Crouse-Hinds MTL1000 Series User manual

ii INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021

DECLARATION OF CONFORMITY

A printed version of the Declaration of Conformity has been provided separately within the original shipment of goods. However,

you can nd a copy of the latest version at http://www.mtl-inst.com/certicates

iii

INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021DRAFT - 05 DRAFT - 23 March 2021 February 2021

CONTENTS

DECLARATION OF CONFORMITY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

1 INTRODUCTION. ....................................................................1

1.1 General.................................................................................1

2 MTL1000 RANGE DESCRIPTION.......................................................1

2.1 Modules ................................................................................1

2.2 Accessories .............................................................................2

3 INSTALLATION PRECAUTIONS........................................................3

3.1 General.................................................................................3

3.2 Installation ..............................................................................3

3.2.1 Modules ...........................................................................3

3.2.2 Cabinet and enclosure mounting .........................................................3

4 COMMON SPECIFICATIONS ..........................................................4

5 MODULES.........................................................................5

5.1 MTL1991 Power feed and alarm module.......................................................5

5.2 Current repeaters .........................................................................5

5.2.1 MTL1141Transmitter repeater power supply...................................................5

5.2.2 MTL1142Transmitter repeater power supply with HART .........................................6

5.2.3 MTL1143Transmitter repeater power supply with HART and repeat output ..........................6

5.2.4 MTL1144 voltage/current input, loop powered isolator ...........................................7

Table 1 MTL1144 switch settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.2.5 MTL1145 loop powered current repeater .....................................................8

5.3 MTL1171,1172 temperature and MTL1173 potentiometer converters.................................9

Table 2 Conguration and DIP switch settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 3 MTL1171 and MTL1172 range DIP switch setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5.3.1 MTL1171 thermocouple input converter .....................................................10

5.3.2 MTL1172 RTD input converter.............................................................10

5.3.3 MTL1173 Potentiometer input converter.....................................................10

5.4 MTL1211 Switch / Proximity Detector input....................................................11

5.5 MTL1249 Current / Voltage input/output repeater ...............................................11

Table 4 MTL1249 Dip Switch settings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.6 MTL1271, 1272 LOOP POWERED temperature converters .......................................13

5.7 MTL1271 loop powered thermocouple input converter...........................................14

5.8 MTL1272 loop powered RTD temperature converter............................................14

6 MTL13XXTRIP AMPLIFIERS .........................................................15

6.1 Introduction ............................................................................15

6.2 Trip level setting .........................................................................15

6.3 Label Indicators/Switches..................................................................15

6.4 Switch settings..........................................................................16

Table 5 Trip switch settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 6 MTL137x Conguration and DIP switch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Table 7 MTL1371 and MTL1372 range DIP switch setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.5 MTL1321 trip amplifier with voltage/current input and 4-20mA output...............................17

6.6 MTL1341 trip amplifier with 4-20mA input/output...............................................18

6.7 MTL1371 trip amplifier converter, thermocouple input/4-20mA output...............................18

6.8 MTL1372 trip amplifier converter, RTD input/4-20mA output ......................................19

6.9 MTL1373 trip amplifier converter, Potentiometer input/4-20mA output ..............................19

7 MAINTENANCE ...................................................................20

7.1 Routine maintenance .....................................................................20

7.2 Enclosures .............................................................................20

8 APPENDIX A ......................................................................20

Table 8 Isolator current consumption for MTL1991 calculation @ 24V.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

iv INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021

IMPORTANT NOTE

This manual describes the installation and use of:

• MTL1000 range of isolating interfaces and accessories.

The MTL1000 products are designed to provide signal isolation and signal conversion between

equipment and areas of a process plant.

WARNING!

This equipment must be installed, operated and maintained only by trained

competent personnel and in accordance with all appropriate international, national

and local standard codes of practice and site regulations for process connected

apparatus and in accordance with the instructions contained here.

The following methods are used on the product and in this manual to alert the user

to important information:-

Caution - read the instructions

Caution - hot surface

1

INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021DRAFT - 05 DRAFT - 23 March 2021 February 2021

1 INTRODUCTION

1.1 General

This instruction manual describes the procedures for installing, connecting, checking and

maintaining MTL1000 range of isolating interfaces and accessories.The MTL1000 products are

designed to provide signal isolation and signal conversion between equipment and areas of a

process plant.

Signal isolation eliminates or reduces the risk of earth loops, surges and noise, all of which can

result in loss of signal integrity or damage to equipment. In addition, some modules offer the

ability to convert signal types to provide level compatibility between system components.

2 MTL1000 RANGE DESCRIPTION

The MTL1000 range of modules and accessories is designed for use with process connected

systems. It consists of compact isolating interface modules mounted on 35mm DIN rail. Power

is provided through a DIN rail mounted power bus, to which, the isolator module is plugged into

when clipped onto the DIN rail. Power is supplied to the isolators via a dedicated power feed

module which also provides current limit protection in the event of a fault.

The MTL1000 range modules provide power and status information via LEDs on the top of

the module. Where module conguration is required, then switches are accessed by the user

through the side cover.

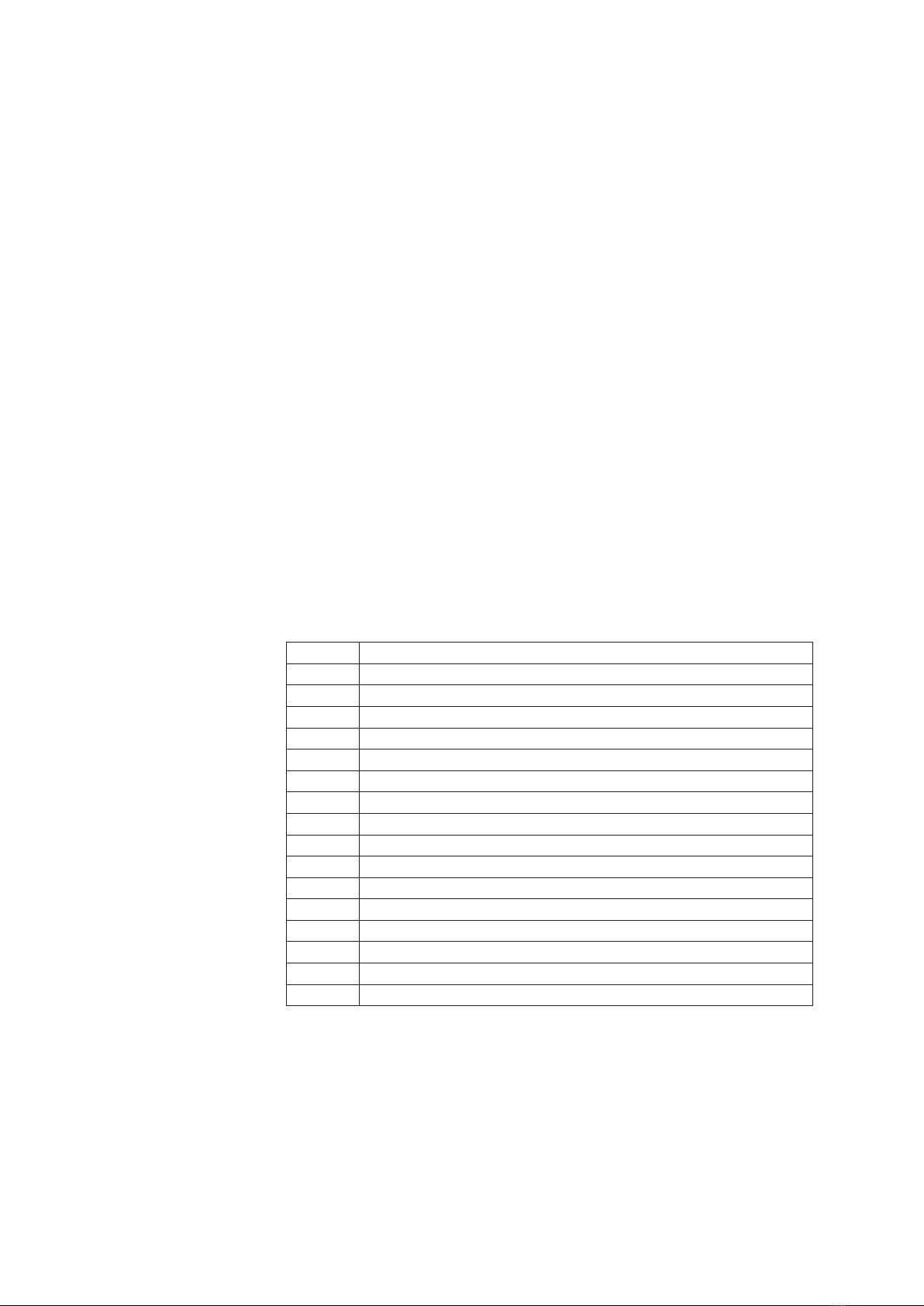

2.1 Modules

The table below lists the modules in the MTL1000 range:

MTL1991 Power feed and alarm module

MTL1141 Transmitter repeater power supply

MTL1142 Transmitter repeater power supply with HART passthrough

MTL1143 Transmitter repeater power supply with HART passthrough and repeat output

MTL1144 V/I to current repeater, loop powered

MTL1171 Thermocouple input converter

MTL1172 Resistance temperature device (RTD) converter

MTL1173 Potentiometer input converter

MTL1271 Thermocouple input converter, loop powered

MTL1272 RTD converter, loop powered

MTL1211 Switch / Proximity detector input

MTL1249 Signal converter, V/I to V/I

MTL1341 Transmitter repeater with 2ch trip amp

MTL1321 Trip amplifier with voltage/current input

MTL1371 Trip amplifier withThermocouple input

MTL1372 Trip amplifier with RTD input

MTL1373 Trip amplifier with Potentiometer input

MTL1000 range - signal conditioning interfaces

2INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021

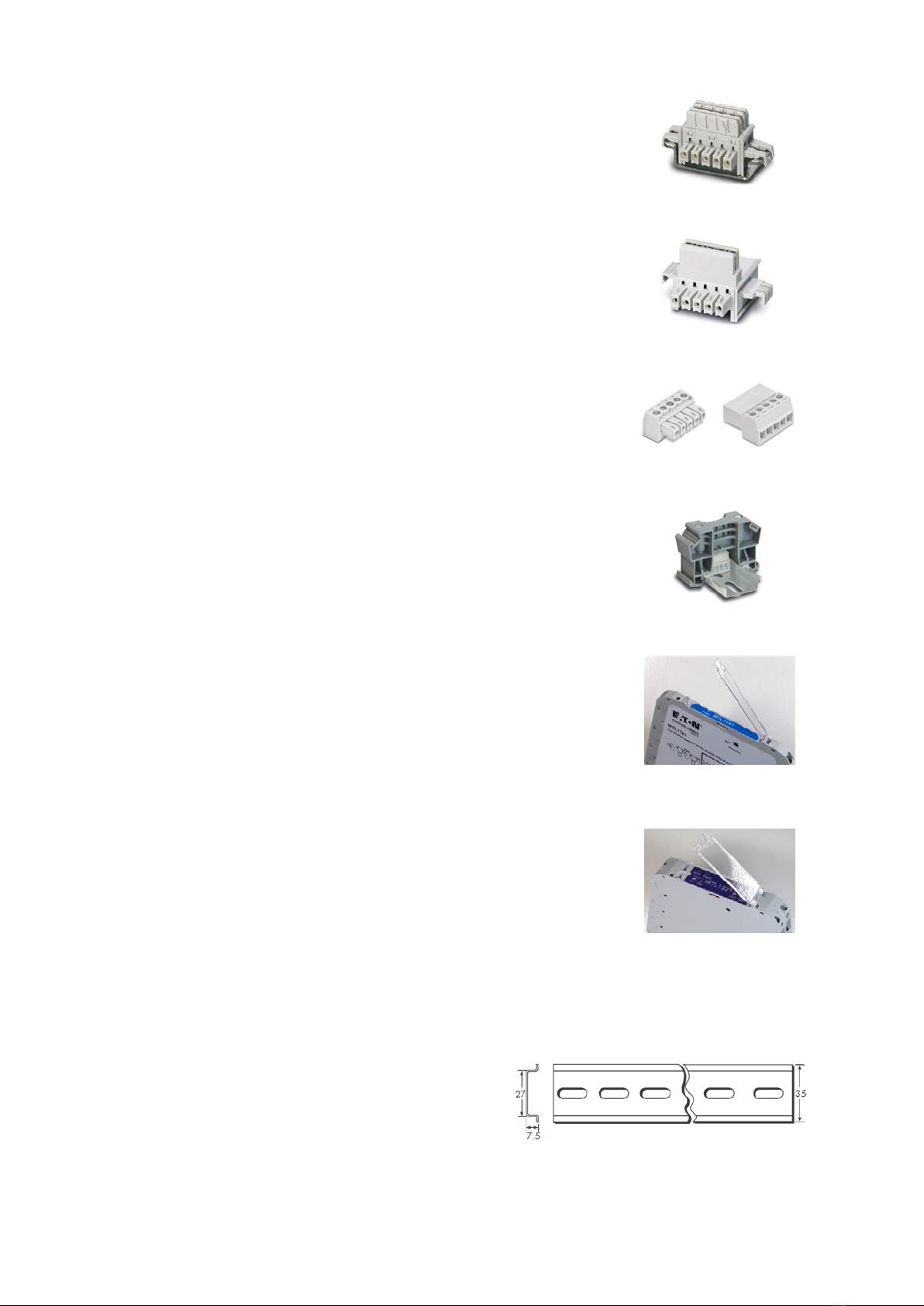

2.2 Accessories

PBUS6.2 DIN rail power bus connector for 2 module

positions (pack of 10)

PBUS17.5 DIN rail power bus connector for 1 module

position (pack of 10)

PBUS02 Power bus, direct connection terminals (1 set)

PBUS03 Module end stop

TH1000 Module tagging holder (pack of 20)

TH1300 Module tagging holder for MTL13xx

series. (pack of 10)

THR2 35mm x 7.5mm x 1m top hat standard

PBUS02

PBUS6.2

PBUS03

PBUS17.5

TH1000

TH1300

THR2

3

INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021DRAFT - 05 DRAFT - 23 March 2021 February 2021

3 INSTALLATION PRECAUTIONS

3.1 General

This equipment must be installed, operated and maintained only by trained competent

personnel and in accordance with all appropriate international, national and local standard codes

of practice and site regulations for apparatus and in accordance with the instructions contained

here.

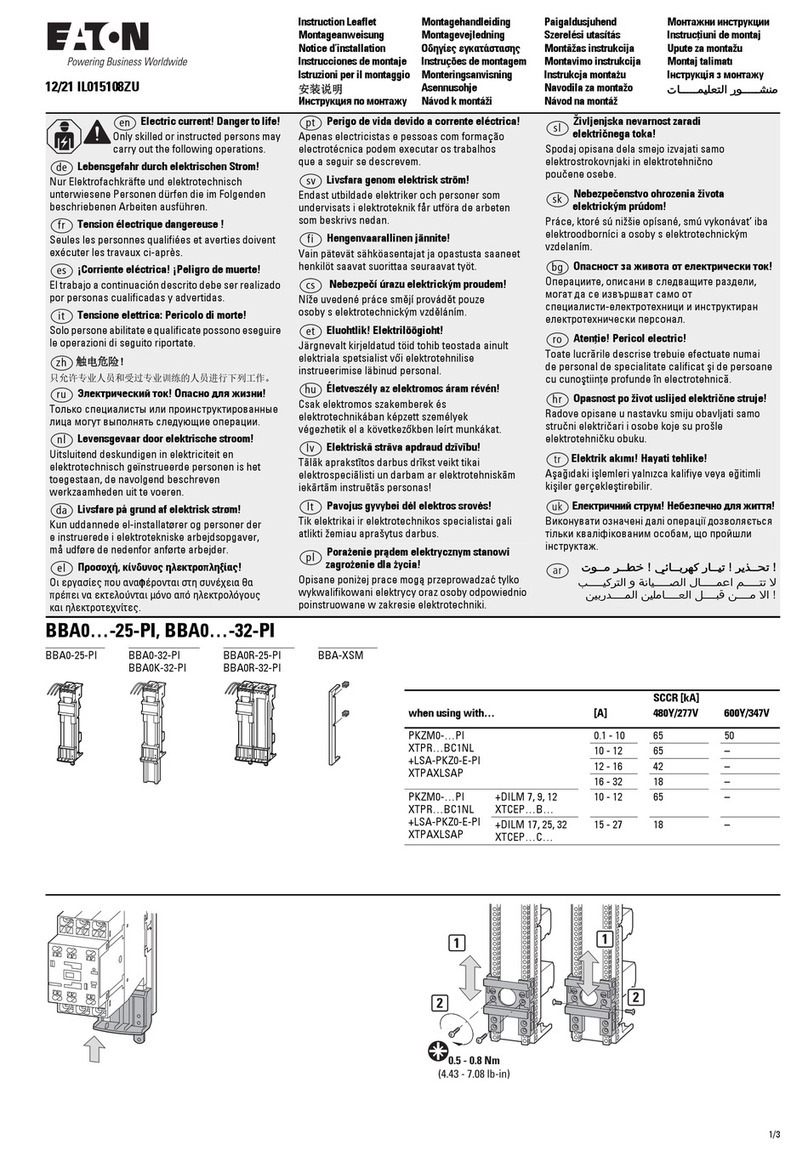

3.2 Installation

3.2.1 Modules

All modules are DIN rail mounted in conjunction with the power bus connector.The power bus

must be installed on the DIN rst with the required number of slots for the modules that will be

tted. Each power bus connector powers 2 isolators.The MTL1991 power feed module, if used,

will occupy one position.This may be located in any position. Power may be connected directly

to the bus using the PBUS02 connector set.These are screw terminals that plug directly into

the power bus at either end of the bus.The power supply should be of the transformer isolated

type to obtain the secondary isolation required for SELV.

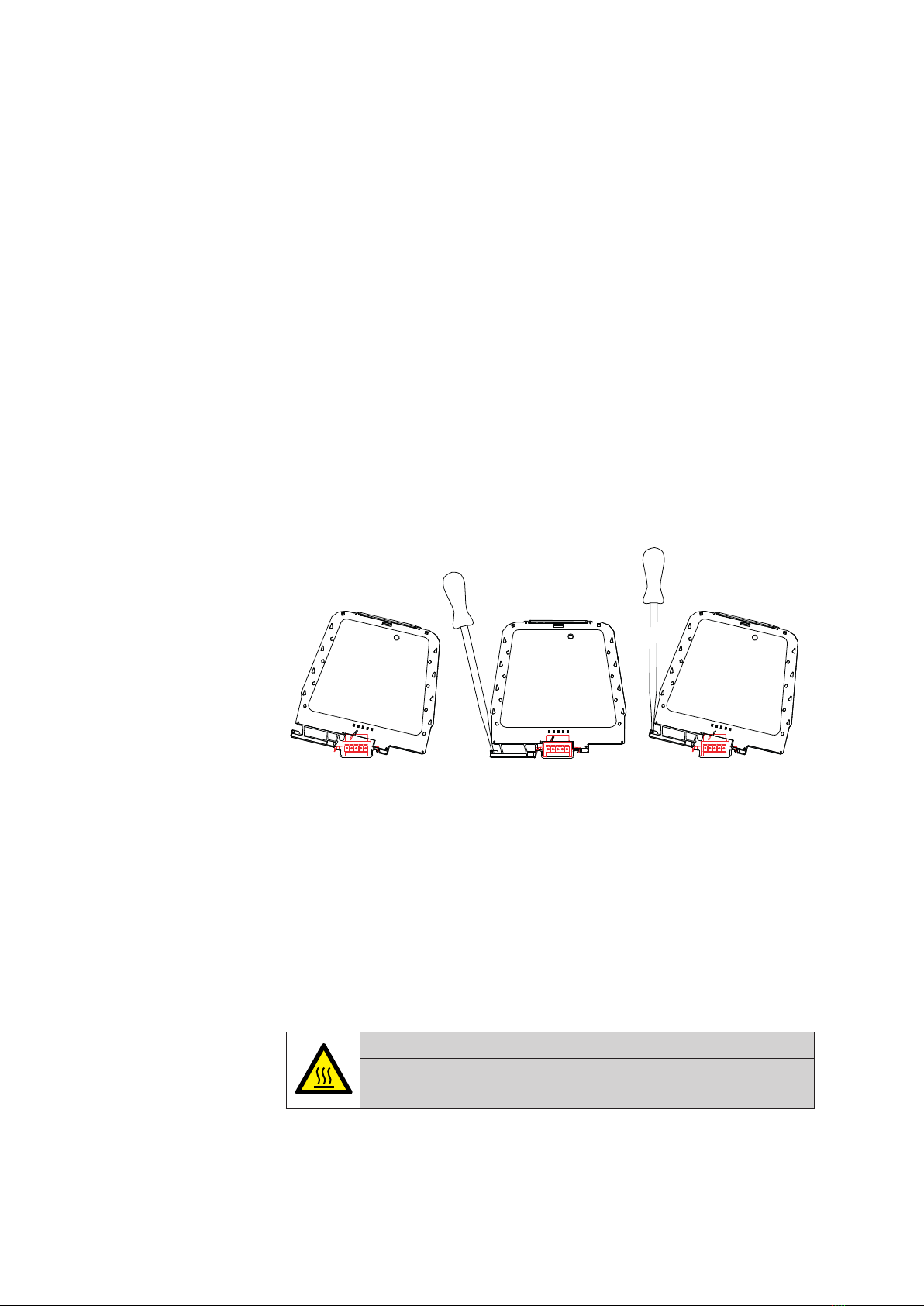

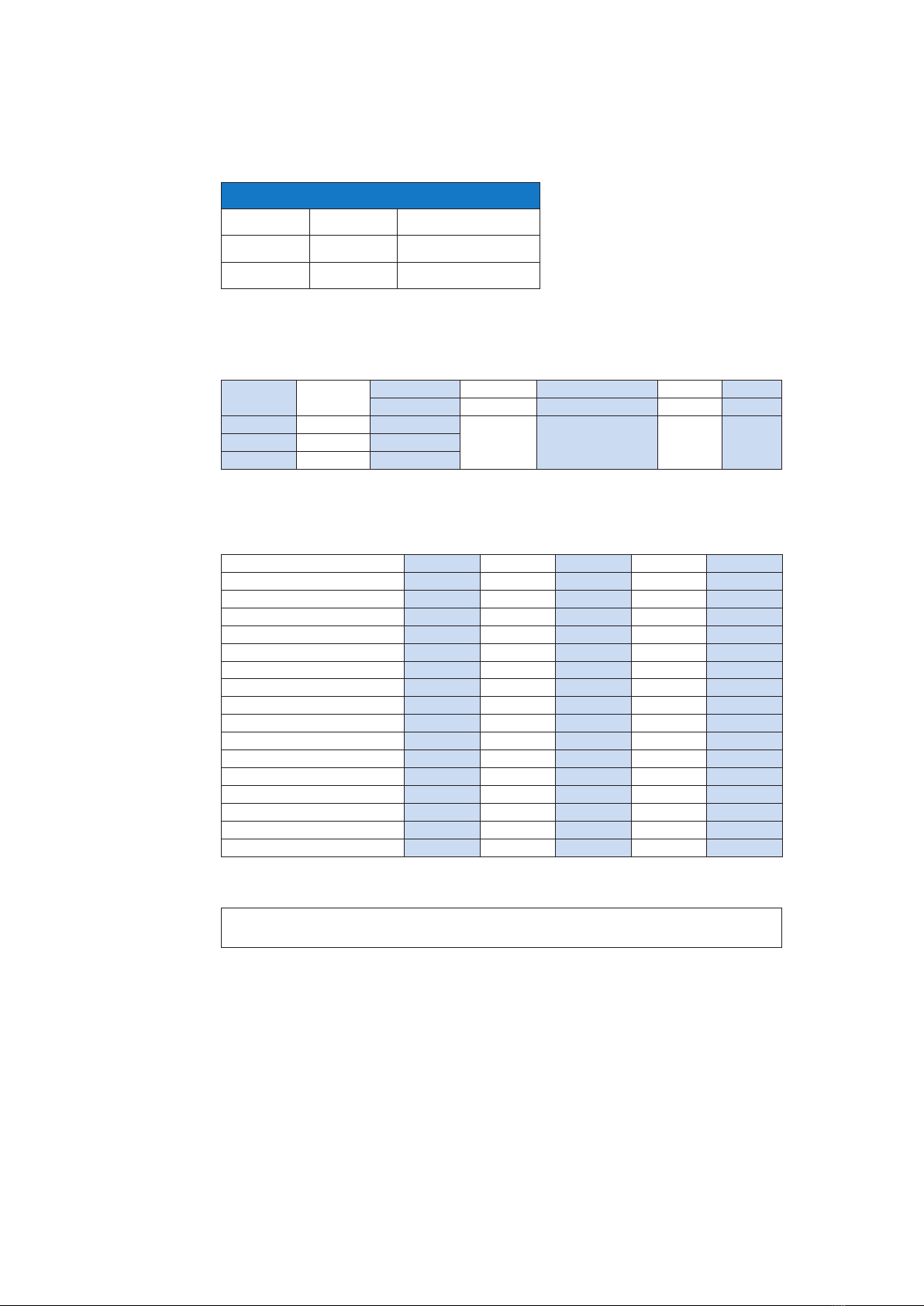

Modules are mounted on the DIN rail by clipping the foot, furthest from the release clip,

on to the DINrail rst. Rotate the module down onto the DIN rail and clip into place (Fig.1).

To release, use a atbladed screwdriver to release the module clip (Fig 2), hold module and

rotate clip upwards. (Fig.3)

3.2.2 Cabinet and enclosure mounting

The MTL1000 modules must be installed in a cabinet or enclosure with an impact

rating of at least 6.5J. Consideration must be given to the management of the internal

temperatures. Space must be provided around the modules to allow airflow.The optimum

transfer of heat is attained when the DIN rail is mounted horizontally but vertical DIN

rails may also be used where adequate space is available, especially in larger cabinets.

Principle sources of heat, such as power supplies, should be located above the modules.

An enclosure depth, measured from the base of the DIN rail, of at least 150mm is

recommended.The absolute minimum is 115mm.

CAUTION

Exercise care when removing modules in operation from the middle of a

group as the surface temperature on the side faces may be hot.

Fitting module to DIN rail Release clip Module removal

Fig. 1 Fig. 2 Fig. 3

4INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021

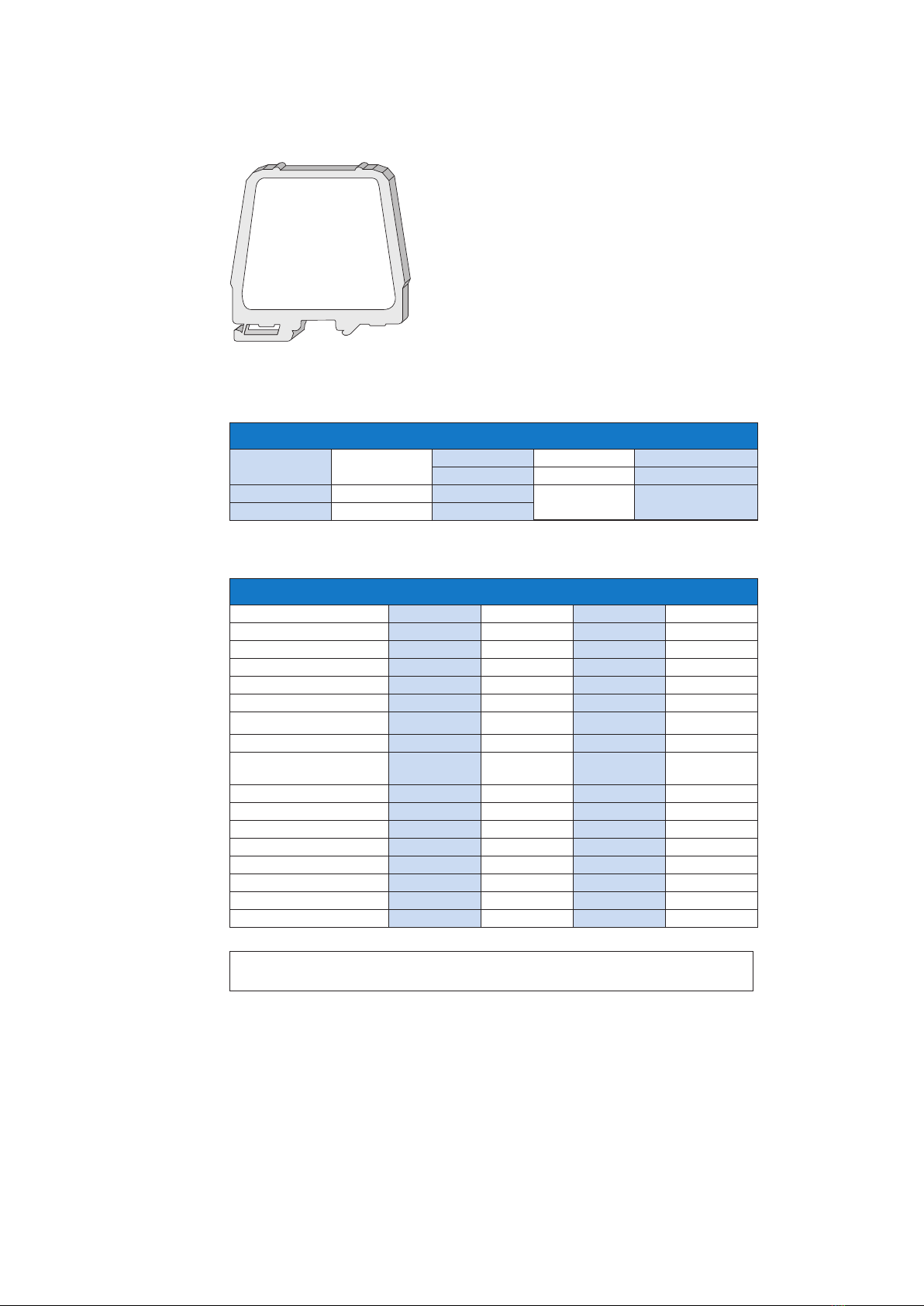

4 COMMON SPECIFICATIONS

For individual product specications please refer to individual product specication sheets.

Terminals

Screw clamp. Conductors of up to 13AWG / 1.8mm dia. stranded or single-

core copper.

Max torque 0.4Nm to 0.6Nm. Cable insulation strip /ferrule length 6-8mm

PBUS02 use wire type Solid / Stranded, 28 – 16 AWG / 0.14-1.3mm dia, – copper

Power supply voltage

18V to 32V DC SELV (UL listed where UL is applicable)

Isolation

250V ac or dc between power, eld and system circuits.

(tested to 1100Vac)

Mounting

T-section 35mm DIN rail (7.5mm or 15mm) to EN 50022

Ambient temperature limits

-20 to +60°C (-6 to +140°F) operating

-40 to +80°C (-40 to +176°F) storage

Humidity

5 to 95% relative humidity

Altitude

<2000m

Weight

6.2mm modules120g,

17.5mm modules 130g

EMC

EN61326 and NE21* Class A equipment

* For 20mS power interruption compliance, a suitable power supply must be used.

Dimensions

Fig. 1 MTL1000 Fig. 2 MTL1300

5

INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021DRAFT - 05 DRAFT - 23 March 2021 February 2021

5 MODULES

5.1 MTL1991 power feed and alarm module

The MTL1991 module is required to feed power to a group of MTL1000 range modules

via the DIN rail power bus. Each power feed module provides reverse voltage protection

and power monitoring. The power monitor relay provides a dry contact output which

may be used for connection into a monitoring system or local indicator.

The number of isolators connected to any one power feed module must be assessed

for power consumption. The maximum load current when feeding power via terminal

5 is 1A. If redundant power inputs are not required then terminal 6 may be used and

a maximum load current of 2 A is acceptable. Check current consumption table in

Appendix A for details. If power is fed directly into terminal 6 and external 3A time delay

fuse must be tted. Alarm relay contact rating is 40Vrms ac/dc 0.5A, resistive.

Where redundant power feeds are required, two MTL1991 modules are tted with one

power feed on each. The maximum load current is 1A.

5.2 Current repeaters

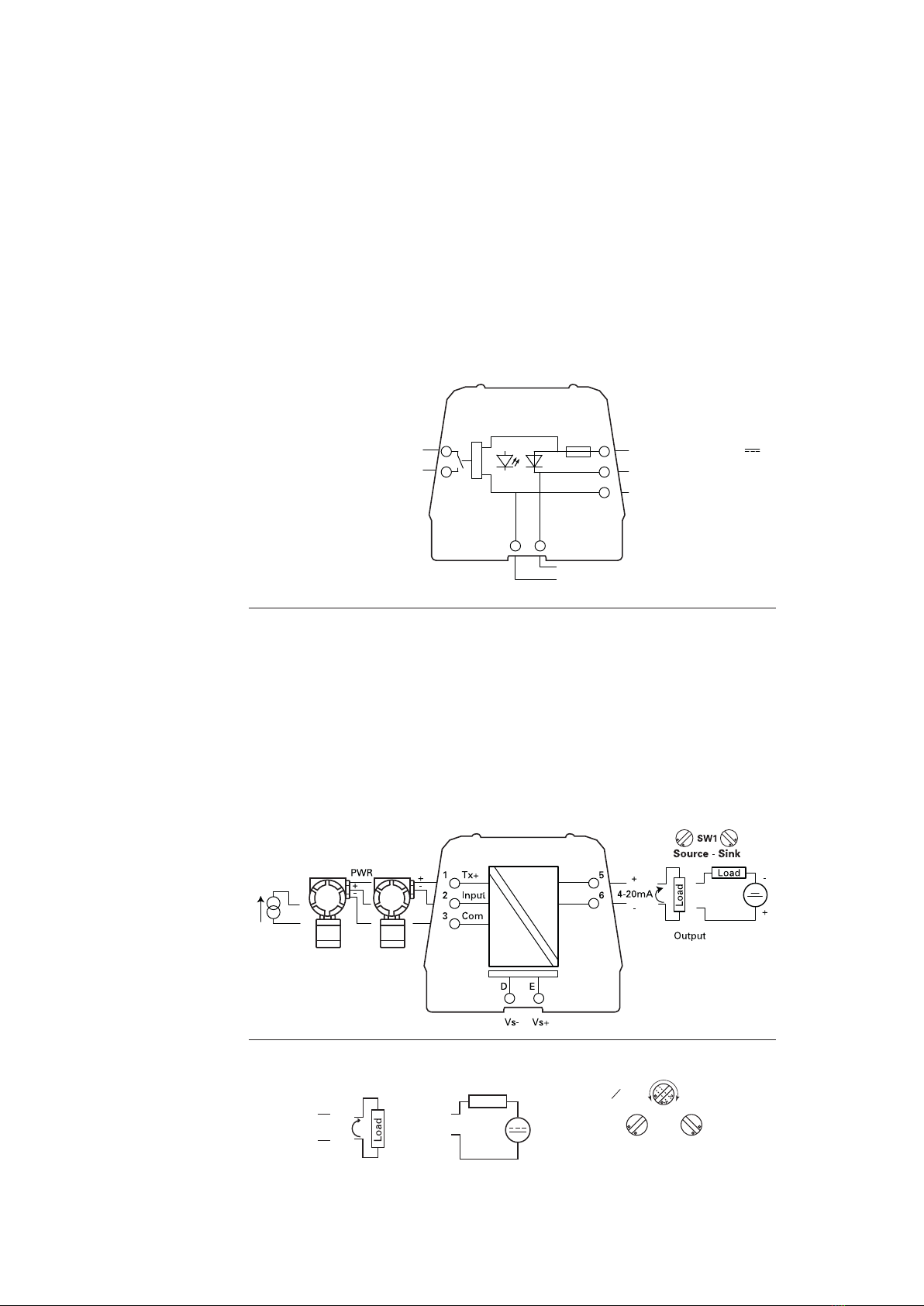

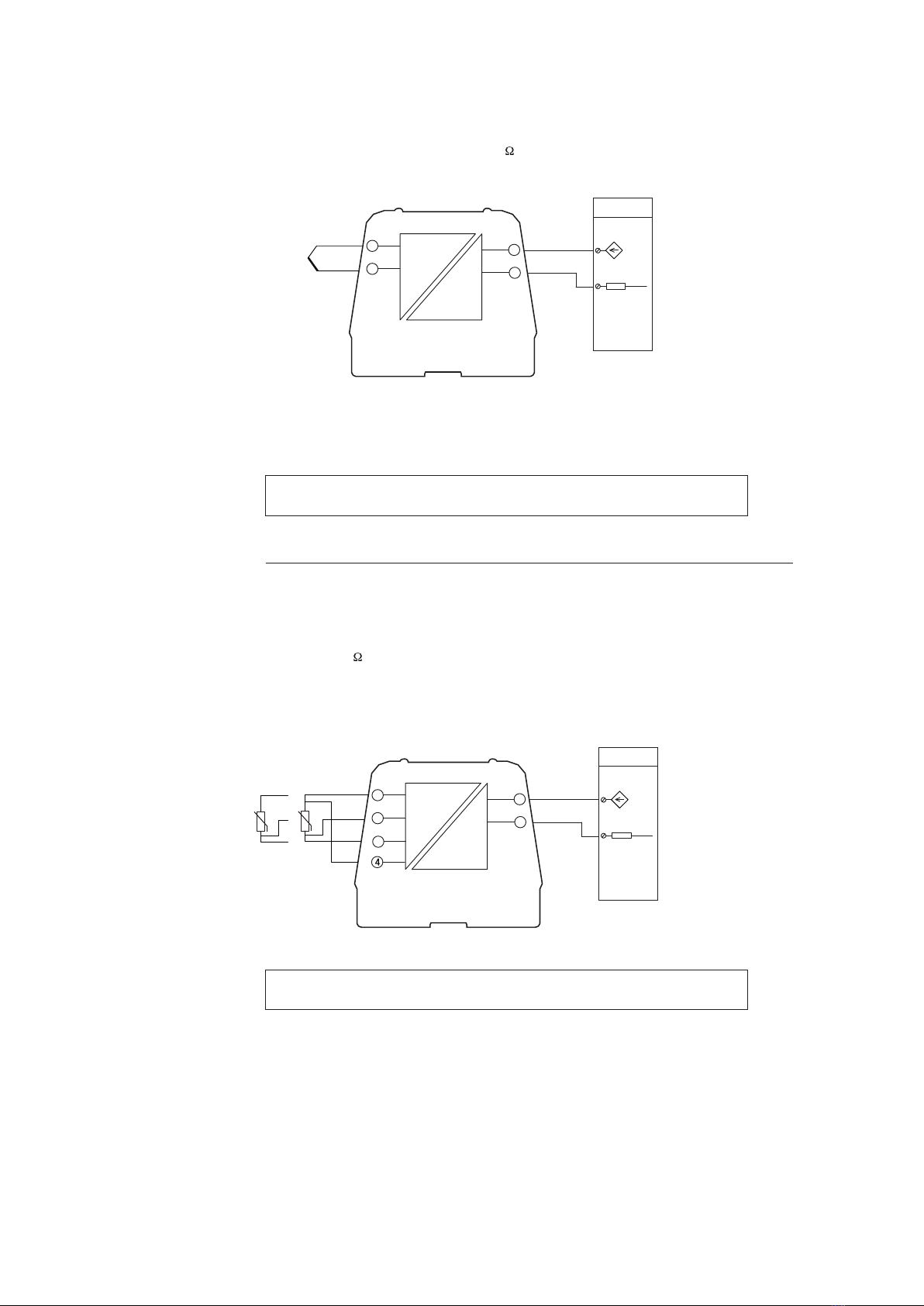

5.2.1 MTL1141 transmitter repeater power supply

Before installing this modules check the connection requirements on the ‘system’ side

of the module.The output may be congured to source or sink current. Current source

is used when the input to the system is passive, ie there is no power supply present

and it presents a resistive load. Current sink is used mainly with a ‘2 wire’ transmitter

input to the system where ‘loop power’ and ‘input’ terminals are provided. Terminal

6 on the MTL1141 is connected to the transmitter supply, and terminal 5 to the input.

See Fig.4. Switch SW1 on the module must be set prior to installation.The module is

supplied with the switch set in ‘source’ mode.

V+ supply input 19-32V dc 1A

D E

ALARM

1

2

5

6

7

2A

Direct V+ supply input (max 2A)

V- supply input

Bus supply output

Vs+

Vs-

MTL1991

MTL1141

Source output

5 +

6

-

4-20mA

Load

Sink output

5

6

-

+

-

+

Power

Label side of module

SW1

Source - Sink

SW1

34turn

Fig. 4 Fig. 5

Source output

5 +

6

-

4-20mA

Load

Sink output

5

6

-

+

-

+

Power

Label side of module

SW1

Source - Sink

SW1

34turn

6INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021

5.2.2 MTL1142 transmitter repeater power supply with HART

Before installing this modules check the connection requirements on the ‘system’ side

of the module.The output may be congured to source or sink current. Current source

is used when the input to the system is passive, i.e. there is no power supply present

and it presents a resistive load. Current sink is used mainly with a ‘2 wire’ transmitter

input to the system where ‘loop power’ and ‘input’ terminals are provided. Terminal

6 on the MTL1142 is connected to the transmitter supply, and terminal 5 to the input.

Switch SW1 on the module must be set prior to installation.The module is supplied

with the switch set in ‘source’ mode. HART communications are passed with both

settings. In source mode the input impedance on the system input must be >240Ω for

HART compliance.

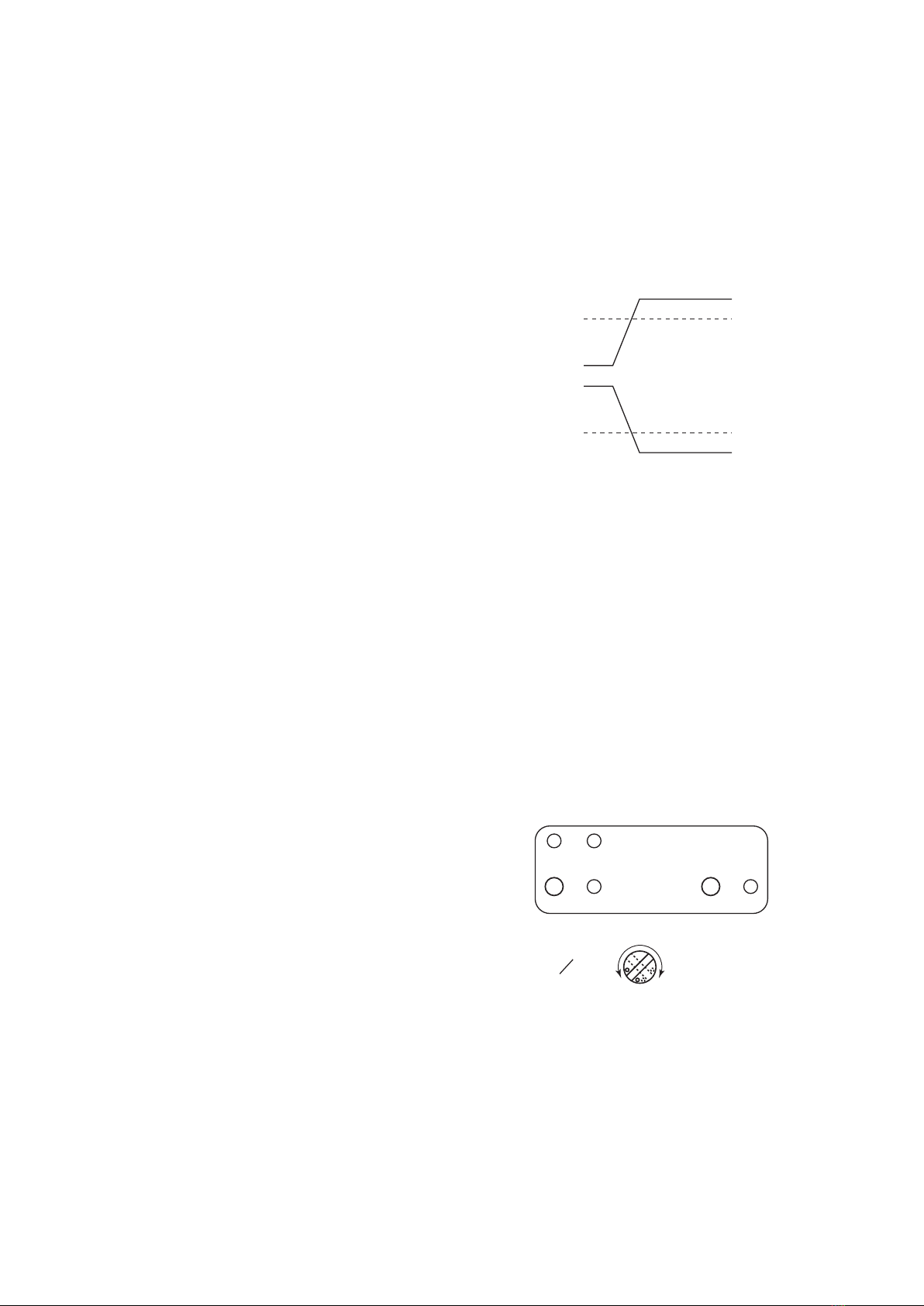

5.2.3 MTL1143 transmitter repeater power supply with HART and repeat output

Before installing this modules check the connection requirements on the ‘system’ side

of the module. Output 1 is congured to source current into a load and provide HART

communications passthrough.

Output 2 on terminals 7 and 8 generates a repeat 4-20mA signal to another device.This

output provides a 4-20mA ‘source’ current to the system input. HART communication

is not provided via this output.

An active current source may also be applied via terminals 2 and 3. HART

communications are not provided when operating in this mode.

PWR

+

-

Tx+

Input

Com

1

2

3

5

6

D E

Vs- Vs+

4-20mA

+

-+

-

Output

+

-

Load

Load

SW1

Source - Sink

MTL1142

Tx+

Input

Com

1

2

3

5

6

D E

Vs- Vs+

4-20mA

+

-

Load

7

84-20mA

+

-

Load

Output 1

Output 2

PWR

+

-

+

-

MTL1143

7

INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021DRAFT - 05 DRAFT - 23 March 2021 February 2021

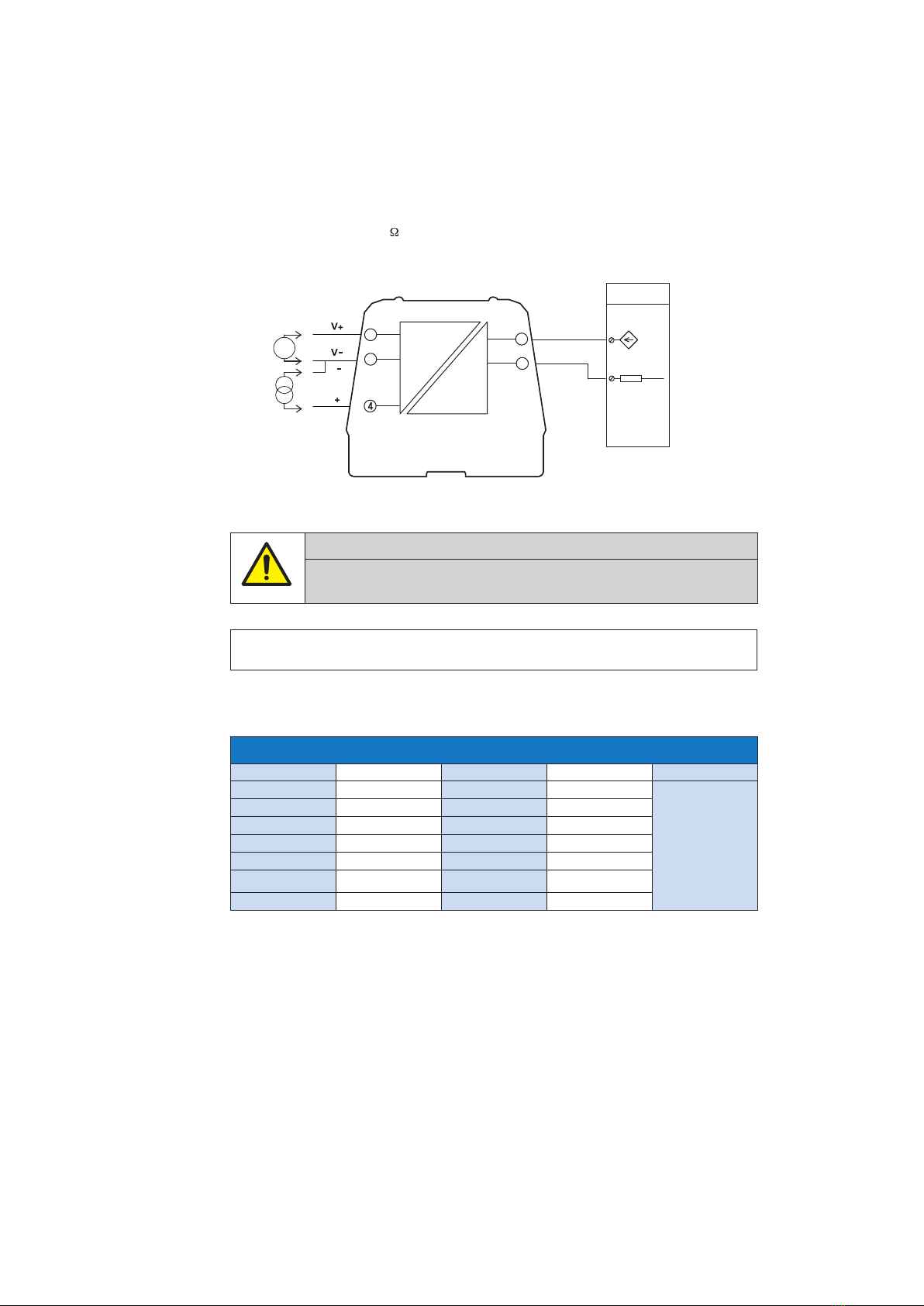

5.2.4 MTL1144 voltage/current input, loop powered isolator

The MTL1144 provides an interface to convert voltage or current signals into 4-20mA for

connection to a system analogue input. Switches are used to select the required input

range.The input terminals are chosen depending on signal type, 1 and 2 for voltage

input and 2 and 4 for current input.

The maximum load resistance is dependent on the available power supply voltage.

Max load = 50(Vs-17)

CAUTION

Do not connect a low impedance voltage source to terminals 2 and 4, damage

may result.

NOTE

Signal source must be isolated from mains supply.

Table 1

MTL1144 switch settings

DS1 DS2 DS3 Input Output

OFF OFF OFF 0-1V

4-20mA

ON OFF OFF 0-5V

OFF ON OFF 0-10V

ON ON OFF 1-5V

OFF OFF ON 0-20mA

ON OFF ON 4-20mA

OFF ON ON 0-100mV

MTL1144

5

6

2

1+

-

System AI

+24V Tx

Power

Limit

2 wire Tx

system input

Load

-ve

Return

V/I

I

I

V

I

I

4-20mA

8INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021

5.2.5 MTL1145 loop powered current repeater

The MTL1145 can be used for both input and output applications. It is primarily

designed for use with analogue outputs and loop powered from the system

output. Power is taken from the analogue output signal to power the isolator. HART

communication passthrough is not provided by this module.

Alternatively the module can be used in a current sink mode where an analogue output

in the eld can be connected to pass a signal into a system input. Power is taken from

theTransmitter power connection on the system and the signal is fed back through the

system input load to 0V.

NOTE

Greater accuracy is provided when operating in Current Source mode.

Signal source must be isolated from mains supply.

MTL1145

Current Source

(Analogue Outpt /Input)

System AO

O/P+

O/P-

I/P converter

/ AI Load

+

-

System AI

MTL1145

Input

Current Sink

(Analogue Input)

2 wire

Tx

Power

Input +

V source

(24V)

Channel

Input

0V / Return

System AI

9

INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021DRAFT - 05 DRAFT - 23 March 2021 February 2021

5.3 MTL1171, 1172 temperature and MTL1173

potentiometer converters

The MTL1171, for thermocouples and MTL1172, for RTD,

convert low level temperature inputs to 4-20mA. Input type

and range setting is performed using switches on the side

of the module. The MTL1173 is for a potentiometer input,

there are no switches on this module.

The sensor types and wire break detection are selected

using switches DS 1-4 and a selection of popular ranges is

available using switches DS 6-9.

See tables 1 and 2.

Current output, voltage output or current sink output is available on the

system terminals by wiring to the appropriate terminals as shown and

setting SW1 to the appropriate position.

Condition Green (PWR) Red (STS)

Power ON/ Normal ON OFF

Power LowVoltage OFF OFF

Field Open circuit ON Flashing

Module failure ON ON

Table 2 Conguration and DIP switch settings

Model Input type DS1 DS2 DS3 DS4 DS5

Type Wire Break Wire Break Drive Trip 1 Trip 2

MTL1x71 THC J Off / K On ON/OFF ON = Upscale

OFF = Downscale N/A N/AMTL1x72 RTD 4W Off 3W On

MTL1173 POT -

Table 3 MTL1171 and MTL1172 range DIP switch setting

RangeTHC/RTD DS6 DS7 DS8 DS9 DS10

0 to 100°C 0000-

0 to 150°C 0001-

0 to 200°C 0010-

0 to 350°C 0011-

0 to 500°C 0100-

0 to 650°C 0101-

0 to 800°C 0110-

0 to 1000°C

(RTD max 850°C) 0111-

-10 to 50°C 1000-

-50 to 50°C 1001-

-50 to 100°C 1010-

-50 to 150°C 1011-

-50 to 250°C 1100-

-50 to 350°C 1101-

-200 to 600°C 1110-

Special (Reserved) 1111-

NOTE

Cycle power supply after setting switches

SW1

Source Sink

LED indicators show

the power and eld

input status

SW1

DS10

MTL117x

DS1

10 INM MTL1000 Rev 9

DRAFT-05DRAFT-23March2021 February2021

MTL1172

MTL1171

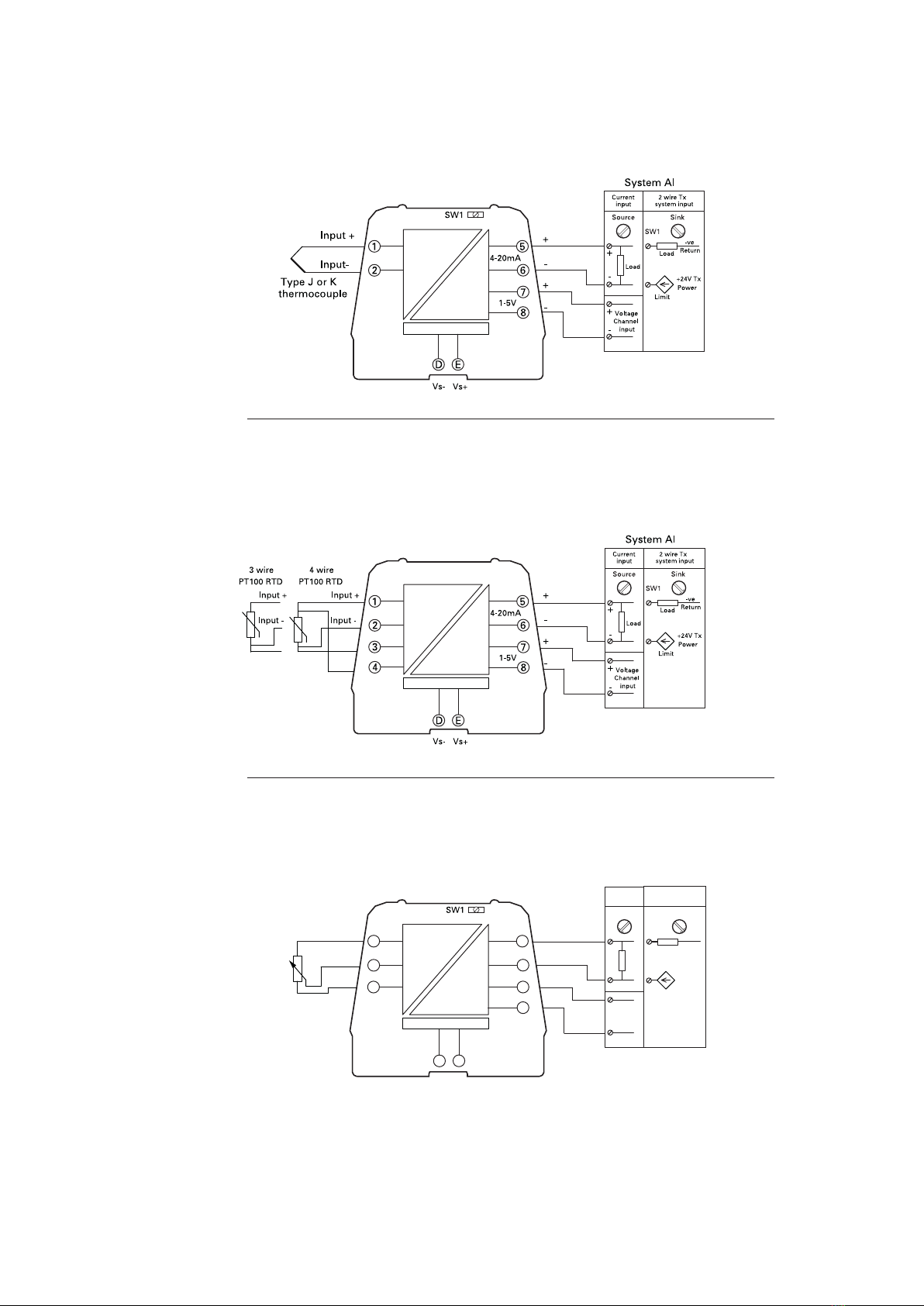

5.3.1 MTL1171 thermocouple input converter

ForType J or K thermocouples. Cold junction compensation is provided by the MTL1171.

Switch settings select open wire detection and up/down scale drive.

5.3.2 MTL1172 RTD input converter

For PT100 RTD sensors. Switch settings select 3 or 4 wire connection and open wire

detection with up/down scale drive.

5.3.3 MTL1173 potentiometer input converter

Potentiometer Input.

MTL1173

ED

5

62

1

4-20mA

7

8

1-5V

+

-

+

-

Potentiometer

input

3

Load

System AI

+

-

Current

input

Voltage

Channel

input

+24V Tx

Power

Limit

2 wire Tx

system input

-

+

SW1

Source Sink

Load

-ve

Return

+24V

11

INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021DRAFT - 05 DRAFT - 23 March 2021 February 2021

5.4 MTL1211 Switch / Proximity Detector input

Switch or proximity detector isolator with the option to select line fault detection or a

repeat output Switches are used to select phase reversal and the repeat output or LFD

alarm output .

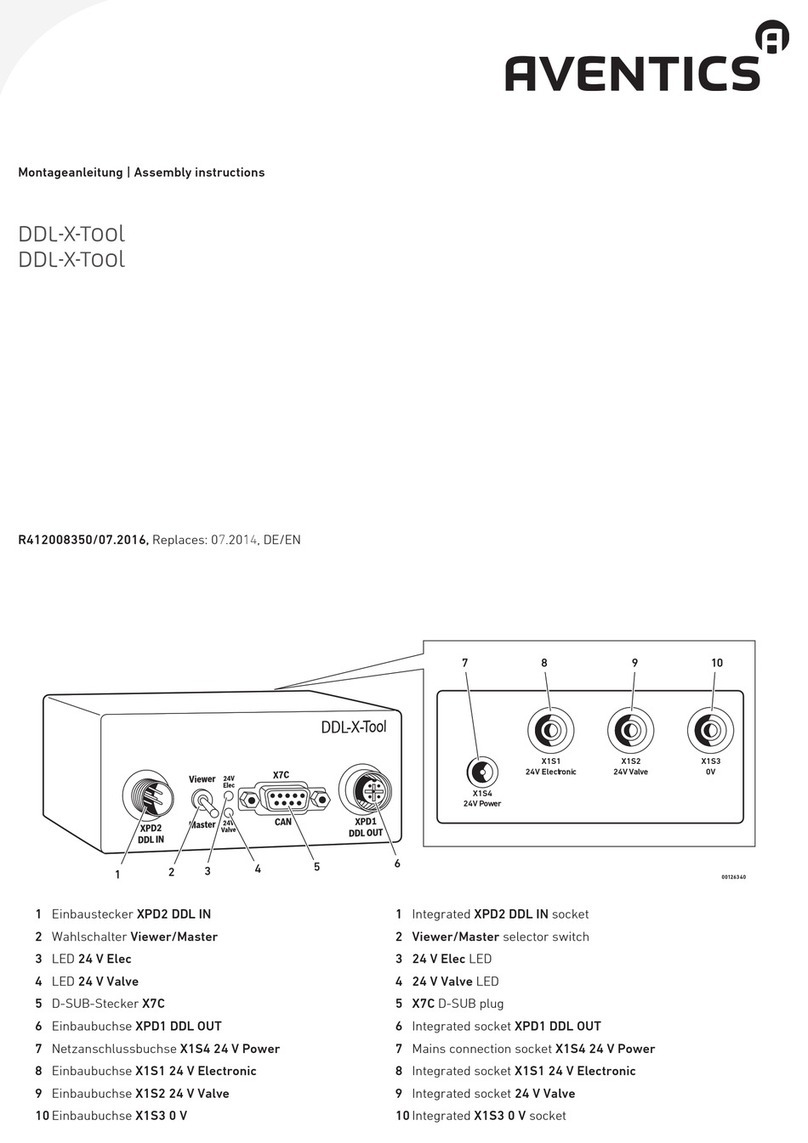

5.5 MTL1249 Current /Voltage input/output repeater

The MTL1249 is a single channel signal conditioner which can accept voltage or current

inputs and provide a voltage or current output.The signal levels are selected by the user

using switches on the module as shown in the table 3.

MTL1211

Output

Repeat/LFD

+24V

+

_

680Ω

22kΩ

On

LFD PR

MTL1249

ED

5

6

2

1

7

8

+

-

+

-

Load

System AI

+

-

Current

input

Voltage

Channel

input

+24V Tx

Power

Limit

2 wire Tx

system input

-

+

SW1

Source Sink

Load

-ve

Return

+24V

V/I

V/I

I

V

V

I

I

12 INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021

Table 4 MTL1249 Dip Switch settings

INPUT DS1 DS2 DS3 DS4 DS5 DS6 INPUT OUTPUT

Voltage

OFF OFF OFF OFF OFF OFF 0-1V

4-20mA

ON OFF OFF OFF OFF OFF 0-5V

OFF ON OFF OFF OFF OFF 0-10V

ON ON OFF OFF OFF OFF 1-5V

Current OFF OFF ON OFF OFF OFF 0-20mA

ON OFF ON OFF OFF OFF 4-20mA

Voltage

OFF ON ON OFF OFF OFF 0-1V

0-20mA

ON ON ON OFF OFF OFF 0-5V

OFF OFF OFF ON OFF OFF 0-10V

ON OFF OFF ON OFF OFF 1-5V

Current OFF ON OFF ON OFF OFF 0-20mA

ON ON OFF ON OFF OFF 4-20mA

Voltage

OFF OFF ON ON OFF OFF 0-1V

0-5V

ON OFF ON ON OFF OFF 0-5V

OFF ON ON ON OFF OFF 0-10V

ON ON ON ON OFF OFF 1-5V

Current OFF OFF OFF OFF ON OFF 0-20mA

ON OFF OFF OFF ON OFF 4-20mA

Voltage

OFF ON OFF OFF ON OFF 0-1V

1-5V

ON ON OFF OFF ON OFF 0-5V

OFF OFF ON OFF ON OFF 0-10V

ON OFF ON OFF ON OFF 1-5V

Current OFF ON ON OFF ON OFF 0-20mA

ON ON ON OFF ON OFF 4-20mA

Voltage

OFF OFF OFF ON ON OFF 0-1V

0-10V

ON OFF OFF ON ON OFF 0-5V

OFF ON OFF ON ON OFF 0-10V

ON ON OFF ON ON OFF 1-5V

Current OFF OFF ON ON ON OFF 0-20mA

ON OFF ON ON ON OFF 4-20mA

Voltage

OFF ON ON ON ON OFF 0-1V

2-10V

ON ON ON ON ON OFF 0-5V

OFF OFF OFF OFF OFF ON 0-10V

ON OFF OFF OFF OFF ON 1-5V

Current OFF ON OFF OFF OFF ON 0-20mA

ON ON OFF OFF OFF ON 4-20mA

Voltage

OFF OFF ON OFF OFF ON 0-100mV 4-20mA

ON OFF ON OFF OFF ON 0-100mV 0-20mA

OFF ON ON OFF OFF ON 0-100mV 0-5V

ON ON ON OFF OFF ON 0-100mV 1-5V

OFF OFF OFF ON OFF ON 0-100mV 0-10V

ON OFF OFF ON OFF ON 0-100mV 2-10V

13

INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021DRAFT - 05 DRAFT - 23 March 2021 February 2021

5.6 MTL1271, 1272 LOOP POWERED temperature converters

The MTL1271, for thermocouples and MTL1272, for RTD,

convert low level temperature inputs to 4-20mA. Input type

and range setting is performed using switches on the side

of the module.

The sensor types and wire break detection are selected

using switches DS 1-3 and a selection of popular ranges is

available using switches DS 4-7.

See tables 1 and 2.

Table 1

Conguration and DIP switch settings

Model Input type DS1 DS2 DS3

Type Wire Break Wire Break Drive

MTL1171 THC J Off / K On ON/OFF ON = Upscale

OFF = Downscale

MTL1172 RTD 4W Off 3W On

Table 2

MTL1271 and MTL1272 range DIP switch setting

RangeTHC/RTD DS4 DS5 DS6 DS7

0 to 100°C 0 0 0 0

0 to 150°C 0 0 0 1

0 to 200°C 0 0 1 0

0 to 350°C 0 0 1 1

0 to 500°C 0 1 0 0

0 to 650°C 0 1 0 1

0 to 800°C 0 1 1 0

0 to 1000°C

(RTD max 850°C) 0 1 1 1

-10 to 50°C 1 0 0 0

-50 to 50°C 1 0 0 1

-50 to 100°C 1 0 1 0

-50 to 150°C 1 0 1 1

-50 to 250°C 1 1 0 0

-50 to 350°C 1 1 0 1

-200 to 600°C 1 1 1 0

Special (Reserved) 1 1 1 1

NOTE

Cycle power supply after setting switches

MTL127x

14 INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021

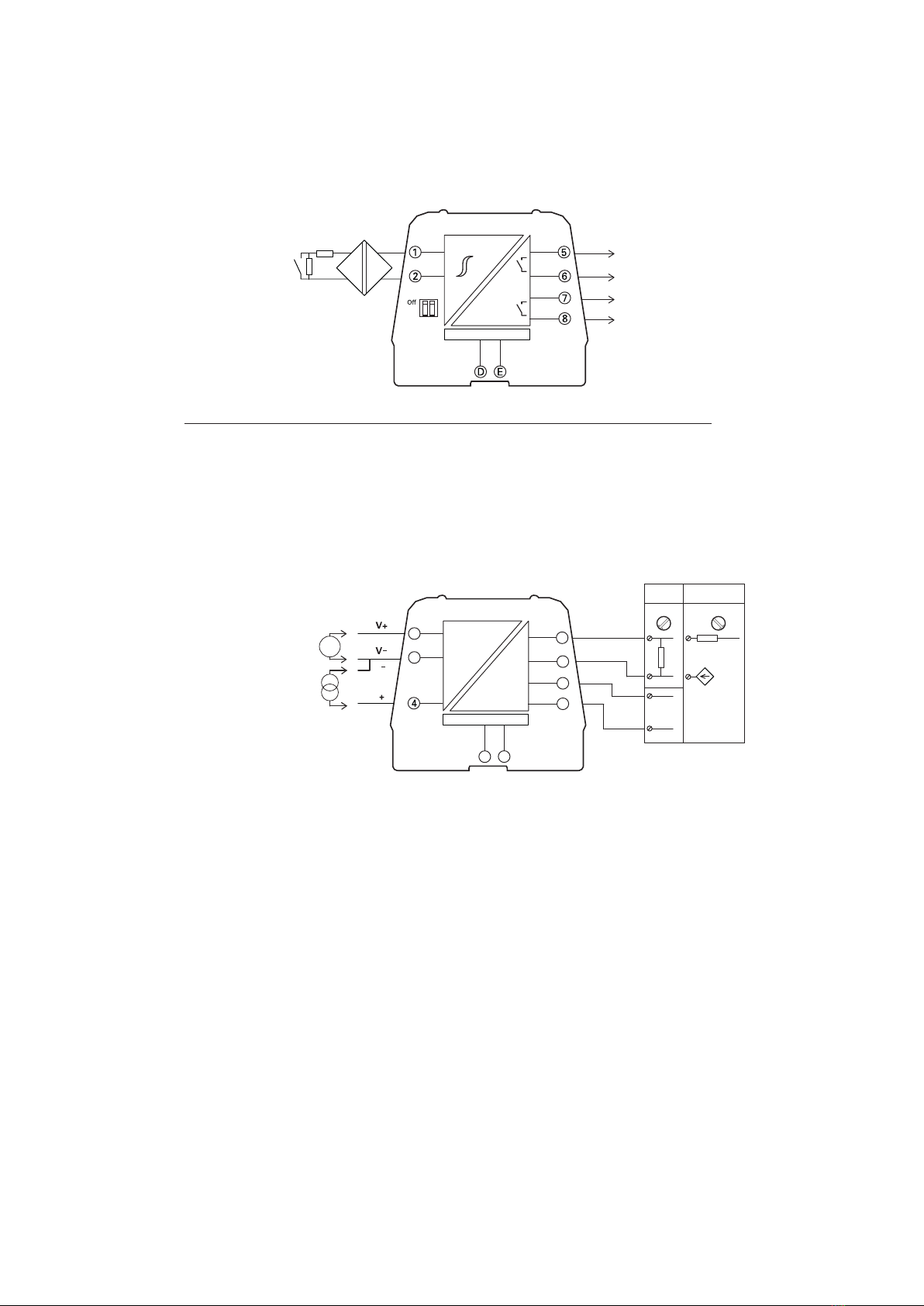

5.7 MTL1271 loop powered thermocouple input converterFor use

withType J or K thermocouples. Range and thermocouple type are set by use of DP

switches on the module.The maximum load resistance is dependent on the available

power supply voltage. Max load = 50(Vs-17)

For range settings please refer toTable 1 for MTL1271/72. Note, no LED indicators are

tted on the loop powered modules.

NOTE

Signal source must be isolated from mains supply.

5.8 MTL1272 loop powered RTD temperature converter

For use with PT100 type sensors. Range is set by use of DP switches on the module.

The maximum load resistance is dependent on the available power supply voltage.Max

load = 50(Vs-17)

ForrangesettingspleaserefertoTable1and2forMTL1271/72.Note,noLEDindicatorsare

tted on the loop powered modules.

NOTE

Signal source must be isolated from mains supply.

Input+

MTL1271

5

6

2

1+

-

System AI

2 wire Tx

system input

Input-

Load

-ve

Return

+24V Tx

Power

Limit

4-20mA

Type J or K

thermocouple

Input+

MTL1272

5

6

2

1+

-

System AI

2 wire Tx

system input

Input-

Load

-ve

Return

+24V Tx

Power

Limit

4-20mA

3

3 wire

PT100 RTD

4 wire

PT100 RTD

Input+

Input-

15

INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021DRAFT - 05 DRAFT - 23 March 2021 February 2021

6 MTL13XXTRIP AMPLIFIERS

6.1 Introduction

The trip amplier modules all use the 17.5mm wide housing with up to 16 terminals

available for eld and system connections. Power can be supplied via the DIN rail power

bus, using the PBUS17.5 power connectors, or directly into the module via screw

terminals 15 and 16.Where the power bus is being used it is recommended power is

fed directly to the bus using the PBUS02 or MTL1991 power feed connections.Two trip

points may be set with high or low level switching.

6.2 Trip level setting

Before setting the trip level the relay

switching action must be set to HighTrip

or LowTrip using the switches on the

side of the module. It is normal to set the

relay so that under non-alarm conditions

the relay contacts are closed.When in

alarm, the relay contacts would normally

be set to open, this will also be the state

when the module is unpowered (failsafe

operation).

DS4 / DS5 Off – High trip, On – Low trip Set these switches with the module off the

DIN rail.

The yellowTrip LEDs are illuminated when the relays are energised.

The switching point for either trip is set by feeding the required process trip level into

the input of the module and pressing one of the two small ‘SET’ buttons on the top of

the module for the appropriate trip.The Power and STS light will ash 5 times.The level

is digitally stored in the module and retained in the event of power loss. Pressing the

SET button again will overwrite the previous setting to the current input level that is

beingapplied at the time.

All models also provide a 4-20mA output which can be set for current source (active) or

current sink (passive) operation as required.

6.3 Label Indicators / Switches

STS RED Off normal operation. On fault. Flashing - temperature input open circuit

PWR GREEN on when power applied

Trip 1YELLOW on when relay 1 energised

Trip 2YELLOW on when relay 2 energised

DSx DIP switches for mode setting

SW1 Current output Sink / Source setting

Relay Off - Contacts open

Relay On - Contacts closed

Relay On - Contacts closed

Relay Off - Contacts open

Set point

Set point

High Trip

Low Trip

STS PWR

O/PSET

TRIP 1 MTL13xx

O/PSET

TRIP 2

SW1

34turn

16 INM MTL1000 Rev 9

DRAFT - 05 DRAFT - 23 March 2021 February 2021

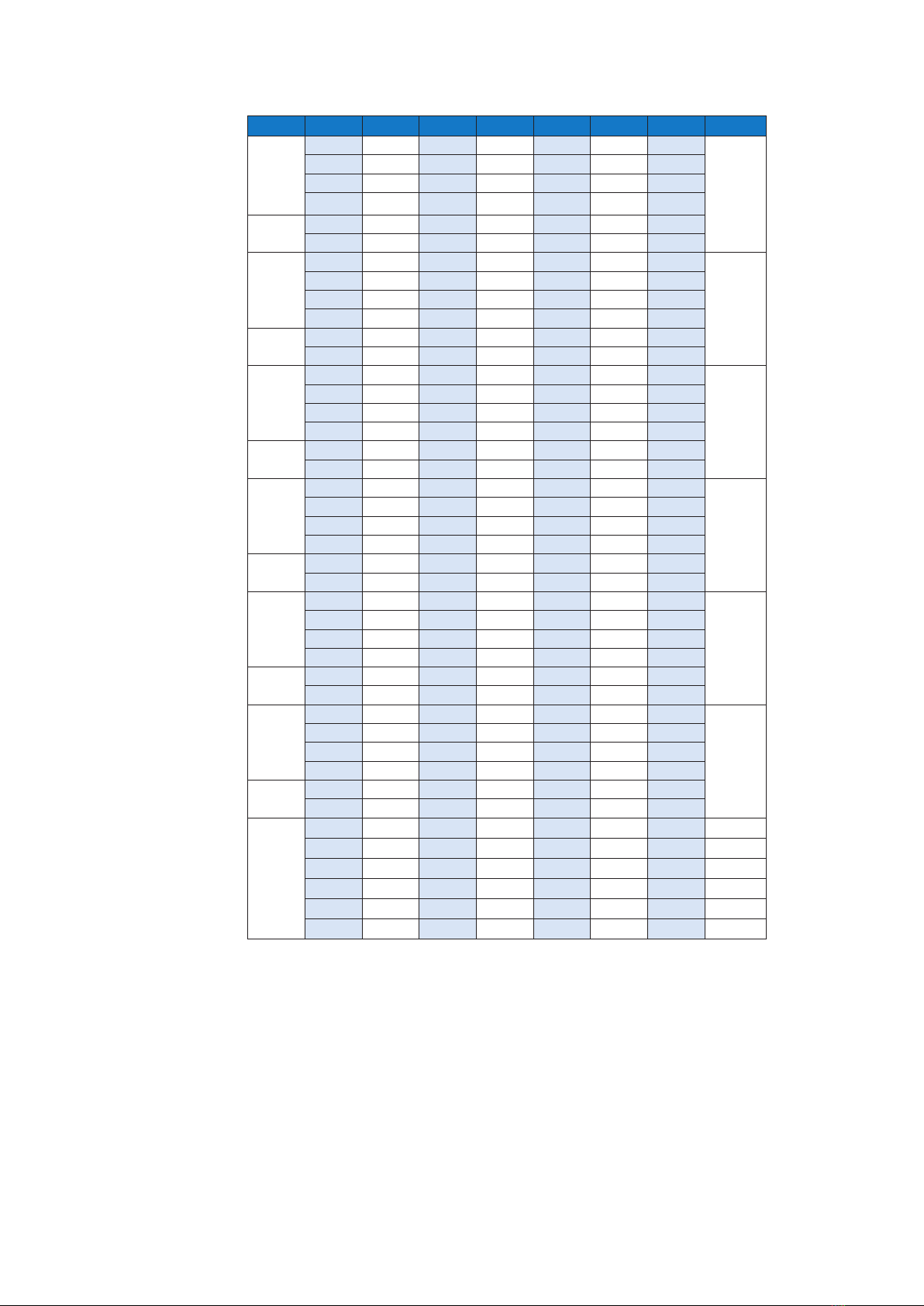

6.4 Switch settings

Table 1

Trip switch settings

MTL13xx

DS4 (trip 1) DS5 (trip 2) Status

ON ON Trip alarm low

OFF OFF Trip alarm high

Table 2

MTL137x Conguration and DIP switch settings

Model Input type DS1 DS2 DS3 DS4 DS5

Type Wire Break Wire Break Drive Trip 1 Trip 2

MTL1371 THC J Off / K On ON/OFF ON = Upscale

OFF = Downscale Off High

On Low

Off High

On Low

MTL1372 RTD 4W Off 3W On

MTL1373 POT -

Table 3

MTL1371 and MTL1372 range DIP switch setting

RangeTHC/RTD DS6 DS7 DS8 DS9 DS10

0 to 100°C 0 0 0 0 -

0 to 150°C 0001-

0 to 200°C 0 0 1 0 -

0 to 350°C 0 0 1 1 -

0 to 500°C 0100-

0 to 650°C 0 1 0 1 -

0 to 800°C 0110-

0 to 1000°C (RTD max 850°C) 0 1 1 1 -

-10 to 50°C 1 0 0 0 -

-50 to 50°C 1001-

-50 to 100°C 1 0 1 0 -

-50 to 150°C 1011-

-50 to 250°C 1 1 0 0 -

-50 to 350°C 1 1 0 1 -

-200 to 600°C 1110-

Special (Reserved) 1 1 1 1 -

NOTE

Cycle power supply after setting switches

This manual suits for next models

17

Table of contents

Popular Industrial Equipment manuals by other brands

ABB

ABB AMXE132 instructions

National Instruments

National Instruments NI-9207 Getting started

Cognex

Cognex In-Sight 3800 Series Reference manual

LNS

LNS Hydrobar Express 220 Startup manual

Miller Weldmaster

Miller Weldmaster Extreme T300 operating manual

Mayr

Mayr ROBA 8981.29 01 Series Original operating instructions