Criterion CRH160C1W User manual

UNDER CABINET RANGE HOOD

CRH160C1W / CRH160C1B / CRH160C1S

QR241W / QR241B / QR241S

Owner’s Manual

2

Table of Contents

Table of Contents ...........................2

Safety Information...........................2

Warranty

One Year Limited Warranty ...................4

Warranty Claim Procedure ....................4

Pre-Installation

Tools/Materials Required .....................5

Package Contents ..........................6

Hardware Included ..........................6

Planning Installation .........................7

Installation ................................10

Operation .................................13

Maintenance

Replacing Filters ..........................14

Replacing Lights...........................14

Care and Cleaning

Range Hood ..............................15

Filters ...................................15

Troubleshooting ...........................16

Specications

Wiring Diagram ...........................17

External Range Hood Diagram ...............18

Service Parts ..............................19

Safety Information

READ AND SAVE THESE INSTRUCTIONS

Warning - To reduce the risk of re, electric shock, or

injury to persons, observe the following:

1. Use this unit only in the manner intended by the manufacturer.

If you have any questions, contact the manufacturer.

2. Before servicing or cleaning unit, switch power off at service

panel and lock service disconnecting means to prevent

power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by

qualied person(s) in accordance with all applicable codes

and standards, including re-rated construction.

4. Sufcient air is needed for proper combustion and exhausting

of gases through the ue (chimney) of fuel burning equipment

to prevent back drafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE), and the local code

authorities.

5. When cutting or drilling into a wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

WARNING: FUEL (GAS) BURNING RANGES MUST BE

VENTED OUTDOORS USING, AT MINIMUM, METAL

DUCTWORK AND RANGE HOODS OF SUFFICIENT CAPACITY.

Follow your fuel burning equipment manufacturer’s guidelines, as

well as, all applicable safety standards published by the National

Fire Protection Association (NFPA), and the American Society for

Heating, Refrigeration and Air Conditioning Engineers (ASHRAE),

and your local code authorities.

DANGER: Turn off the power circuit breaker or the

power switch on the junction box before installing

or servicing this unit. Touching circuitry inside the

range hood while it is energized will result in death

or serious injury.

DANGER: All electrical wiring must be properly

installed, insulated, and grounded. Improper

insulation and grounding will result in deadly

electrical shock.

DANGER: If installing this unit over a gas range,

turn off the gas at the source before installing or

servicing this unit.

WARNING: Attempting to install or service this unit

when you do not have the necessary technical or

electrical background could result in personal injury.

WARNING: The unit has sharp edges. Always

wear safety gloves during installation, cleaning, or

servicing.

WARNING: Always leave safety grills and lters in

place. Without these components, operating fans

could catch on to hair, ngers, or loose clothing.

WARNING: Stay clear of the rotating fan when the

motor is running.

WARNING: Keep this appliance clean and free of

grease and residue build-up at all times to prevent

res.

CAUTION: This device is for general ventilating use

only. Do not use to exhaust hazardous or explosive

materials and vapors.

3

Safety Information (continued)

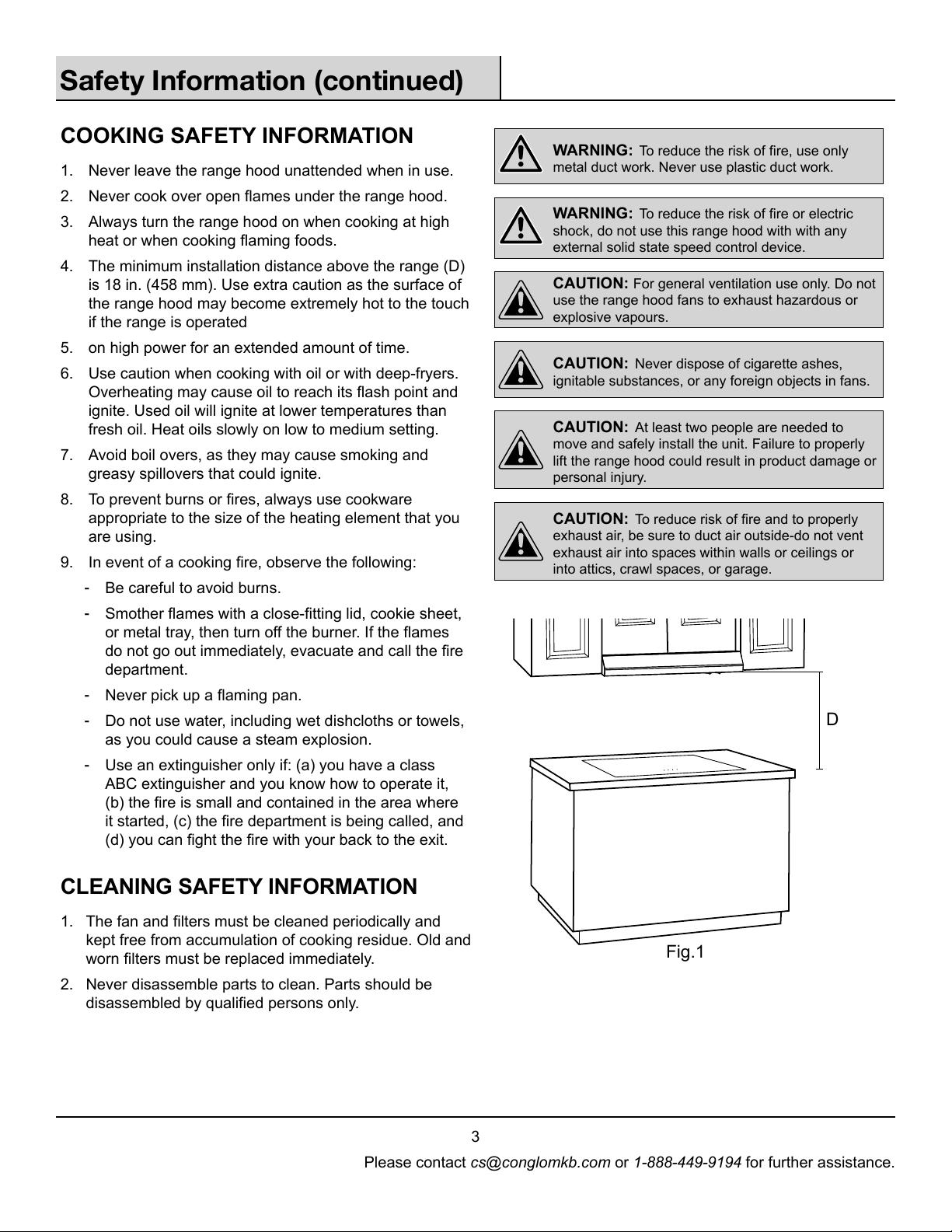

COOKING SAFETY INFORMATION

1. Never leave the range hood unattended when in use.

2. Never cook over open ames under the range hood.

3. Always turn the range hood on when cooking at high

heat or when cooking aming foods.

4. The minimum installation distance above the range (D)

is 18 in. (458 mm). Use extra caution as the surface of

the range hood may become extremely hot to the touch

if the range is operated

5. on high power for an extended amount of time.

6. Use caution when cooking with oil or with deep-fryers.

Overheating may cause oil to reach its ash point and

ignite. Used oil will ignite at lower temperatures than

fresh oil. Heat oils slowly on low to medium setting.

7. Avoid boil overs, as they may cause smoking and

greasy spillovers that could ignite.

8. To prevent burns or res, always use cookware

appropriate to the size of the heating element that you

are using.

9. In event of a cooking re, observe the following:

-Be careful to avoid burns.

-Smother ames with a close-tting lid, cookie sheet,

or metal tray, then turn off the burner. If the ames

do not go out immediately, evacuate and call the re

department.

-Never pick up a aming pan.

-Do not use water, including wet dishcloths or towels,

as you could cause a steam explosion.

-Use an extinguisher only if: (a) you have a class

ABC extinguisher and you know how to operate it,

(b) the re is small and contained in the area where

it started, (c) the re department is being called, and

(d) you can ght the re with your back to the exit.

CLEANING SAFETY INFORMATION

1. The fan and lters must be cleaned periodically and

kept free from accumulation of cooking residue. Old and

worn lters must be replaced immediately.

2. Never disassemble parts to clean. Parts should be

disassembled by qualied persons only.

WARNING: To reduce the risk of re, use only

metal duct work. Never use plastic duct work.

WARNING: To reduce the risk of re or electric

shock, do not use this range hood with with any

external solid state speed control device.

CAUTION: For general ventilation use only. Do not

use the range hood fans to exhaust hazardous or

explosive vapours.

CAUTION: Never dispose of cigarette ashes,

ignitable substances, or any foreign objects in fans.

CAUTION: At least two people are needed to

move and safely install the unit. Failure to properly

lift the range hood could result in product damage or

personal injury.

CAUTION: To reduce risk of re and to properly

exhaust air, be sure to duct air outside-do not vent

exhaust air into spaces within walls or ceilings or

into attics, crawl spaces, or garage.

D

Fig.1

4

Warranty

ONE YEAR LIMITED WARRANTY

A thorough inspection must be made before installation and any damage must be promptly reported. We will not be liable

for failures or damage that could have been discovered or avoided by proper inspection and testing prior to installation.

This product is warranted to be free from defects in materials or workmanship for one (1) year from the date of purchase. Proof

of purchase (original sales receipt) from the original consumer purchaser must be made available for all warranty claims.

This warranty is non-transferable and shall be voided if the unit is removed from its initial installation or if it is not installed

following the manufacturer’s instructions. It does not apply in the event of product damage due to the use of other than

genuine replacement parts, (Replacement parts may be obtained by e-mail at [email protected] or by calling 1-888-

449-9194 between 8:30 am - 5:00 pm EST) installation error, abuse, misuse or improper care and maintenance (whether

performed by a plumber, contractor, service provider or member of the purchaser’s household). The warranty excludes

damage due to aggressive air or water conditions, harsh or abrasive cleaners and/or materials.

Under no circumstance shall we be held liable for personal injury or property damage resulting from improper installation

or use of this product. We will not be held liable for inconvenience caused by loss of use of this product, costs incurred

for labour or materials, removal and installation of replacement units, or any other incidental or consequential damages.

Costs relating to obtaining access for repair or replacement are the responsibility of the user.

Our obligation shall be limited to the repair or replacement of a unit (at our discretion) that may prove, by our sole

examination, to be defective under normal use and service during the warranty period.

Any failure of this product that is not traceable to a defect in material or workmanship is not covered by this warranty.

These non-warrantable items include, but are not limited to:

-Improper installation not in accordance with manufacturer’s instructions.

-Dents and/or scratches incurred during shipping, handling, or installation.

-Change in colour or nish due to chemical usage.

-Damage caused by failure to follow care and cleaning guidelines, including damage caused by the use of abrasive

cleaners.

-Alterations made to the unit by the purchaser or installer.

-Damage caused by accidental impact, re, ood, freezing, and normal wear.

-Bends and warping caused by forced connections, over-tightened ttings, and inadequate support during

installation.

-Any defects or damage to light bulbs.

This warranty does not extend to commercial and institutional installation or use.

WARRANTY CLAIM PROCEDURE

If a claimable defect occurs or replacement parts are needed, please contact our customer service team at cs@

conglomkb.com or 1-888-449-9194 (Service available in English and French, Monday - Friday from 8:30 am - 5 pm, EST).

Before you make your call, please ensure that you have:

-Model number or description.

-Proof of sale.

-Details regarding the defect and/or part number.

-Name(s) and address(es) of the owner and/or installer.

5

Pre-Installation

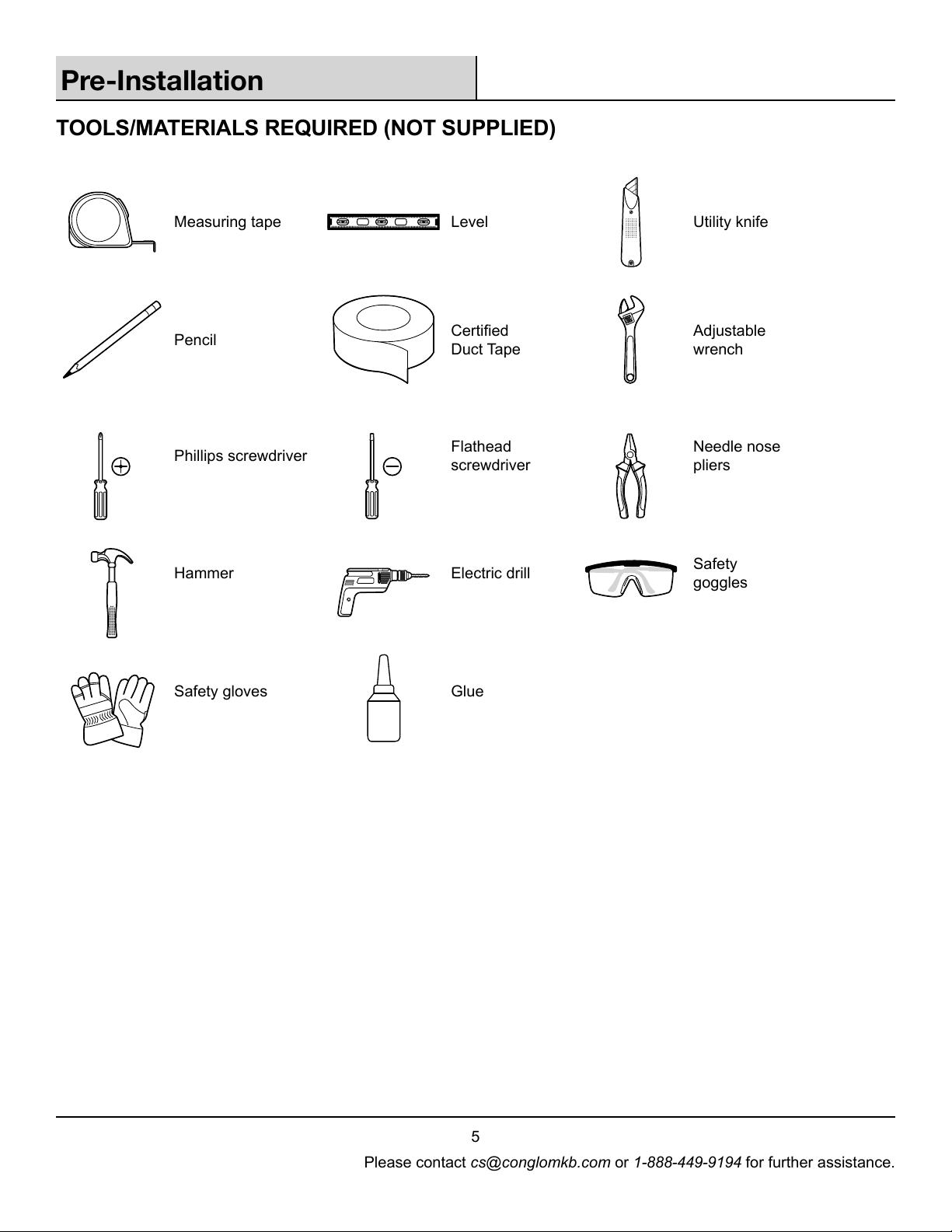

TOOLS/MATERIALS REQUIRED (NOT SUPPLIED)

Measuring tape Level Utility knife

Pencil Certied

Duct Tape

Adjustable

wrench

Phillips screwdriver Flathead

screwdriver

Needle nose

pliers

Hammer Electric drill Safety

goggles

Safety gloves Glue

6

Pre-Installation (continued)

PACKAGE CONTENTS

Carefully check the unit for damage and/or missing parts prior to installation. If there is any damage or if you are

missing parts, do not proceed with the installation. Report damage and/or missing parts immediately to our customer

service team at cs@conglomkb com or 1-888-449-9194 (Service available in English and French, Monday - Friday

from 8:30 am - 5:00 pm EST). Please do not dispose of packaging before you are satised with your new product.

DC

B

A

Part Description Quantity

A Range hood 1

BAluminum & charcoal lter 1

CRetangular damper (located inside the hood) 1

D Strips 3

HARDWARE INCLUDED

NOTE:

Parts not shown in actual size.

AA BB CC

Part Description Quantity

AA Long tapping screws (ST4x18mm) 4

BB Short tapping screws (ST4x10-F-Hmm) 6

CC Wire Connectors 3

7

Pre-Installation (continued)

PLANNING INSTALLATION

Number of people required: 2 or more

1. Before installation, measure all distances to ensure the

proper position of the range hood (A).

-The minimum distance (1) from the cooking surface

to the range hood is 18 in. (458 mm). If your range

species a different distance, use the greater distance

of the two. For best performance, this distance (1)

should not exceed 25 in. (635 mm).

-Dimension (2) should be at least 30 in (762 mm). The

range hood should be approximately the same size as

the cook top.

2. If the bottom of the cabinet (3) above the location where the

range hood is to be installed is recessed, attach appropriately

sized wood ller strips (4) on each side using wood screws.

3. Screws are provided to secure the range hood to most types

of cabinets, but consult a qualied installer to verify that the

supplied screws are suitable for your cabinets.

4. Put a thick, protective covering over your counter, cooktop,

or range to protect it from damage and dirt during installation.

Remove any hazardous objects around the area.

WARNING: Always wear safety goggles and

gloves during installation.

Fig.2

1

A

2

2

44

43

VENTING OPTIONS:

a. Determine if your existing venting system is top venting or back venting, and ensure that the openings in the cabinet

or wall for the damper and for power access are in appropriate locations and are of appropriate sizes, as per Fig. 3 if

it is top venting or Fig. 4 if it is back venting.

b. If this is a new installation, choose the venting method that suits your needs. Cut out openings for the damper

and for power access in the cabinet bottom or exterior wall, depending on the direction of venting chosen.

Fig.3 Fig.4

260

10-1/4

7.48"

(190mm)

1.54"

(39mm)

2.05"

(52mm)

”

260

10-1/4”

8

Pre-Installation (continued)

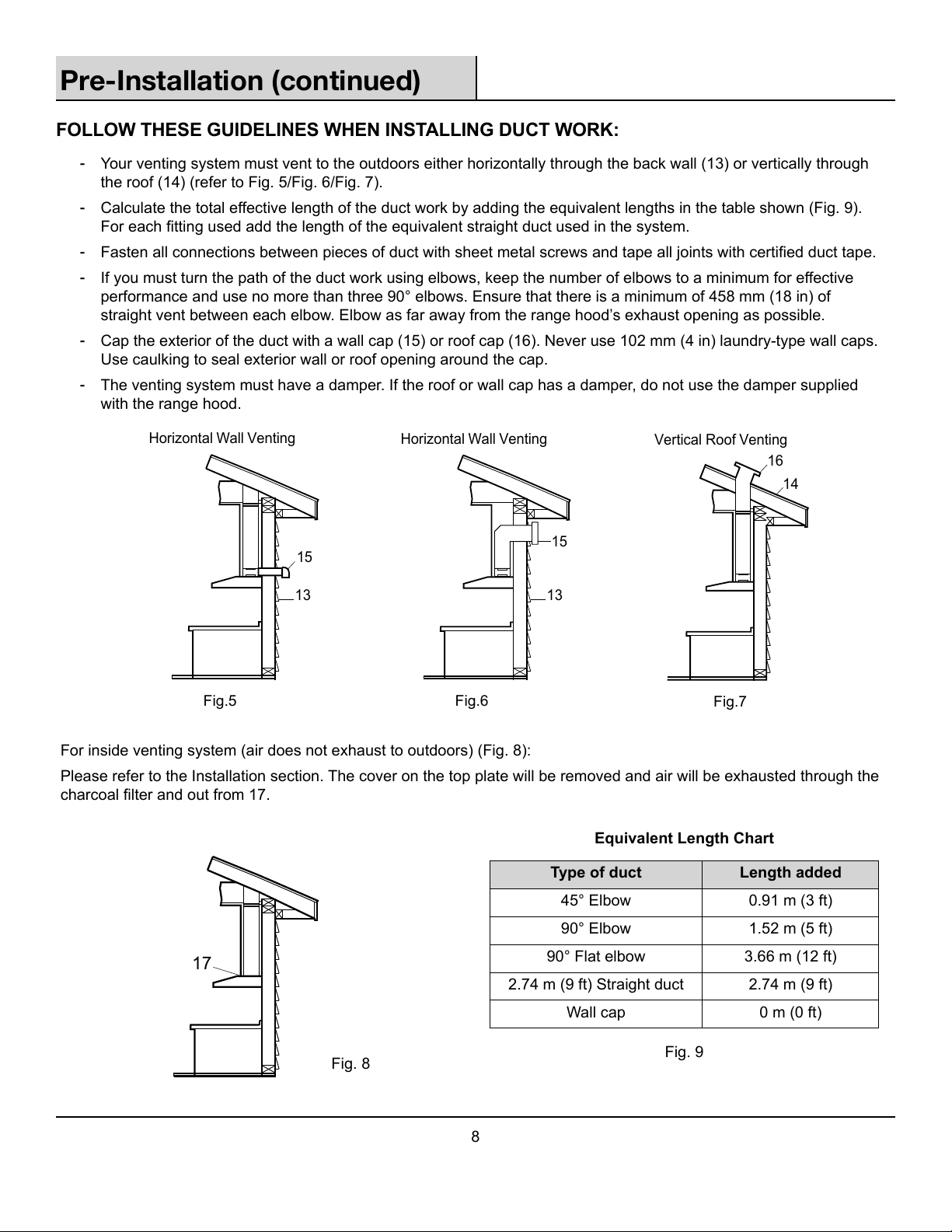

FOLLOW THESE GUIDELINES WHEN INSTALLING DUCT WORK:

-Your venting system must vent to the outdoors either horizontally through the back wall (13) or vertically through

the roof (14) (refer to Fig. 5/Fig. 6/Fig. 7).

-Calculate the total effective length of the duct work by adding the equivalent lengths in the table shown (Fig. 9).

For each tting used add the length of the equivalent straight duct used in the system.

-Fasten all connections between pieces of duct with sheet metal screws and tape all joints with certied duct tape.

-If you must turn the path of the duct work using elbows, keep the number of elbows to a minimum for effective

performance and use no more than three 90° elbows. Ensure that there is a minimum of 458 mm (18 in) of

straight vent between each elbow. Elbow as far away from the range hood’s exhaust opening as possible.

-Cap the exterior of the duct with a wall cap (15) or roof cap (16). Never use 102 mm (4 in) laundry-type wall caps.

Use caulking to seal exterior wall or roof opening around the cap.

-The venting system must have a damper. If the roof or wall cap has a damper, do not use the damper supplied

with the range hood.

13

15

Horizontal Wall Venting

Fig.5

Vertical Roof Venting

14

16

Fig.7

13

Horizontal Wall Venting

Fig.6

15

For inside venting system (air does not exhaust to outdoors) (Fig. 8):

Please refer to the Installation section. The cover on the top plate will be removed and air will be exhausted through the

charcoal lter and out from 17.

17

Fig. 8

Equivalent Length Chart

Type of duct Length added

45° Elbow 0.91 m (3 ft)

90° Elbow 1.52 m (5 ft)

90° Flat elbow 3.66 m (12 ft)

2.74 m (9 ft) Straight duct 2.74 m (9 ft)

Wall cap 0 m (0 ft)

Fig. 9

9

Pre-Installation (continued)

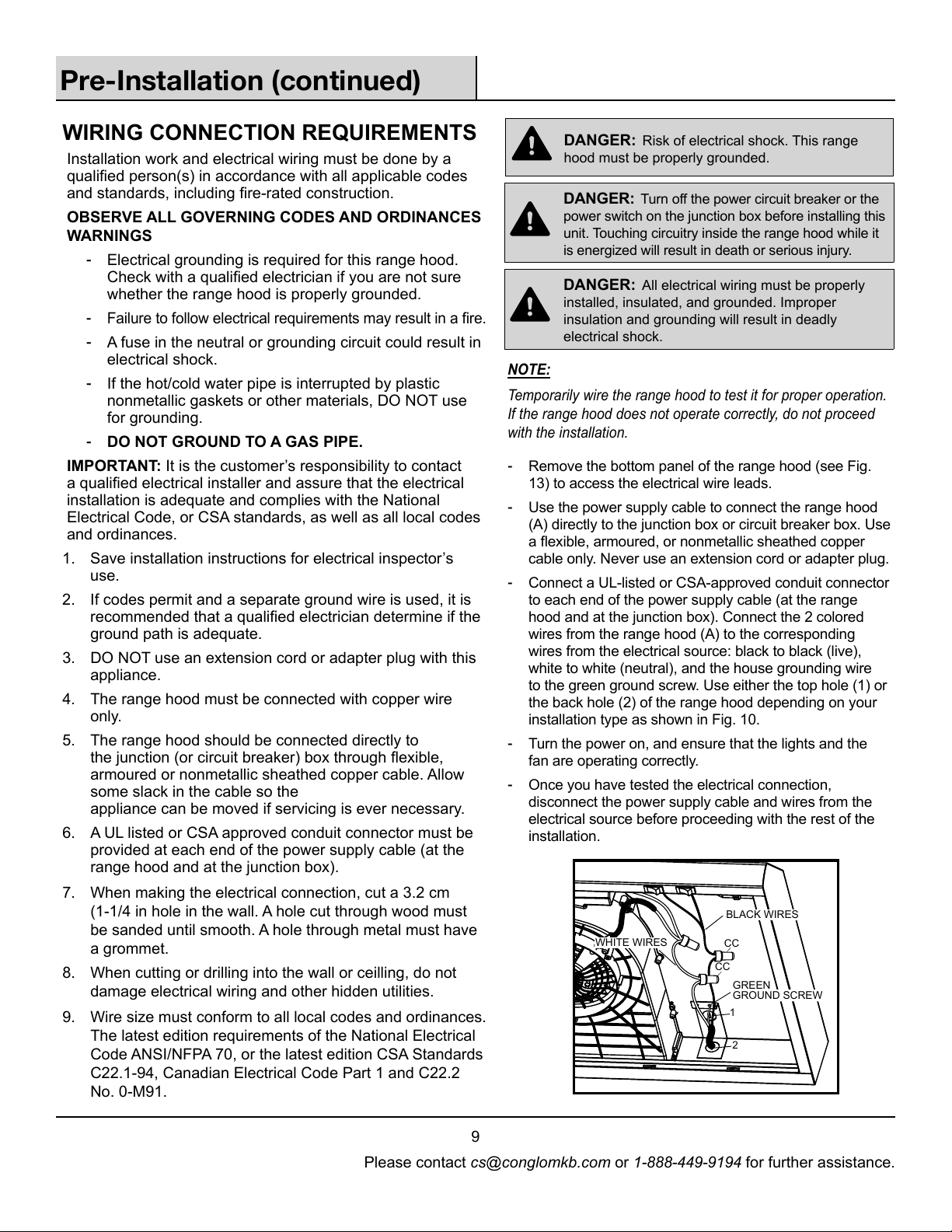

WIRING CONNECTION REQUIREMENTS

Installation work and electrical wiring must be done by a

qualied person(s) in accordance with all applicable codes

and standards, including re-rated construction.

OBSERVE ALL GOVERNING CODES AND ORDINANCES

WARNINGS

-Electrical grounding is required for this range hood.

Check with a qualied electrician if you are not sure

whether the range hood is properly grounded.

-Failure to follow electrical requirements may result in a re.

-A fuse in the neutral or grounding circuit could result in

electrical shock.

-If the hot/cold water pipe is interrupted by plastic

nonmetallic gaskets or other materials, DO NOT use

for grounding.

-DO NOT GROUND TO A GAS PIPE.

IMPORTANT: It is the customer’s responsibility to contact

a qualied electrical installer and assure that the electrical

installation is adequate and complies with the National

Electrical Code, or CSA standards, as well as all local codes

and ordinances.

1. Save installation instructions for electrical inspector’s

use.

2. If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine if the

ground path is adequate.

3. DO NOT use an extension cord or adapter plug with this

appliance.

4. The range hood must be connected with copper wire

only.

5. The range hood should be connected directly to

the junction (or circuit breaker) box through exible,

armoured or nonmetallic sheathed copper cable. Allow

some slack in the cable so the

appliance can be moved if servicing is ever necessary.

6. A UL listed or CSA approved conduit connector must be

provided at each end of the power supply cable (at the

range hood and at the junction box).

7. When making the electrical connection, cut a 3.2 cm

(1-1/4 in hole in the wall. A hole cut through wood must

be sanded until smooth. A hole through metal must have

a grommet.

8. When cutting or drilling into the wall or ceilling, do not

damage electrical wiring and other hidden utilities.

9. Wire size must conform to all local codes and ordinances.

The latest edition requirements of the National Electrical

Code ANSI/NFPA 70, or the latest edition CSA Standards

C22.1-94, Canadian Electrical Code Part 1 and C22.2

No. 0-M91.

DANGER: Risk of electrical shock. This range

hood must be properly grounded.

DANGER: Turn off the power circuit breaker or the

power switch on the junction box before installing this

unit. Touching circuitry inside the range hood while it

is energized will result in death or serious injury.

DANGER: All electrical wiring must be properly

installed, insulated, and grounded. Improper

insulation and grounding will result in deadly

electrical shock.

NOTE:

Temporarily wire the range hood to test it for proper operation.

If the range hood does not operate correctly, do not proceed

with the installation.

-Remove the bottom panel of the range hood (see Fig.

13) to access the electrical wire leads.

-Use the power supply cable to connect the range hood

(A) directly to the junction box or circuit breaker box. Use

a exible, armoured, or nonmetallic sheathed copper

cable only. Never use an extension cord or adapter plug.

-Connect a UL-listed or CSA-approved conduit connector

to each end of the power supply cable (at the range

hood and at the junction box). Connect the 2 colored

wires from the range hood (A) to the corresponding

wires from the electrical source: black to black (live),

white to white (neutral), and the house grounding wire

to the green ground screw. Use either the top hole (1) or

the back hole (2) of the range hood depending on your

installation type as shown in Fig. 10.

-Turn the power on, and ensure that the lights and the

fan are operating correctly.

-Once you have tested the electrical connection,

disconnect the power supply cable and wires from the

electrical source before proceeding with the rest of the

installation.

CC

CC

BLACK WIRES

WHITE WIRES

GREEN

GROUND SCREW

1

2

10

Installation

WARNING: FUEL (GAS) BURNING RANGES MUST BE VENTED OUTDOORS USING, AT MINIMUM, METAL DUCTWORK

AND RANGE HOODS OF SUFFICIENT CAPACITY. Follow your fuel burning equipment manufacturer’s guidelines, as well as, all

applicable safety standards published by the National Fire Protection Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and your local code authorities.

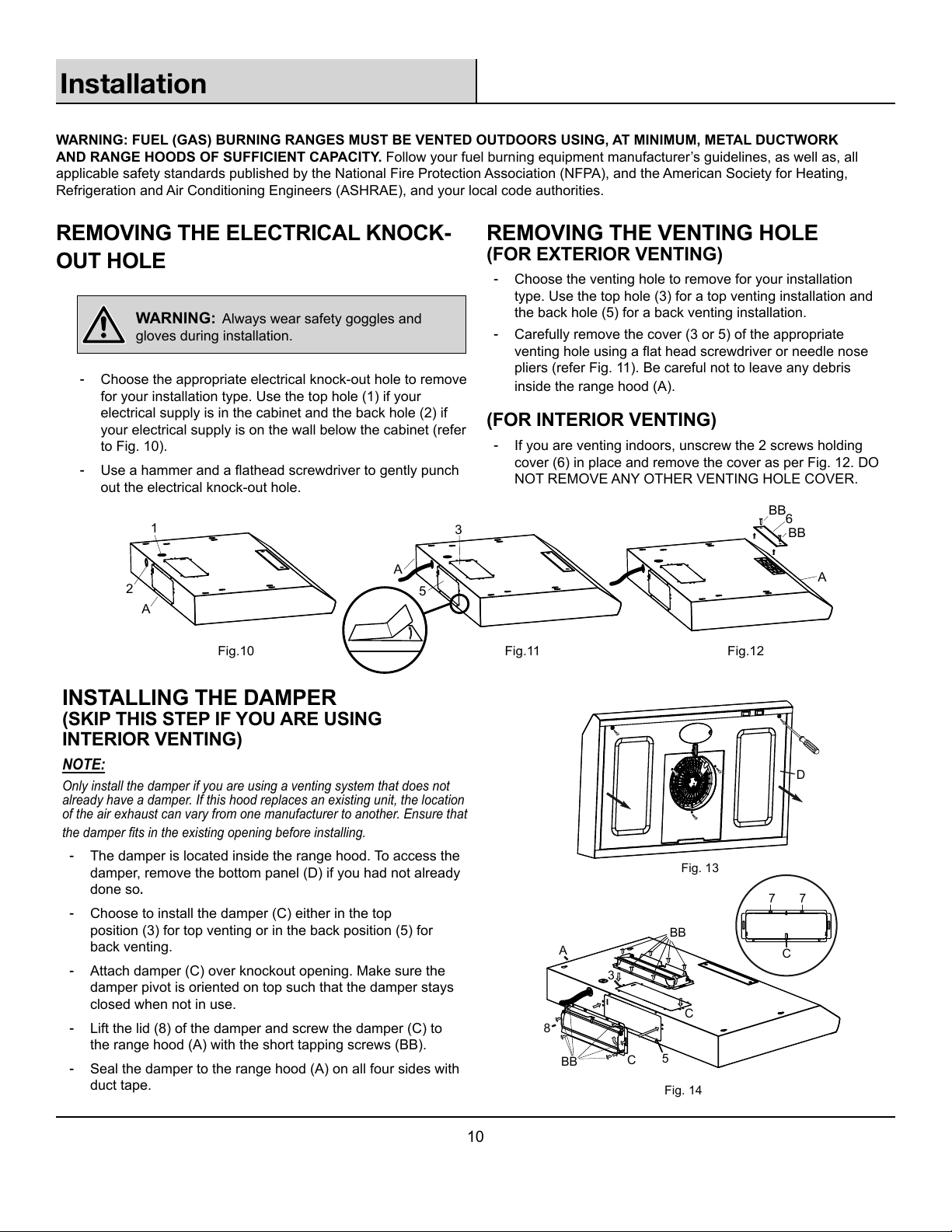

REMOVING THE ELECTRICAL KNOCK-

OUT HOLE

WARNING: Always wear safety goggles and

gloves during installation.

-Choose the appropriate electrical knock-out hole to remove

for your installation type. Use the top hole (1) if your

electrical supply is in the cabinet and the back hole (2) if

your electrical supply is on the wall below the cabinet (refer

to Fig. 10).

-Use a hammer and a athead screwdriver to gently punch

out the electrical knock-out hole.

REMOVING THE VENTING HOLE

(FOR EXTERIOR VENTING)

-Choose the venting hole to remove for your installation

type. Use the top hole (3) for a top venting installation and

the back hole (5) for a back venting installation.

-Carefully remove the cover (3 or 5) of the appropriate

venting hole using a at head screwdriver or needle nose

pliers (refer Fig. 11). Be careful not to leave any debris

inside the range hood (A).

(FOR INTERIOR VENTING)

-If you are venting indoors, unscrew the 2 screws holding

cover (6) in place and remove the cover as per Fig. 12. DO

NOT REMOVE ANY OTHER VENTING HOLE COVER.

5

BB

BB

Fig.10 Fig.11 Fig.12

A

2

1

A

36

A

INSTALLING THE DAMPER

(SKIP THIS STEP IF YOU ARE USING

INTERIOR VENTING)

BB

D

BB

8

A

C

C

3

5

Fig. 13

Fig. 14

7

C

7

NOTE:

Only install the damper if you are using a venting system that does not

already have a damper. If this hood replaces an existing unit, the location

of the air exhaust can vary from one manufacturer to another. Ensure that

the damper ts in the existing opening before installing.

-The damper is located inside the range hood. To access the

damper, remove the bottom panel (D) if you had not already

done so.

-Choose to install the damper (C) either in the top

position (3) for top venting or in the back position (5) for

back venting.

-Attach damper (C) over knockout opening. Make sure the

damper pivot is oriented on top such that the damper stays

closed when not in use.

-Lift the lid (8) of the damper and screw the damper (C) to

the range hood (A) with the short tapping screws (BB).

-Seal the damper to the range hood (A) on all four sides with

duct tape.

11

Installation (continued)

INSTALLING THE RANGE HOOD

DANGER: Turn off the power circuit breaker or the

power switch on the junction box before installing

this unit. Touching circuitry inside the range hood

while it is energized will result in death or serious

injury.

DANGER: If installing this unit over a gas range,

turn off the gas at the source before installing or

servicing this unit.

-Lift the range hood (A) up under the cabinet to determine

its nal position. Mark the location of the four keyhole

mounting slots (1) on the underside of the cabinet.

-Set the range hood (A) aside on a protective surface.

-Drill four pilot holes in the locations that you marked.

-Screw the four long tapping screws (AA) into the pilot

holes. Do not tighten the screws all the way – leave

the screw heads about 7 mm (0.28 in) from the cabinet

surface.

-Lift the range hood (A) into position, feeding the power

cable and the electrical wires through the power access

opening. Allow some slack in the cable and wires so

that the appliance can be moved if servicing is ever

necessary.

-Position the range hood (A) so the large end (2) of the

keyhole mounting slots (1) are over the screws (AA).

Then push the range hood (A) toward the wall so the

screws (AA) are in the neck (3) of the keyhole slots.

Tighten the screws (AA). Ensure that the range hood (A)

is securely fastened to the cabinet before releasing it.

-If applicable, test the damper blade to ensure it rotates up

and down freely.

-If applicable, connect the duct work to the range hood

(A). Seal the joints with duct tape to ensure an airtight t.

-Use the supplied ller strips (optional) to ll any gaps

between the range hood and the back splash. Secure

them using double sided tape and an appropriate

adhesive.

-Reinstall the bottom panel and lters as showin in Fig. 17.

FINAL STEP

-Reconnect the power supply cable and wires to the

electrical supply. Turn the power on and ensure that

the lights and fan are operating correctly.

Fig. 15

Fig. 16

Fig. 17

AA AA

11

A

AA

2

3

1

12

Installation (continued)

INSTALLING THE CHARCOAL FILTER

(SKIP THIS STEP IF YOU ARE USING EXTERIOR VENTING)

NOTE:

The charcoal lter should only be installed if you are not using an external venting system.

-Turn the lter clip to either side and lift the aluminum lter.

-Place the charcoal lter (B) in place, ensure that it covers the air outlet entirely.

-Turn the lter clip so that the end of the clip holds the lter rmly in place.

A

A

B

13

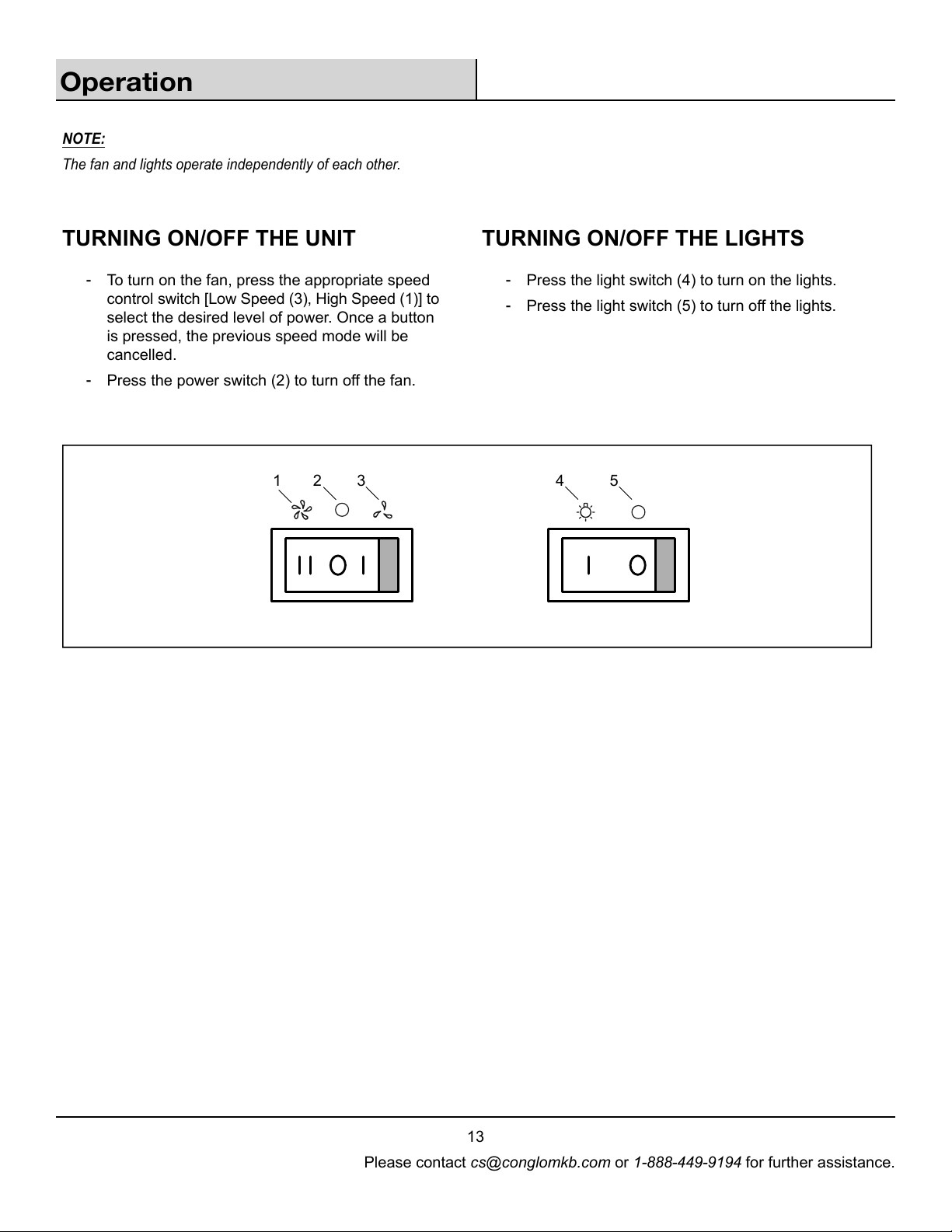

Operation

NOTE:

The fan and lights operate independently of each other.

TURNING ON/OFF THE UNIT

-To turn on the fan, press the appropriate speed

control switch [Low Speed (3), High Speed (1)] to

select the desired level of power. Once a button

is pressed, the previous speed mode will be

cancelled.

-Press the power switch (2) to turn off the fan.

TURNING ON/OFF THE LIGHTS

-Press the light switch (4) to turn on the lights.

-Press the light switch (5) to turn off the lights.

41 2 3 5

14

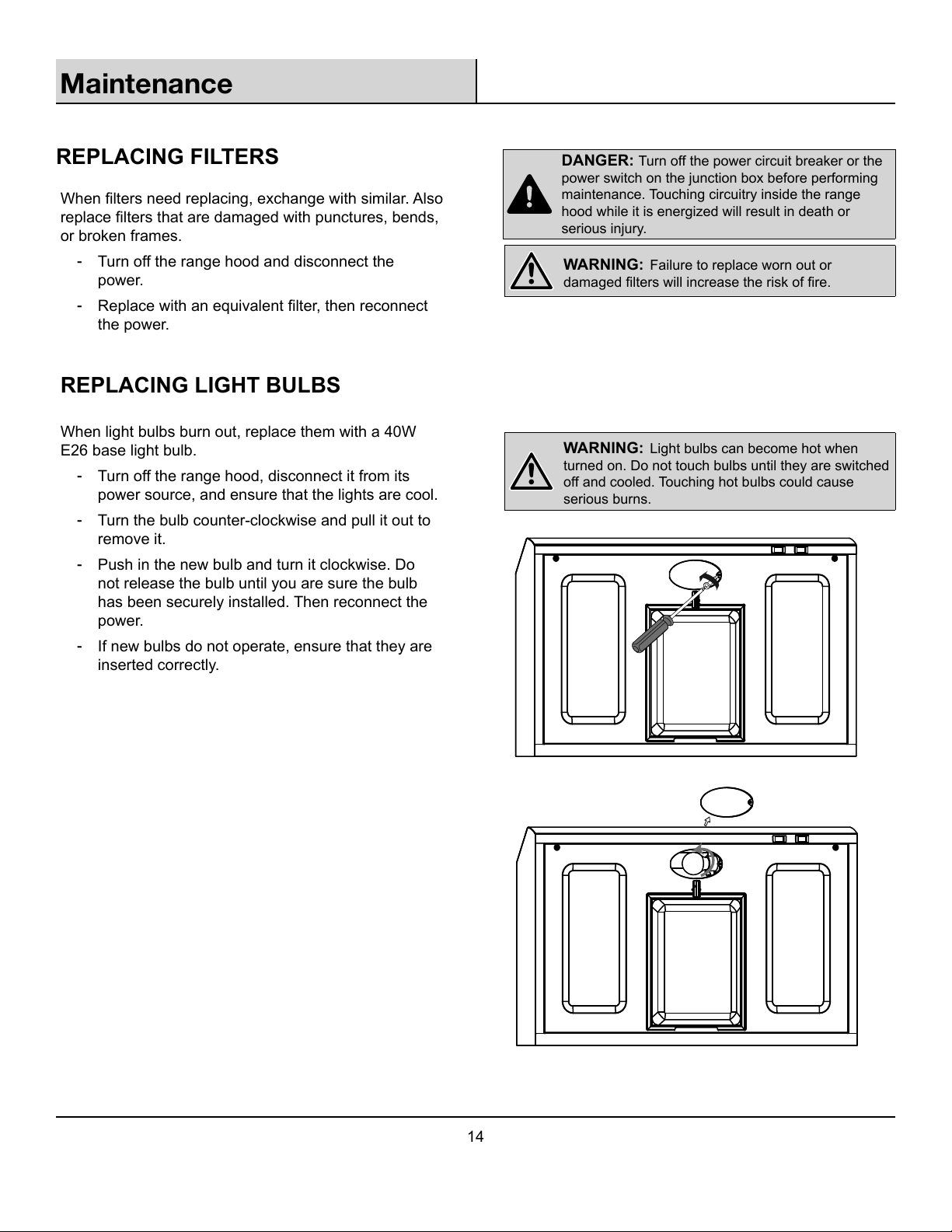

Maintenance

REPLACING FILTERS

When lters need replacing, exchange with similar. Also

replace lters that are damaged with punctures, bends,

or broken frames.

-Turn off the range hood and disconnect the

power.

-Replace with an equivalent lter, then reconnect

the power.

REPLACING LIGHT BULBS

When light bulbs burn out, replace them with a 40W

E26 base light bulb.

-Turn off the range hood, disconnect it from its

power source, and ensure that the lights are cool.

-Turn the bulb counter-clockwise and pull it out to

remove it.

-Push in the new bulb and turn it clockwise. Do

not release the bulb until you are sure the bulb

has been securely installed. Then reconnect the

power.

-If new bulbs do not operate, ensure that they are

inserted correctly.

DANGER: Turn off the power circuit breaker or the

power switch on the junction box before performing

maintenance. Touching circuitry inside the range

hood while it is energized will result in death or

serious injury.

WARNING: Failure to replace worn out or

damaged lters will increase the risk of re.

WARNING: Light bulbs can become hot when

turned on. Do not touch bulbs until they are switched

off and cooled. Touching hot bulbs could cause

serious burns.

15

Care and Cleaning

RANGE HOOD

WARNING: Failure to maintain basic standards of care and cleaning of the range hood will increase

the risk of re.

The range hood should be cleaned (regularly internally and externally) to preserve its appearance and performance.

Do: Do Not:

-Always clean in the direction of the grain

(original

polish lines).

-Clean the range hood periodically with hot,

soapy water and a clean cotton cloth.

-Always rinse well with clean water two or

three times after cleaning. Wipe completely

dry with a soft non-abrasive cloth.

-After cleaning, you may polish with a non-

abrasive stainless steel polish or cleaner.

Always rub lightly and with the grain

-Ensure that the venting system is free of

debris, if you have one.

-Do not use corrosive or abrasive detergents,

steel wool, or scouring pads. These will scratch

and damage the stainless steel surface.

-Do not use any products containing chloride,

uoride, iodide, or bromide on this product, as

they will deteriorate the surface rapidly.

-Do not allow cleaning compounds, salt solutions,

disinfectants, or bleaches to remain in contact

with the product for extended periods of time.

-Do not allow any deposits to remain for long

periods of time on the range hood. Rinse with

water immediately and wipe dry with a clean

cloth.

-Do not let plaster dust or any other construction

residue enter the hood. During construction or

renovation, cover the hood.

-Combustible products used for cleaning such

as acetone, alcohol, ether, or benzol are highly

explosive and should never be used close to a

range or stove.

FILTER

The lter tted by the factory is intended to lter out residue and grease from cooking. You do not need to replace them

on a regular basis, but you should keep them clean.

Do: Do Not:

-Clean the lter once a month using non-

abrasive detergents, either by hand or in the

dishwasher. When using a dishwasher, set

the dishwasher to a low temperature and a

short cycle setting. The lter may become

discoloured in a dishwasher, but this does

not affect its performance.

-Allow lters to completely dry before re-

installing them in the range hood.

-Do not allow oil to accumulate over

more than 80% of the lter surface. Oil

accumulations may drip oil onto the range.

-Do not wash charcoal lter. The charcoal

lter should be replaced when it is covered

in grease and has reached its maximum

absorbancy.

16

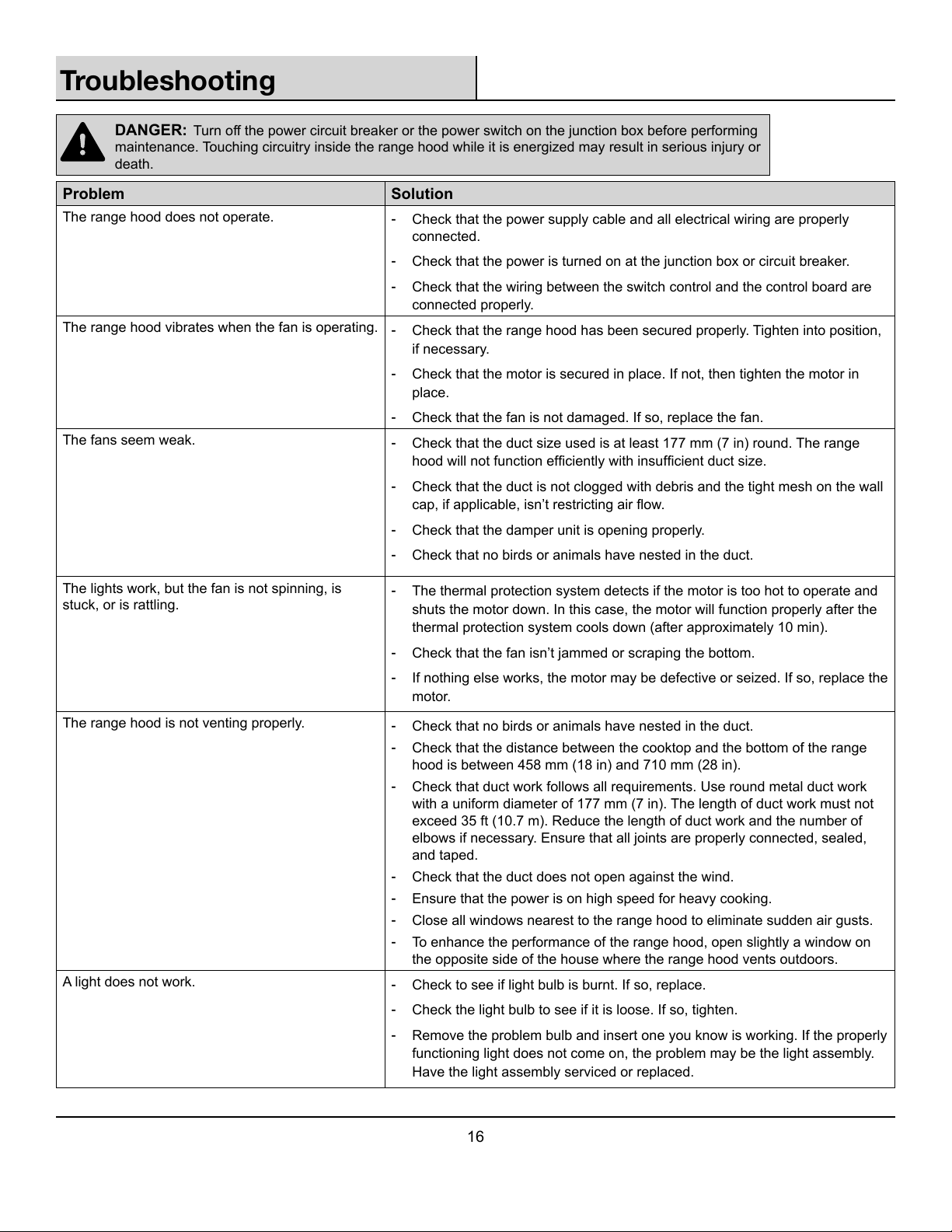

Troubleshooting

DANGER: Turn off the power circuit breaker or the power switch on the junction box before performing

maintenance. Touching circuitry inside the range hood while it is energized may result in serious injury or

death.

Problem Solution

The range hood does not operate. -Check that the power supply cable and all electrical wiring are properly

connected.

-Check that the power is turned on at the junction box or circuit breaker.

-Check that the wiring between the switch control and the control board are

connected properly.

The range hood vibrates when the fan is operating. -Check that the range hood has been secured properly. Tighten into position,

if necessary.

-Check that the motor is secured in place. If not, then tighten the motor in

place.

-Check that the fan is not damaged. If so, replace the fan.

The fans seem weak. -Check that the duct size used is at least 177 mm (7 in) round. The range

hood will not function efciently with insufcient duct size.

-Check that the duct is not clogged with debris and the tight mesh on the wall

cap, if applicable, isn’t restricting air ow.

-Check that the damper unit is opening properly.

-Check that no birds or animals have nested in the duct.

The lights work, but the fan is not spinning, is

stuck, or is rattling.

-The thermal protection system detects if the motor is too hot to operate and

shuts the motor down. In this case, the motor will function properly after the

thermal protection system cools down (after approximately 10 min).

-Check that the fan isn’t jammed or scraping the bottom.

-If nothing else works, the motor may be defective or seized. If so, replace the

motor.

The range hood is not venting properly. -Check that no birds or animals have nested in the duct.

-Check that the distance between the cooktop and the bottom of the range

hood is between 458 mm (18 in) and 710 mm (28 in).

-Check that duct work follows all requirements. Use round metal duct work

with a uniform diameter of 177 mm (7 in). The length of duct work must not

exceed 35 ft (10.7 m). Reduce the length of duct work and the number of

elbows if necessary. Ensure that all joints are properly connected, sealed,

and taped.

-Check that the duct does not open against the wind.

-Ensure that the power is on high speed for heavy cooking.

-Close all windows nearest to the range hood to eliminate sudden air gusts.

-To enhance the performance of the range hood, open slightly a window on

the opposite side of the house where the range hood vents outdoors.

A light does not work. -Check to see if light bulb is burnt. If so, replace.

-Check the light bulb to see if it is loose. If so, tighten.

-Remove the problem bulb and insert one you know is working. If the properly

functioning light does not come on, the problem may be the light assembly.

Have the light assembly serviced or replaced.

17

Specications

Model Dimensions Rating Control

Type

Max.

Fan CFM Speeds Light Bulb

Wattage

Venting

Options

QR241

29.8 in (758 mm) W

120V~60Hz

1.1A

Rocker

Switches

160 ±

10%

High 1 x 40W

Incandescent E26

base light bulb

Top venting

Back venting

Recirculating/

Inside venting

18.4 in (468 mm) D

Low

4 in (100 mm) H

WIRING DIAGRAM

BLACK

RED

II I IO O

BLUE

BLACK BLACK

BLACK

LN

120~60Hz

6uF / 250V

GRAY

YELLOW

YELLOW & GREEN

WHITE

WHITE

L

1 40W E26

WHITE

18

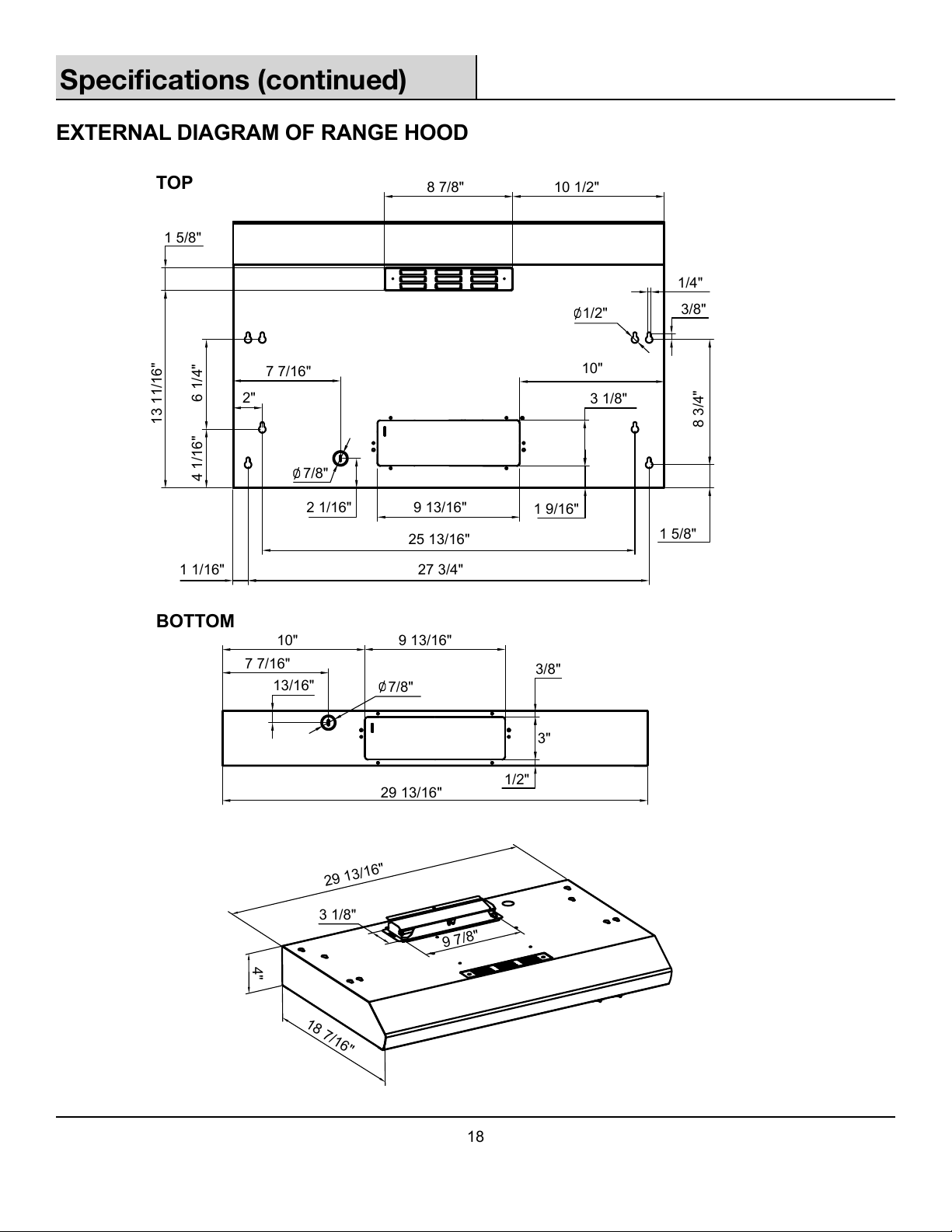

Specications (continued)

EXTERNAL DIAGRAM OF RANGE HOOD

10"

3 1/8"

1/2"

1/4"

3/8"

8 3/4"

6 1/4"

4 1/16"

13 11/16"

1 5/8"

1 9/16"

27 3/4"

25 13/16"

9 13/16"

2 1/16"

1 1/16"

7/8"

7 7/16"

1 5/8"

8 7/8"

10" 9 13/16"

29 13/16" 1/2"

3"

3/8"

7/8"

7 7/16"

13/16"

10 1/2"

2"

29 13/16"

9 7/8"

3 1/8"

18 7/16"

4"

TOP

BOTTOM

19

Service Parts

If you are missing parts or if you require replacement parts, please contact our customer service team at

or 1-888-449-9194 (8:30 am – 5 pm, EST, Monday–Friday). Identify the required part(s) and have the part number(s) ready.

A B C D E F

GHL

JK

MNPQRS

Part Description Code Quantity

A Rectangular Damper QHR186 1

B Rocker Switches Left/Right QHR212 1

C Capacitor QHR213 1

D Motor QHR214 1

E Filter Clip QHR168 1

F White Filler Strips* QHR190 3

F Stainless Steel Filler Strips* QHR220 3

F Black Filler Strips* QHR221 3

G Blower QHR191 1

H Light Cover QHR192 1

J Blade QHR215 1

K Bulb Holder QHR203 1

L Bulb QHR174 1

MReector QHR194 1

N Internal vent cover QHR195 1

P Charcoal Filter QHR216 1

Q Aluminum Filter QHR177 1

RLong Tapping Screws (ST4x18mm) QHR178 4

STapping Screws (ST4x10-F-Hmm) QHR179 6

*If ller strips are required, please be sure to verify the part code for the proper color that matches your unit.

Imported by:

St-Laurent, Québec, H4S 2C3

1-888-449-9194 | cs@conglomkb.com

(service available in English and French, Monday - Friday from 8:30 am - 5 pm EST)

www.conglomkb.com

Made in China

This manual suits for next models

5

Table of contents

Popular Ventilation Hood manuals by other brands

Hatco

Hatco PMGH-60 Installation, operating, service and parts manual

Teka

Teka DVN 64030 TCL BK user manual

Hoover

Hoover HVE 93 User instructions

AEG

AEG DK 9160-9190 Operating and installation instructions

Whirlpool

Whirlpool UXT5230AYB0 Installation Instructions and Use & Care Guide

Smeg

Smeg HOBD682D1 installation manual