Cromtech TFF150HP Administrator Guide

CROMTECH™ FIRE FIGHTING PUMP

SINGLE IMPELLER

Thank you for your selection of a Cromtech Fire Fighting Pump

Single Impeller. This Operation Manual explains its use, installation,

checking and maintenance. We highly recommend that you retain

this manual for ready reference regarding its proper handling.

Spare Parts & Service

Phone: 1300 554 524

Freecall Fax: 1800 636 281

spareparts@crommelins.com.au

www.crommelins.com.au

Head Office (08) 9350 5588

OPERATION & INSTRUCTION MANUAL

2

Thank you very much for purchasing a Cromtech Fire Fighting Pump –Single Impeller

which can be used for domestic farming, fire fighting and general use. This manual covers

its operation and maintenance.

Please take a moment to familiarise yourself with the proper operation and maintenance

procedures in order to maximise the safe and efficient use of this product.

Keep this owner’s manual at hand, so that you can refer to it at anytime. Due to constant

efforts to improve our products, certain procedures and specifications are subject to

change without notice.

When ordering spare parts please have handy your products model number and serial

number. Record these numbers in the boxes below for future reference –the location of

these numbers vary depending on product.

CONTENTS

Introduction and Contents.................................................................................... 2

Safety….................................................................................................................. 3

Operating Instructions ....................................................................................... 4

Type of Water, Fixed Installation, Storage and Warranty.................................... 5

Specification Chart…............................................................................................. 6

Trouble Shooting Guide…...................................................................................... 7

Parts Diagram & List…........................................................................................... 8

SERIAL NO.

MODEL NO.

3

SAFETY

This manual contains important information on how to use the Cromtech Fire Fighting

Pump –Single Impeller model TFF150HP properly and safely. Please read through this

manual before you attempt to operate the machine.

This fire fighting pump is designed to give safe and dependable service if operated

according to the instructions.

•Always make a pre-operation inspection before starting the engine. (For more

information read the engine operational manual).

•Do not place flammable objects near the unit.

•Children and pets must keep away from the area of operation at all times.

•Never allow anyone to operate the unit without proper instructions.

•You must know how to stop the engine quickly and understand the operation of all

controls.

•Ensure the operating space is well ventilated. Avoid operating the machine in a closed

room, tunnel or other poorly ventilated places, as the exhaust fumes contain deadly

poisonous carbon monoxide. If the machine is unavoidably operated in such a place,

discharge the exhaust outside the room by a suitable means.

•Mufflers and other hot parts of the machine are dangerous. Do not touch them with

hands or any other body parts.

•Observe the following cautions when transporting. Close the fuel tank cap securely and

close the fuel tap tightly during transportation. Drain petrol from the fuel tank before

transporting over a long distance or on rough roads.

•Stop engine without fail before replenishing the fuel tank. Never replenish fuel while the

engine is running or remains hot otherwise spilled or evaporated fuel is liable to catch

fire from the engine spark or muffler heat. Wipe off spilled fuel before starting engine.

•To prevent injury, wear the following protective items: Wear ear plugs and any other

protective items required by job conditions.

COMPONENTS

Priming Cap

Non Return Valve

(Internal)

Inlet

Outlets (x3)

Drain Plug

Air Cleaner

Fuel Cap

4

OPERATING INSTRUCTIONS

Suction and discharge pipes:

To avoid air locks and make priming easy the suction pipe should be laid so that it rises

evenly from the water source to the pump. All pipe joints have to be sealed airtight and

they should be the same size or larger than the pump inlet and discharge outlet.

PRIMING

•To prime the pump, remove the priming plug and fill pump and suction pipe with water.

Pump has a non-return valve and is capable of drawing air from the normal size suction

pipes and hoses. Replace plug and start pump. If it pumps a small amount then stops,

turn it off, check the suction pipe for leaks and repeat the priming procedure until the

pump works well.

•When filled with water, self-priming pumps will gradually draw air from the suction line.

If priming a long or large diameter pipe, additional water may have to be added to the

pump at 3 minute intervals.

N.B. Do not run the pump dry of water for extended periods as it will destroy the

mechanical seal and void warranty.

HOW THE PUMP OPERATES

Before starting the pump, make sure the non-return valve is freely able to move. If the

pump fails to prime, there could be a problem with the suction pipe such as a leak, worn

impeller or too strong of a suction lift. Self-priming pumps will not self-prime with high

discharge head. If this is the case, the suction flap valve should be removed and a suction

foot valve installed on the hose.

SUCTION STRAINER

A suction hose strainer may be needed for portable pump use. This stops gravel or any large

debris getting into the pump and causing damage.

ENGINE

Engine user manual is enclosed. Using low speed extends the life of your engine. When

continually pumping, we recommend operation at approximately 3000rpm. In contrast,

high speed will increase the pump’s performance when needed as in fire fighting or intense

situations. However, be aware that pump life will eventually suffer if high speed is

continually applied.

5

TYPE OF WATER

If any liquid contains stringy or large material that may cause obstruction, a suction

strainer should be used. If the pump is needed for chemicals, you must check the pump

compatibility with your local dealer.

FIXED INSTALLATIONS

In some installations and only if the pump is used under stressful conditions, such as

pumping uphill for long distances, the pump may not work on start up.

To rectify this, a check valve should be installed between the pump and the pipe and a

gate valve should be installed on the pump discharge. If it still fails, open the valve to

release a full flow of water and close it again. It should now pump fully. Under some

conditions the procedure might have to be repeated at each start up.

STORAGE

•Make sure that the engine is completely cooled off before storage.

•Clean up oil and dust accumulation on rubber parts.

•Drain pump completely of all water.

•Cover the machine and store it in a dry place.

•For long-term storage of this petrol unit, remove fuel from the fuel tank. Also remove

fuel remaining in the fuel line and chamber of the carburettor. To drain fuel from the

chamber of the carburettor, remove the drain plug provided at the chamber and drain

the fuel.

WARRANTY

Consult the Crommelins Machinery Warranty Information leaflet, supplied with your new

product, for details of your machinery warranty including consumer advice and

information about accessing a service agent to repair your product. You can also visit our

website at www.crommelins.com.au to find your local service agent who will be able to

assist with all warranty claims.

6

FIRE FIGHTING PUMP –SINGLE IMPRELLER SPECIFICATION CHART

MODEL

TFF150HP

Inlet (inch)

1 ½”

Outlet (inch)

1 x 1 ½”& 2 x 1”

Total Head (m)

60m

Volume max. (L/min)

360L/min

Volume max. (L/hr)

21,600L/HR

Max. Suction lift (m)

8m

Pump Type

Aluminium

Suction Type

Self-priming

Impeller

Single

Axle Seal Material

Ceramic-carbon

Engine Make

Honda

Engine Type

GP160

Starting System

Recoil Start

Fuel Type

Petrol

Fuel Tank (L)

3.6L

Noise Level (db@7m)

70db

Weight (kg)

25kg

Manufacturers Warranty

1 year

Engine Warranty

1 year

7

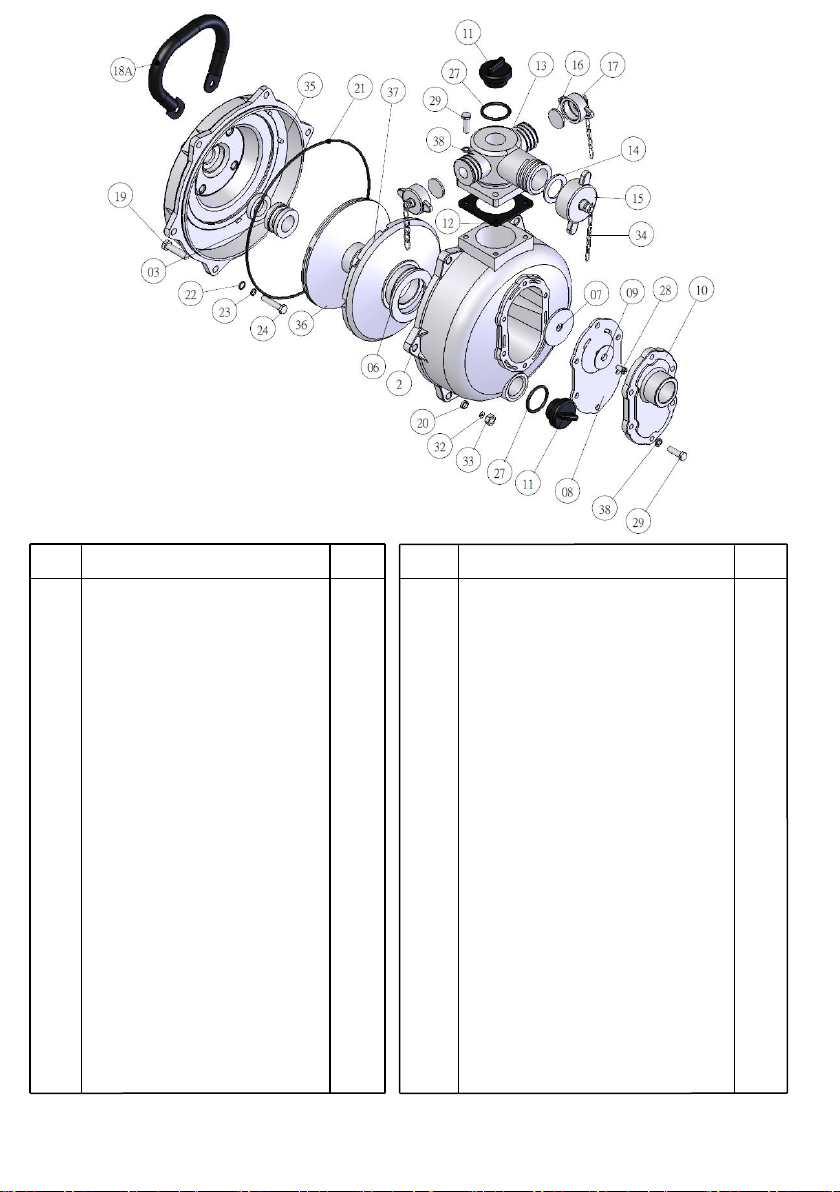

PARTS DIAGRAM AND LIST

TROUBLE SHOOTING GUIDE

PROBLEM

CAUSE

SOLUTION

Engine won’t start

1. Engine switch in OFF

position

2. No fuel in engine

3. Worn, fouled or dirty

spark plug

4. Engine not level or

engine oil level too

low

1. Turn engine switch to ON

position

2. Fill fuel tank or turn on fuel

supply

3. Replace with factory

recommended spark plug

4. Place engine on level surface

or fill crankcase with oil (refer

to engine manufacturers

instruction manual)

Engine with low power

1. Throttle control lever

not set to full throttle

position

1. Set throttle control lever to

full position

Engine runs rough

1. Dirty air filter

2. Out of petrol

3. Stale petrol

4. Spark plug wire not

connected to spark

plug

1. Clean or replace air cleaner

2. Fill fuel tank

3. Drain fuel tank, fill with fresh

fuel

4. Connect wire to spark plug

Pump will not prime

within 30 seconds

1. Air leak on suction

side

2. Blocked impeller

3. Pump too far away

from water level

1. Check couplings/hoses

2. Clear blockage

3. Lower pump to within 8

metres of water level

8

No. Description Qty No. Description Qty

02 Casing Outer (Ali Alloy) 1 22 O’Ring 7x11 4

03 Seal Assembly 1 23 Washer (Stainless) 5/16” 4

06 Seal Ring, Volute 1 24 Set Screw, UNF 5/16”x 1 ½ “ 4

07 Flap Valve Weight 1 (Stainless)

08 Flap Valve Rubber 1 27 O’Ring 31.5 x 39.5 2

09 Flat Valve Washer 1 28 Screw ¼ “ x ½ “ 1

10 Cover, Suction (Inlet 1 ½ “) 1 29 Set Screw 5/16” x 1” 9

11 Priming & Drain Plug (Cap) 2 32 Washer, Inside Ratchet 3/8”x17 6

12 Gasket, Discharge Bend 1 33 Nut, UNF 3/8” 6

13 Discharge Tee (Outlet 1 ½ “) 1 34 Chain 3

14 Rubber Gasket 1 35 Casing Inner (Aluminium Alloy) 1

15 Butterfly Nut (1 ½ “) 1 36 Impeller, Close (H) Type 1

16 Rubber Gasket (1”) 2 37 Diffuser (H) 1

17 Butterfly Nut (1”) 2 38 Washer 5/16” 11

18A Handle 1 41 Foot 5/16” 2

19 Set Screw, UNF 3/8”x 1 ½ “ 6 41-1 Nut, UNF 5/16” 2

20 Washer 3/8 6 41-3 Spring Washer 2

21 O’Ring 241x247 1 51 Shaft Sleeve 1

Table of contents

Other Cromtech Water Pump manuals

Popular Water Pump manuals by other brands

Oase

Oase AquaMax Eco Premium 6000/12 V manual

Grundfos

Grundfos Hydro Multi-B instructions

EBARA

EBARA WINNER Operating and maintenance manual

Tuthill

Tuthill KINNEY DRSP Installation and operation manual

Intex

Intex Quick-Fill Operation instructions

BRINKMANN PUMPS

BRINKMANN PUMPS SXC2824-R operating instructions