CRi SLM User manual

www.cri-inc.com

SLM Spatial Light Modulator

User’s Manual Rev. 1.5

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

Cambridge Research & Instrumentation, Inc. (CRi)

35-B Cabot Road, Woburn, MA 01801 USA

Tel: 781-935-9099 Fax: 781-935-3388 Toll-Free (US): 1-800-383-7924

Page – 2

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

SLM Spatial Light Modulator

Page – 3

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

Page – 4

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

Foreward ..............................................................................................................................7

F.1 Summary Instructions.......................................................................................................................................7

F.2 Warnings and Cautions .....................................................................................................................................7

F.3 Design Change Disclaimer ...............................................................................................................................7

F.4 Patents...............................................................................................................................................................7

F.5 User Support .....................................................................................................................................................7

F.6 Warranty............................................................................................................................................................7

Chapter 1: Introduction.......................................................................................................9

1.1 General..............................................................................................................................................................9

1.2 Unpacking the SLM........................................................................................................................................10

1.3 Controls and Indicators...................................................................................................................................10

1.4 Start-Up Guide................................................................................................................................................11

Chapter 2: Specications ..................................................................................................13

Chapter 3: Theory of Operation........................................................................................19

3.1 Optical Modulation.........................................................................................................................................19

3.2 Memory Architecture......................................................................................................................................20

3.3 Dual-Mask Units.............................................................................................................................................21

Chapter 4: Controlling the SLM .......................................................................................23

4.1 General............................................................................................................................................................23

4.2 SLM Command Set ........................................................................................................................................23

4.3 SLM Control Panel .........................................................................................................................................26

4.4 MATLABTM Interface .....................................................................................................................................27

4.5 LabVIEWTM Interface.....................................................................................................................................30

4.6 C + + Interface................................................................................................................................................30

Software License Agreement .............................................................................................37

Table of Contents

Page – 5

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

Page – 6

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

Foreword

F.1 Summary Instructions

READ THIS USER’S MANUAL BEFORE USING THE

SPATIAL LIGHT MODULATOR (SLM) SYSTEM.

F.2 Warnings and Cautions

IMPORTANT: Please take special care not to subject the SLM

to pulsed laser energy in excess of its rated damage threshold

level. See Chapter 2: Specications.

F.3 Design Change Disclaimer

Cambridge Research & Instrumentation, Inc. (hereafter called

“CRi”) reserves the right to change product design at any time

without notice to anyone, which may subsequently affect the

contents of this manual. CRi will make every reasonable effort

to ensure that the User’s Manual is up-to-date and corresponds

with the currently shipping SLM System.

F.4 Patent

The SLM Dual Mask products are protected by US Patent

5,719,650.

F.5 User Support

If you have difculty when setting up, operating, or

maintaining your SLM System, please contact your CRi

representative. Visit our website at http://www.cri-inc.com

or contact our Technical Support department, Toll-Free

(US) at 1-800-383-7924. You may contact CRi via e-mail at

(US Eastern Standard Time), Monday through Friday.

F.6 Warranty

CRi warrants its SLM System and other items of its

manufacture for a period of one year from the date of

shipment against defects in material and/or workmanship,

provided its installation, application, and maintenance are

within specications. Normal wearing parts are excluded.

This warranty covers only items manufactured by CRi. CRi

will correct, by repair or replacement, at its option and at its

expense, any proven defects in items of its manufacture,

subject to the above terms, provided immediate written

notice of such defects is given. Repair or replacement will be

provided F.O.B. (Freight On Board) at CRi’s factory.

The total nancial obligation of CRi, under this warranty, does

not exceed the purchase price of the items of its manufacture

as set forth on normal pricing schedules. We will not assume

any expense or liability for repairs made by others without our

prior written consent.

This warranty is void and CRi will be free from all obligations

hereunder if the items of its manufacture have been misused,

reprocessed or reused, repaired or modied without our written

consent.

CRi assumes no liability for damages or injuries resulting

from the misuse, misapplication, or unauthorized repair or

modication of its equipment. We assume no liability to users

of our equipment or to any other person or persons for special

or consequential damages of any kind and from any cause

arising out of or in any way connected with the use of the

equipment.

All warranty and post-warranty service is non-transferable

from the original shipping address to another without the prior

written consent of CRi.

Page – 7

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

Page – 8

Addendum to Spatial Light Modulator (SLM) User’s Manual Rev. 1.5

Document number MD15326-1.5

November 11, 2010

This document lists additions and changes to the SLM User’s Manual brought about by the introduction of the new,

smaller SLM-128 enclosure. The SLM-640 enclosure remains unchanged. It also lists steps necessary to properly install

the USB drivers for Windows 7 (32-bit and 64-bit).

Section Page Change or Addition

1.3 10 Controls and Indicators

USB LED has been removed

TTL/Sync Trigger (BNC) has been changed to an SMA connector

Power Jack 2.1 mm connector is unchanged, but the supplied universal power adapter is

now a +5V unit instead of a +24V unit. A new overvoltage circuit prevents damage to the

SLM if a higher-voltage power supply is accidentally used.

1.4 11 Start-Up Guide

There is no longer a separate USB LED that lights when the USB cable is plugged in to

the SLM.

See the drawing of the new SLM-128 (MA 20707, Assy, SLM 128, Mini). The SLM-640

remains unchanged.

Software installation under Windows® 7 (32-bit or 64-bit)

The current software installer (version 1.3.4) was written for Windows® XP Professional

(SP-2 or later). While CRi does not expressly support the Windows® 7 operating system

yet, the following steps enable you to install USB drivers compatible with Windows® 7.

1. IMPORTANT: Do not plug the SLM into the computer until you are instructed to

do so.

2. Go to http://www.ftdichip.com/Drivers/VCP.htm and download the most recent

driver package for your operating system.

3. Unzip the downloaded file and save the contents to a folder on your desktop or

another location where you can find it again.

4. Run the CRi SLM Setup.exe program.

5. When the installer is finished, plug the SLM into the computer. You will receive a

Windows error message that not all the drivers were properly installed. Don’t

worry, this is normal.

6. Go to the Device Manager and locate Other Devices >> USB <-> Serial.

7. Right-click on USB <-> Serial and choose Update Driver Software

8. Click “Search automatically for updated driver software”. Windows should

automatically find the folder containing the latest USB drivers and install them. If

it does, go to Step . If it does not, proceed to Step 9.

9. Click “Browse my computer for driver software”, navigate to where you

previously saved the contents of the USB driver package, and click Next.

10. If Windows warns you about verifying the publisher of the software, click “Install

this driver anyway”.

11. Go to the Device Manager and right-click on Other Devices >> USB <-> Serial

Port.

12. Click “Browse my computer for driver software”, navigate to where you

previously saved the contents of the USB driver package, and click Next.

13. If Windows warns you about verifying the publisher of the software, click “Install

this driver anyway”.

14. At this point, in Device Manager the Ports (COM & LPT) category should appear.

15. Since the SLM is plugged into your computer, a numbered COM port will also

appear. Make a note of the COM number.

16. You can now launch the CRi demo program SlmGui.exe located in C:\Program

Files (x86)\CRi\SLM and enter the COM number for the SLM. After a moment,

the program will recognize the SLM.

Table 13 Chapter 2: Specifications

Housing: Mechanical Mounting changes to: 2 x ¼” – 20 and 2 x M6 threaded holes

[SLM-128] and 3 x ¼” – 20 and 2 x M6 threaded holes [SLM-640]. Overall size changes

to: 5.29” x 6.90” x 0.98” [SLM-128] 7.2” x 12.8” x 1.54” [SLM-640]

Figure 2-2 14 Examples of single-mask and dual-mask system assembly

The new SLM-128 models have a different optical arrangement (see attached diagram).

The distances for the SLM-640 remain the same.

Figure 18 SLM housing dimensions

See the attached drawing (MA 20707, Assy, SLM 128, Mini)

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

Chapter 1: Introduction

1.1 General

The SLM-128 and SLM-640 liquid crystal modulator arrays

provide independent control of each element in a linear array

of 128 or 640 pixels, respectively. The arrays are 5 mm high,

and the pitch is 100 μm, resulting in total array apertures of

12.8 mm for SLM-128 models and 64.0 mm for SLM-640

models. As shown in Figure 1-1.

Single-array models are congured at the factory for phase

or amplitude modulation, while dual-array models consist

of two precisely aligned modulators, providing a unique and

convenient method for simultaneous modulation of both

phase and amplitude at each pixel. The patented dual-mask

conguration can operate either as a phase and amplitude

modulator of specically polarized incident light or as simply

a phase modulator of arbitrarily polarized incident light. For

a detailed description of these operational modes, refer to

Chapter 3: Theory of Operation.

The three modulation schemes can operate in either

transmissive or reective mode. The reective mode is

enabled by replacing the output polarizer with an optional

mirror, which causes light to pass through the system

twice, and thus doubles the optical action of the modulator.

Each instrument is equipped with a set of custom optics to

optimize performance in one of two wavelength ranges: 488

nm to 900 nm (VN models) or 900 nm to 1620 nm (NM

models).

Special circuitry and timing ensure that the output signal is

free from DC content to guarantee the longest life of the liquid

crystal. Each signal is 10.0V full scale with 12-bit (4096 levels)

resolution. Electronics and optics are integrated into a single

compact enclosure, to which polarizers, mirrors, or ancillary

optics can be attached using optional accessory bezels.

All SLM systems communicate via a standard USB interface,

and can be controlled with a set of ASCII commands,

software drivers for C++, MATLABTM and LabVIEWTM,

or a standalone Windows®, graphical user interface. For a

detailed description of commands and drivers, see Chapter

4: Controlling the SLM. Software drivers are included on the

CD-ROM and are loaded during installation.

Page – 9

As indicated in Figure 1-1, SLM-128 models have a reference

pixel, while SLM-640 models do not. The reference pixel is

driven by the same signal as pixel 0.

Model Selector

SLM - xxx - m- ww

xxx = number of pixels 128 or 640

m = modulation mode amplitude (A), phase

(P) or dual (D)

ww = wavelength range 488 nm to 900 nm (VN)

900 nm to 1620 nm (NM)

Between May 2003 and May 2004 certain SLM’s were equipped

with high-speed RS-232 serial interfaces. For more information

refer to User Manual Rev 1.2. SLM’s have been equipped with

USB serial interfaces since June 2004.

01 2 3 . . .

1

2

7

1

2

6

100 µm pixel pitch

reference pixel

2 µm inter-pixel gap

5 mm

12.8 mm

01 2 3 . . .

6

3

9

6

3

8

100 µm pixel pitch

2 µm inter-pixel gap

5 mm

64.0 mm

2 mm

Figure 1-1: SLM-128 and SLM-640 pixel diagram

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

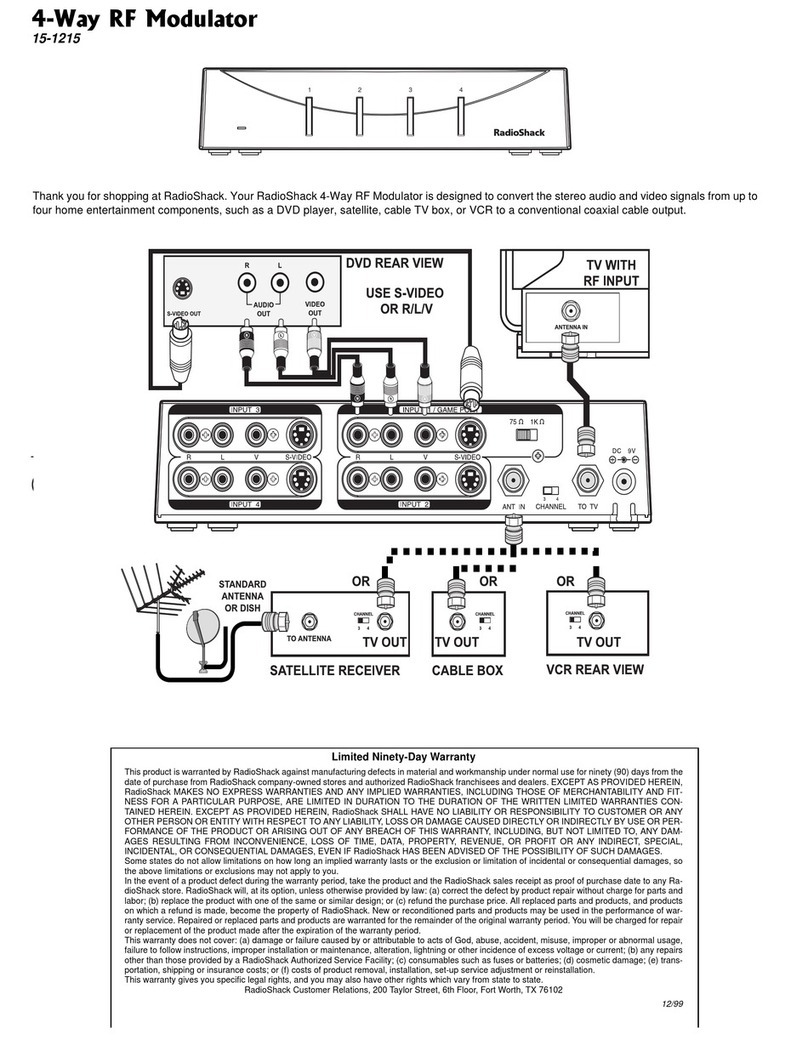

1.2 Unpacking the SLM

The SLM is shipped in a padded transport case, along with the

following list of items shown in Figure 1-2:

Power adapter with worldwide adapter plugs

USB type-A to type-B cable

Installation CD-ROM and User’s Manual

Additional bezels are included if appropriate, such as

when the reective mode option is purchased

1.3 Controls and Indicators

The controls and indicators for all SLM models are located on

the side panel of the enclosure, and are shown in Figure 1-3.

Each component is described below.

•

•

•

•

Power Switch

This is a pushbutton power switch. It lights green when

switched on.

Status LED

This LED is an indicator of the current state of the system. It

can be in one of the following four states:

Solid green: no errors

Blinking green: communication in progress with no errors

Solid red: command processing error

Blinking red: error occurred; communication in progress

USB LED

This LED provides status regarding the USB interface. It can

be in one of the following two states:

Off: no USB connection

Solid green: a USB connection is established.

TTL/Sync Trigger (BNC)

This BNC connector enables cycling between predened

modulation states using a synchronization pulse. TTL or

3.3V logic pulse levels can be used. Triggering occurs on the

upward edge. The trigger signal must be held for at least 100µs

in each of the high and low states.

USB Connector

This is the connector for the communications interface and is a

USB type B connector.

Power Jack

This is the connector through which power (+24V DC) is

supplied to the SLM. The power jack accepts the 2.1 mm plug

of the included +24V universal power adapter.

Page – 10

Warning: Use of supplies other than the +24V DC supply provided

with the SLM will void the warranty and could damage the circuitry.

Always keep the trigger voltage in the range [0-5V] to avoid

damaging the SLM circuitry.

Figure 1-3: Controls and Indicators

Figure 1-2: Inside the Transport Case

SLM Instrument

Power adapter and

worldwide adapter plugs

USB type-A to

type-B cable

Installation CD-ROM User’s Manual

Additional Bezels (optional)

STAT

USB

Power

Switch

Status

LED

USB

LED

TTL/Sync

Trigger

(BNC)

USB Type-B

connector

Power Jack

+24V

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

1.4 Start-up Guide

Remove the SLM from the transport case and mount it on an

optical table using the mounting holes on the bottom plate.

There are two holes with M6 threads with 50 mm spacing,

and three holes with ¼-20 threads with 2-inch spacing, all

centered on the middle of the SLM array as shown in Figure

1-4. DO NOT FORCE THESE THREADS as they are similar

in appearance.

Once the SLM is securely mounted on the optical table,

prepare it for use. The apertures are protected with blue

protective lm to guard against dust in shipping. Peel the blue

lm from the entrance and exit faces. The entrance and exit

faces are shown in Figure 1-5 and 1-6.

Place the installation CD-ROM into your CD-ROM drive.

If the software installer is not automatically launched, use

Windows Explorer to list the CD-ROM contents and double-

click on the le named setup.exe. The installer will guide you

through the installation, and load the SlmGui program and

drivers for MATLABTM, LabVIEWTM, and libraries for use in

your own C / C ++ / VB programs, if these were requested

during installation.

The power adapter includes various plug sets for use in the

US, Europe, the UK, Japan, and Australia. If it is not set up

with the proper plug for your country, replace it with the

proper plug adapter. The power supply is a universal switching

type and will work with AC outlets providing 50/60 Hz over

the voltage range 90 to 240 VAC. Plug the adapter into an

outlet and attach the 2.1 mm plug to the jack on the side of

the SLM. Press the large power switch, which should light

up with a green color. The LED just below the power switch,

marked STAT, should light almost immediately thereafter. This

indicates that the SLM electronics are functioning normally.

Connect the USB cable to the appropriate connector on the

side panel of the SLM and the other end to your Windows

2000 or Windows XP Professional host computer. The

computer will detect the presence of the SLM and ask you

to locate the USB driver les. Select the option indicating,

that you wish to search the CD-ROM. Alternately, you can

download the driver les from the CRi website www.cri-inc.

com. If you downloaded the drivers from the website, browse

and select the location of the downloaded and decompressed

driver folder. Once the driver les have been installed, your

computer should be able to recognize the SLM and you will

see that the green LED marked USB will light. If you look in

Windows Device Manager, you may notice that a new COM

Page – 11

Figure 1-4: The bottom face contains cooling vents, mounting holes and an

information label

Leave all the top vents and at least four of the bottom vents

unobstructed to provide proper airow for cooling. If possible,

provide a good thermal path between the SLM and the

optical table. That will minimize thermal drift in the liquid

crystal cell due to electronics warm-up and to air currents

in the room. It is normal that enclosure temperature will

be between 5 °C and 10 °C above ambient when running,

depending on how well it is thermally coupled with the optical

table.

The SLM is a precision optical device with coated surfaces.

Keep it clean and dust-free using pressurized dry air or

nitrogen. Avoid any mechanical contact. If necessary the

surface can be drag-wiped with lab-grade methanol and soft

lint-free cleaning tissue.

SLM Model Modulation Input Bezel Output Bezel

SLM-xxx-A Amplitude Polarizer Polarizer

SLM-xxx-P Phase Blank Polarizer

SLM-xxx-D Amplitude and Phase Polarizer Polarizer

SLM-xxx-D Phase only* Blank Blank

SLM Model Modulation Input Bezel Output Bezel

SLM-xxx-A Amplitude Polarizer Mirror

SLM-xxx-P Phase Polarizer Mirror

SLM-xxx-D Amplitude and Phase Polarizer Mirror

SLM-xxx-D Phase only* Blank Mirror

Bezel Conguration for Transmissive Mode Modulation

Bezel Conguration for Reective Mode Modulation

*Dual-mask systems can be used as phase modulators of arbitrarily

polarized light. Please refer to Chapter 3 for more details

Figure 1-5: Entrance Face Figure 1-6: Exit Face

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

port has appeared. This new port is assigned to the SLM.

During installation a shortcut to the SLM graphical user

interface program SlmGui has been placed on the Start bar

under Programs CRi SlmGui. Run the SlmGui program.

In the interface name text box shown in Figure 1-7 select the

name of the serial port assigned to the SLM. Next, click the

load button. The program will download a variety of patterns

to the SLM. The STAT LED will light momentarily to indicate

data transmission. Now, click on the frame select control.

You can scroll up and down using the up and down arrow

keys on the keyboard, or you can select a particular entry

with the cursor. As you do so, the program is changing the

drive pattern being generated by the SLM. If you observe the

behavior of light passing through the SLM, you will see that it

is modulated in different ways by the various frame patterns.

For more information on the SlmGui program see section 4.3

in Chapter 4.

If you have reached this point successfully, the SLM is

installed properly and is working. You are ready to proceed

to the rest of the manual to get a fuller understanding of the

instrument, and begin programming it for use in your research.

Page – 12

Figure 1-7: SlmGui Interface

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

Chapter 2: Specifications

Page – 13

SLM-128 SLM-128-D SLM-640 SLM-640-D

Optics

Number of Masks 1 2 1 2

Pixels per Mask 128 128 640 640

Pixel Height 5000 µm (5 mm)

Pixel Pitch 100 ± 0.005 µm

Inter-Pixel Gap 12.0 µm

Inter-Mask Alignment 2, 3 - ± 2.0µm - ±2.0µm

Inter-Mask Separation 2, 4 - 1.03 mm - 1.03 mm

Spectral Range 5488 – 900 nm (VN models), 900 – 1620 nm (NM models)

Transmission VN Model13 > 88% > 85% > 88% > 85%

Transmission NM Model13 > 92% > 90% > 92% > 90%

Pulse Damage Threshold 100 µJ/cm2(490 nm, 50 fs, 1kHz), 200 µJ/cm2(890 nm, 50 fs, 1kHz)

Maximum Modulation 6, 7 3� radians at longest wavelength

Modulation Temp. Coefcient 8-0.3% modulation per °C

Response Time 9 - 12 35 ms (2� radians at 900 nm – VN model), 70 ms (2� radians at 1620 nm – NM model)

Electronics

Drive Waveform Bipolar 3.3 kHz square wave

Drive Resolution 12 bit, 2.44 mV per step

Frame Buffers 128 128 32 32

Interfaces USB 1.1, 5V / 3.3V logic trigger (TTL compatible)

Power +24V DC, via universal adapter (included)

Housing

Mechanical Mounting 3 x ¼” – 20 and 2 x M6 threaded holes

Overall Size 7.2” x 12.8” x 1.54”

Environmental

Operating Temperature 18 °C to 35 °C

Storage Temperature -15 °C to 50 °C

Median size of the photolithographic gap between adjacent

pixel electrodes. Actual optical response within this gap and in

the adjacent region is determined by electrostatics and the liquid

crystal material properties.

Applies to dual-mask models only.

Lateral misalignment between pixel 0 of the rst and second

mask.

Separation along the optical path between rst and second mask,

in medium (n=1.51).

For standard models. Operation over the range of 400–1650 nm

is possible with derated performance due to reduced coating and

polarizer efciency outside the optimal range.

Used single-pass, (i.e. in transmission). Modulation is doubled

when the SLM is used in reection, since the light traverses the

optics twice.

Specied at the longest wavelength in the operating range.

Maximum modulation is greater at shorter wavelengths.

1.

2.

3.

4.

5.

6.

7.

Properties of liquid crystal vary with temperature which, in turn

changes the modulation response of the SLM. The temperature

coefcient is typically decrease in 0.3 % modulation per

increase in 1 °C.

All response times are measured at 25 °C, and improve at

higher temperatures.

Settling time to 95% for step from minimum modulation to

listed modulation.

Settling is faster for transition in the opposite direction, (i.e.,

from stated modulation to minimum modulation).

Includes the electronic circuitry response from trigger pulse or

P (frame-select) command.

Without polarizers.

8.

9.

10.

11.

12.

13.

NOTES:

CRi, 35-B Cabot Road Woburn, MA 01801 USA :: (Toll-Free US) 1-800-383-7924, (P) +1-781-935-9099, (F) +1-781-935-3388 :: [email protected] :: www.cri-inc.com

Page – 14

30 µm glue line

dual mask stack

two single mask stacks + glue line

Figure 2-1: Optics Stack Diagram

Figure 2-2: Examples of single-mask and dual-mask system assembly

0.7 mm coated glass 0.5 mm glass

LC: 16 µm for NM models

10 µm for VN model s

0.5 mm coated

glass cover

10 µm glue line

34.19 mm

fixed

1.5 mm 1.5 mm

polarizer polarizersingle LC optics

x2

3.52 mm

fixed

x1

depends on VN or NM

INPUT

x1 = 28.95 mm for NV models

x1 = 28.94 mm for NM models

x2 = 1.72 mm for VN models

x2 = 1.73 mm for NM models

OUTPUT

EXAMPLE 1

34.19 mm

fixed

1.5 mm 1.7 mm

polarizer mirrordual LC optics

x2

3.52 mm

fixed

x1

depends on VN or NM

INPUT

x1 = 28.22 mm for NV models

x1 = 28.21 mm for NM models

x2 = 2.45 mm for VN models

x2 = 2.46 mm for NM models

EXAMPLE 2

RETURN

Single-Mask Stack Dual-Mask Stack

Table of contents