Specifications subject to change without notice

ITOH DENKI USA, INC

135 Stewart Road rev15-0115

PH: 570-820-8811 Hanover Industrial Estates

FX: 570-820-8838 Wilkes-Barre, PA 18706-1462 Page 7 of 25

Installation Precautions –

IMPORTANT, PLEASE READ BEFORE INSTALLATION

Use a sensor that would have an active

output when the zone is occupied

Example: A retro-reflective photo-

sensor would need to be dark-operate

The HBM responds to the active signal

received from the sensor to denote zone

occupation. If the incorrect type is used, the

HBM would “think” that a zone is occupied

when it is really clear. Not only would there

be problems in ZPA logic operation, but there

will also be JAM errors appearing.

system after applying

ESTOP signal

Make sure transported articles are not

between photo-sensors.

Any article between photo-sensors will not be

recognized as occupying a zone. Therefore

any upstream articles being transported may

collide into them.

Keep away from the system when it is

first powered ON. When the system is first powered ON and

there is no signal from the photo-sensor for

presence of an article, the zone will RUN for

a short time at a slow speed to receive or

advance any articles which may be between

photo-sensors. There may be a risk for

bodily injury because of moving rollers and

transported articles.

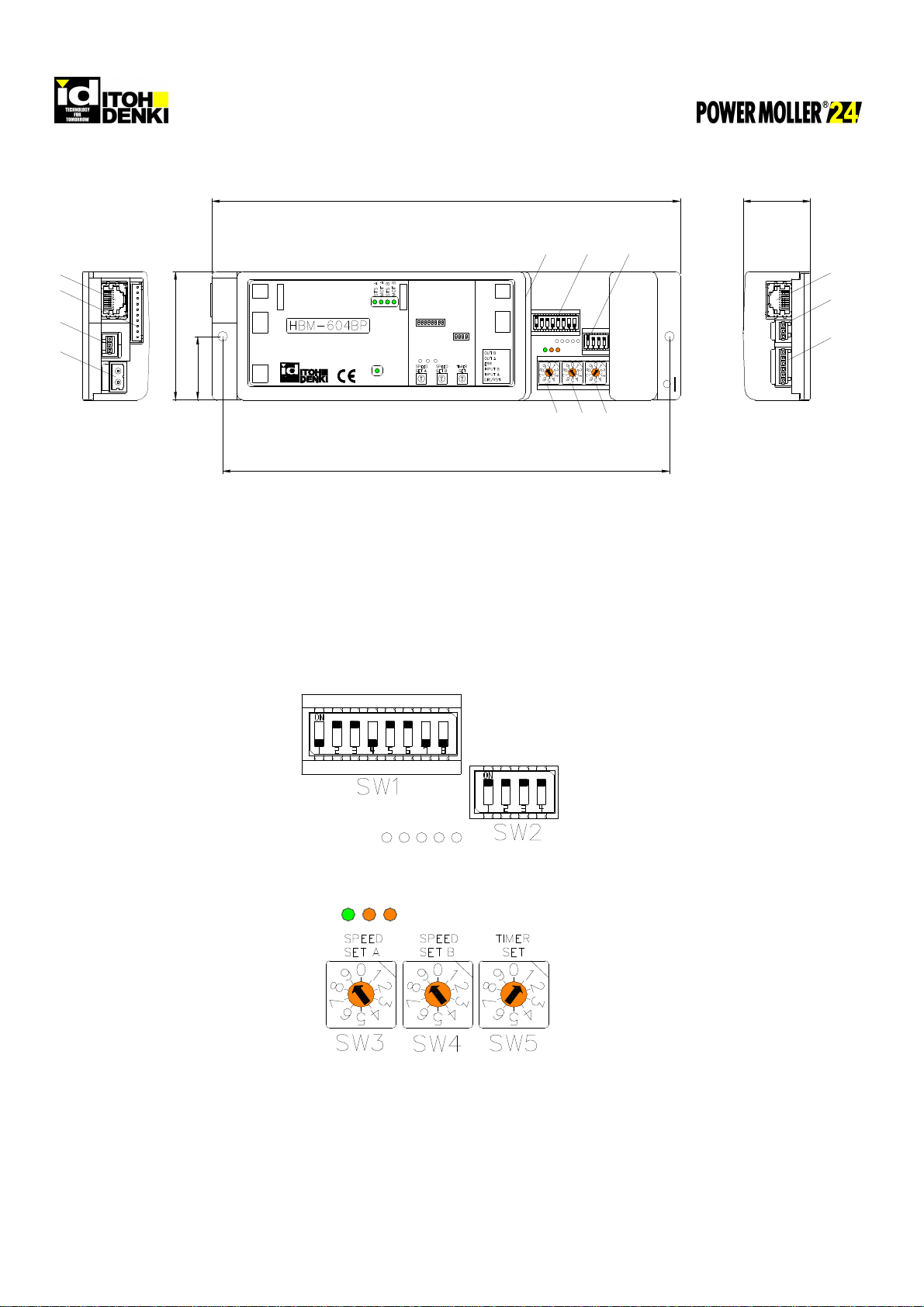

Using as a slave card be sure the timer

switch SW5 to zero (0) for slave mode This eliminates all timer functions and

communication. Roller(s) will not run on

initial start up in slave mode

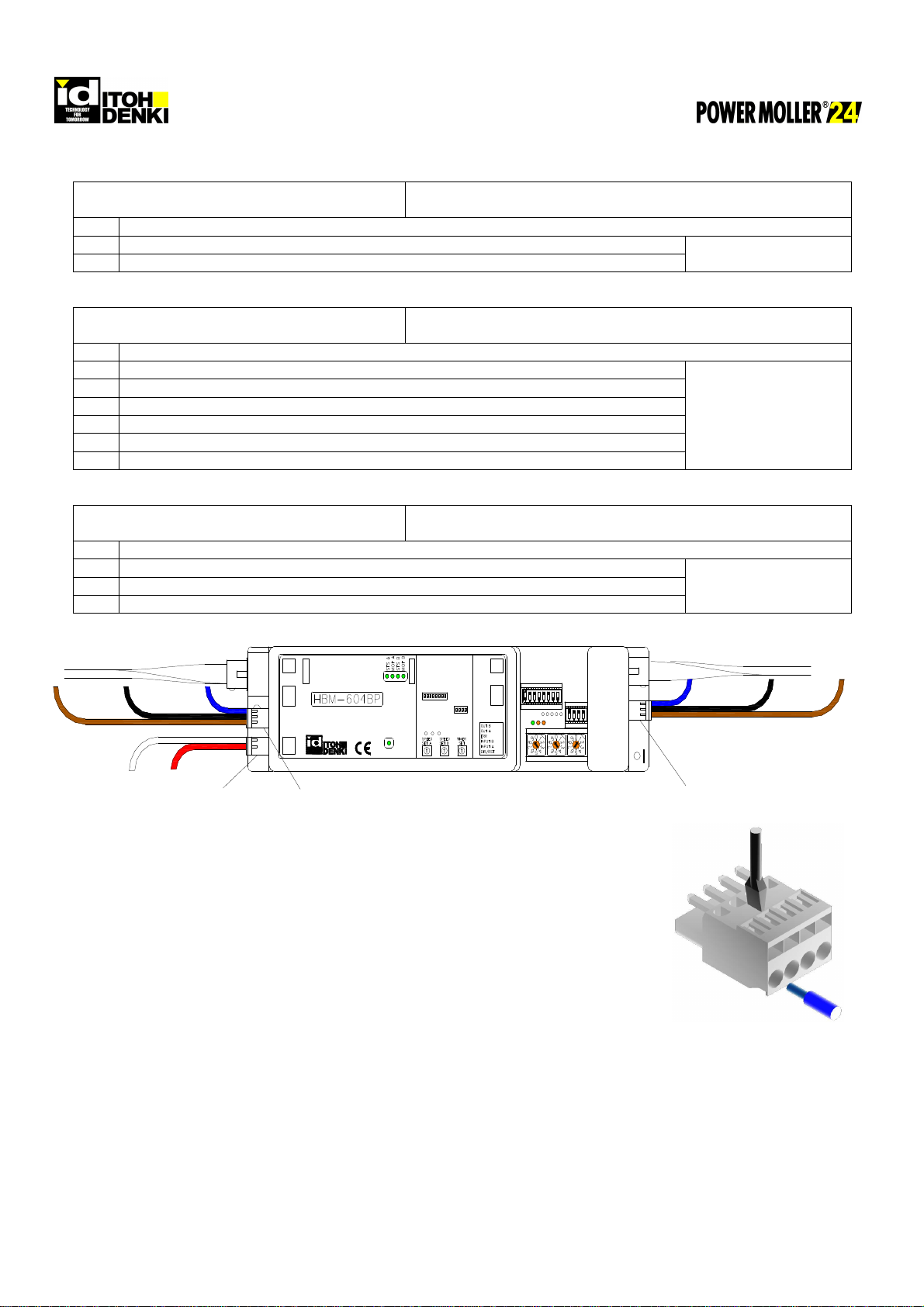

RJ-45 connectors

8-wire cables

Straight-through wiring pattern

Straight-through wiring means that the

connectors on both ends of the cable are

wired in the exact same pattern.

Cross-over wiring or any other wiring pattern

will cause communication problems.

connection to PNP

output(s)

DO NOT connect an output terminal

(CN2-4, CN2-5) set for PNP directly to

0V, GND, or a low impedance input on a

controller.

When the PNP signal is active, the low

impedance input will draw a high current and

subsequently damage the output circuit.

Damage may also occur to the input circuit

on the controller.

supplies 0V line of all power supplies on the

same conveyor line (powering the

card/rollers, & controls) need to be

physically linked together.

This completes the signal path from one

section of the conveyor (powered by a power

supply) to the adjacent section of conveyor

(powered by another power supply) and

allows for proper communication through the

cable and external interfaces.