Cromtech CTP301 User manual

CTP301

OPERATION MANUAL

3 INCH CLEAR WATER PUMP

Pg. 2

Thank you for purchasing a Cromtech Pump.

This manual provides understanding of the operaon

and maintenance of your pump. Please read this

manual carefully before operang.

For any quesons regarding operaon or maintenance,

please consult your local service agent. Find your local

service agent at www.crommelins.com.au.

IMPORTANT ICONS

Important informaon is disnguished by the nocaons

below. The Safety Alarm Symbol ( !) alerts you to

potenal hazards. Please obey all safety informaon in the

symbol to avoid any possible injury or even death.

!DANGER: - Indicates a hazardous situaon which, if

not strictly complied with, will result in substanal property

damage, serious injury or DEATH.

!WARNING: Indicates a hazardous situaon which, if

not strictly complied with, may result in property damage,

!CAUTION: Indicates a hazardous situaon which, if

not strictly complied with, could result in property damage

or injury.

!NOTE: Indicates important informaon to simplify

operaon and understanding.

!WARNING: PLEASE READ AND UNDERSTAND THIS

MANUAL BEFORE OPERATING THE PUMP.

!NOTE: We connually seek advancements in product

design and quality. Therefore, there may be minor

discrepancies in actual machine and the printed manual.

INDEX:

Warranty ..................................................................... 4

Safety Warnings .......................................................... 5

CTP301 Features ......................................................... 7

Pump Specicaons .................................................... 8

Features ..................................................................... 8

Connecng hoses ........................................................ 9

Operang Checklist ..................................................... 10

Operang area ........................................................... 10

Operang condion ................................................... 10

Check engine oil .......................................................... 11

Check fuel levels .......................................................... 12

Priming the pump ........................................................ 13

Starng the pump ....................................................... 14

Stopping the pump .................................................... 15

Maintenance ............................................................... 16

Engine Maintenance ................................................. 16

Engine oil ................................................................ 18

Adding oil ............................................................... 18

Changing oil ........................................................... 18

Air lter ................................................................. 19

Oil bath lter ......................................................... 19

Spark plug .............................................................. 20

Spark arrestor ........................................................ 21

Adjustments .......................................................... 21

Troubleshoong ......................................................... 22

Storage and transport ................................................ 23

Storage ..................................................................... 23

Long term storage .................................................... 23

Transport .................................................................. 23

Pg. 3

WARRANTY

CROMTECH™and CROMMELINS™ are a registered trademark of The

Crommelin Group. Crommelins warrants their goods against defects in

materials and workmanship under normal use and service.

The Crommelin Group warranty does not cover fair wear commensurate

with the age of the product, any damage caused by accident, abuse, misuse,

neglect or failure to observe proper operang instrucons or proper

machinery maintenance as described in the instrucon manual.

It is the owner’s responsibility to regularly maintain a product in accordance

with the owner’s manual and only use the equipment for its designed

purpose.

Our goods come with guarantees that cannot be excluded under the

Australian Consumer Law. You are entled to a replacement or refund for

a major failure and for compensaon for any other reasonably foreseeable

loss or damage. You are also entled to have goods repaired or replaced if

the goods fail to be of acceptable quality and the failure does not amount to

a major failure.

CONSUMER ADVICE

Any claim under these warranes must be made in the warranty period

from the date of purchase of the product.

There are over 185 naonal authorised service/repair agents available, visit

www.crommelins.com.au for their details and locaons.

To make a claim under the warranty, you must return the product (with

proof of purchase) to the closest warranty agent or to the place of purchase.

Where a failure does not amount to a major failure, Crommelins Machinery

is entled to choose between providing you with a repair, replacement or

refund. To obtain compensaon, you would need to provide documentary

evidence of the loss or damage suered, and documentary evidence that

such loss or damage was a reasonably foreseeable consequence of a failure

by The Crommelins Group to comply with a consumer guarantee under the

Australian Consumer Law.

Crommelins Operaons Pty Ltd trading as The Crommelin Group,

Crommelins Australia and Crommelins Machinery

THE CROMMELIN GROUP:

Ph: (08) 9350 5588 Fax: (08) 9451 6381

recepon@crommelins.com.au

www.crommelins.com.au

PO Box 352, BENTLEY WA 6982

ABN 11 008 889 656

Pg. 4

SAFETY WARNINGS

! WARNING: DO NOT Operate this pump unl you have

read ALL safety, operaon, and maintenance instrucons

listed in this manual.

• Failure to follow the instrucons may result in property

damage, INJURY or DEATH.

! WARNING: Modicaons to any part of the pump is

not allowed and may void your warranty.

!DANGER: FIRE OR EXPLOSION - Gasoline is highly

ammable and extremely explosive.

• Fire or explosion can cause severe burns or death.

• Keep ammable items away while handling gasoline.

• Fill fuel tank outdoors and in a well-venlated area with

the pump stopped.

• Always wipe o spilled fuel and wait unl the fuel has

dried before starng the pump.

• DO NOT operate the engine with known leaks in the fuel

system.

• Use proper fuel storage and handling procedures. DO

NOT store fuel or other ammable materials nearby.

• Empty the fuel tank before storing or transporng the

pump.

• Keep re exnguisher handy and be prepared if a re

starts.

!DANGER: TOXIC FUMES - The exhaust of the pump

engine contains carbon monoxide, an odorless, colorless,

poison gas. Using engine indoors CAN KILL YOU!

• NEVER use pump inside any building or any kind of

enclosure, EVEN IF doors and windows are open.

• Place the pump in a well-venlated area and consider

wind and air currents when posioning the pump

!DANGER: MOVING PARTS - Moving parts can cause

severe injury. Keep hands and feet away.

• DO NOT operate pump with covers, shrouds, or guards

removed.

• DO NOT wear loose-ng clothing, dangling drawstrings

or items that could become caught. Tie up long hair and

remove jewelry.

• NEVER place ngers, hands, or body near the engine

when it is running.

Pg. 5

!DANGER: KICKBACK - Rapid retracon of the starter

cord will pull hand and arm towards the engine faster than

you can let go.

• Unintenonal startup could result in an injury.

!WARNING: CLEAR WATER ONLY - Do not use the pump

for ammable or corrosive liquids, chemical solvents, or

alkali liquids. For example; Gasoline, alcohol, seawater, oil,

wine or milk.

• Keep hands and body far away from discharge outlet of

the pump.

• Never secure the sucon hose with clamps to the pump

during operaon.

• Never put hand or body into an operang pump or

sucon hose.

!WARNING: OPERATION - Operate the pump on rm

dry ground and ensure it is not in mud or water, especially

when used next to ponds, ditches or water source.

• Never place hoses where they can be run over. If the

hose does lay across a road, place a specially made

metal plate over the hose to protect it from damage or

kinks.

• Never block the inlet or outlet ports.

• Never start the pump without the lter aached to the

sucon hose.

• ALWAYS Prime the pump upon inial start. Keep enough

water in the pump. DO NOT run pump without water in

it.

• DO NOT operate pump without reading the instrucons

• Children and pets must keep away from the area of

operaon at all mes.

• DO NOT operate while intoxicated or distracted

Pg. 6

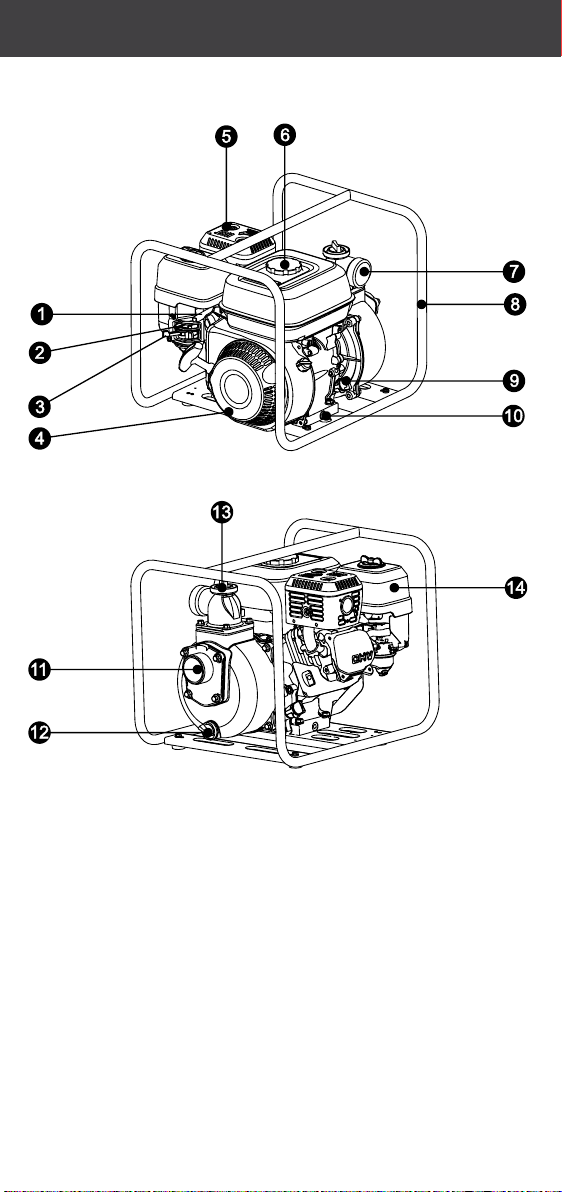

CTP301 FEATURES

① Throttle control ② Choke lever

③ Fuel switch ④ Recoil starter

⑤ Muffler ⑥ Fuel cap

⑦ Outlet ⑧ Frame

⑨ Oil dipstick ⑩ Oil drain

⑪ Inlet ⑫ Outlet drain plug

⑬ Inlet water plug ⑭ Air filter

Pg. 7

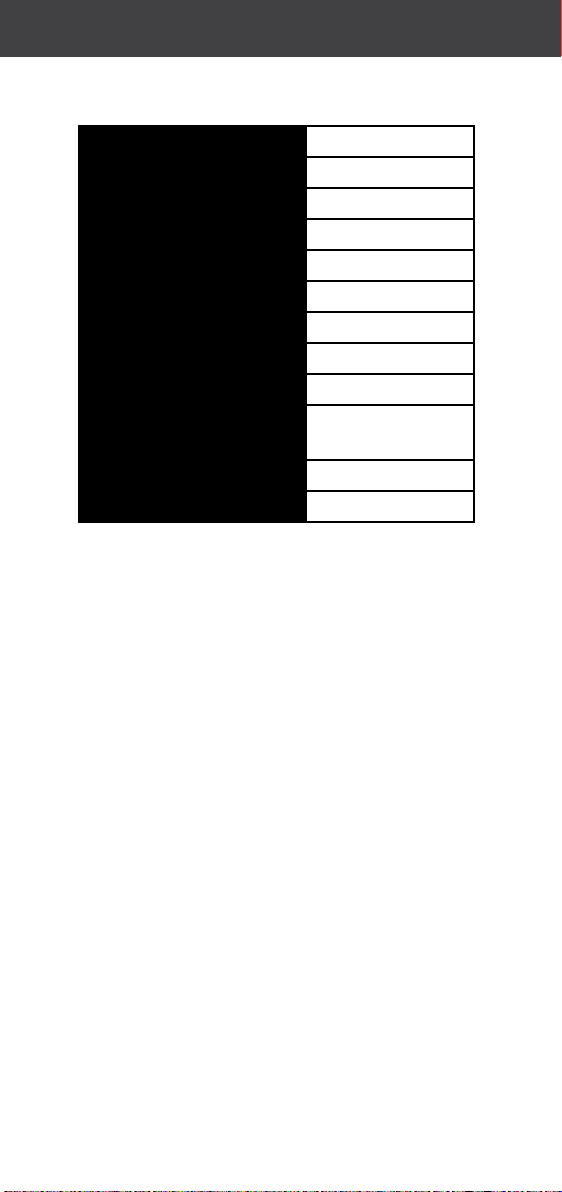

PUMP SPECIFICATIONS

Model CTP301

Max. Water Flow (L/min) 900L/min

Max. Total Head (m) 30m

Max. Sucon Depth 7m

Engine Cromtech

Max. Power 4.5kW

Max. Speed (rpm) 3800rpm

Fuel Tank 2.6L

Oil Capacity 0.6L

Outlet 3” (with 2” hose

tail supplied)

Weight (kg) 26kg

Packaging (LxWxH) 530x415x445mm

FEATURES

• 3” to 2” Reducon hose tail supplied

• Mechanical seal (ceramic carbon)

• Petrol powered

• Recoil start

• 1 Year Cromtech warranty

• Emptying ponds, dams and large water tanks

• Agricultural and general purpose

Pg. 8

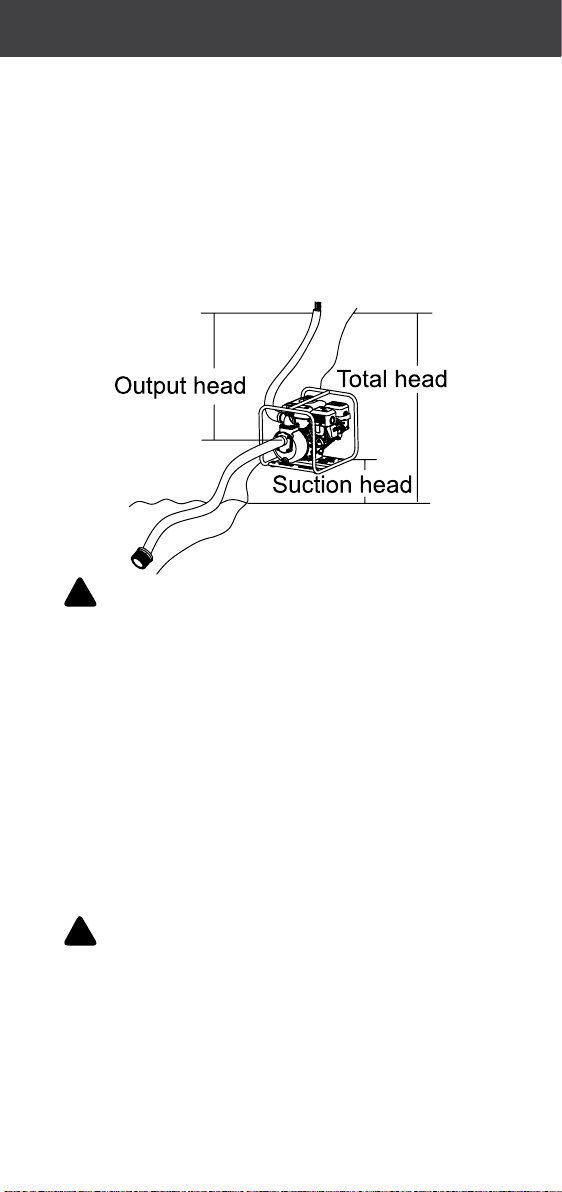

CONNECTING THE HOSES

! NOTE: DO NOT Operate this pump unl you have read

ALL safety, operaon, and maintenance Instrucons listed

in this manual.

1. Pump connecons - Check you have been provided with

all the following parts (Parts may vary from dierent

models). Connect them as follows;

1.1 Connect the lter to the sucon hose.

! CAUTION: Ensure that the lter is securely

connected so it can prevent debris being passed

into the pump. Keep the sucon hose at least

200mm below depth ensuring it is fully submerged

and there are no obstrucons.

1.2 Connect the sucon hose to the inlet port

! CAUTION: It is recommended that the sucon

hose be made of hardened pipe and it is short in

length (7m maximum based on sucon depth).

1.3 Connect the outlet hose to the outlet port

! CAUTION: The maximum water ow for the

pump is based on rpm, outlet size and hose size.

It is recommended to use a 3” hose for maximum

water ow. Fasten all hoses to the pump so they

cannot loosen under high pressure.

Suction hose

❶ Inlet port

❷ Rubber sealing gasket

❸ Hose tail

❹ Hose nut

❺ Clamp

❻ Sucon hose

Pg. 9

❶ Outlet port

❷ Rubber sealing gasket

❸ Hose tail

❹ Hose nut

❺ Clamp

❻ Outlet pipe

OPERATING CHECKLIST

1. OPERATING AREA - This pump is for outdoor use only.

Always keep the area around the water pump clear.

Place the pump in a well-vented area and carefully note

the wind and air currents. Place the water pump on rm

horizontal surface before running. The pump should not

exceed a height more than its maximum sucon depth

as it may not pump or could overheat.

! DANGER: TOXIC FUMES - The exhaust of the

pump engine contains carbon monoxide, an odorless,

colorless, poison gas. Using pump indoors CAN KILL

YOU! NEVER use inside any building or any kind of

enclosure, EVEN IF doors and windows are open.

2. OPERATING CONDITION - Check for loose or damaged

parts, signs of oil or fuel leaks, and any other condion

that may aect proper operaon. Repair or replace all

damaged or defecve parts immediately.

Remove any excessive dirt or debris, especially around

the muer and recoil starter.

! DANGER: Failing to correct problem(s) before

operaon could result in property damage, serious

injury or DEATH.

Pg. 10

CHECK ENGINE OIL

! WARNING: This engine is not lled with oil from the

factory. Any aempt to crank or start the engine before it

has been properly lled (with the recommended type and

amount of oil) may result in engine damage and void your

warranty.

1. ENGINE OIL - Place the engine on a level surface with

engine stopped. Remove the dipsck and wipe it clean.

Reinsert dipsck into oil ll neck; wait, DO NOT thread

cap into tube.

2. Remove the dipsck again and check oil level. Level

should be at top of indicator on dipsck.

3. If lower, ll to the upper limit (marked with “H”) of the

dipsck with the recommended oil. Reinsert and fully

ghten the dipsck.

! WARNING: Oil is a major factor aecng

performance and service life of an engine. Use 4-stroke

automove oil SAE30.

Pg. 11

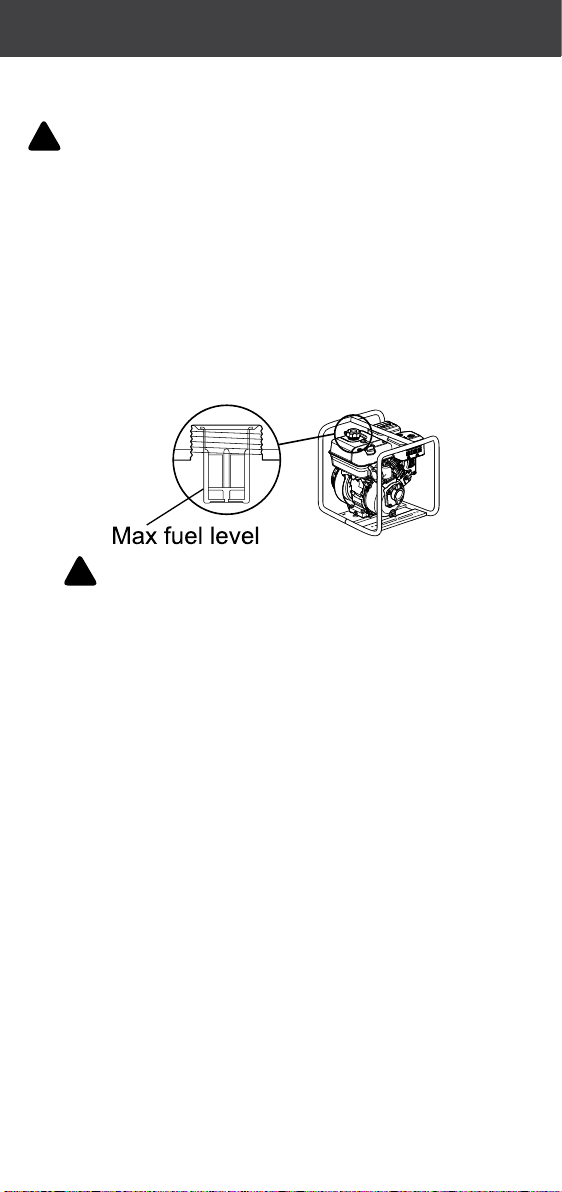

CHECK FUEL LEVELS

! CAUTION: Pressure can build up in the fuel tank. Allow

the engine to cool for at least two minutes before removing

fuel cap. Loosen the fuel cap slowly to relieve any pressure

in the tank

• ENGINE FUEL - With the engine stopped, check the fuel

level gauge. Rell the fuel tank if necessary.

• Use clean, fresh, regular unleaded gasoline only. DO

NOT mix oil with gasoline.

• Be sure not to ll above the upper limit mark, always ll

to the level indicator, or ll to 25mm le from fuel tank

(to allow room for fuel expansion).

! DANGER: FIRE OR EXPLOSION - Gasoline is highly

ammable and extremely explosive. A re or explosion

can cause severe burns or death.

• Keep ammable items away while handling

gasoline.

• Fill fuel tank outdoors and in a well-venlated area

with the engine stopped.

• Always wipe o spilled fuel and wait unl the fuel

has dried before starng the engine.

• DO NOT operate the engine with known leaks in

the fuel system.

• Use proper fuel storage and handling procedures.

DO NOT store fuel or other ammable materials

nearby.

• Empty the fuel tank before storing or transporng

this engine.

• Keep re exnguisher handy and be prepared if a

re starts.

NEVER use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur.

It is important to prevent gum deposits from forming

in fuel system, such as the carburetor, fuel lter, fuel

hose or tank during storage. Also, any alcohol-blended

Pg. 12

fuels (called gasohol, ethanol or methanol) can aract

moisture, which leads to separaon and formaon of

acids during storage.

Acidic fuel can damage the fuel system of an engine

while in storage. Be sure to review the Storage

instrucons.

Gasoline/Alcohol Blends: up to 10% alcohol, 90%

unleaded gasoline by volume is approved as a fuel.

Other gasoline/alcohol blends are not approved.

Eects of old, stale or contaminated fuel may void your

warranty.

! CAUTION: To minimise gum deposits in your fuel

system and to insure easy starng, do not use gasoline

le over from the previous season.

PRIMING THE PUMP

! CAUTION: Operang a pump with no water will

damage the seals, which may void the warranty.

• PRIME THE PUMP - Fill the pump with water before

starng it. Remove the water inlet rubber plug and ll

pump head with water.

Pg. 13

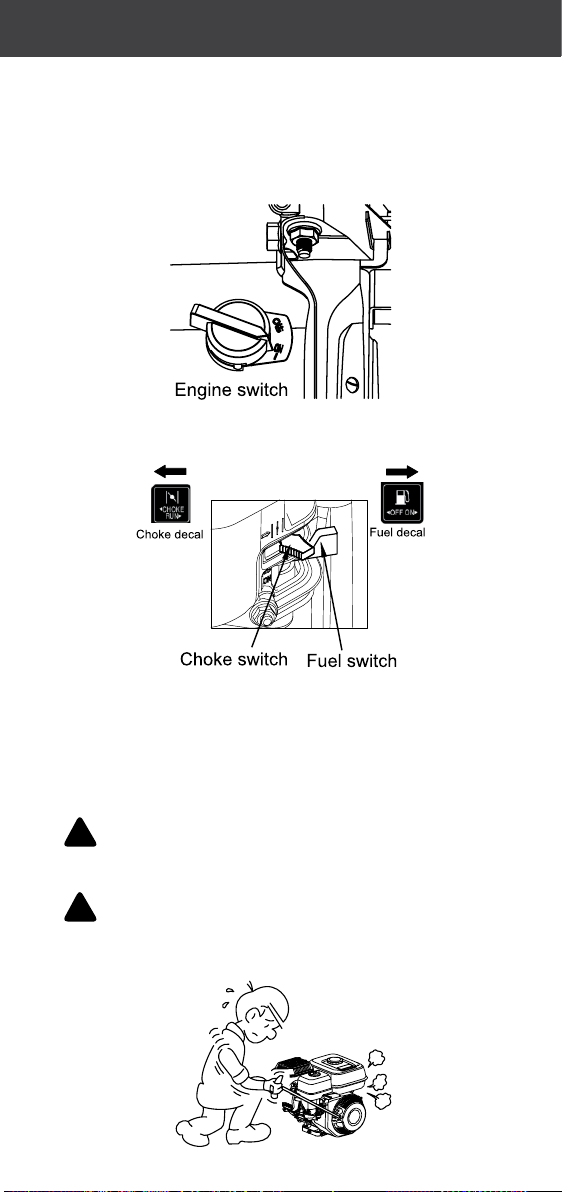

STARTING THE PUMP

1. Check the hoses are connected and the pump is primed

before operang the pump.

2. Turn the start switch to the ‘ON’ posion

3. Turn the choke lever to the ‘ON’ posion

4. Turn the fuel switch to ‘ON’ posion.

5. Push the throle lever 1/3 the way (from low speed to

high speed) across.

6. RECOIL START - Pull the starter handle unl feel

resistance force to start the engine, and then pull more

quickly to start it.

! CAUTION: Ensure that the recoil rope is not

damaged and repair if required.

! DANGER: Rapid retracon of the starter cord will

pull hand and arm towards the engine faster than you

can let it go. Unintenonal startup could result in an

injury.

Pg. 14

7. Switch ‘OFF’ the choke lever once the engine is started.

Do not run the engine for long periods of me with

choke lever in the ‘ON’ posion.

8. Push the throle lever to high speed to run the engine

under its standard speed.

STOPPING THE PUMP

1. Turn the throle lever to low speed and run the engine

for 1-2 minutes more.

2. Turn the switch to ‘OFF’ posion to stop the pump.

3. Turn fuel switch to ‘OFF’ posion.

Pg. 15

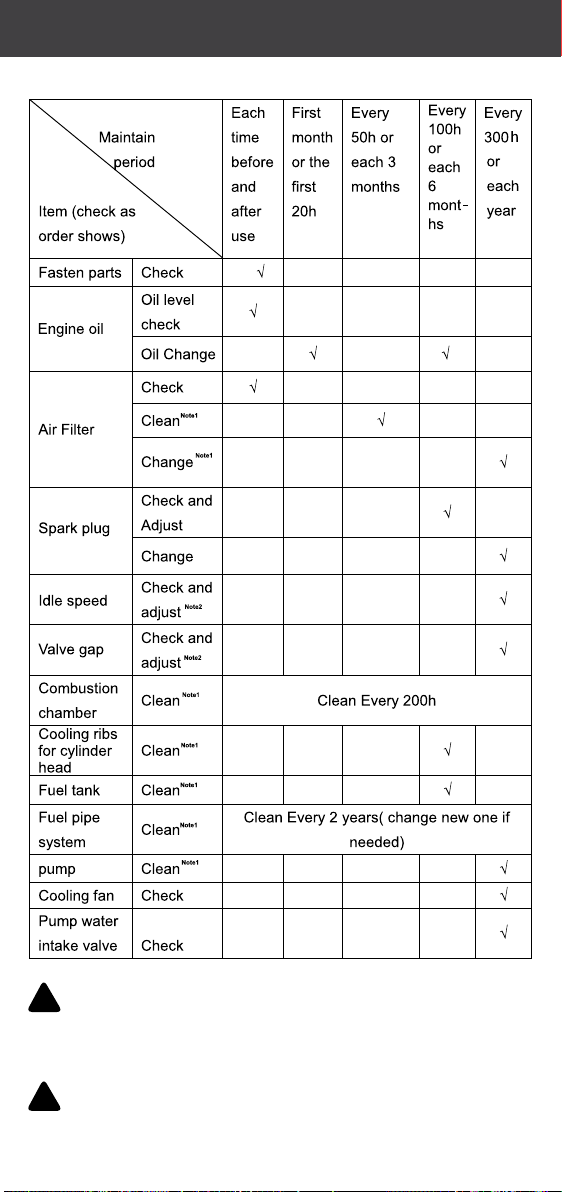

MAINTENANCE

! NOTE: It is owner’s/operator’s responsibility to

complete all scheduled maintenance in a mely manner.

• Ensure the pump is regularly checked before operang.

• Always follow the inspecon and maintenance

recommendaons and schedule in this manual.

! DANGER: Accidental starts can cause severe injury

or death. Remove and ground spark plug wire before

performing any service.

! DANGER: Improper maintenance or failure to correct

a problem before operaon can cause a malfuncon and

result in property damage, serious injury or DEATH.

Improper maintenance will void your warranty.

! CAUTION: The lter element may contain PAHs,

PAHs are harmful for your health. Please wear gloves for

protecon during air lter maintenance.

1. MAINTENANCE SCHEDULE - Service the pump in a clean,

dry and at area.

Follow the service intervals indicated in the chart.

Service your pump more frequently when operang in

dusty or adverse condions.

Contact your local service agent for parts.

2. GENERAL MAINTENANCE - Regularly check the engine

oil, air lter, spark plug and pump.

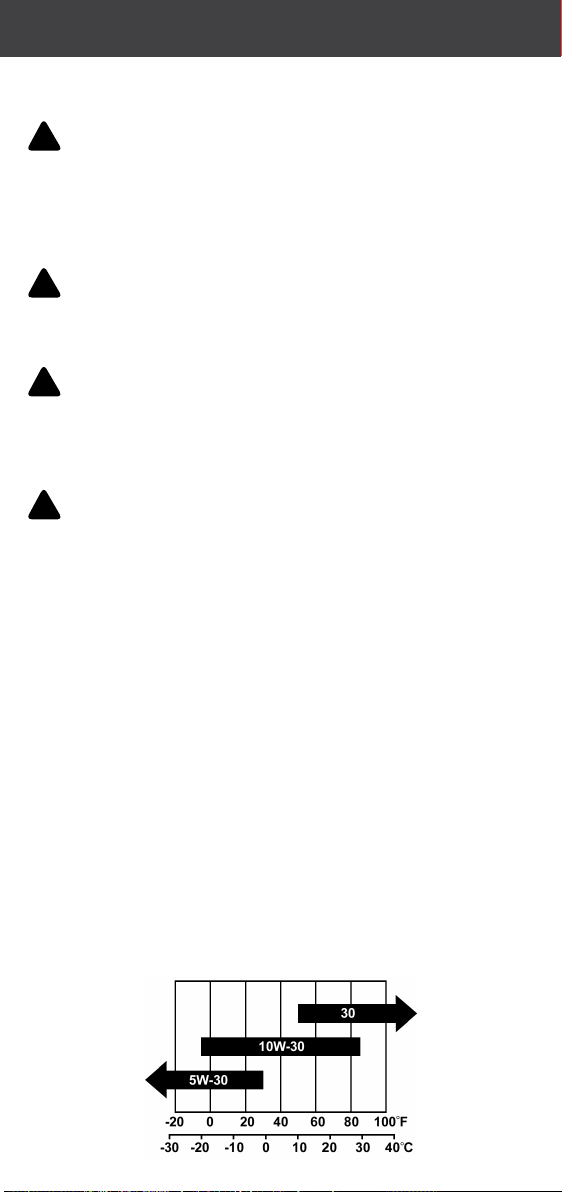

2.1 - ENGINE OIL - SAE30 is recommended for general, all-

temperature use. Other viscosies shown in the chart

may be used when the average temperature in your

area is within the indicated range.

Pg. 16

! NOTE 1: If the pump engine is running in dusty or

severe environments, more frequent maintenance is

required.

! NOTE 2: All major maintenance should be completed

by an authorised local service agent.

Pg. 17

2.2 - ADDING ENGINE OIL - Check oil levels are at the

correct level.

i. Place the engine on a level surface.

ii. Remove the dipsck and wipe it clean.

ii. Reinsert and check the dipsck for oil level.

! CAUTION: Reinstall dipsck into tube; rest on oil

ll neck, DO NOT thread cap into tube.

iv. Add the recommend oil to the upper limit of the

dipsck.

2.3 - CHANGING OIL - If the oil is dirty, replace with new

oil.

! CAUTION: Change oil when the engine is warm

from operaon.

i. Place the engine on a level surface.

ii. Prepare a tray to catch the oil.

iii. Remove the oil drain plug and allow the oil to drain

completely.

iv. Replace and fully ghten the drain plug.

v. Add recommended oil to the upper limit.

vi. Reinstall and fully ghten the dipsck.

vii. Dispose of used oil at an approved waste

management facility.

Pg. 18

2.4 - AIR FILTER - Check the air lter/s are clean and

change if required.

I. Loosen the nut to remove the lter cover.

Ii. Loosen the wing nut to remove the lter.

Iii. Clean/change the lter/s.

Foam lter: Clean the foam lter using warm

water with detergent. Dry the lter by pressing it

into a clean dry towel. Aer drying, lightly apply

clean engine oil to the lter.

Paper lter: Lightly tap the lter so that the dirt

can fall o. Never brush the dirt, which may

push the dirt into the lter. If the dust does not

remove and the lter is sll dirty, replace it.

Iv. Reassemble the lter back to the units.

V. Fasten cover with the screw down nut.

! WARNING: DO NOT run the engine without

the air lter, serious damage can result.

Pg. 19

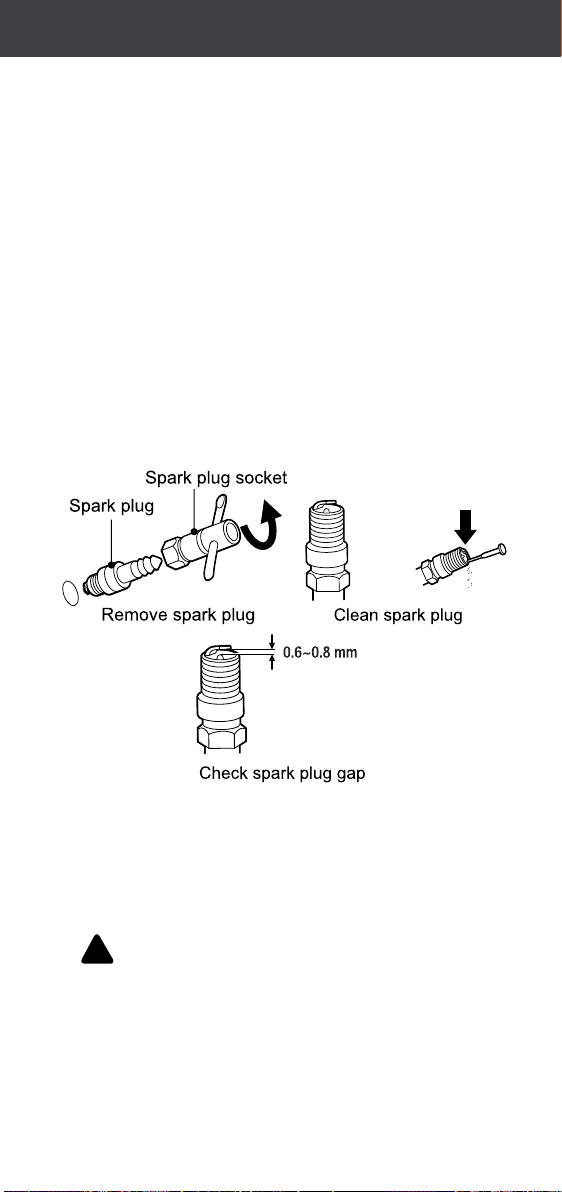

2.6 - SPARK PLUG - Check the spark plug is clean and

change if required.

I. Clean any dirt from the spark plug cap and spark

plug base.

Ii. Remove the spark plug cap.

Iii. Using socket wrench to loose and remove the spark

plug.

Iv. lnspect the spark plug and spark plug washer, if it’s

damaged or worn, replace with new one. Clean the

spark plug with wire brush before reng.

V. Check spark plug gap. Carefully bend side electrode

to adjust the gap if necessary.

SPARK PLUG GAP: 0.6mm to 0.8mm

SPARK PLUG: LG F7RTC

Vi. Carefully thread the plug into the engine by hand.

Vii. Aer the spark plug seated, use spark plug wrench

to ghten it. Spark Plug ghten Torque: 20-25 N.m

Viii. Aach the spark plug wire to the plug.

Viii. Replacement spark plug: LG F7RTC

! WARNING: Only use recommended spark plug

or equivalent. DO NOT use spark plugs that have

improper heat range.

Pg. 20

Table of contents

Other Cromtech Water Pump manuals

Popular Water Pump manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED UOP 12 B1 Translation of the original instructions

Liberty Pumps

Liberty Pumps LCU-15 installation manual

Enerpac

Enerpac EP3104D instruction sheet

Grundfos

Grundfos Sololift2 WC-1 Installation and operating instructions

Graco

Graco Mini Fire-Ball 246775 quick start guide

Aquatec

Aquatec HydroPro HZ2010 quick start guide

Becker

Becker DVX 3.80/0-43 operating instructions

PFT

PFT RITMO XL FU 230 operating instructions

RIDGID

RIDGID 1460-E operating instructions

Franklin Electric

Franklin Electric Little Giant 6EN-CIA-SFS instruction sheet

CountyLine

CountyLine CLW750 owner's manual

EINHELL

EINHELL BG-DP 5025 N operating instructions