Cruisair Zephyr User manual

Zephyr (ZF) & Cuddy dc

❖

INSTALLATION • OPERATION

Zephyr & Cuddy dc Self-Contained

Cooling Only A/C Kits

Revised: 5-11-07

L-2028

3❖English

L-2028

Table of Contents

Zephyr and Cuddy dc Units • Installation

Warning .............................................................................. 4

Notice ................................................................................. 4

Introduction ......................................................................... 4

Cuddy dc ............................................................................ 4

Unpacking and Inspection .................................................. 4

Safety Considerations ........................................................ 4

Placement Of System ......................................................... 5

Spacing Allowances & Unit Dimensions ............................. 5

How It Works ...................................................................... 6

Mounting Brackets .............................................................. 6

Condensate Drains ............................................................. 6

Blower Assembly ................................................................ 6

Supply & Return Air Grills

and Transition Boxes ........................................................ 6

Ducting ............................................................................... 7

Manual Control Panel Installation ....................................... 7

Electrical Connections, Grounding & Bonding for AC

Powered Zephyr ............................................................... 7

Electrical Connections, Grounding & Bonding for DC

Powered Cuddy dc .......................................................... 7

Electrical System and Wiring for DC Powered Cuddy dc .... 8

Notice and ABYC Standards: ............................................. 8

Seawater Pump and Plumbing ........................................... 8

Installation Checklist

(review prior to and after installation) ............................... 9

Zephyr and Cuddy dc Units • Operation

Operation .......................................................................... 10

Troubleshooting Guidelines .............................................. 10

Zephyr and Cuddy dc Units • Maintenance

Seawater Strainer ............................................................. 12

Condenser Coil Cleaning ................................................. 12

Return Air Filters ............................................................... 12

Winterization ..................................................................... 12

Zephyr and Cuddy dc Kits • Parts List 12

Owner’s Limited Warranty 15

Limited Warranty Periods 17

Descriptions of Figures 18

Cruisair Worldwide Service Dealer Locator 27

4❖English

L-2028 Installation

Zephyr and Cuddy dc Units • Installation

Powered Cuddy dc”. Cuddy dc owners may skip the sections

that are subtitled “for AC Powered Zephyr.”

Cuddy dc kits contain the air conditioning unit and these

three components: a Dedicated Power Module (DPM), a 2-

knob mechanical control, and the water pump. Each of these

components is connected to the a/c unit with a polarized plug.

These plugs are configured unique to each component. The

DPM is sized to run the Cuddy dc system only and should not

be used for any other appliance(s). See Figure 14 in the back

of this manual for DPM specifications

! WARNING The DPM is not ignition protected and must not

be installed in the engine compartment or in any area with

flammable or compressed gasses or liquids (see the Safety

Considerations section of this manual for more information).

Dometic recommends using a separate battery bank dedi-

cated to run the Cuddy dc. For specific instructions, please

see the two sections in this manual titled “Electrical System

and Wiring for DC Powered Cuddy dc” and “Electrical Con-

nections, Grounding & Bonding for DC Powered Cuddy dc.”

! WARNING The compressor and fan on the Cuddy dc air

conditioning unit are AC voltage components, running on

115VAC supplied by the DPM. The pump and 2-knob

mechanical control also run on 115VAC supplied by the DPM.

Once the DPM is connected to the dedicated 12VDC battery

bank, then all necessary power distribution to each of the

components is handled through the polarized plugs—truly a

“plug & play” system.

Unpacking and Inspection

When the equipment is received, all items should be carefully

checked against the packing list to ensure all cartons have

been received. Move units in the normal “up” orientation as

indicated by the arrows on each carton. Examine cartons for

shipping damage, removing the units from the cartons if

necessary. If the unit is damaged, the carrier should make the

proper notation on the delivery receipt acknowledging the

damage.

CAUTION: When unpacking and installing the control, care

must be taken not to kink or break the copper cap tube when

uncoiling the sensing bulb. The cap tube is hollow and kinking

or sharp bends will inhibit system operation.

Safety Considerations

Never install your air conditioner in the bilge or engine room

areas. Insure that the selected location is sealed from direct

access to bilge and/or engine room vapors. Do not terminate

condensate drain line within three (3) feet of any outlet of

engine or generator exhaust systems, nor in a compartment

Warning

This manual contains essential safety information concerning

the safe and proper installation and operation of Zephyr and

Cuddy dc self-contained direct expansion air conditioners. It is

very important that you read and understand the contents of

this manual thoroughly before attempting to install any

Cruisair equipment. If there are any statements in this manual

that you do not understand, contact the Dometic Environmen-

tal Applications Department (Dometic) for assistance. Phone

(804) 746-1313, Fax (804) 746-7248 (8:00am - 5:00pm

United States Eastern Time).

Notice

As of July 1, 1992, United States federal law prohibits the

intentional release of refrigerant gases into the environment,

including the R-22 refrigerant mostly used in Cruisair air

conditioning systems. Special care must be taken when

installing, charging and servicing Cruisair equipment to

prevent any loss of refrigerant.

Cruisair does not recommend the practice of using refrigerant

to purge air and moisture from the system at installation. This

formerly used practice of purging is in violation of United

States federal law.

Introduction

You have just purchased the first complete built-in marine air

conditioning system designed for self installation. We are

confident you will find the added comforts experienced in your

boat to be well worth the money spent. If, upon opening your

new system, you discover any parts are missing, contact your

dealer immediately.

Before attempting to install your new Zephyr (AC powered) or

Cuddy dc (DC powered) air conditioning system, you must

read this installation manual completely. Failure to perform

certain tasks in the proper sequence could result in an

inoperative system as well as a voided warranty.

Cuddy dc

The new Cuddy dc marine air conditioner is very similar to

the standard Zephyr but is unique in one way–it is designed to

be run on 12VDC battery power. Most of the installation,

operation and maintenance information in this manual applies

to both types of air conditioners, the AC voltage Zephyr and

the DC voltage Cuddy dc. Installation of either unit is nearly

identical with the exception of the power supply and how that

power is connected to the unit, control and pump. With that in

mind while reading this manual, please read the Installation,

Operation, and Maintenance sections titled “Zephyr and

Cuddy dc Units”, and especially the sections subtitled “for DC

5❖English

L-2028 Installation

housing an engine or generator, nor in a bilge, unless the

drain is connected properly to a sealed condensate or shower

sump pump. Failure to comply may allow bilge or engine room

vapors to mix with the air conditioners return air and contami-

nate living areas which may result in injury or death.

Consideration should be given to installing a trap in the

condensate drain line(s) so that normal discharge of conden-

sate can fill the trap and prevent the ingress of carbon

monoxide (CO) or other potentially harmful vapors.

Installation and servicing of this system can be hazardous

due to system pressure and electrical components. When

working on this equipment, always observe precautions

described in the literature, tags and labels attached to the unit.

Follow all safety codes. Wear safety glasses and work gloves

and place a fire extinguisher close to the work area. The

following is a summary of the labels on the unit:

! DANGER Electrical shock hazard. Disconnect voltage at

main panel or power source before opening any cover. Failure

to comply may result in injury or death.

! WARNING This component does not meet Federal require-

ments for ignition protection. Do not install in spaces contain-

ing gasoline engines, tanks, LPG/CPG cylinders, regulators,

valves or fuel line fittings. Failure to comply may result in injury

or death.

NOTICE This component is charged with hydrochlorofluoro-

carbon (HCFC) refrigerant R22. Effective July 1, 1992 it shall

be unlawful for any person to knowingly vent or otherwise

knowingly release any class 1 (CFC) or class 2 (HCFC)

substance as a refrigerant in a manner which permits such

substance to enter the atmosphere per the clean air act of

1990. Public law 101-549 Title IV Section 608-c. Failure to

comply may result in severe penalties, including fines and

imprisonment. Note: The Cuddy dc unit is charged with

R417A.

! WARNING To minimize the hazard of electrical shock and

personal injury, this component must be effectively grounded.

Refer to the installation guidelines for further information.

! WARNING The compressor and fan on the Cuddy dc air

conditioning unit are AC voltage components, running on

115VAC supplied by the DPM. The pump and 2-knob

mechanical control also run on 115VAC supplied by the DPM.

Disconnect voltage at main panel or power source before

opening any cover. Failure to comply may result in injury or

death.

Placement Of System

Selecting a good location for your air conditioner is the most

important part of your preparations. Be sure to consider the

size of the area you are cooling, the air distribution needs,

and the size of the unit you have chosen. Keeping in mind that

cool air has a tendency to fall, it is highly recommended that

you locate the supply air grill as high as possible in the cabin.

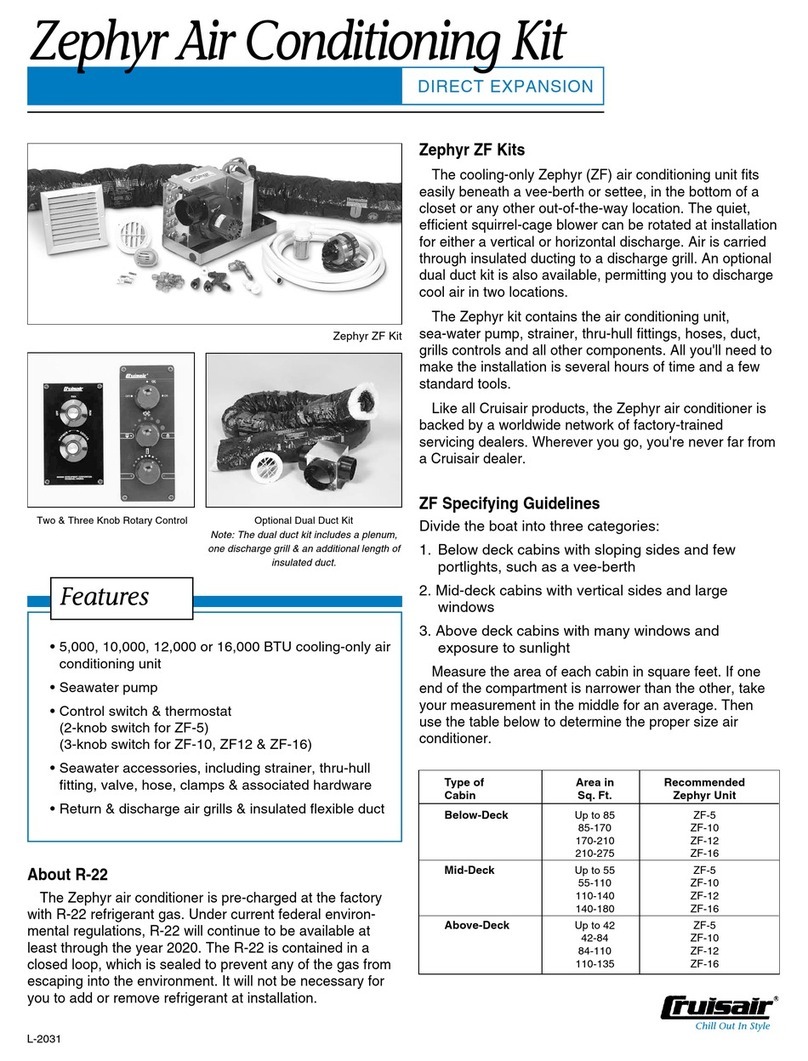

Figure 1a at the back of this manual shows the single duct

application and Figure 1b shows a dual duct application.

The air conditioning unit should be installed as low as

possible, but never in the bilge or engine room areas.

Insure that the selected location is sealed from direct

access to bilge and/or engine room vapors. Installing the

unit as low as possible (such as under a V-berth, dinette seat

or bottom of a locker) and ducting the supply air as high as

possible, creates an ideal air flow condition. This type of

installation will prevent short or premature cycling.

The unit should be positioned on a firm, level, horizontal

surface and the condensate drain line should run downward

from the unit to a suitable drain location. Plan all connections

which must be made including ducting, condensate drain,

seawater in and out, electrical power connections, location of

control, and seawater pump placement, to assure easy

access for routing and servicing.

Tools Required for Installation

• Screw drivers

• Pliers

• Pipe wrench

• Wire cutters/crimpers

• Drill & 7/8" bit

• Jig saw

• Duct tape

• Electrical tape

• Teflon tape

• Bedding compound to seal thru hull fittings

• Hardware to secure unit, pump, strainer, grills & control

panel

Spacing Allowances & Unit Dimensions

The following space allowances should be considered when

mounting the unit:

1. Allow a minimum of 6" (152mm) around the perimeter of

the unit in the area of the seawater and condensate drain

piping.

2. Allow a minimum of 3" (76mm) of air space in front of the

evaporator coil for the return air intake if it is adjacent to a

bulkhead.

3. Allow a minimum of 3" (76mm) of air space for the electric

blower motor ventilation. For Cuddy dc systems, allow at

least 1" (25mm) above DPM for adequate ventilation.

4. For flexible ducting connection, allow 2" (51mm) for the

duct ring, 1" (25mm) for the duct bend radius and add

diameter of the ducting to get the total clearance distance

(2" [51mm] + 1" [25mm] + duct diameter) as measured

from the blower outlet (this also applies to clearance

needed behind the supply air grill). Note that the blower

and duct ring can be positioned either vertically or

horizontally. See Figure 2 at the back of this manual.

6❖English

L-2028 Installation

These space allowances are suggested minimums. Enough

space should be allocated for installation and serviceability.

See Figure 2 at the back of this manual for space allowances

and unit dimensions.

How It Works

The air conditioning unit consists of four main components

and a refrigerant gas circulating through the system. The

BLOWER draws warm cabin air across the fins on the

EVAPORATOR where the heat from the air is transferred to

the refrigerant in the evaporator coil. As the refrigerant

evaporates from a liquid into a gas it absorbs the heat from

the cabin air. The COMPRESSOR then compresses the

refrigerant gas and pumps it through the outer tube in the

CONDENSER COIL. The seawater pump circulates cool

seawater through the inner tube in the condenser coil, this

cools the refrigerant in the outer tube and condenses it from a

gas into a liquid. The heat from the refrigerant is exchanged to

the seawater and discharged overboard. The liquid refrigerant

is then passed through the EVAPORATOR COIL and the

cycle repeats. Removing heat from the cabin air lowers its

temperature. The cooled air is blown through the ducting and

out the supply air grill(s). See Figure 3 at the back of this

manual for component identification.

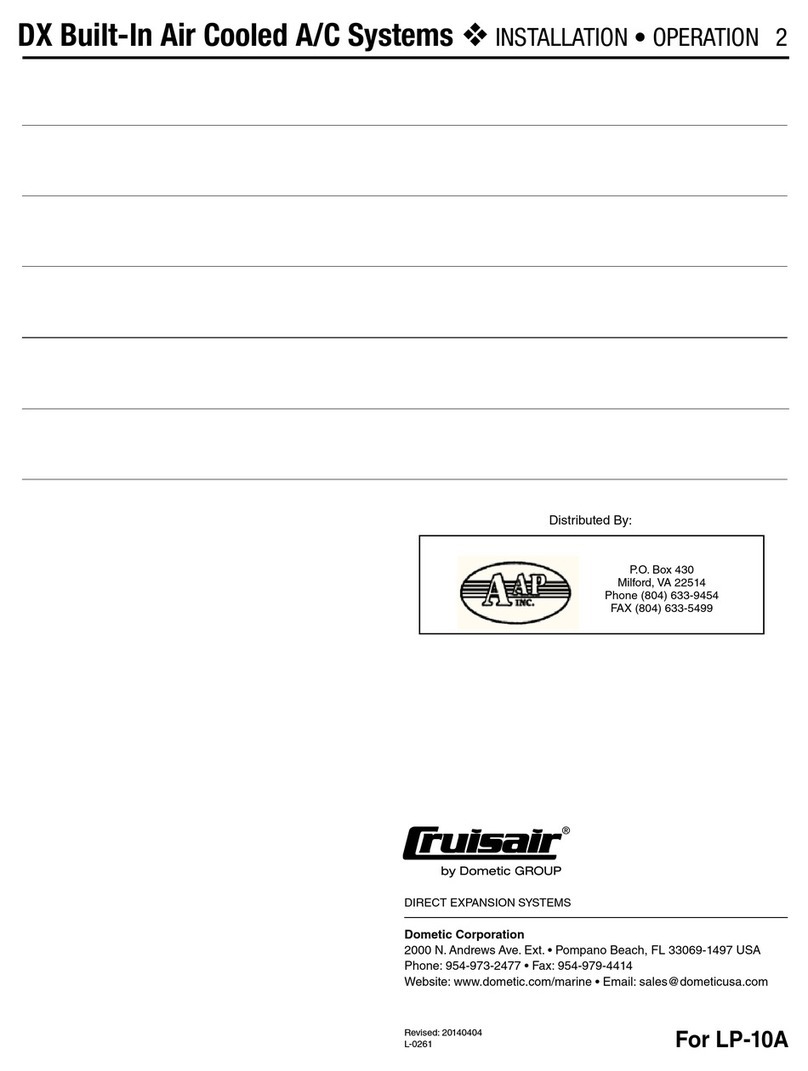

Mounting Brackets

The air conditioning unit is supplied with a base pan that also

serves as a condensate pan. Mounting clip brackets and

screws (4) are provided to secure the base pan onto a flat,

horizontal surface. See Figure 4 at the back of this manual.

Condensate Drains

The condensate drain pan is 1¾" high with two drain loca-

tions. During conditions of high humidity, condensate may be

produced at a rate of approximately ½gallon (1.9 liters) per

hour. With this in mind, it is important to route condensate

drains downward to a sump pump. It is not recommended to

route condensate drains to the bilge. After the condensate

drain installation is complete, test the installation by pouring a

quart of water into the pan and checking for good flow.

For installation of the condensate drain (refer to Figure 5 at

the back of this manual):

1. Remove the aft facing watertight plug from the base pan

of the air conditioning unit.

2. Slip the solid washer and the liquid-seal washer onto the

PVC fitting in that order.

3. Connect the fitting through the exposed hole in the base

pan with the locking nut.

4. Securely tighten with two (2) wrenches to provide a

proper seal.

5. Attach a 5/8" (16mm) I.D. reinforced hose to the hose

barb and secure with stainless steel hose clamps.

6. Install the condensate drain hose downhill from the unit

and aft to a sump - hose should have a trap.

7. Two drain fittings may be used and the hoses teed

together provided there is a minimum 2" (51mm) drop

from the bottom of the base pan to the tee connection.

Note:

Do not terminate condensate drain line within 3 feet (91cm) of

any outlet of engine or generator exhaust systems, nor in a

compartment housing an engine or generator, nor in a bilge,

unless the drain is connected properly to a sealed conden-

sate or shower sump pump.

Blower Assembly

Horizontal or vertical supply air discharge may be acheived by

rotating the blower. Its design allows the blower to be rotated

by removing the screws holding the blower plate to the

evaporator coil shroud. Rotate the blower to allow the most

direct flow of air to the supply air grill. To rotate the 10-16K

blowers, remove the two plastic plugs for access to the

mounting screws.

Supply & Return Air Grills

and Transition Boxes

As previously indicated, install the supply air grille(s) as high

as possible and the return air grille as low and close to the air

conditioning unit as possible to insure direct uninterrupted

airflow to the evaporator. In no instance should the supply are

grille discharge be directed towards the return air grille, as this

will cause the system to short cycle.

The cut out for the 3" (76mm) round supply air grille for the

3.5K unit is 3" (76mm) in diameter and the flange is 3

7

/

8

"

(99mm) in diameter. The cut out for the 4" (102mm) round

supply air grille for the 5K unit is 4" (102mm) in diameter and

the flange is 5½" (140mm) in diameter. The cut out for the

rectangular supply air transition box used with the 10 & 12K

units is 11

5

/

8

" (295mm) by 5

5

/

8

" (148 mm) and for the 16K unit

it is 13

5

/

8

" (346mm) by 5

5

/

8

" (148 mm). Connect the 6"

(152mm) or 7" (178mm) oblong duct ring to the transition box

by first placing the ring on the box and tracing the hole. Cut

the oblong hole out of the box. Secure the ring to the box with

rivets (trim ¼" [6mm] from ring flanges if necessary). Com-

pletely seal the joint between ring and box with silicone. A

minimum clearance of 3" (76mm) plus the duct diameter size

is required behind the grille for attaching the ducting (see

earlier section, “

Spacing Allowance and Unit Dimensions

”).

The cut outs for the return air grilles are as follows: 7-5/8"

(194mm) square for the 3.5K & 5K units, 11-5/8" (295mm)

square for the 10K & 12K units, and 13-5/8" (346mm) x 11-5/

8" (295mm) (width x height) for the 16K unit. The return air

grille should have a minimum of 4" (107mm) of clearance in

front of it, free from any furniture or other obstructions. The

return air filter, mounted to the front of the evaporator,

7❖English

L-2028 Installation

removes debris from the air prior to the air being drawn

across the evaporator coil and fins. Dust and lint can clog and

reduce airflow across the evaporator coil resulting in poor

performance. See the “

Maintenance

” section for filter cleaning

instructions.

Ducting

Good airflow is critical for the performance of the entire

system. It is highly dependent on the quality of the ducting

installation. The ducting should be run as straight, smooth and

taut as possible minimizing the number of 90 degree bends

(two tight 90 degree bends can reduce airflow by 25 percent).

The following is a summary of proper ducting connections:

1. Pull back the fiberglass insulation exposing the inner

mylar duct hose.

2. Slide the mylar duct hose around the mount ring until it

bottoms out.

3. Screw 3 or 4 stainless steel sheet metal screws through

the duct hose into the transition ring. Make sure to catch

the wire in the duct hose with the heads of the screws. Do

not use band clamps, as the hose will slide off.

4. Wrap duct tape around the ducting and ring joint to

prevent any air leaks.

5. Pull the insulation back up over the mylar to the ring and

tape this joint.

6. Remove excess ducting and use the same connection

method at the supply air grill.

Manual Control Panel Installation

The manual control panel should be located within cap tube

length of the air conditioning unit. The dimensions for the

2-knob panel is 3¼" (83mm) x 5½" (140mm). The cut out size

for the 2-knob panel is 2½" (64mm) wide by 4¾" (121mm) tall.

The 3-knob panel is configured either vertically or horizontally.

Dimensions for the 3-knob is 2

15

/

16

" (75mm) x 7

15

/

16

" (202mm).

The cut out size for the 3-knob panel is 2" (51mm) by

6¾"(171mm). (Refer to Figures 6 and 7 at the back of this

manual.) Once the cut out is made, carefully uncoil the copper

cap tube with return air sensor (copper bulb) and route the

control wires and cap tube through the hole and back to the

unit

using caution not to kink the cap tube

. Mount the

return air sensor into the clips provided on the evaporator coil.

If the return air sensor cannot be mounted on the evaporator

coil, mount it behind the return air grill. The sensor must be

mounted in the return air stream. Make electrical connections

according to the wiring diagrams provided. (See wiring

diagrams, Figures 8, 9, 10 and 11 at the back of this manual.)

Electrical Connections, Grounding & Bonding

for AC Powered Zephyr

All Zephyr units have a five position terminal strip mounted

inside the electric box. The terminal strip is labeled for proper

connections of the electrical supply, ground wires and pump

circuits. Wiring diagrams are provided in the electrical box and

in this manual. The correct size circuit breaker should be used

to protect the system as specified on the air conditioning unit’s

data plate label. A minimum of 12 AWG boat cable should be

used to supply power to the air conditioning unit and to the

seawater pump (see next paragraph). All connections to the

terminal strip shall be made with ring terminals supplied with

the Zephyr kit. Turn off AC (alternating current) power

supply circuit breaker before opening electrical box and

accessing the terminal strip.

Each air conditioning unit installed requires its own dedicated

circuit breaker. If there is only one air conditioning unit

installed, the seawater pump does not require a circuit

breaker; the wiring from the seawater pump is connected to

the terminal strip on the unit. (See wiring diagrams, Figures 8,

9 and 10 at the back of this manual.) A minimum of 12 AWG

boat cable should be used to extend the wires on the pump, if

necessary, using the butt slices included with the kit. If two or

more air conditioning units use the same seawater pump, the

pump wires will be connected to a pump relay panel (PRP)

which in turn has its own dedicated circuit breaker (see the

wiring diagram furnished with the PRP). Any electrical

connections in the bilge below the waterline should use heat

shrink type butt splices.

The air conditioning unit must be connected to the boat’s

bonding system to prevent corrosion due to stray electrical

current. All pumps, metallic valves and fittings in the seawater

circuit that are isolated from the air conditioning unit by PVC

or rubber hoses must be individually bonded to the boat’s

bonding system also. This will help eliminate any possibility of

corrosion due to stray current.

Note: Failure to properly ground and bond the

system will void the warranty!

Electrical Connections, Grounding & Bonding

for DC Powered Cuddy dc

All Cuddy dc units are connected by polarized plugs to the

Dedicated Power Module DPM, pump, and control (available

separately or in kit). These plugs are configured unique to

each component. Wiring diagrams and schematics are

provided in this manual (see Figure 11 at the back of this

manual). A 60 amp circuit breaker or fuse should be installed

at the positive side of the battery to protect the wires. Any

electrical connections in the bilge below the waterline should

be heat shrink type.

Turn off DC power supply circuit breaker before making

connections.

The air conditioning unit and its components must be con-

nected to the boat’s bonding system to prevent corrosion due

to stray electrical current. There is a bonding ground stud on

the Dedicated Power Module. This stud must be connected to

the vessel’s bonding stud, which is typically on the engine

8❖English

L-2028 Installation

block. This connection must be made per ABYC specifica-

tions. All pumps, metallic valves and fittings in the seawater

circuit that are isolated from the air conditioning unit by PVC

or rubber hoses must be individually bonded to the boat’s

bonding system also. This will help eliminate any possibility of

corrosion due to stray current.

Note: Failure to properly ground and bond the system will

void the warranty!

Electrical System and Wiring for DC Powered

Cuddy dc

Dometic recommends a separate set of batteries dedicated

for the Cuddy dc air conditioning system. Deep cycle AGM or

Gel Cell batteries are the best for this application. If need be,

please contact your Dometic dealer for assistance in sizing

batteries.

The Cuddy dc kit contains the Dedicated Power Module

(DPM). The DPM is meant to be used for the Cuddy dc

system only and is sized to do so (see Figure 14 at the back

of this manual for DPM specifications).

When connecting the DPM to the batteries, maintain correct

wire size as shown in the DC Wire Sizing Table (see Figure 15

at the back of this manual), keep wire runs as short as

possible, and with as few intermediate connections as

possible, to avoid unnecessary resistance or voltage drop.

See wiring diagram Figure 11 for location of customer-

installed 60 amp fuse. Use an ignition protected fuse holder if

installed in the engine compartment or in any area with

flammable or compressed gasses or liquids (see the Safety

Considerations section of this manual for more information). A

standard ABYC approved battery disconnect switch is also

recommended and should be used any time the system

needs servicing. Do not forget to maintain proper color

coding, (red = positive, black = negative) to aid in future

electrical troubleshooting. If the wires are incorrectly con-

nected (positive and negative reversed), the air conditioning

unit will not start and the DPM will be damaged.

The DPM is wired to the FAN setting on the two-knob switch

assembly and is energized only when the Cuddy dc is

running (see the Operation section of this manual). For DC

wire sizing, see Figure 15 at the back of this manual.

As batteries age, their peak voltage lowers and they dis-

charge quicker. This, of course, can affect the air conditioner

performance as well as other DC devices. The battery

condition should be maintained and monitored regularly and

weak batteries should be replaced. A battery isolator, com-

biner or selector switch will allow simultaneous charging while

preventing the discharge of a fully charged battery into a

depleted one.

Over current protection, in addition to fuse provided, must be

supplied for the ungrounded conductor at the main switch-

board, per ABYC E-9. Use a 60 amp breaker for 12 VDC

systems. This provides protection from possible short circuits.

When dockside, the Cuddy dc unit can operate against the

batteries while using the AC battery charger (50 amp min) as

a backup (most marine battery chargers will shut off when the

battery is fully charged).

Ensure that all DC electrical connections are made in

compliance with American Boat and Yacht Council (ABYC)

standards section E-9.

Notice and ABYC Standards:

Field wiring must comply with ABYC electrical standards.

Power to the unit must be within the operating voltage range

indicated on the data plate. Properly sized fuses and circuit

breakers must be installed for branch circuit protection. See

equipment rating plate for maximum size. All air conditioning

units must be effectively grounded to minimize the hazard of

electric shock and personal injury. The following standards

apply:

1. AC (alternating current) grounding (green) wire must be

provided with the AC power conductors and connected to

the ground terminal (marked “GRND”) at the AC power

input terminal block of the unit(s), per ABYC standard E-8.

2. Connections between the vessel’s AC system grounding

conductor (green wire) and the vessel’s DC (Direct

Current) negative or bonding system should be made as

part of the vessel’s wiring, per ABYC standard E-9.

3. When servicing or replacing existing equipment contain-

ing a chassis-mounted “ground” stud, the service person

or installer must check the vessel’s wiring for the exist-

ence of the connection required in item 2 above.

ABYC standards are available from:

American Boat and Yacht Council

613 Third Street, Suite 10

Annapolis, MD 21403

Phone: (410) 990-4460, Fax: (410) 990-4466

Seawater Pump and Plumbing

Several guidelines should be followed during the installation

of the seawater system. Since the circulation pump is

centrifugal and not self-priming, it must be mounted so that it

is always at least one foot below the water line regardless of

which tack the vessel is on. Pump may be mounted horizon-

tally or vertically, however the discharge must always be

above the inlet. Pump head should be rotated toward the

direction of water flow.

Install the seawater speed scoop

intake as far below the water line and as close to the keel

as possible in any application, but especially on a

sailboat, to keep the intake in the water when the boat

heels over so that air does not get into the system.

The

speed scoop intake must face forward and not be shared with

any other pump. A seawater strainer is mandatory between

9❖English

L-2028 Installation

the shut off valve (seacock) and the pump to protect the pump

from any foreign matter.

Failure to install a seawater

strainer will void the pump warranty

. The seawater system

should be installed with an upward incline from the speed

scoop & seacock, through the strainer, to the inlet of the pump

and then up to the inlet of the air conditioning unit’s condenser

coil. The discharge from the air conditioning unit should then

run to the seawater outlet thru-hull fitting which should be

located where it can be visually checked for water flow and as

close as practicable to the waterline to reduce noise. All hose

connections shall be secured by means of double/reversed

stainless steel hose clamps. Use teflon tape on all threaded

connections. The following is a summary of the seawater

system installation:

1. Install the speed scoop thru-hull inlet as close to the keel

and as far below the water line as possible, facing forward.

Bed the scoop with a marine sealant designed for

underwater use.

2. Install a bronze, full flow seacock on the speed scoop

thru-hull inlet.

3. Install a seawater strainer below the level of the pump

with access to filter.

4. Mount the pump above the strainer and at least one foot

below the waterline.

5. Connect the seacock and strainer with an uphill run of

5/8" reinforced marine grade hose.

6. Connect the discharge from the pump uphill to the bottom

inlet of the air conditioning unit’s condenser coil with 5/8"

reinforced marine grade hose. Connect the discharge

from the condenser coil to the overboard discharge thru-

hull fitting with 5/8" reinforced marine grade hose.

7. Avoid loops, high spots or the use of 90° elbows with

seawater hose (each 90° elbow is equivalent in pressure

drop to 2.5' of hose and a 90° elbow on the pump outlet is

equivalent to 20' of hose).

8. Double clamp all hose connections with stainless steel

clamps, reversing the clamps.

9. Use teflon tape on all threaded connections.

10.

Connect all metallic parts in contact with seawater to

the vessel’s bonding system including the speed

scoop inlet, strainer, pump and the air conditioner

.

Refer to Figure 12, 13a , and 13b at the back of this manual

for seawater kit installation drawings.

Installation Checklist

(review prior to and after installation)

Seawater cooling system

• Speed scoop located as far below the water line and as

close to the keel as possible

• Shut off valve and speed scoop properly sealed and tight

• Seawater pump at least one foot below water line and

securely mounted

• Strainer mounted below pump with access to filter

• Double/reversed stainless steel hose clamps on all hose

connections

• Teflon tape on all threaded connections

• Hose runs uphill from speed scoop to strainer, pump and

air conditioning unit

• Water flowing freely from overboard discharge while pump

is running

Air Conditioner Unit Mounting

• Not in engine room or bilge areas, must be sealed away

from exhaust or fumes

• Proper spacing allowed around unit

• Attached to solid level platform with four hold down clips

provided

• Condensate drain routed aft and down hill to a sealed sump

(not bilge), and should have a trap

Grills and Ducting

• Supply air grill mounted as high as possible

• Return air grill mounted as low and as close to the unit as

possible

• Return air grill mounted away from exhaust and bilge vapors

• Ducting is pulled taut, straight and properly connected with

no excess

Electrical for AC Powered Zephyr

• All butt connections on pump wire tightly crimped and heat

shrunk

• AC power source installed and grounded/bonded in

accordance with ABYC standards

• Control wires connected to terminal strip with ring

terminals

Electrical for DC Powered Cuddy dc

• All polarized plugs connected securely with an audible

“snap”

• DC power source installed and grounded/bonded

inaccordance with ABYC standards

• Bonding ground stud on Dedicated Power Module con-

nected to vessel’s bonding system per ABYC

10 ❖English

L-2028 Operation

Zephyr and Cuddy dc Units • Operation

Operation

Manual Control Panel Operation:

2-knob (2KB), 3.5-5K units; 3-knob (3KB), 10, 12, 16K

units, see figures 6 & 7.

1. Ensure seawater intake ball valve (seacock) is open.

2. Turn top (MODE) control knob to OFF.

3. Turn on air conditioning unit circuit breaker. If the seawater

pump has its own circuit breaker, turn that on too.

4. Turn top (MODE) control knob to FAN, this energizes the

fan (and the DPM in Cuddy dc systems).

5. Turn THERMOSTAT control knob to the coolest position

by rotating it fully clockwise.

6. Turn middle (FAN) control knob to highest setting

(for 3KB switch only).

7. Verify that the fan is running and that there is steady

airflow out of the supply air grill.

8. Turn top (MODE) control knob to RUN (for 2KB switch)

and ON (for 3KB switch). This will start the compressor

and seawater pump.

9. Check for a steady solid stream of seawater from the

overboard discharge.

10. To set the THERMOSTAT, allow sufficient time for the unit

to cool the area to the desired temperature. When the

area is sufficiently cooled, turn the thermostat knob slowly

toward the center position until it clicks once. The

thermostat is now set to maintain a constant temperature.

Important

Do not turn the unit off and immediately turn it back on. Wait

at least 30 seconds (2 minutes for the Cuddy dc) for system

refrigerant pressures to balance.

Troubleshooting Guidelines

Before you call for service, review this list. It may save you

time and expense. This list contains common occurrences

that are not a result of defective workmanship or materials. If

you need service after trying these procedures, call your

nearest Cruisair dealer.

Problem: System will not start.

Possible Reason/Solution

1. Air conditioner circuit breaker is off. Turn circuit breaker

on at ship’s panel.

2. Wiring at terminal strip is miswired (VAC unit only).

Check wiring diagram; correct if necessary.

3. Input line voltage is insufficient (VAC unit only). Check

power source for proper voltage. Check wiring and

terminals for proper sizes and connections.

4. Cuddy dc plugs are not connected tightly (DC unit

only). Check polarized plugs from unit to pump, power

module, and control. There should be an audible “snap”

when plugs go together.

5. Batteries are not fully charged (DC unit only). Turn

Cuddy dc unit off and charge battery bank.

6. DC power wires are incorrectly sized (DC unit only).

See the “Electrical System and Wiring for DC Powered

Cuddy dc” section of this manual. Ensure that DC power

wires are sized and connected correctly.

7. Dedicated Power Module (DPM) is in lockout mode

(DC unit only).

The DPM has a protective overload lockout feature that

will cause it to shutdown in case of a problem. When this

occurs, turn Cuddy dc off and wait 2 minutes before

turning back on. If that does not solve the problem, then

continue reading:

a) If DPM has overheated (≥167°F [75°C]) then ensure that it

has at least one inch of air space above unit for, and is in

an area that provides, proper ventilation.

b) If compressor has overheated then check water pump,

strainer and hoses. When operating properly, there should

be a steady stream of water from the overboard dis-

charge. Strainer may need cleaning. Ensure that hoses

are not kinked or restricted in some other way. Pump

should come on with the compressor when control is set

to RUN.

c) If refrigerant pressure is too high, then turning the system

off for 2 minutes should correct that by allowing pressure

to equalize. Note: Turning the Cuddy dc on and off too

quickly may cause a high-pressure shutdown. During

normal operation wait at least 2 minutes from the time

control is turned off until it is turned back on.

d) If DC voltage is too high (>16-17VDC) or too low

(<10.5VDC), then check battery bank for correct charge.

Charge batteries if need be. Note: Turn Cuddy dc off and

charge batteries for 5 minutes. Try turning Cuddy dc on

again. If it runs, then that is a good indicator the batteries

were low. Fully charge batteries at this time.

e) If there is a dead short in the wiring, then disconnect

power supply and repair wiring.

If, after trying all of the above, the fan runs, but the

compress and pump do not, then that is a good indicator

there is a problem with the compressor and/or pump.

Whereas, if the fan does not come on at this time, then

that is a good indicator there is a problem with the fan or

the DPM. Either way, call for a service technician – please

see listing in back of this manual.

11 ❖English

L-2028 Operation

Problem: No cooling.

Possible Reason/Solution

1. Selector knob may not be in “cool” position. Reset

selector knob.

2. Temperature set point is above ambient temperature.

Lower temperature setting.

3. Obstructed water flow. Clean seawater strainer. Check

for good steady flow from overboard discharge.

4. Pump may be air locked. Remove hose from pump

discharge to purge air from line.

5. Coil iced. See below.

Problem: Coil iced.

Possible Reason/Solution

1. Thermostat set point is too low. Check setting on

temperature knob. If setting is extreme for conditions,

raise set point.

2. Improper air flow. Clean return air filter or remove

obstructions from return air stream. Check for crushed or

restricted ducting. Ducting run must be as straight as

possible; remove any excess ducting.

Problem: Short cycling compressor.

Possible Reason/Solution

1. Cold supply air returning directly to return air grill.

Redirect supply air so that it is not directed into the return

air stream.

Problem: System runs continuously.

Possible Reason/Solution

1. Port hole or hatch open. Close all port holes and

hatches.

2. Thermostat setting is excessive for conditions. Raise

thermostat setting to cycle compressor.

12 ❖English

L-2028 Maintenance

Zephyr and Cuddy dc Units • Maintenance

Seawater Strainer

Ensure that the pump receives adequate seawater flow by

regularly cleaning the strainer basket. Periodically check the

overboard discharge for a steady stream of water. Check

seawater intake speed scoop for obstructions. Make sure

hoses are not looped, kinked or crushed.

Condenser Coil Cleaning

Coils can become fouled over a period of time due to marine

growth or scale build-up. This both obstructs water flow and

prohibits proper heat transfer. To clean coils, flush with a 5%

muriatic or hydrochloric acid and fresh water solution.

Disconnect system hoses from coil and pump the solution

through until clean. Rinse with fresh water and reconnect

hoses. Follow manufacturer’s safety guidelines for all cleaning

solutions.

Return Air Filters

Check the return air filter about once a month and clean as

necessary. To clean the filter, remove it from the unit, rinse

with water, air dry and reinstall.

Winterization

There are several methods of winterization, some of which

work better than others. The four various methods employed

using a 50/50 non-polluting biodegradable anti-freeze/water

solution are:

1. Pumping of anti-freeze solution into the overboard thru-

hull fitting, and discharging through the intake thru-hull

fitting.

2. Use of the seawater pump to pump anti-freeze solution

through the system and discharging through the over-

board thru-hull fitting. Close seacock, remove hose from

strainer discharge, raise hose above pump (so pump

does not lose its prime) and pour in anti-freeze solution.

Pump solution through system. The strainer and hose to

seacock will also need to be drained of water.

3. Use of pressurized air injected at the overboard discharge

fitting and the water being discharged through the

seawater intake fitting.

4. Use of pressurized air to force water from the intake

through the overboard discharge.

Note:

Collect all discharged liquids and recycle or dispose of in a

proper manner.

Any method that causes the anti-freeze solution to flow

downward is the method of choice. By this means, the anti-

freeze solution will displace any water trapped and eliminate

the possibility of freezing in hidden areas.

In addition, since the seawater pump utilizes a magnetically

driven impeller, the impeller should be removed from the wet

end assembly, wiped with an alcohol solution, and stored in a

warm, dry area until commissioning takes place.

13 ❖English

L-2028

Zephyr and Cuddy dc Kits • Parts List

Cuddy dc Kits

CD3.5HV 12VDC

Condensate hose barb assembly with 4 mounting brackets included with

unit.

P/N Qty Description

222-110094 1 DPM Dedicated Power Module 12V with

MX-Plug

222-110110 1 MCP 2-KB CDH V BL MYL 12V 150L 2-Knob

Control

225-410108 1 Pump PML150 with MX150L-Plug 115V no

fittings

-OR- -OR- (kit has one pump, PML150 or PML250)

225-410112 1 Pump PML250 with MX150L-Plug 115V no

fittings

Extension Cables with Plugs for

Cuddy dc Systems

222-120200 1 3m (9.8') Cable with Plugs from Cuddy dc to

DPM

222-120201 1 6m (19.7') Cable with Plugs from Cuddy dc to

DPM

222-120202 1 3m (9.8') Cable with Plugs for Cuddy dc to

Pump

Zephyr ZF3.5 Kits

ZF3.5 115V

Condensate hose barb assembly with 4 mounting brackets included with

unit.

P/N Qty Description

222-110087 1 ZFSA1-XB 2-Knob Control dual voltage

225-500226 1 Pump PML250 115V no fittings

Air Distribution Kits

Kits (sold separately) are for use with Cuddy dc or Zephyr 3.5K units only:

226-000301 Kit Air Distribution Kit - Black (includes next 3 items)

333437 1 3" Round Plastic Supply Air Grill, Euro, Black

217-000773 1 8x8TRAF Alum Return Air Grill w/Filter, Black

226-600045 10' 3" Ducting, Insulated Flexible

226-000300 Kit Air Distribution Kit - White (includes next 3

items)

333439 1 3" Round Plastic Supply Air Grill, Euro, White

217-000728 1 8x8 RAF Alum Return Air Grill w/Filter, White

226-600045 10' 3" Ducting, Insulated Flexible

Zephyr ZF5 Kits

ZF5 115V, or ZF5CK 220V/50Hz

Condensate hose barb assembly with 4 mounting brackets included with unit.

P/N Qty Description

226-600014 5' 4" Ducting, Insulated Flexible

330571 1 Grill, Circular Off White

332743 1 Grill, 8x8TRA Anodized

222-110087 1 ZFSA1-XB 2-Knob Control dual voltage

334220 1 Thru Hull, 5/8" Plastic

226-600006 25' Hose, Seawater 5/8"

335360 1 Bush, PVC Red 1/2" MPT x 1/4" FPT

335120 3 Adapt, PVC 1/2" MPT x 1/2" HB

335080 2 Adapt, PVC 1/2" FPT x 1/2" HB

225-600021 1 Strainer (w/ Bracket 1/2" FPT)

332822 PDS-250 115V Seawater Pump

-OR- 1 -OR- (kit has one pump, 115V or 220V)

332831 PDS-250C 220V Seawater Pump

369617 17 Clamp, Hose #06SS Thin

330482 1 Ball Valve 1/2" SS Hndl (Bronze)

369699 1 Strainer, Speed Scoop 1/2" Bronze

338439 3 Terminal Butt Splice 16-14 Blue

336750 6 Terminal Ring 10-12 Yellow

Zephyr ZF10 Kits

ZF10 115V, or ZF10CK 220V/50Hz

Condensate hose barb assembly with 4 mounting brackets included with

unit.

P/N Qty Description

226-600015 10' 6" Ducting, Insulated Flexible

229-800025 1 Transition Box ABS 12x6x4.5

228-700017 1 6" ABS Oblong Transition Ring

217-300131 1 12x6TV Alum Supply Air Grill

217-300125 1 12x12TRA Alum Return Air Grill

222-110088 ZFSA1-ZB 115V 3-Knob Mech. Control

-OR- 1 -OR- (kit has one control, 115V or 220V)

222-110093 ZFSA1-ZCB 220V 3-Knob Mech. Control

334220 1 Thru Hull, 5/8" Plastic

226-600006 25' Hose, Seawater 5/8"

335360 1 Bush, PVC Red 1/2" MPT x 1/4" FPT

335120 3 Adapt, PVC 1/2" MPT x 1/2" HB

335080 2 Adapt, PVC 1/2" FPT x 1/2" HB

225-600021 1 Strainer (w/ Bracket 1/2" FPT)

332822 PDS-250 115V Seawater Pump

-OR- 1 -OR- (kit has one pump, 115V or 220V)

332831 PDS-250C 220V Seawater Pump

369617 17 Clamp, Hose #06SS Thin

330482 1 Ball Valve 1/2" SS Hndl (Bronze)

369699 1 Strainer, Speed Scoop 1/2" Bronze

338439 3 Terminal Butt Splice 16-14 Blue

336750 6 Terminal Ring 10-12 Yellow

Optional Dual Duct Kit

226-600014 10' 4" Ducting Insulated Flexible

229-000029 1 Plenum Tee Box, 6", 6", 4"

339284 1 4" Plastic Grill, White

14 ❖English

L-2028

Zephyr ZF12 Kits

ZF12 115V, or ZF12CK 220V/50Hz

Condensate hose barb assembly with 4 mounting brackets included with unit.

P/N Qty Description

226-600015 10' 6" Ducting, Insulated Flexible

229-800025 1 Transition Box ABS 12x6x4.5

228-700017 1 6" ABS Oblong Transition Ring

217-300131 1 12x6TV Alum Supply Air Grill

217-300125 1 12x12TRA Alum Return Air Grill

222-110088 ZFSA1-ZB 115V 3-Knob Mech. Control

-OR- 1 -OR- (kit has one control, 115V or 220V)

222-110093 ZFSA1-ZCB 220V 3-Knob Mech. Control

334220 1 Thru Hull, 5/8" Plastic

226-600006 25' Hose, Seawater 5/8"

335360 1 Bush, PVC Red 1/2" MPT x 1/4" FPT

335120 3 Adapt, PVC 1/2" MPT x 1/2" HB

335080 2 Adapt, PVC 1/2" FPT x 1/2" HB

225-600021 1 Strainer (w/ Bracket 1/2" FPT)

332822 PDS-250 115V Seawater Pump

-OR- 1 -OR- (kit has one pump, 115V or 220V)

332831 PDS-250C 220V Seawater Pump

369617 17 Clamp, Hose #06SS Thin

330482 1 Ball Valve 1/2" SS Hndl (Bronze)

369699 1 Strainer, Speed Scoop 1/2" Bronze

338439 3 Terminal Butt Splice 16-14 Blue

336750 6 Terminal Ring 10-12 Yellow

Optional Dual Duct Kit

226-600014 10' 4" Ducting Insulated Flexible

229-000029 1 Plenum Tee Box, 6", 6", 4"

339284 1 4" Plastic Grill, White

Zephyr ZF16 Kits

ZF16 115V, or ZF16CK 220V/50Hz

Condensate hose barb assembly with 4 mounting brackets included with unit.

P/N Qty Description

226-600000 10' 7" Ducting, Insulated Flexible

229-800026 1 Transition Box ABS14x6x4.5

228-700019 1 7" ABS Oblong Transition Ring

217-300134 1 14x6TV Alum Supply Air Grill

217-000221 1 14x12TRA Alum Return Air Grill

222-110088 ZFSA1-ZB 115V 3-Knob Mech. Control

-OR- 1 -OR- (kit has one control, 115V or 220V)

222-110093 ZFSA1-ZCB 220V 3-Knob Mech. Control

334220 1 Thru Hull, 5/8" Plastic

226-600006 25' Hose, Seawater 5/8"

335120 3 Adapt, PVC 1/2" MPT x 1/2" HB

335080 2 Adapt, PVC 1/2" FPT x 1/2" HB

225-600021 1 Strainer (w/ Bracket 1/2" FPT)

300823 1 Adapt, PVC 3/4" MPT x 1/2" HB

332724 1 Coupling, PVC 3/4" FPT x 3/4" FPT

332823 PDS-500 115V Seawater Pump

-OR- 1 -OR- (kit has one pump, 115V or 220V)

332824 PDS-500C 220V Seawater Pump

369617 17 Clamp, Hose #06SS Thin

330482 1 Ball Valve 1/2" SS Hndl (Bronze)

369699 1 Strainer, Speed Scoop 1/2" Bronze

338439 3 Terminal Butt Splice 16-14 Blue

336750 6 Terminal Ring 10-12 Yellow

Optional Dual Duct Kit

226-600014 10' 4" Ducting Insulated Flexible

229-800428 1 Plenum Tee Box, 7", 7", 4"

339284 1 4" Plastic Grill, White

15 ❖English

Owner’s Limited Warranty

As hereinafter described, Dometic Environmental Corporation limits the duration of any implied warranty to the duration

of the underlying express warranty and also disclaims any liability for consequential or incidental damages arising from

any application, installation, use or malfunction of any warranted product.

Section I

What does the Limited Warranty cover?

Products manufactured by Dometic Environmental Corpora-

tion (Dometic) are under limited warranty to be free from

defects in workmanship or materials under normal use and

service with the obligation of Dometic under this limited

warranty being limited to replacing or repairing any

component(s) which shall disclose defects within the time

limits defined in Section III and which, upon examination by

Dometic, shall appear to the satisfaction of Dometic to be

defective or not up to specifications.

This Limited Warranty is made in lieu of all other express

warranties, obligations, or liabilities on the part of

Dometic. In addition, Dometic shall not be responsible

for any incidental or consequential damages.

In those

instances in which a cash refund is made, such refund shall

effect the cancellation of the contract of sale without reserva-

tion of rights on the part of the purchaser. Such refund shall

constitute full and final satisfaction of all claims which

purchaser has or may have against Dometic due to any

actual or alleged breach of warranty, either express or

implied, including, without limitation, any implied

warranty of merchantability or fitness for a particular

purpose. Some states do not allow the exclusion or limita-

tion of incidental or consequential damages so the above

limitation may not apply to you. The terms and conditions of

this warranty shall be governed by the laws of the Common-

wealth of Virginia.

The Dealer is not an agent for Dometic except for the

purpose of administering the above warranty to the extent

herein provided, and Dometic does not authorize the dealer

or any other person to assume for Dometic any liability in

connection with such warranty, or any liability or expense

incurred in the replacement or repair of its products other

than those expressly authorized herein. Dometic shall not be

responsible for any liability or expense except as is specifi-

cally authorized and provided in this section.

Dometic reserves the right to improve its products through

changes in design or material without being obligated to

incorporate such changes in products of prior manufacture,

and to make changes at any time in design, materials, or

part of units of any one year's model, without obligation or

liability to owners of units of the same year's model of prior

manufacture.

This warranty gives you, the purchaser, specific legal rights,

and you may also have other rights which vary from state to

state. You also have implied warranty rights, including an

implied warranty of merchantability, which means that your

product must be fit for the ordinary purposes for which such

goods are used.

The duration of any implied warranty

rights is limited to the duration of the express warranty

as found in Section III.

Some states do not allow limitations

on how long an implied warranty lasts, so the above limita-

tion may not apply to you.

Section II

What does this Limited Warranty not cover?

This Warranty Shall Not Apply to:

1. Failures resulting from improper installation or use

contrary to instructions.

2. Failures resulting from abuse, misuse, accident, fire, or

submergence.

3. Any part manufactured by Dometic which shall have

been altered so as to impair its original characteristics.

4. Any parts which fail as a result of misuse, improper

application or improper installation.

5. Items not manufactured by Dometic, i.e., items which are

purchased from another manufacturer and supplied as

received by Dometic without alteration or modification

except as any part of an Dometic-manufactured unit or

component.

6. Components or parts used by or applied by the pur-

chaser as an integral part of products not manufactured

by Dometic.

7. Warranty does not cover damage to components that

comprise a Custom Wrapped Box Evaporator refrigera-

tion system (aka: catch boxes, fish boxes, etc.) when the

box is installed in such a way that the customer can

move it. These damages may include, but are not limited

to: crimped refrigerant linesets (copper tubing or flexible

linesets), refrigerant leaks, moisture ingression into the

refrigeration system, subsequent damage to condensing

unit from being operated with low refrigerant charge or

moisture in the system, broken refrigerant connections,

broken thermostat sensors, and/or broken constant

pressure valves.

Installation and application of Dometic components is not

warranted by Dometic because Dometic has no control or

authority over the selection, location, application, or installa-

tion of these components.

Section III

What is the period of coverage?

See the Limited Warranty Periods, document # L-0694, for

the period of coverage.

16 ❖English

L-0123 Revised: 6-5-06

All Dometic components bear a data plate on which there

are model and serial numbers. The serial number is date

coded. To determine whether or not any Dometic component

is in warranty, proceed as follows:

1. Determine the manufacture date of the component from

the serial number on the data plate. If you are not familiar

with the date code, write or call the Dometic Customer

Service Department at (804)746-1313, to obtain the

manufacture date. The hours of the Customer Service

Department are 8:00 am - 5:00 pm (USA, Eastern Time

Zone) Monday through Friday excluding holidays.

2. It is possible that there might exist a considerable time

lag between the date a component is manufactured and

the date it is put in service. In such instances, the date of

manufacture could indicate that the item is out of

warranty. However, based on the date the equipment is

first put in service, the item may still be covered by the

Dometic warranty described in Section I. For proof of

date put in service, Dometic will require a copy of the bill

of sale of the Dometic equipment from the installer or

new boat dealer to the original owner.

Section IV

How do you get service? Please Read the follow-

ing Warranty Procedure.

WARRANTY PROCEDURE

If the failure of a Dometic component is determined to be

covered under the Dometic warranty and the time in service

is determined to be within the warranty time limit, the owner

has the following three options:

1. Preferred option: Have a Dometic authorized Servicing

Dealer perform the work needed. The customer should

call Dometic's Service Department for a recommenda-

tion as to the closest dealer. If the customer already

knows an authorized servicing dealer, the dealer should

be contacted directly.

2. If the customer contacts Dometic's Service Department

for a Servicing Dealer and Dometic has no one in that

particular area, Dometic will authorize the use of a local

service company and Dometic will work with the local

company to assist in any way possible.

3. The customer may send his equipment back to the

factory to have the repair work done. Dometic will make

every effort to return the equipment to the customer

within a three week time period. If the claim represents a

legitimate warranty problem, Dometic will pay the freight

both ways. Dometic prefers option one and two, if at all

possible.

The customer may contact the Dometic Service Department

at (804) 746-1313.

WARNING

Dometic Environmental Corporation (Dometic) manufacturers of Cruisair, Dometic

Auxiliary A/C, Dometic Refrigerators and Freezers, Eskimo Ice, Grunert, Marine

Air, and Sentry products, makes the following safety warnings concerning the

application, installation, use and care of its products. Although these warnings are

extensive, there may be specific hazards which may arise out of circumstances

which we have not outlined herein. Use this as a guide for developing an

awareness of potential hazards of all kinds. Such an awareness will be a key

factor in assuring your SAFETY and comfort.

ELECTRICITY - Many Dometic products operate on 115, 230 or 440 volt AC

power. Such voltages can be LETHAL; therefore, the chassis, cabinets, bases,

etc., on all components must be grounded together and connected to the vessel's

grounding system. Sparks can occur as switches, thermostats and relays open

and close in the normal operation of the equipment. Since this is the case,

ventilating blowers for the removal of hazardous fumes or vapors should be

operated at least 5 minutes before and during operation of any Dometic product or

group of Dometic products. All electrical connections must be covered and

protected so accidental contact cannot be made by persons using the equipment,

as such contact could be LETHAL.

ELECTROLYSIS - Electrical leakage of any component can cause electrolytic

deterioration (electrolysis) of thru-hull components which could result in leakage

serious enough to sink a vessel which could result in loss of life. All Dometic

components must be kept clean and dry and checked periodically for electrical

leakage. If any electrical leakage is detected, the component should be replaced

or the fault causing the leakage corrected before the component is put back into

service.

GAS - Dometic Air Conditioning and Refrigeration components utilize R-22

(Chlorodifluoromethane), R134a refrigerant (Tetrafluoroethane), R-407C (which

contains Diflouromethane [HFC-32], Pentafluoroethane [HFC125], and 1.1.1.2 -

Tetrafluoroethane [HFC134a]), R404A (R125/R143a/R134 [44%/52%/4%]), or

R417a, which are non-toxic, non-flammable gases; however, these gases contain

no oxygen and will not support life. Refrigerant gas tends to settle in the lowest

areas of the compartment. If you experience a leak, evacuate all personnel, and

ventilate area. Do not allow open flames in the area of leaks because refrigerant

gas, when burned, decomposes into other potentially LETHAL gases. Refrigerant

components operate at high pressure and no servicing should be attempted

without gloves, long-sleeved clothing and eye protection. Liquid refrigerant gas

can cause severe frost burns to the skin and eyes.

VENTILATION - To cool or heat air, Dometic Air Conditioning and Refrigeration

components are designed to move air through a heat exchanger by a blower or

propeller fan. This design necessarily produces a suction on one side of the air

handling component and a pressure on the other side. Air handling components

must be installed so that the suction-pressure action does not: (1) pressurize an

area to the extent that structural failure occurs which could cause harm to

occupants or bystanders, or (2) cause a suction or low pressure in an area where

hydrogen gas from batteries, raw fuel vapor from fuel tanks, carbon monoxide

from operating propulsion engines, power generators or heaters, methane gas

from sewage holding tanks, or any other dangerous gas or vapor could exist. If an

air handling unit is installed in such a manner that allows potentially lethal gases

or vapors to be discharged by the air handling unit into the living space, this could

result in loss of life.

Maximum protection against the introduction of dangerous gases or vapors into

living spaces can be obtained by providing living spaces which are sealed from all

other spaces by use of airtight bulkheads and decks, etc., and through the

introduction of clean air into the living space. Bear in mind that the advent of air

conditioning, whether it be for cooling or for heating, naturally leads to the practice

of closing a living space tightly. Never close all windows and doors unless

auxiliary ventilating systems, which introduce clean outside air into the living

space, are used. Always leave enough window and door openings to provide

adequate ventilation in the event potentially lethal gases or fumes should escape

from any source.

CONDENSATE - All cooling units produce water condensate when operating on

the cooling cycle. This water must be drained from the cooling unit overboard. If

condensate is allowed to drip on a wooden structure, rotting or decay and

structural failure may occur which could result in loss of life. If condensate is

allowed to drip on electrical components, deterioration of the electrical compo-

nents could result in hazardous conditions. When an air conditioning system is in

operation, condensate drains may be subjected to negative pressure. Always

locate condensate drains as far as possible from points where engine waste and

other dangerous gases are exhausted so no such dangerous gases can be drawn

into the condensate drains.

Warning

Never sleep in a closed area on a boat when any equipment, which functions as a

result of the combustion of a volatile fuel, is in operation (such as engines,

generators, power plants, or oil-fired heaters, etc.). At any time, the exhaust

system of such devices could fail, resulting in a build-up of LETHAL gases within

the closed area. Warning Revised: 6-5-06

17 ❖English

Cruisair Direct Expansion (DX)

and Modulating Systems

• New, complete system installation using any member of the

SMX family.

The warranty includes the pump.

2 year warranty including Parts and Labor

• New, complete system installation using an electro-

mechanical control (3-knob).

The warranty includes the pump.

1 year warranty including Parts and Labor

• New, complete model sold as a partial system retrofit to

an existing system.

Includes SMX family.

1 year warranty including Parts and Labor

Cruisair Tempered Water

• New, complete system installation using any member of the

SMX family.

2 year warranty including Parts and Labor

NOTE: Excludes pump which has a 1 year warranty

• New, complete model sold as a partial system retrofit to an

existing system.

Includes SMX family.

1 year warranty including Parts and Labor

Refrigerators/Freezers/Fish Boxes

The below warranty periods do not apply to systems that are

installed as described in Section II, item #7, of the Owner’s

Limited Warranty, document # L-0123.

• New installation of entire system including condensing unit,

line sets, evaporator, etc.

1 year warranty including Parts and Labor

• New complete model sold as a partial system retrofit to an

existing Cruisair system.

1 year warranty including Parts and Labor

• New installation of condensing unit only, with line sets,

evaporators, etc. done by others i.e. not Cruisair pre-

charged line sets and evaporators.

1 year warranty including parts and labor on me-

chanical and electrical parts of condensing unit only.

Ice Makers, Remote and Self-Contained

• New installation of an entire Self-Contained Ice Maker

1 year warranty including Parts and Labor, including

water pump.

• New installation of an entire Remote Ice Maker, including

condensing unit, remote display, auger unit, linesets

1 year warranty including Parts and Labor, including

water pump.

• New installation of an Remote Ice Maker Auger and

Condensing unit only, with linesets done by others i.e. not

Eskimo pre-charged linesets

1 year warranty including Parts and Labor on me-

chanical and electrical parts of the auger and con-

densing unit only.

• New complete component sold as a partial system retro-fit

to an existing Eskimo system

1 year warranty including Parts and Labor on new

component only.

Note: Use of saltwater as feedwater to make ice will void warranty

on the auger section of the unit.

Sentry Battery Chargers

• New SM and FR series installation.

2 year warranty including Parts and Labor

• New G-series installation.

1 year warranty including Parts and Labor

Replacement Parts

• Replacement parts and components

Example: A-509, 40401-30.

90 day warranty, Parts only

• Replacement Compressors for other than Tempered Water

Systems - example: R3101-16T, DX equipment - installed in

an existing Cruisair system or a competitor’s system.

1 year warranty including Parts and Labor

• Replacement compressors for Tempered Water - example:

30130-36 installed in an existing Cruisair system.

1 year warranty including Parts and Labor

• A Tempered Water compressor - example: 30130-36

installed with competitor’s equipment.

90 day warranty, Parts only

Revised: 7-18-06 L-0694

Limited Warranty Periods

Please read and keep this document with your important paperwork. Use it as a reference in the future. If you have any questions, please

contact the Dometic Environmental Corporation Service Department at (804)746-1313 for clarification.

Note: Any model or replacement part that has been installed due to a warranty failure will carry only the remainder of the original warranty. All

warranties begin when the customer takes possession of the equipment. The warranty is extended to all owners of the equipment commencing the

date the original owner takes possession of it. Proof of original purchase may be required. Replacement parts, such as filters, fuses and MOVs,

are not covered under our warranty. Fuses and MOVs are used as safety devices to protect Cruisair equipment against over-current conditions

caused by lightning or inductive switching environments. We reserve the right to change our warranty policies and procedures as well as our

warranty allowances without notice.

18 ❖English

L-2028

Fig. 1a Single Duct Installation

Fig. 1b Dual Duct Installation

Fig. 2 Spacing Allowances & Unit Dimensions for

Mounting

Fig. 3 Component Identification

Fig. 4 Mounting Bracket Drawing

Fig. 5 Condensate Drain Drawing

Fig. 6 Three-Knob Switch Assembly

Fig. 7 Two-Knob Switch Assembly

Fig. 8 Wiring Diagram of ZF3.5

Fig. 9 Wiring Diagram of ZF5

Fig. 10 Wiring Diagram of ZF10-16

Fig. 11 Wiring Diagram of Cuddy dc CD3.5HV 12VDC

Fig. 12 Seawater Pump and Plumbing Drawings

Fig. 13a Seawater Installation for ZF3.5-12

Fig. 13b Seawater Installation for ZF16

Fig. 14 Dedicated Power Module (DPM) Specs Tables for

Use With Cuddy dc Systems Only

Fig. 15 DC Wire Sizing Table

Descriptions of Figures

19 ❖English

L-2028

Fig. 1a - Typical Single Duct Installation for ZF3.5-5

Fig. 2 - Spacing Allowances & Unit Dimensions for Mounting

Fig. 1b- Typical Dual Duct Installation for ZF10-16

DIMENSIONS

Unit Capacity 3,500 BTU 5,000 BTU 10,000 BTU 12,000 BTU 16,000 BTU

(in/mm) (in/mm) (in/mm) (in/mm)

(in/mm)

A – Duct Size 3.0/76 4.0/102 6.0/152 6.0/152 7.0/178

B – Base Depth 8.0/203 8.0/203 8.4/213 8.4/213 10.3/261

C – Overall Depth 9.0/229 11.6/294 12.2/310 12.2/310 14.2/361

D – Width 15.0/381 16.0/407 19.0/483 19.0/483 20.0/508

E – Height 9.3/235 11.6/294 12.9/328 13.3/337 13.5/343

20 ❖English

L-2028

Fig. 4 - Mounting Bracket Fig. 5 - Condensate Drain

Fig. 3 - Component Identification

This manual suits for next models

1

Table of contents

Other Cruisair Air Conditioner manuals

Popular Air Conditioner manuals by other brands

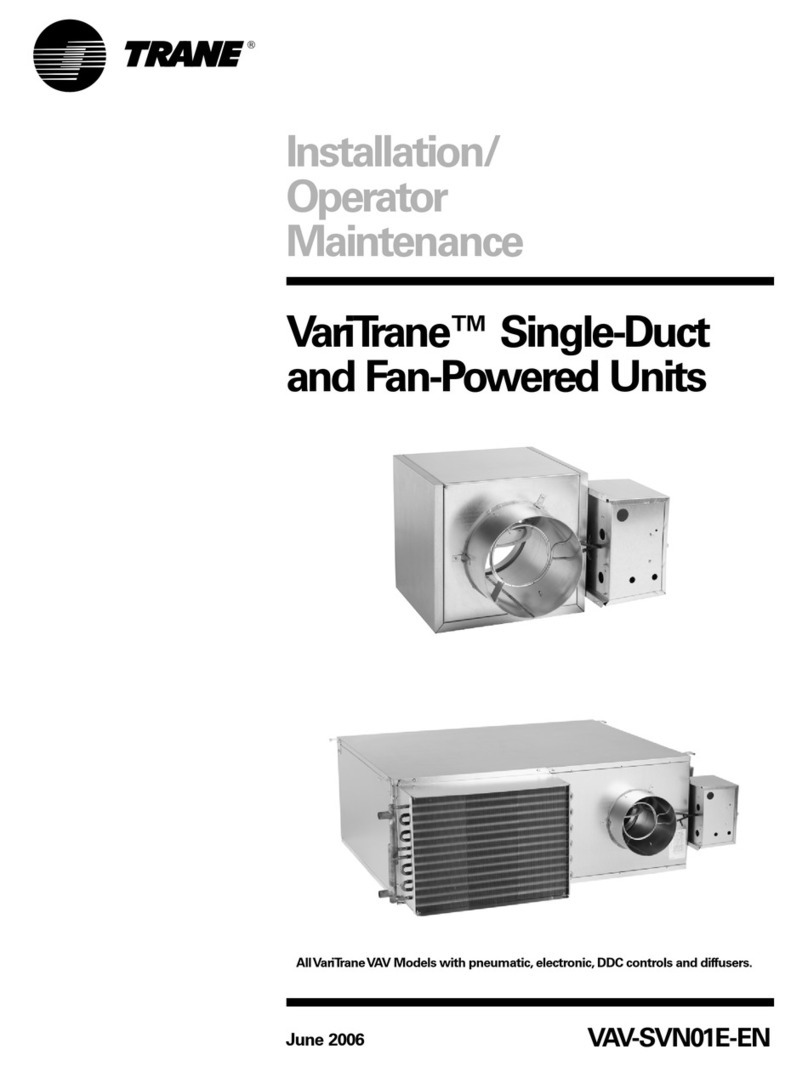

Trane

Trane VariTrane VAV Series Installation & operator's manual

GD Midea Refrigeration Equipment

GD Midea Refrigeration Equipment MSG-18HRN2 Technical & service manual

Samsung

Samsung AM KN4DCH Series installation manual

Samsung

Samsung NS 4CREA Series User & installation manual

Fujitsu

Fujitsu Mini-Split manual

Daikin

Daikin 2MXM68A2V1B installation manual