Cryo-con 54 User manual

A Quick Start Guide to the Model 54

USER DOCUMENTATION AND UTILITY SO TWARE

User documentation, utility software, LabView drivers and sensor curves

are on the CD provided. Additionally, they are available at:

http://www.cryocon.com/CCdownload/CustomerCD 2.zip

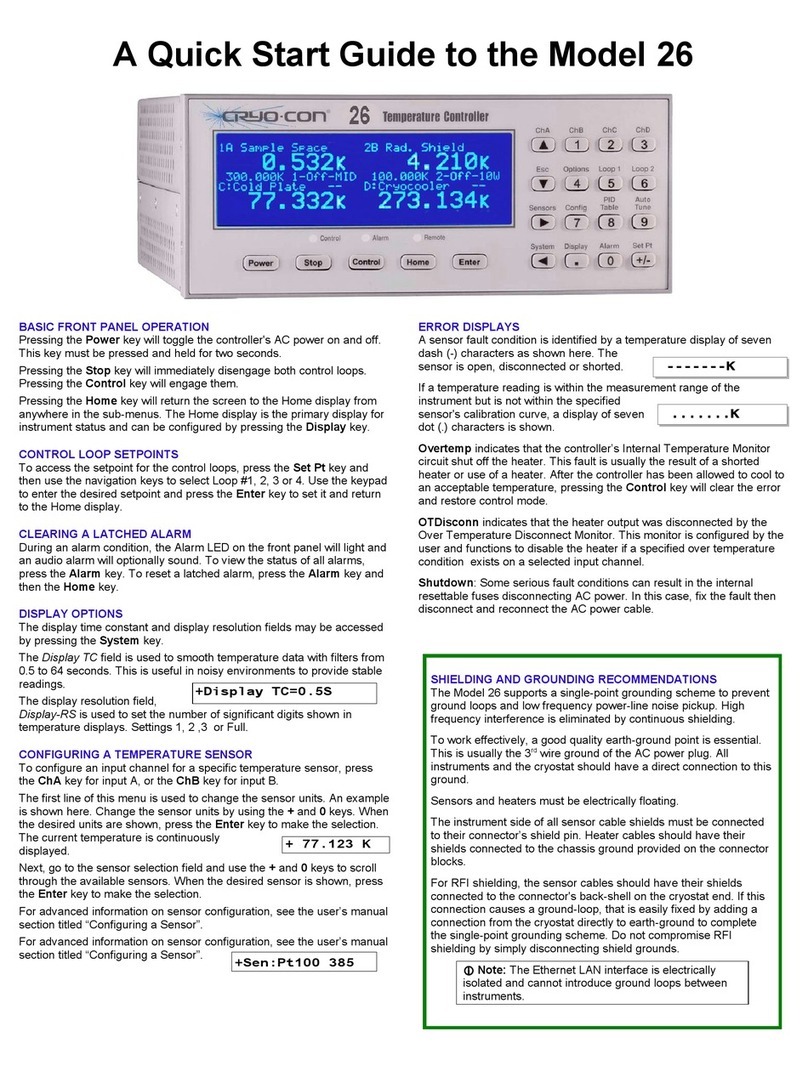

BASIC RONT PANEL OPERATION

Pressing the Power key will toggle the controller's AC power on and off.

This key must be pressed and held for more than two seconds.

Pressing the Stop key will immediately disengage both control loops.

Pressing the Control key will engage them.

Pressing the Home key will return the screen to the Home display from

anywhere in the sub-menus. The Home display is the primary display for

instrument status and can be configured by pressing the Display key.

CONTROL LOOP SETPOINTS

To access the setpoint for the control loops, press the Set Pt key and

then use the navigation keys to select Loop # , 2, 3 or 4. Use the keypad

to enter the desired setpoint and press the Enter() key to set it and

return to the Home display.

CLEARING A LATCHED ALARM

During an alarm condition, the Alarm LED on the front panel will light and

an audio alarm will optionally sound. To view the status of all alarms,

press the Alarm(5) key. To reset a latched alarm, press the Alarm(5) key

and then the Home key.

DISPLAY OPTIONS

The display time constant and display resolution fields may be accessed

by pressing the System(9) key.

The Display TC field is used to smooth temperature data with filters from

0.5 to 64 seconds. This is useful in noisy environments to provide stable

readings.

The display resolution field, Display-RS is used to set the number of

significant digits shown in temperature displays. Settings , 2,3 or Full.

CON IGURING A TEMPERATURE SENSOR

To configure an input channel for a specific temperature sensor, press

the Input( ) key. Then, use the drop-down box to select the desired input

channel.

Touch the Units: indicator to select the units displayed.

Touch the Sensor: field to select the desired sensor from a list.

For resistance measurements using Constant-Voltage AC excitation,

select the ACR sensor, then set a Bias Range and Bias Level. The range

sets the full scale range and level sets the percent of that range.

For advanced information on sensor configuration, see the user’s manual

section titled “Configuring a Sensor”.

ERROR DISPLAYS

A sensor fault condition is identified by a clipping or clamping message

as shown here. This usually indicates that the

sensor is open, disconnected or shorted.

If a temperature reading is within the measurement range of the

instrument but is not within the specified sensor's

calibration curve, a display of seven dot (.)

characters is shown.

Overtemp indicates that the controller’s Internal Temperature Monitor

circuit shut off the heater. This fault is usually the result of a shorted

heater. After the controller has been allowed to cool to an acceptable

temperature, pressing the Control key will clear the error and restore

control mode.

OTDisconn indicates that the heater output was disconnected by the

Over Temperature Disconnect Monitor. This monitor is configured by the

user and functions to disable the heater if a specified over temperature

condition exists on a selected input channel.

..Clip..

.......

SHIELDING AND GROUNDING RECOMMENDATIONS

The Model 54 supports a single-point grounding scheme to prevent

ground loops and low frequency power-line noise pickup. High

frequency interference is eliminated by continuous shielding.

To work effectively, a good quality earth-ground point is essential.

This is usually the 3rd wire ground of the AC power plug. All

instruments and the cryostat should have a direct connection to this

ground.

Sensors and heaters must be electrically floating.

The instrument side of all sensor cable shields must be connected

to their connector’s shield pin. Heater cables should have their

shields connected to the chassis ground provided on the connector

blocks.

For RFI shielding, the sensor cables should have their shields

connected to the connector's back-shell on the cryostat end. If this

connection causes a ground-loop, that is easily fixed by adding a

connection from the cryostat directly to earth-ground to complete

the single-point grounding scheme. Do not compromise RFI

shielding by simply disconnecting shield grounds.

i Note: The Ethernet LAN interface is electrically

isolated and cannot introduce ground loops between

instruments.

AC POWER CONNECTION

Before connecting AC power, check the input voltage setting through the

window on the power entry module to ensure that it is set properly. If not,

please refer to the User's Manual section titled Fuse Replacement and

Voltage Selection. For operation with 220V, select the 230V setting and,

above 235V, select 240V.

CON IGURING CONTROL LOOPS

Control loops are configured by pressing the Loop(2) key.

Select the desired control loop from

the first drop-down box.

Set the control type by touching the

Type: field and the output range by

touching the Range: field.

Set the setpoint and tuning

parameters as desired.

Control Loop # is a four-range

output that can supply a maximum

of 75W into a 25 load.

The second control loop is a three range output that can supply a

maximum of 25W into a 25 load.

Loop #3 is fixed range output that can supply a maximum of .0W into a

00 load.

Loop #4 is a non-powered analog voltage output. Output is selectable at

0 or 5 Volts full scale.

CONTROL MODES

For information on how to determine PID values for the control loop,

please refer to the user’s manual section titled “Autotuning” for automatic

generation, or to “Appendix D: Tuning Control Loops”.

Type Description

Off Control loop is OFF.

Man

Manual control mode. A constant heater output

power is applied. The Pman field selects the output

power as a percentage of full-scale.

PID

Standard PID control. The Pgain, Igain and Dgain

fields hold the PID values. Igain is in seconds and

Dgain is in inverse seconds.

Table PID control mode where the PID coefficients are

generated from a stored, user supplied PID table.

RampP Temperature ramp control.

RampT Ramp using a PID table.

Rear Panel Connections

SENSOR CONNECTIONS

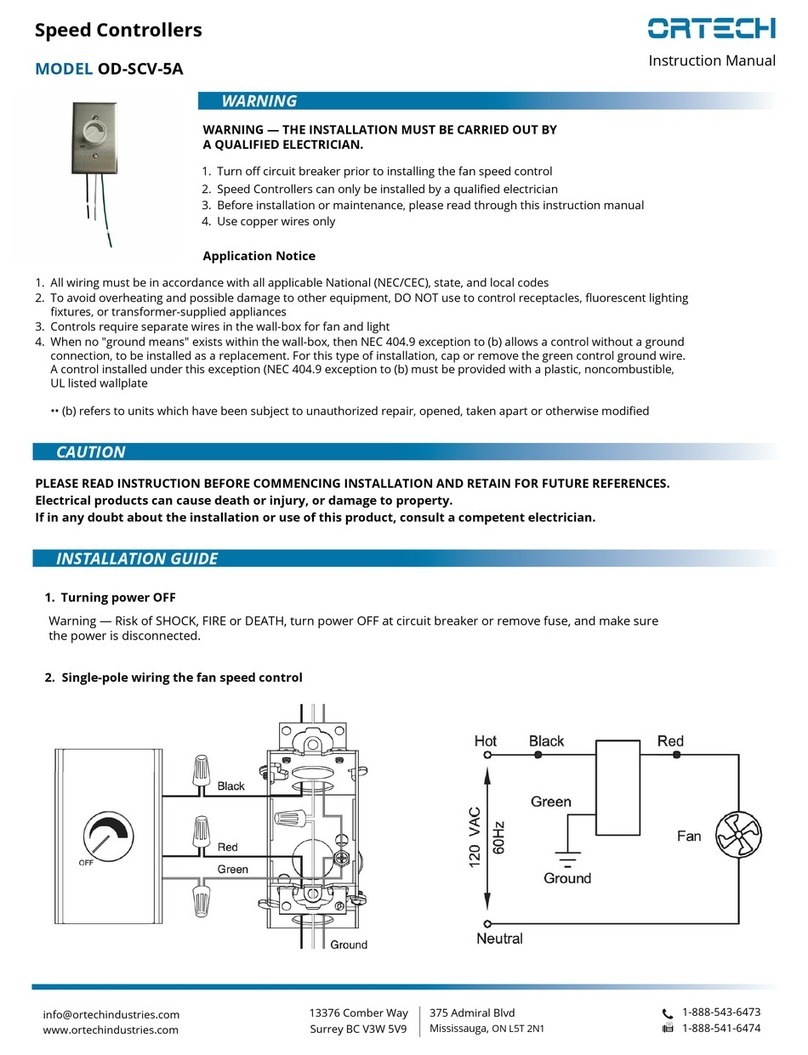

Silicon Diode and all resistor type sensors should be connected using the

four-wire method. It is strongly recommended that sensors be connected

using shielded, twisted pair wire. Wires are connected as shown below

and the shield should be connected to the metal back-shell of the

connector.

Pin unction

1Aux Power Ground

2Sense (+), V+

3Sense (-), V-

4Excitation (+), I+

5Excitation (-), I-

6Aux Power:+5VDC

TERMINAL BLOCK CONNECTIONS

Cryogenic Control Systems, Inc.

PO Box 7012

Rancho Santa e, CA 92067

QS54 8/20

Telephone: 858-756-3900

E-mail: [email protected]

www.cryocon.com

Range Max. Output Power

2550

75W 75W --

Hi 25 W 50 W

Mid 2.5W 5.0 W

Low 0.25 W 0.50 W

Loop Output Power

Loop #1

Pin unction

Hi Heater Output High

Lo Heater Output Low

GND Ground

Loops #2, #3, #4 and Relays

Pin unction

1Loop #2 Heater Output High

2Loop #2 Heater Output Low

3Relay # N.O.

4Relay # Common.

5Relay #2 N.O.

6Relay #2 Common.

7Loop #3 output High

8Loop #3 output Low

9Loop #4 output High

10 Loop #4 output Low

Other Cryo-con Controllers manuals