap. (Electrolytic),

40 MFD. @ 250 V.

Filter (Electrolytic), 30 MFD. @ 350 V.

Filter (Electrolytic), 10 MFD. @ 350 V.

Filter (Electrolytic), 10 MFD. @ 350 V.

Voltage Doubler Cap. (Electrolytic),

40 MFD. @ 250 v.

Filter (Electrolytic), 30 Mtr.D. @ 350 V.

Filter (Electrolytic), 10 MFD. @ 350 V.

Decoupling (Electrolytic), 10 MFD. @ 350 V.

Pre-amp. Cathode Bypass (Electrolytic),

25 MFD. @ 50 V.

Tone Compensation, .02 MFD. @ 400 V.

Audio Coupling, .05 MFD. @ 400 V.

Audio Coupling, ,01 MFD. @ 400 V.

AF Plate Bypass, 500 MMFD. @ 500 V.

Audio Coupling, .05 MFD. @ 400 V.

Tone Compensation, .01 MFD. @ 400 V.

Audio Coupling, .05 MFD. @ 400 V,

Voltage Divider, 500 MFD. @ 500 V.

Bias Oscillator Grid Cap., .003 MFD.

@ 600 v.

Fixed Trimmer, 3000 MMFD. @ 500 V,

Bias Oscillator Coupling, 500 MMFD.

@ 500 v.

Voltage Divider, 250 MMFD. @ 500 V.

Line Isolation, .1 MFD. @ 200 V.

Line Filter, .05 MFD. @ 400 V.

Volume Control and Switch, 500K Ohm

Tone Control, 500K Ohm

Indicator Lamp Flash Control, 500K Ohm

Pre-Amp. Grid, 1 Meg., 1/2 Watt

Pre-Amp. Cathode, 2?00 Ohm, l/2Watt

Pre-Amp. Plate, 220K Ohm, 112 Watt

Tone Compensation, 18K Glm, 1,/2 Watt

Pre-Amp. Cathode, 2700 Ohm, l/2Waltt

Pre-Amp. Plate, 220K Ohm, 1/2 Watt

Filter, 22K Ohm, 1/2 Watt

AF Grid, I Meg., l/2 w^tt

AF Catlrode, 1500 Otrm, 1/2Watt

AF Plate, 100K Ohm, l/2Watt

Voltage Divider, 2?0K Ohm, l/2Watt

Oscillator Grid, 6800 Ohm, 1/2 Watt

Series Neon Lamp, 1 Meg., 1/2 Watt

Series Neon lamp, 2?K Ohm, 1 Watt

Voltage Divider, 4?0K Otrm, l/2$latt

Filter, 1000 Ohm, 1 Watt

Series Phono Jack, 33K Ohm, 1/2 Watt

Ortprt Grid, 33K Otrm, l/2Walt

Ortput Grid, 33K Otrm, l/2Watt

Ortput Catlode, ?5 Ohm, 1 Watt

Bleeder, 15K Ohm, l Watt

Filter, 6800 Ohm, 2 Watt

Filter (Wire Wound), 350 Ohm, 5 Watt

Surge Limiter (Wire Wound), 50 Ohm,

5 Watt

Filament String, 56 Ohm, I'iy'att

Filament String, 56 Ohm, I Watt

Filament String, 56 Ohm, 1 Watt

Power Transformer

Driver Transformer

OrtErt Transformer

PM Speaker

Cone, 3.2 Ohm Voice Coil

Bias Oscillator Coil

Record-Playback Switch

Selenium Rectifier

Selenium Rectifier

Selenium Rectifier

Selenium Rectifier

Neon Indicator

Neon hdicator

ELECTRICAL PARTS LIfIT

Item No. Descriotion

v1

v2

V3

Pre-amp. 12AX?

AF Amplifier, 6C4

Oscillator, 6C4

Table of contents