2 It is prohibited to duplicate this manual or parts of this in any way or shape, without the written consent of the author © 2023

INDEX

CH. 1. CONTENTS AND CONSULTATION METHOD...........................................................................................................3

1.1. PURPOSE OF THE MANUAL..........................................................................................................................................3

1.1.1 IMPORTANCE OF THE MANUAL...................................................................................................................................3

1.1.2. STORAGE, UPDATES, ADDITIONS AND REPLACEMENT...........................................................................................3

1.2. MEANING OF THE SYMBOLS........................................................................................................................................4

1.3. DEFINITIONS ..................................................................................................................................................................6

CH. 2. GENERAL INFORMATION AND CHARACTERISTICS ..............................................................................................9

2.1. TECHNICAL FEATURES.................................................................................................................................................9

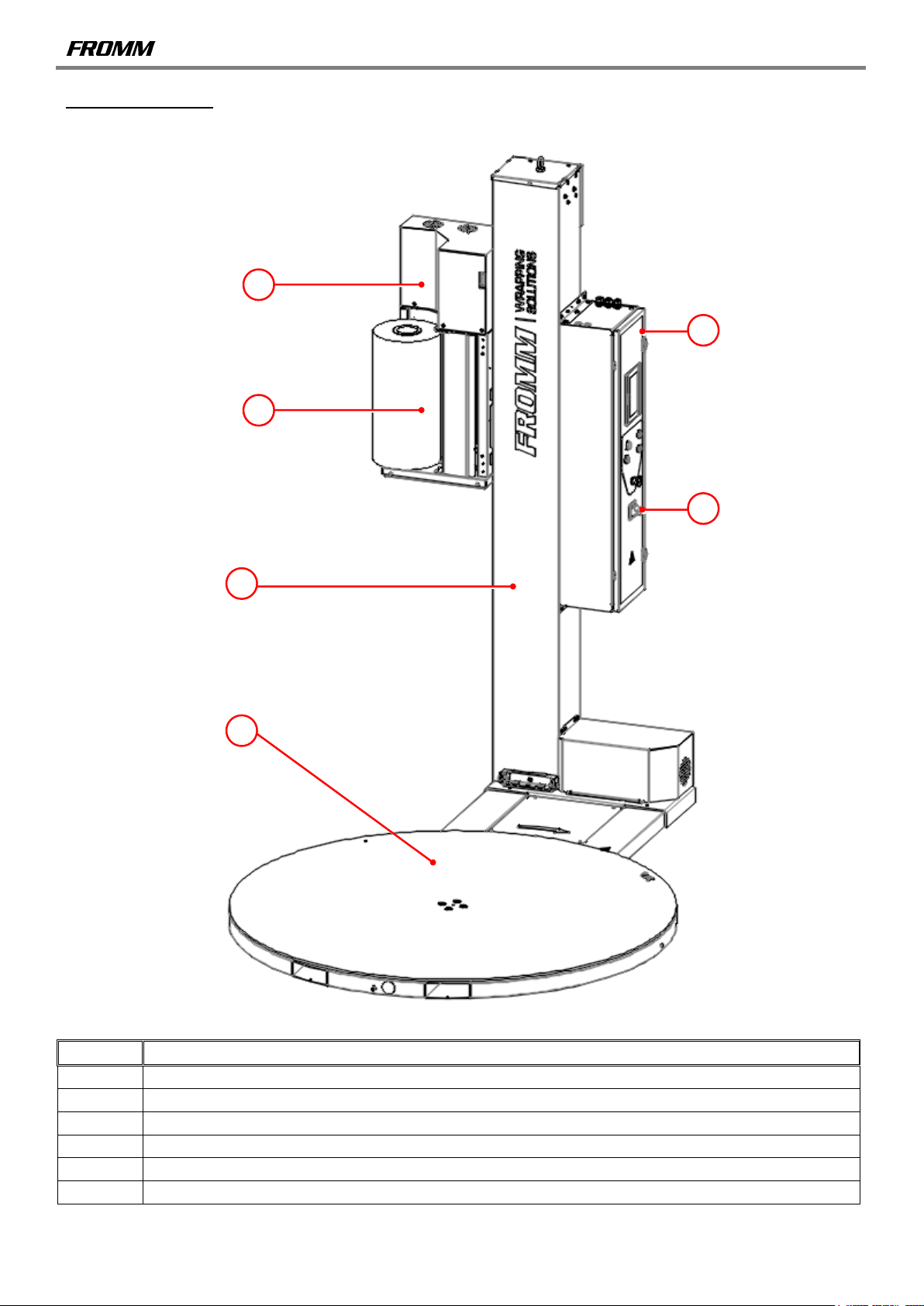

2.1.1. PURPOSE - AIM - CONSTRUCTIVE PARTS..................................................................................................................9

2.1.2. PERFORMANCE...........................................................................................................................................................11

2.1.3. TECHNICAL AND CONSTRUCTIVE DATA OF SUPPLY .............................................................................................11

2.2. PROCESSED PRODUCTS - HANDLED OR GENERATED..........................................................................................11

2.3. EMISSION OF AIRBORNE NOISE................................................................................................................................11

2.4. SERVICE CONDITIONS................................................................................................................................................12

2.5. ELECTRICAL EQUIPMENT POWER SUPPLY.............................................................................................................13

2.6. NORMAL, IMPROPER, INCORRECT / FORBIDDEN / REASONABLY PREDICTABLE INCORRECT USE................14

CH. 3. CONSISTENCY OF SUPPLY....................................................................................................................................18

3.1. MACHINE IDENTIFICATION.........................................................................................................................................18

3.2. CERTIFICATION............................................................................................................................................................18

3.3. WARRANTY CONDITIONS...........................................................................................................................................19

3.4. DECLARATION OF CONFORMITY...............................................................................................................................20

CH. 4. SAFETY INSTRUCTIONS.........................................................................................................................................21

4.1. INTRODUCTION............................................................................................................................................................21

4.2. OBLIGATIONS AND DUTIES........................................................................................................................................22

4.2.1. PLANT MANAGEMENT OBLIGATIONS........................................................................................................................22

4.2.2. PERSONNEL MAIN REQUIREMENTS .........................................................................................................................22

4.3. ENVIRONMENTS, WORK AND TRANSITING PLACES...............................................................................................24

4.4. GENERAL MACHINE PROTECTION REGULATIONS .................................................................................................25

4.5. MOVING STRUCTURES...............................................................................................................................................26

4.6. LIFTING MEANS............................................................................................................................................................26

4.7. PERSONAL PROTECTIVE EQUIPMENT AND FIRST AID...........................................................................................26

4.8. INDICATIONS ON RESIDUAL RISKS PRESENT.........................................................................................................27

4.9. PLATES .........................................................................................................................................................................36

4.10. DESCRIPTION OF THE SAFETY FUNCTIONS............................................................................................................38

CH. 5. TRANSPORT, INSTALLATION AND HANDLING.....................................................................................................43

5.1. STORAGE, TRANSPORT AND HANDLING .................................................................................................................43

5.1.1. STORAGE .....................................................................................................................................................................43

5.1.2. SIZE, WEIGHT AND HANDLING OF THE INDIVIDUAL PARTS...................................................................................44

5.1.3. REMOVING THE PACKAGE - OPENING INSTRUCTIONS –ASSEMBLY INSTRUCTIONS.......................................45

5.2. PRELIMINARY PREPARATION AND ADJUSTMENT OPERATIONS..........................................................................49

5.2.1. FILM LOADING..............................................................................................................................................................49

5.2.2. TROLLEY BRAKING SYSTEM......................................................................................................................................49

5.3. POWER SUPPLIES.......................................................................................................................................................50

5.3.1. ELECTRIC .....................................................................................................................................................................50

CH. 6. USING THE MACHINE..............................................................................................................................................52

MACHINE OPERATION, CONTROL PANEL, OPERATING PANEL,..........................................................................................52

ERRORS 52

6.1. MACHINE OPERATION ................................................................................................................................................52

6.2. CONTROL PANEL.........................................................................................................................................................53

6.3. OPERATING PANEL.....................................................................................................................................................55

6.3.1. MANUAL MODE ............................................................................................................................................................57

6.3.2. AUTOMATIC MODE......................................................................................................................................................59

6.3.3. MENU SUPERVISOR SETTING 1.................................................................................................................................68

6.4. ERRORS........................................................................................................................................................................71

CHAP.7. MAINTENANCE.........................................................................................................................................................74

7.1. ROUTINE MAINTENANCE............................................................................................................................................75

7.1.1. INTERVENTIONS EXECUTABLE BY THE OPERATORS............................................................................................76

7.1.2. INTERVENTIONS EXECUTABLE BY MAINTENANCE TECHNICIANS ONLY.............................................................77

7.2. EXTRAORDINARY MAINTENANCE.............................................................................................................................80

7.2.1. OPERATIONS THAT CAN ONLY BE PERFORMED BY MANUFACTURER TECHNICIANS ......................................80

7.3. CLEANING.....................................................................................................................................................................81

CHAP.8. DEMOLITION AND DISPOSAL.................................................................................................................................84

8.1. DEMOLITION.................................................................................................................................................................84

8.2. DISPOSAL.....................................................................................................................................................................85

CHAP.9. IDENTIFICATION DATA............................................................................................................................................86

9.1. MANUFACTURER.........................................................................................................................................................86

9.2. MACHINE TYPE............................................................................................................................................................86

9.3. DOCUMENT ..................................................................................................................................................................86