Schako RS-N Operating instructions

Ferdinand Schad KG

Steigstraße 25-27

D-78600 Kolbingen

Telephone +49 (0) 74 63 - 980 - 0

Fax +49 (0) 74 63 - 980 - 200

www.schako.de

Additional operating instructions

according to ATEX 94/9/EC

Silencer

RS-N/RS-M/

MWK-OB/MWS-OB/MWK-MB/MWS-MB

Contents

Construction subject to change. No return possible!

Operating and mounting instructions

according to ATEX for RS-N/RS-M/MWK-OB/MWS-OB/MWK-MB/MWS-MB

Z10/03 - 2 06.02.2018Version:

General conditions ...............................................................................................................................3

General description and instructions ..........................................................................................................................................3

Personnel qualification and training ...........................................................................................................................................3

Safety-conscious work ...............................................................................................................................................................3

Designated use ..........................................................................................................................................................................3

Delivery and storage ..................................................................................................................................................................3

Mounting information ................................................................................................................................................................3

Maintenance ..............................................................................................................................................................................3

Hazard caused by non-observance of the safety instructions ....................................................................................................3

Models and dimensions ......................................................................................................................... 5

Dimensions ................................................................................................................................................................................5

Dimensions of accessories ........................................................................................................................................................7

Information regarding assembly and commissioning ................................................................................................................8

Information regarding maintenance and inspection ...................................................................................................................8

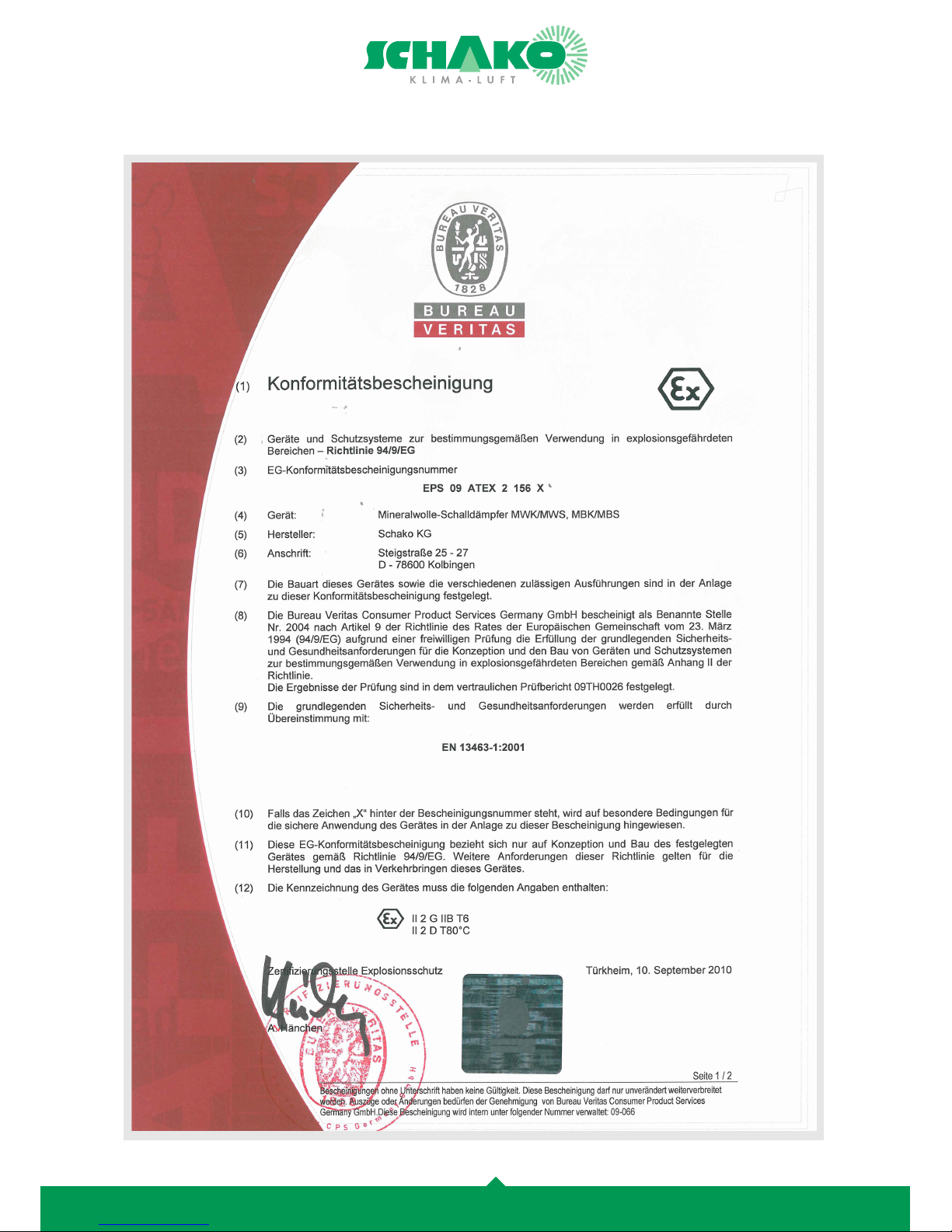

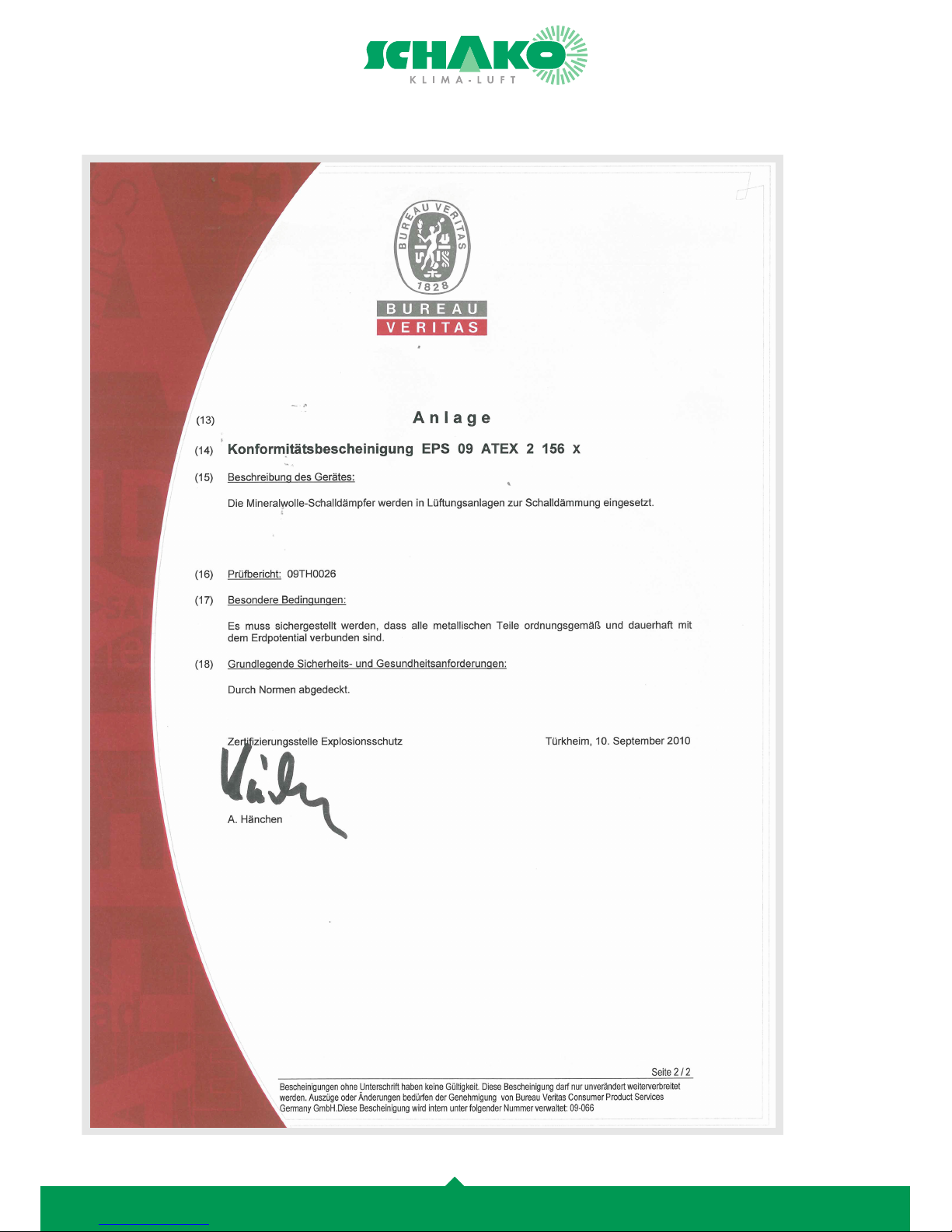

Certificate of conformity .........................................................................................................................9

Operating and mounting instructions according to ATEX for

RS-N/RS-M/MWK-OB/MWS-OB/MWK-MB/MWS-MB

Z10/03 - 3

Construction subject to change. No return possible!

06.02.2018Version:

General conditions

General description and instructions

These additional operating instructions must be observed prior

to mounting and commissioning the device.

These additional operating instructions contain basic informa-

tion regarding its use in areas subject to explosion hazards to be

observed during assembly, operation and maintenance.

Prior to mounting and commissioning and during maintenance

work, the present additional operating instructions must be read

by the installer and the responsible skilled personnel/system

operator!

Personnel qualification and training

The personnel for assembly, inspection and maintenance must

have the relevant qualification for this work.

The area of responsibility, competence and monitoring of the

personnel must be exactly regulated by the system operator. If

the personnel does not have the required knowledge, it must be

trained and instructed. Moreover, the system operator must en-

sure that the contents of the additional operating instructions

are understood completely by the personnel.

Safety-conscious work

The safety instructions given in these additional operating in-

structions, the existing national and international regulations on

explosion protection, accident prevention and the system oper-

ator's internal work, operating and safety regulations must be

observed.

Designated use

The devices have been designed for use in ventilation systems

in areas subject to explosion hazards according to ATEX of Cat-

egory II, Zones 1, 2 and Category III, Zones 21, 22.

These devices are not suitable for use in unreleased Ex zones.

The operating safety of the delivered devices is only guaranteed

when used in accordance with their designated use.

Delivery and storage

Upon receipt, the devices must be checked for completeness

and transport damage. If delivered incompletely or damaged,

the forwarding company and the SCHAKO KG have to be in-

formed immediately.

The device must not be exposed directly to weather, solar radi-

ation and moisture.

Mounting information

Mounting, electrical connection work and commissioning must

be carried out by skilled personnel only and in accordance with

the recognised technical rules and the safety and accident pre-

vention regulations.

Maintenance

Only a device subjected to proper maintenance and kept in per-

fect condition can guarantee safe and reliable operation.

When defective parts are replaced with spare parts, only SCHA-

KO original spare parts may be used. The SCHAKO KG cannot

be held liable for any damage caused by using spare parts that

are not original and will not give any warranty.

Hazard caused by non-observance of the safety in-

structions

Non-observance of the safety instructions can result both in

putting persons and the environment and operating units at risk.

Likewise, non-observance of the safety instructions will result in

the loss of any claims for damages.

Operating and mounting instructions according to ATEX for

RS-N/RS-M/MWK-OB/MWS-OB/MWK-MB/MWS-MB

Z10/03 - 4

Construction subject to change. No return possible!

06.02.2018Version:

Description

Silencing of the duct silencer

type RS-N in accordance with the

absorption principle is done by means of an annular chamber

filled with mineral wool according to DIN 4102 A2 non-flamma-

ble, mineral wool with glass silk cover. The RS-M type contains

an additional central baffle with mineral wool filling and glass

silk cover which is covered with a galvanised perforated sheet in

abrasion-resistant manner toward the air flow.

For maintenance, service, retrofitting, etc., inspection openings

in sufficient number and size must be provided on-site.

Baffles with frame profile in nozzle design reduce the pressure

loss by up to 55% compared with conventional baffles. This

gives high energy-saving in the operation of the system!

The baffles and baffle silencers are delivered in a hygienic de-

sign to VDI 6022. The objective of the VDI 6022 "Hygienic plan-

ning, design, operation and maintenance of air-conditioning

installations" is a hygienically impeccable interior air quality, i.e.,

avoidance of microbial contamination of the inhaled air. Accord-

ingly, installation components must not emit any substances, fi-

bres or odours hazardous to health, and must not promote the

growth of microorganisms. The hygienic qualification tests and

the data verified within the scope of the RAL quality inspection

are basic quality characteristics of our sound isolation compo-

nents.

The mineral wool silencers type MWS-OB / MWS-MB have been

successfully tested by TÜV SÜD Life Service in accordance with

the following rules:

For maintenance, service, retrofitting, etc., inspection openings

in sufficient number and size must be provided on-site.

Installation of baffles or silencers:

When baffles are delivered separately, the determined perform-

ance data are only reached if the manufacturer's installation in-

structions and the recognised technical rules are observed. The

mineral wool silencer should be laid out inside the ventilation in-

stallation in front of the air filter so that possible fibre separa-

tions stay in the filter.

Attention:

The baffle height <200mm cannot be delivered in the nozzle de-

sign.

Design only possible in folded form!

The baffle silencers from SCHAKO have been awarded the RAL

quality mark 595 by the RAL Quality Association. The SCHAKO

KG is a member of the RAL Quality Association for Silencers

The silencers have the following ATEX marking:

These silencers meet the regulations of the ATEX directives and

can be used in ventilation systems in areas subject to explosion

hazards.

The silences have been certified for explosion protection group

II for Zones 1, 2 & 21, 22.

Zones 1 and 2 represent the application range containing gases,

while Zones 21 and 22 represent the application range contain-

ing dusts.

Classification by zone must be established by the system oper-

ator or planner in compliance with current standards.

Note:

In explosion-protected zones, only devices that have an ATEX

approval for this use may be used.

Technical data, information

- VDI 6022, Sheet 1: Hygienic requirements of ventilation

and air-conditioning systems

- VDI 6022, Sheet 2: Hygienic requirements of ventilation

and air-conditioning systems - Measurement methods and

investigations during hygienic controls and hygienic in-

spections

- DIN 1946, Sheet 2: Air-conditioning technology - Health re-

quirements

- The grounding terminals of the silencers must be connected

to the potential bonding.

QUALITY MARK

BAFFLE-TYPE SILENCER

II 2 G IIB T6

II 2 D T80°C

II 3 G IIB T6

II 3 D T80°C

EPS 09 ATEX 2 158 X

EPS 09 ATEX 2 156 X

Operating and mounting instructions according to ATEX for

RS-N/RS-M/MWK-OB/MWS-OB/MWK-MB/MWS-MB

Z10/03 - 5

Construction subject to change. No return possible!

06.02.2018Version:

Models and dimensions

Dimensions

RS-N

x

-

P

= available

= not available

= Packing thickness

outside

external

Available sizes

NW ød øD

P (mm)

50 100 150

71 69 175 275 -

80 78 180 280 -

90 88 190 290 -

100 98 200 300 -

112 110 212 312 -

125 123 225 325 -

140 138 240 340 -

150 148 250 350 -

160 158 260 360 -

180 178 280 380 -

200 198 300 400 -

224 222 325 425 -

250 248 350 450 -

280 278 380 480 580

300 298 400 500 600

315 313 415 515 615

350 348 450 550 650

355 353 455 555 655

400 398 500 600 700

450 448 - 650 750

500 498 - 700 800

560 558 - 760 860

600 598 - 800 900

630 628 - 830 930

710 708 - 910 1010

Selection chart packing thickness

NW L=500 L=950 L=1450 L=1950

P (mm) P (mm) P (mm) P (mm)

50 100 150 50 100 150 50 100 150 50 100 150

71 xx-xx-x--x--

80 xx-xx-x--x--

90 xx-xx-x--x--

100 xx-xx-x--x--

112 xx-xx-x--x--

125 xx-xx-x--x--

140 xx-xx-x--x--

150 xx-xx-xx--x-

160 xx-xx-xx--x-

180 xx-xx-xx--x-

200 xx-xx-xx--x-

224 xx-xx-xx--x-

250 xx-xx-xx--x-

280 xx-xxxxxx--x

300 xx-xxxxxx--x

315 xx-xxxxxx--x

350 xx-xxxxxx--x

355 xx-xxxxxx--x

400 xx-xxxxxx--x

450 ----xx-xx--x

500 ----xx-xx--x

560 -----x-xx--x

600 -----x-xx--x

630 -----x-xx--x

710 -----x-xx--x

Operating and mounting instructions according to ATEX for

RS-N/RS-M/MWK-OB/MWS-OB/MWK-MB/MWS-MB

Z10/03 - 6

Construction subject to change. No return possible!

06.02.2018Version:

RS-M

x

-

P

= available

= not available

= Packing thickness

T = Baffle width

Central baffle

external

external

Available sizes

NW ød øD T

(mm)

P (mm)

50 100 150

350 348 450 550 650 60

355 353 455 555 655 60

400 398 500 600 700 60

450 448 550 650 750 60

500 498 600 700 800 75

560 558 - 760 860 100

600 598 - 800 900 100

630 628 - 830 930 100

710 708 - 910 1010 150

Selection chart packing thickness

NW L=950 L=1450 L=1950

P (mm) P (mm) P (mm)

50 100 150 50 100 150 50 100 150

350 xxxxxx--x

355 xxxxxx--x

400 xxxxxx--x

450 xxxxxx--x

500 xxxxxx--x

560 -xx-xx--x

600 -xx-xx--x

630 -xx-xx--x

710 -xx-xx--x

Operating and mounting instructions according to ATEX for

RS-N/RS-M/MWK-OB/MWS-OB/MWK-MB/MWS-MB

Z10/03 - 7

Construction subject to change. No return possible!

06.02.2018Version:

Silencing baffle type MWK-OB/MWK-MB

Baffle silencer type MWS-OB/MWS-MB

Available sizes

All combined lengths, heights and widths available!

If desired, also available as D 300!

Technical data on request.

The model D300 is assembled with mineral fibre boards

100+200 mm.

Detail X

at D=100/200 and H2>200 at D=300 and/or at H2<200

round design rectangular design

Dimensions of accessories

Additional angled frame

(at an extra charge)

Detail Y

L1=L2 H1=H2 D = 100

S = >40, <100

B1 (mm)

D = 200

S = >50, <200

B1 (mm)

n(mm) (mm)

500

750

1000

1250

1500

1750

2000

2250

2500

3000

250 140 - 200 250 - 400 1

500 280 - 400 500 - 800 2

750 420 - 600 750 - 1200 3

1000 560 - 800 1000 - 1600 4

1250 700 - 1000 1250 - 2000 5

1500 840 - 1200 1500 - 2400 6

1750 980 - 1400 1750 - 2800 7

2000 1120 - 1600 2000 - 3200 8

Operating and mounting instructions according to ATEX for

RS-N/RS-M/MWK-OB/MWS-OB/MWK-MB/MWS-MB

Z10/03 - 8

Construction subject to change. No return possible!

06.02.2018Version:

Information regarding assembly and commissioning

Prior to being installed in the ventilation system, the silencers

must be checked for damage. Damaged silencers must not be

installed.

The device may only be used in accordance with its designated

use in air ventilation systems for supply air and return air.

Use only approved fastening material for mounting.

No additional parts must be fastened to the silencer.

The silencer must be connected to the ventilation duct network

on both sides in electrically conducting fashion.

In order to avoid the risk static charges, the silencer must be

connected to the potential bonding on the grounding connection

provided for this purpose.

Make sure that the ventilation systems are not subjected to any

anomalous operating conditions, such as vibrations, pressure

surges or high proportions of solids in the medium.

Information regarding maintenance and inspection

Proper maintenance increases operational safety and the serv-

ice life of the device. This is why the devices should be subjected

to regular inspection.

If inspection dates are prescribed by law, they must be complied

with.

The operating personnel must be informed, prior to starting

maintenance and inspection work.

The personal safety measures must be looked up in the safety

data sheet. Hazard caused by contact or inhaling hazardous sub-

stances must be excluded by taking appropriate safety meas-

ures.

Prior to maintenance or inspection, all system components up-

and downstream of the device must be switched off and secured

against being switched on again.

The following inspection criteria must be observed:

- Visual inspection of the device

- Check the fastening of the device

- Check the grounding connection for tight fit and good contact

- Functional check

- For additional inspections, please refer to the technical docu-

mentation or additional maintenance instructions

Operating and mounting instructions according to ATEX for

RS-N/RS-M/MWK-OB/MWS-OB/MWK-MB/MWS-MB

Z10/03 - 9

Construction subject to change. No return possible!

06.02.2018Version:

Certificate of conformity

Operating and mounting instructions according to ATEX for

RS-N/RS-M/MWK-OB/MWS-OB/MWK-MB/MWS-MB

Z10/03 - 10

Construction subject to change. No return possible!

06.02.2018Version:

Operating and mounting instructions according to ATEX for

RS-N/RS-M/MWK-OB/MWS-OB/MWK-MB/MWS-MB

Z10/03 - 11

Construction subject to change. No return possible!

06.02.2018Version:

Operating and mounting instructions according to ATEX for

RS-N/RS-M/MWK-OB/MWS-OB/MWK-MB/MWS-MB

Z10/03 - 12

Construction subject to change. No return possible!

06.02.2018Version:

This manual suits for next models

5

Table of contents

Popular Ventilation Hood manuals by other brands

Indesit

Indesit HHBS 6.4 F LM X Instructions for use

KOBE

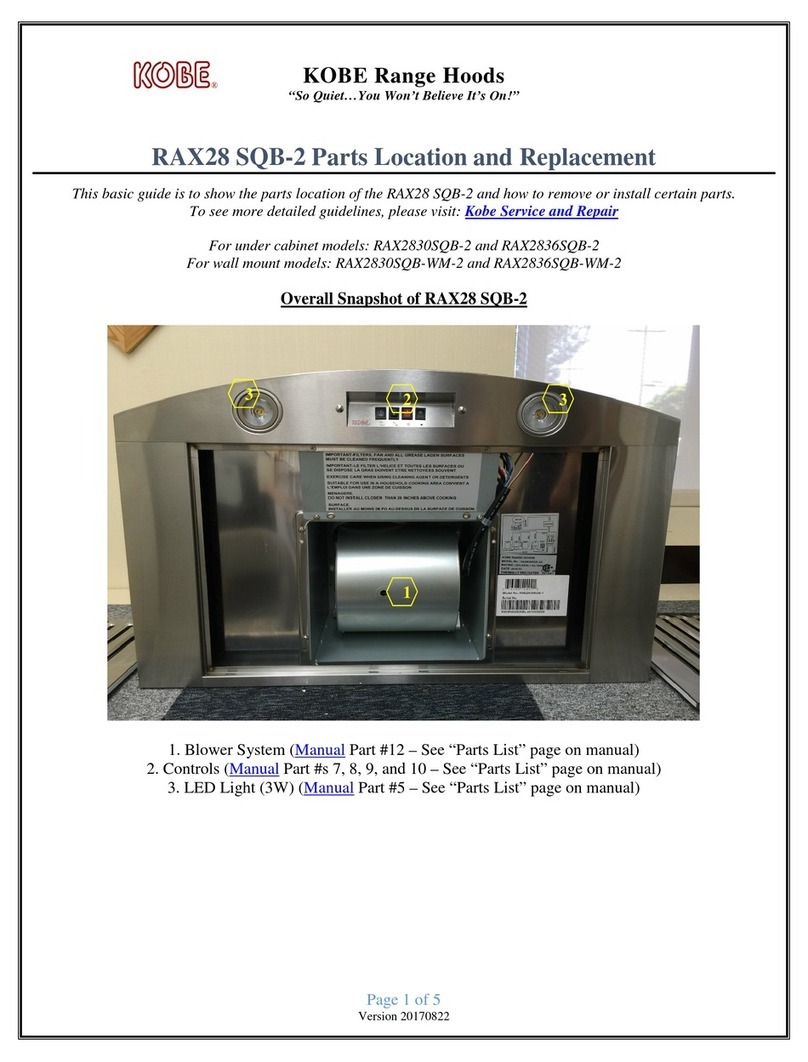

KOBE RAX28 SQB-2 Parts Location and Replacement

ROBINHOOD

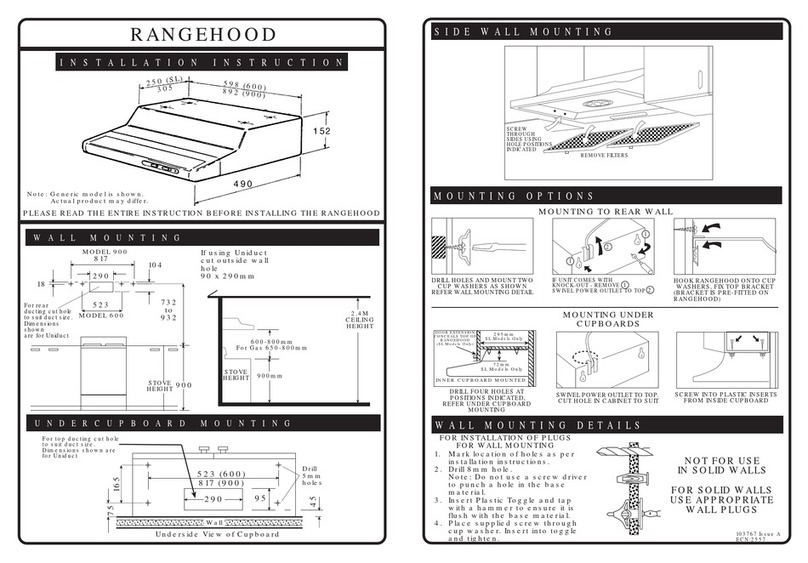

ROBINHOOD RWE3CL6SS Installation and operating instructions

ROBINHOOD

ROBINHOOD Slimline 600 Installation instruction

Electrolux

Electrolux LFG315X user manual

Hankel

Hankel DKE 156 instruction manual

Fujioh

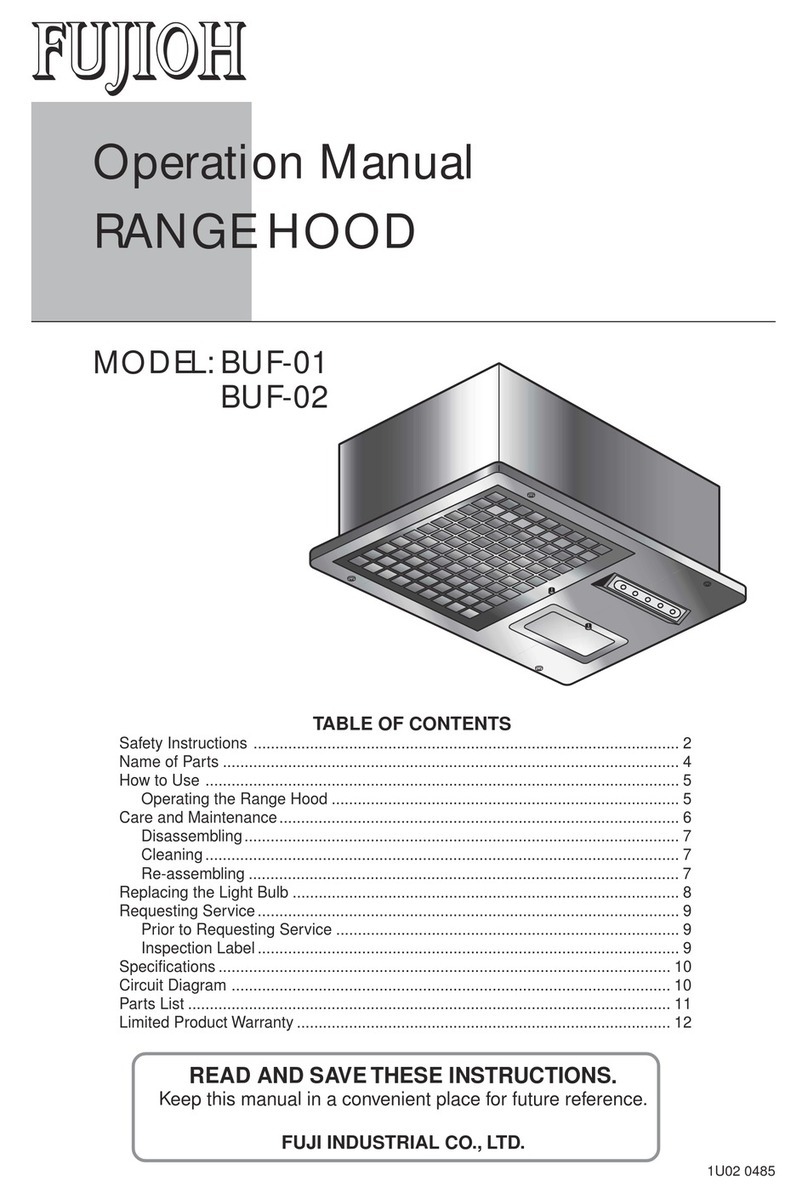

Fujioh BUF-0 Operation manual

Mitsubishi Electric

Mitsubishi Electric Lossnay LGH-15RX5-E Brochure & specs

Küppersbusch

Küppersbusch KD9980.0TGE Instructions for assembly and use

Zanussi

Zanussi ZHC 631 Installation, use and maintenance handbook

Elisa

Elisa EPR628S1 Installation instruction guide

Gram

Gram EFU 642-00 X instruction manual